RA3 – Computer Controlled Recirculating Air Conditioning Unit

RA3 is a floor standing unit, with all the features of the RA2 plus a recirculation feature via an enclosed chamber. Some of the air exiting the chamber can be recycled back into the conditioning duct.

Description

RA3 is a floor standing unit, with all the features of the RA2 plus a recirculation feature via an enclosed chamber. Some of the air exiting the chamber can be recycled back into the conditioning duct.

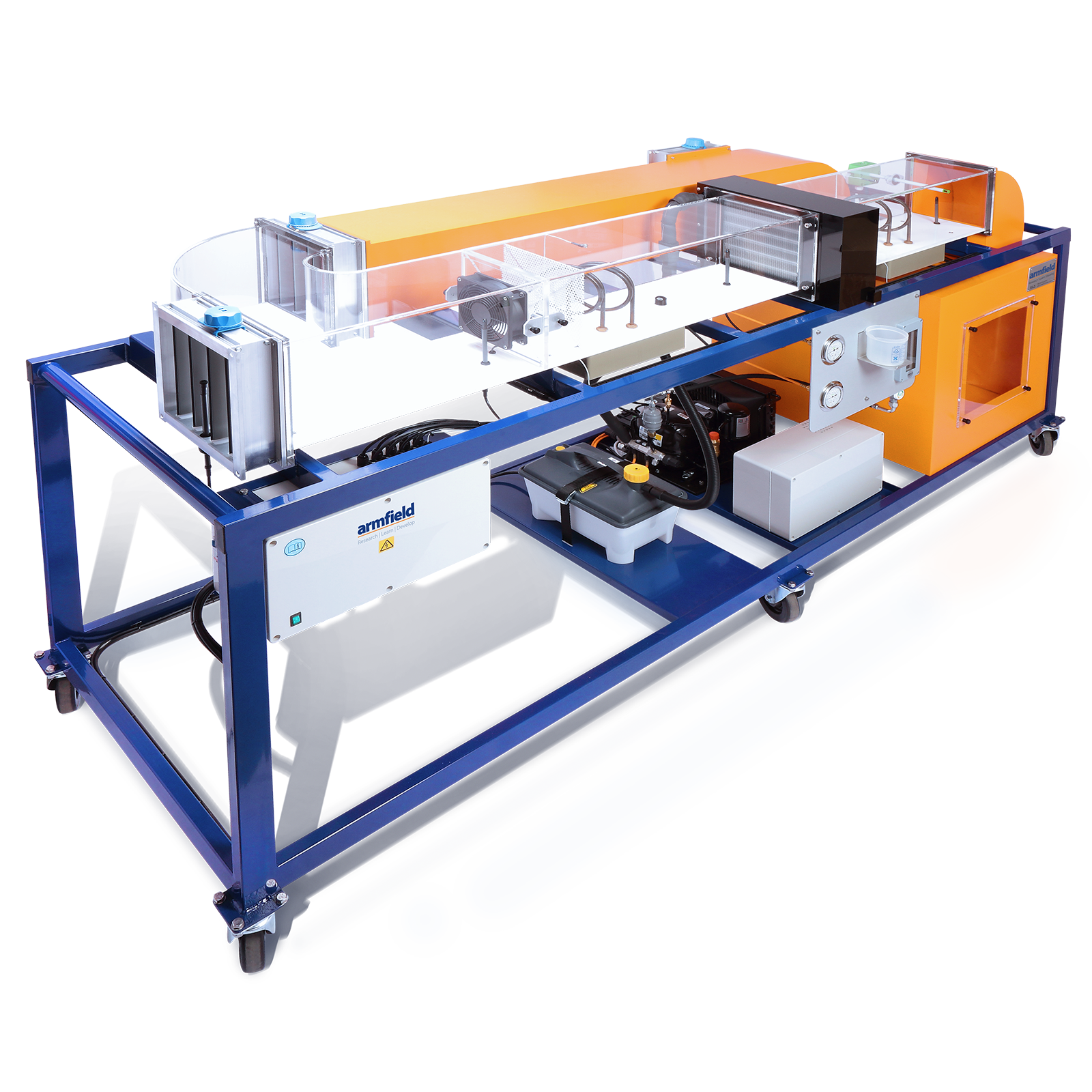

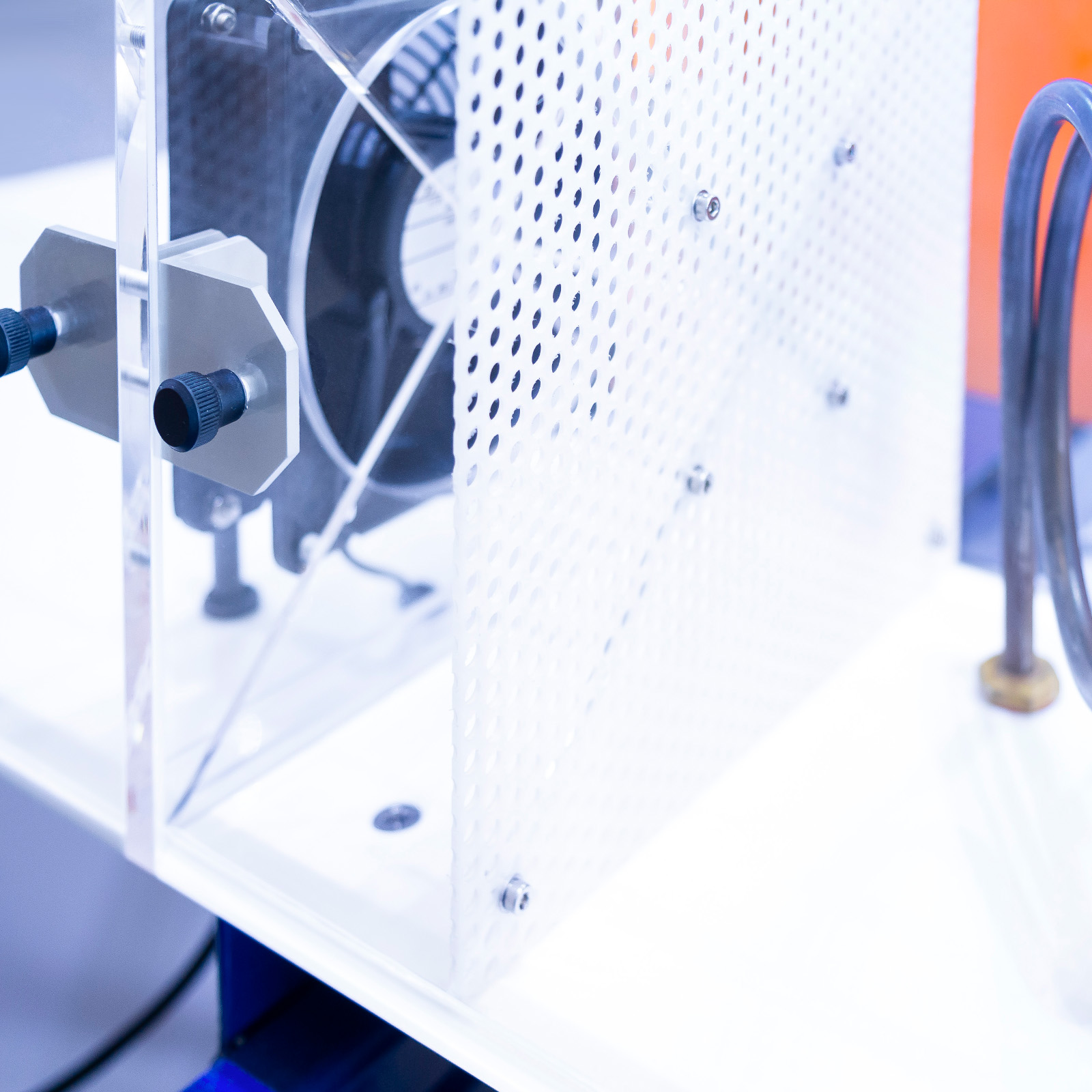

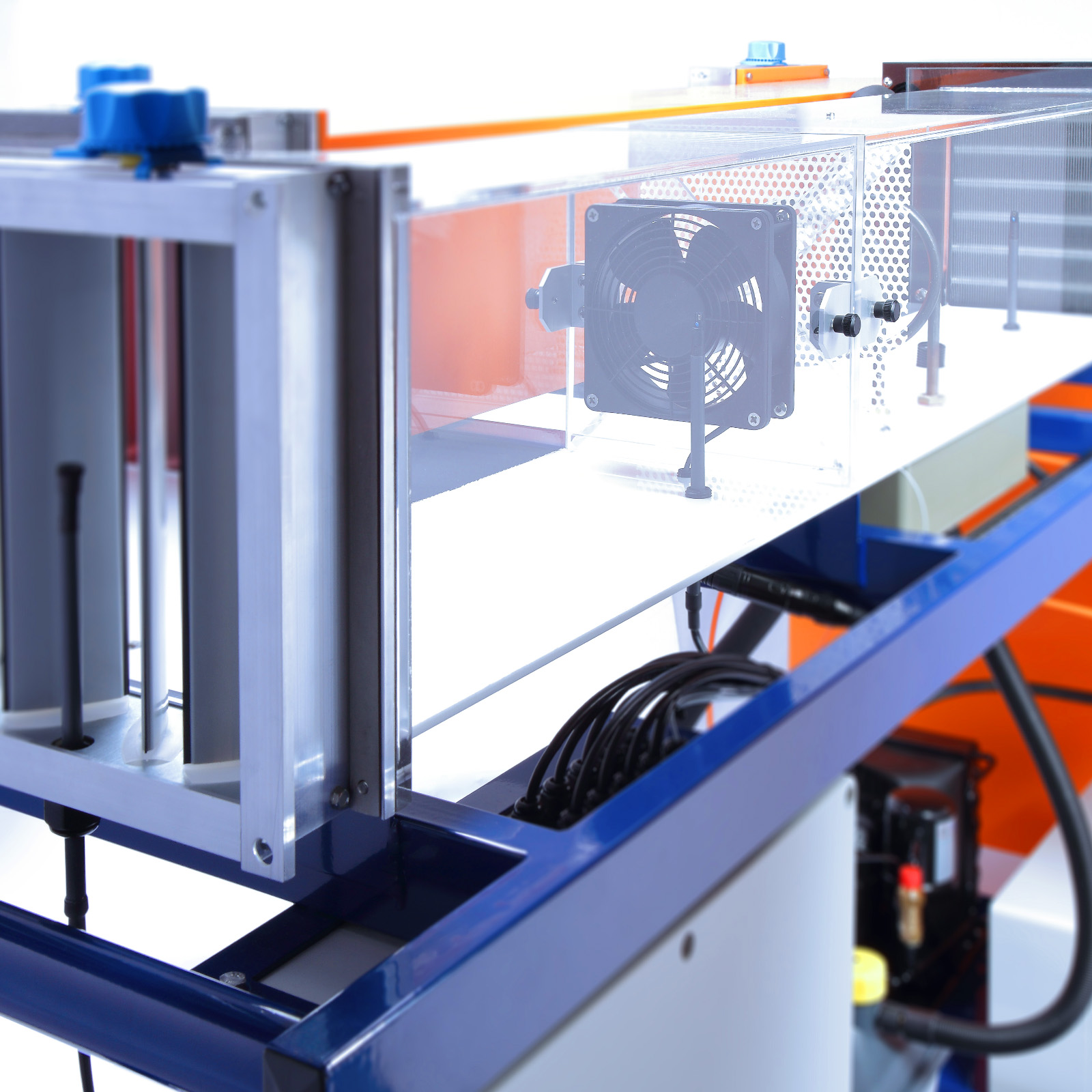

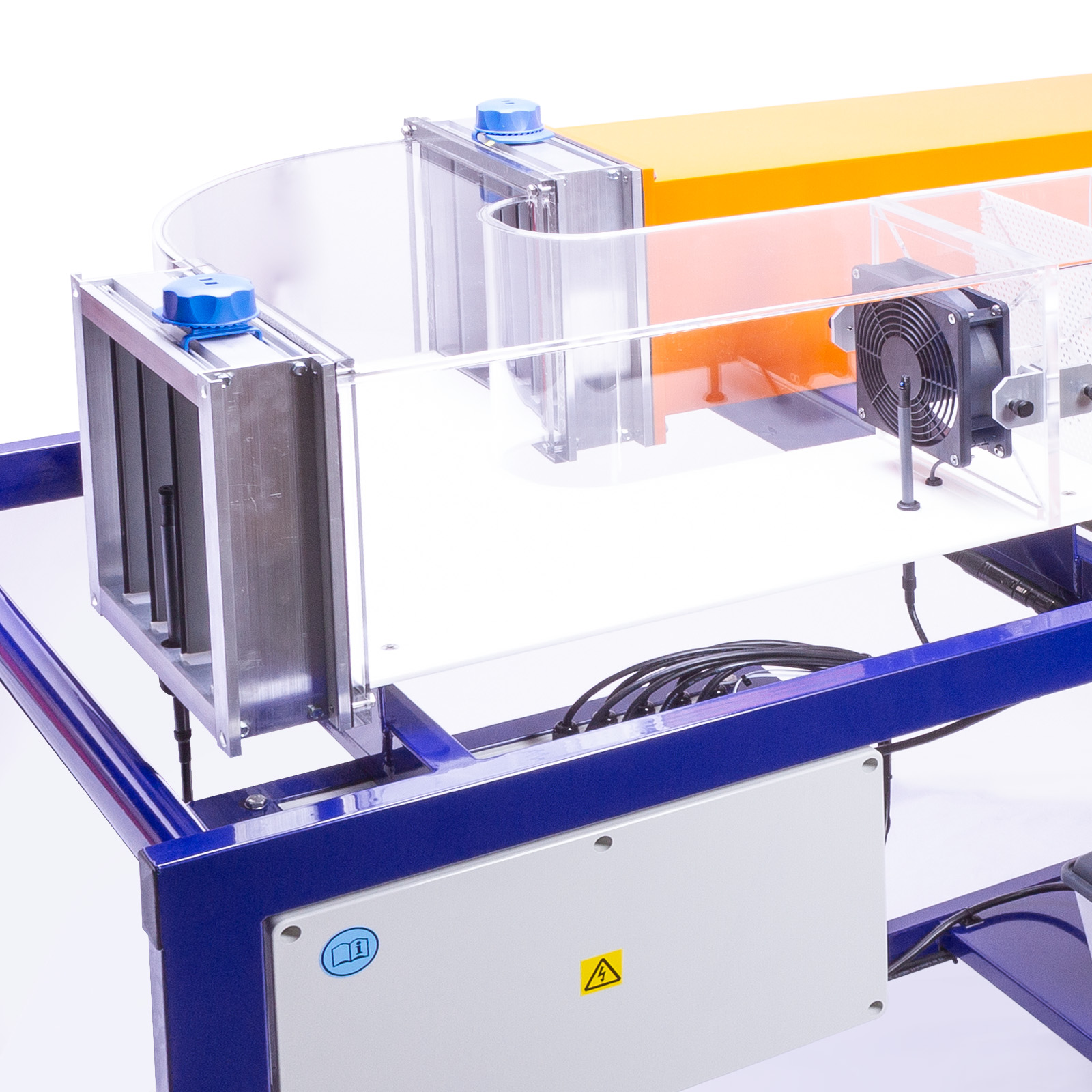

The RA3 is a floor standing, self contained unit comprising a square ventilation duct mounted on a mild steel frame. The duct has a clear acrylic section allowing visibility of all components.

