archive page

Author: armfield

Remote access to the essentials of Process Control

Introduce students to the fundamentals and principles of process control and provide a thorough understanding in the control of physical processes with Armfield’s Essentials Process Control range.

Level, flow, temperature and pressure as the controlled variable can all be demonstrated via four independent process units. The concepts of closed loop control, including on/off control, proportional control, proportional/integral and proportional/integral/derivative (PID) control can be explored and demonstrated.

All units are computer controlled and can be remotely operated enabling seamless teaching in a distant or remote learning environment.

Contact Us at sales@armfield.com

Armfield INC USA host trials on our demonstration equipment

Armfield Inc would like to welcome you at our laboratory in New Jersey, USA to host trials on our demonstration equipment, after a short closure due to Covid19.

Titus Porter is pictured here during a customer dairy trial using our flagship FT174X modular HTST/UHT processing system, also available is the FT102LT carbonator/filler.

Social distancing rules are in place for staff and customer safety, to discuss your next product innovation contact us at armfield.com

Armfield welcomes Nancy Manik

Our new Area Sales Manager for Asia, joining the Educational Sales Team.

Nancy brings years of experience working within the academic and pharmaceutical industry within the global market, where she assisted researchers set up their new laboratories and provide core facility systems for a multi user environments.

Nancy is looking forward to supporting and looking after educational sales agents and customers in Asia.

You can reach her on nancy.manik@armfield.com for any enquiries.

Armfield launches its new laboratory

A new laboratory is launched at Armfield! Available with a large range of equipment to process varying applications related dairy, beverage, pharmaceutical, food, oils ingredients and other liquid processes. These units can be utilised to confirm your need and give you confidence to purchase the Armfield equipment.

Also available is a full trials facility for business to business trials requirements. With trained personnel available at all times you are guaranteed useable results in real time, on hand support and a full data acquisition file included with a written report.Now with social distancing rules in place, trained and experienced staff can test products on your behalf and send you the data to prove our concepts and results, or provide virtual trials.

Speak to our sales team to find out more:

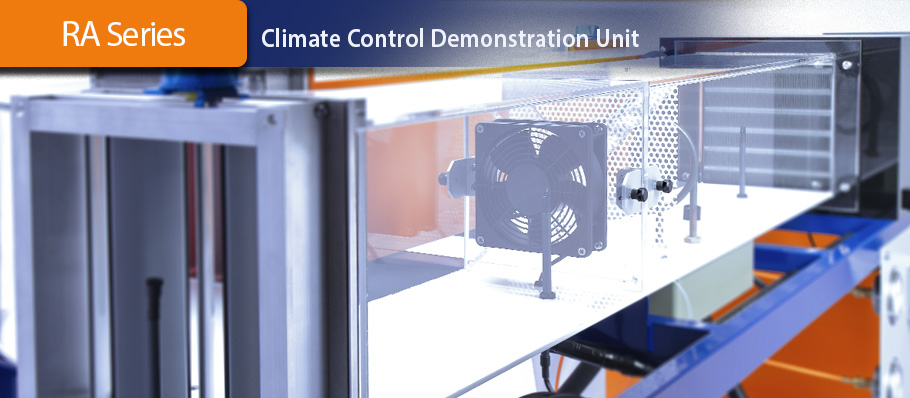

RA3 Recirculating Air Conditioning Unit

Armfield’s Recirculating Air Conditioning Unit is a climate control demonstration unit.

Variable louvres within the unit allow investigation of 0 to 100% re-circulation.

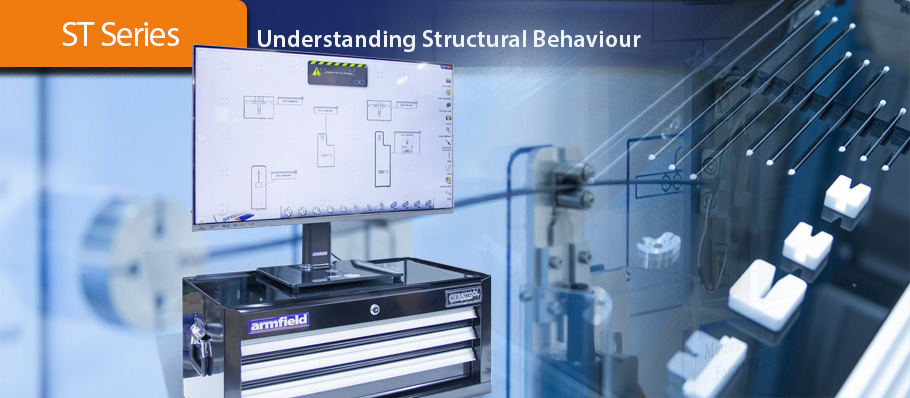

Understanding Structural Behaviour

Armfield have teamed up with Dr David Brohn (who is also working with the Institution of Structural Engineers on this topic) to develop a range of hardware and software specifically to address this issue of understanding structural behaviour. This is a highly modular system with almost an infinite range of possibilities.

To simplify purchasing, the components are available in a number of kits depending on requirements, there are eight standard projects including:

– Cantilever beam

– Simply supported beam

– Two span beam

– Pinned beam

– Rigid right angle joint

– Rigid portal frame

– Portal frame with pinned connection

– Portal frame with pinned support

The equipment provides an unsurpassed and unique learning experience when the display software is coupled with the sensors, actuators and analysis software.

Armfield Fluid Machines

The FM53 Plunger Pump Demonstration Unit replicates those used in industry in a wide variety of applications such as cleaning or process technology in the chemical industry.

The plunger or ram pump is used for pumping small quantities of liquid at high pressure. Electronic sensors measure the instantaneous cylinder pressure within the pump, the pump displacement and the cumulative flow.

Computer controlled with datalogging the FM53 is one of Armfield’s vast range of units with remote access capabilities.

See the extensive range of fluid machine demonstration units at www.armfield.co.uk/fm or contact sales@armfield.co.uk to discuss your remote access needs.

Montana State University

Armfield recently visited Stephanie Wettstein at the chemical engineering department, Montana State University to complete the installation of the UOP3CC Continuous Computer Controlled Distillation Column.

As innovators of educational engineering equipment Armfield have developed this state-of-the-art laboratory based distillation column to enable safe hands on practical training for student engineers and plant operators as well as empowering research in different fields to be conducted.

The UOP3CC enables a range of demonstrations from the introductory stages of a process engineering course through to the more complex demonstrations of modern control strategies.

Armfield’s professional services team offer installation, commissioning and training on site to ensure that laboratories and research centres are able to fully utilise all equipment at the earliest opportunity.

See more at www.armfield.com

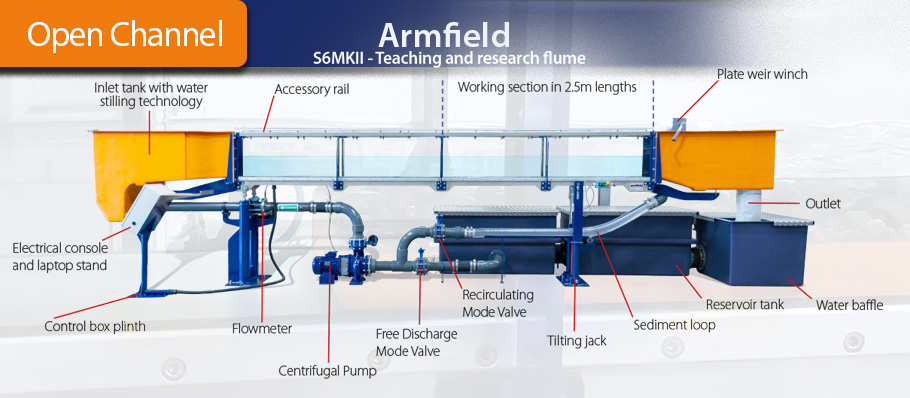

Armfield S6-MKII laboratory flow channel

The Armfield S6-MKII laboratory flow channel is one of the most important tools available to the hydraulics or civil engineer whether engaged in teaching basic principles or researching solutions to practical problems. Many applications in fluid mechanics are associated with the flow of water through an open channel where the water has a free surface that is exposed to the air at atmospheric pressure.

The flumes are available in different lengths from 5 to 15m (in 2.5m sections) and examples are installed in educational and research establishments throughout the world.

A comprehensive range of accessories and measuring instruments are available including discharge control, wave generation and a closed loop for sediment transport studies.

See more at www.armfield.co.uk

Kombucha and Armfield

The ancient recipe for Kombucha involves only tea leaves, sugar, water and the mother culture of bacteria and yeast. Adjusting the quantities of the ingredients will change the flavour of the final beverage so no two drinks from different brewers will taste the same.

The process must be monitored and refined to maintain your unique flavour and keep consistency between batches. This is where Armfield can help with the FT140X.

The temperature of the drink can be monitored and controlled throughout the process meaning it is kept consistent between consecutive batches. With built in low-speed agitators you can periodically mix the batch to improve the contact of the yeast and bacteria to the sugars, lowering the time needed to ferment and increasing your final yield. The double jacket gives close temperature control throughout the fermentation process giving you repeatable and unbeatable results.

For bottling your winning products, the Armfield FT102X gives consistent filling and carbonation (if required) capabilities for reproducible results every batch.

Contact us – www.armfield.co.uk

Subscribe to our occasional newsletter for the latest product updates from Armfield Engineering.