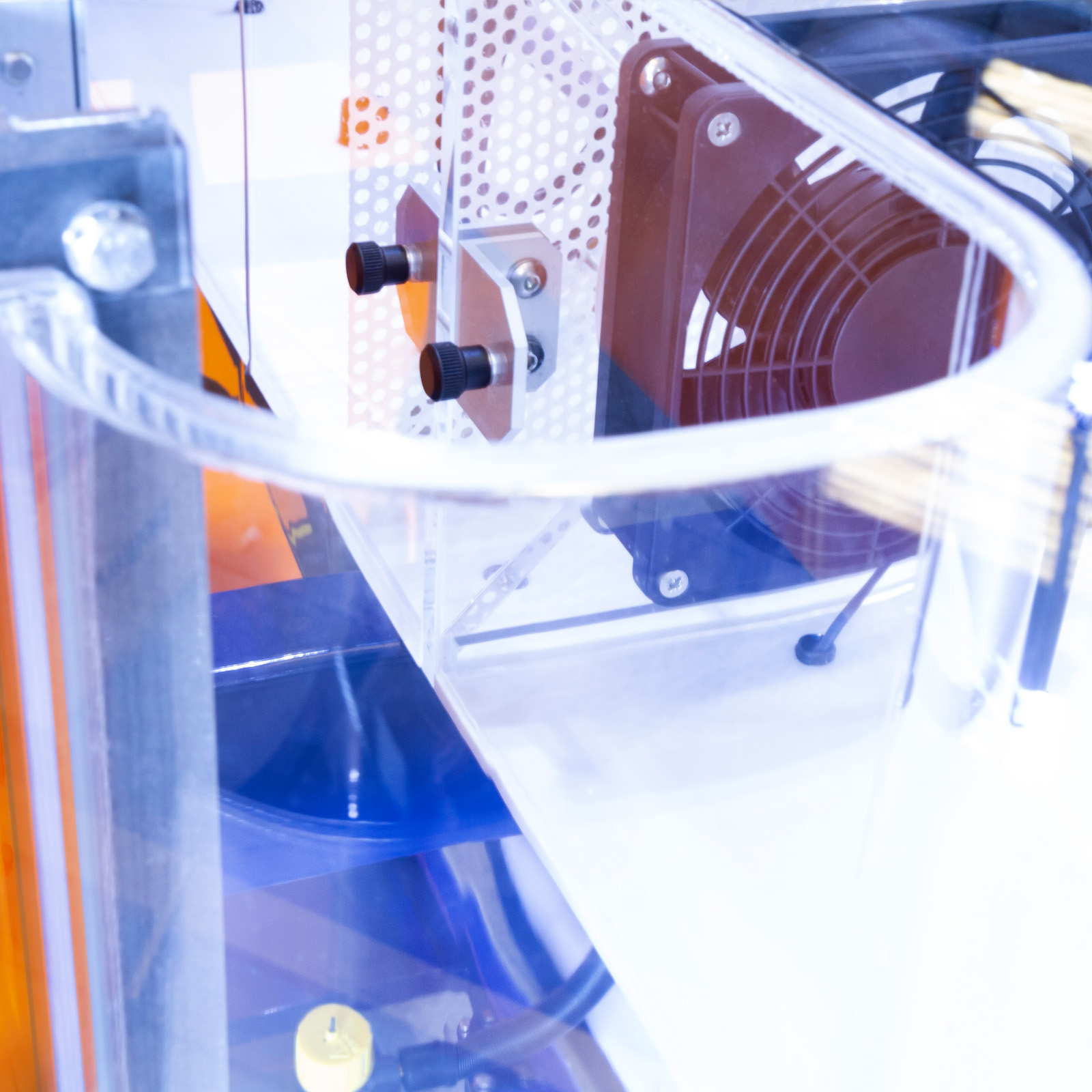

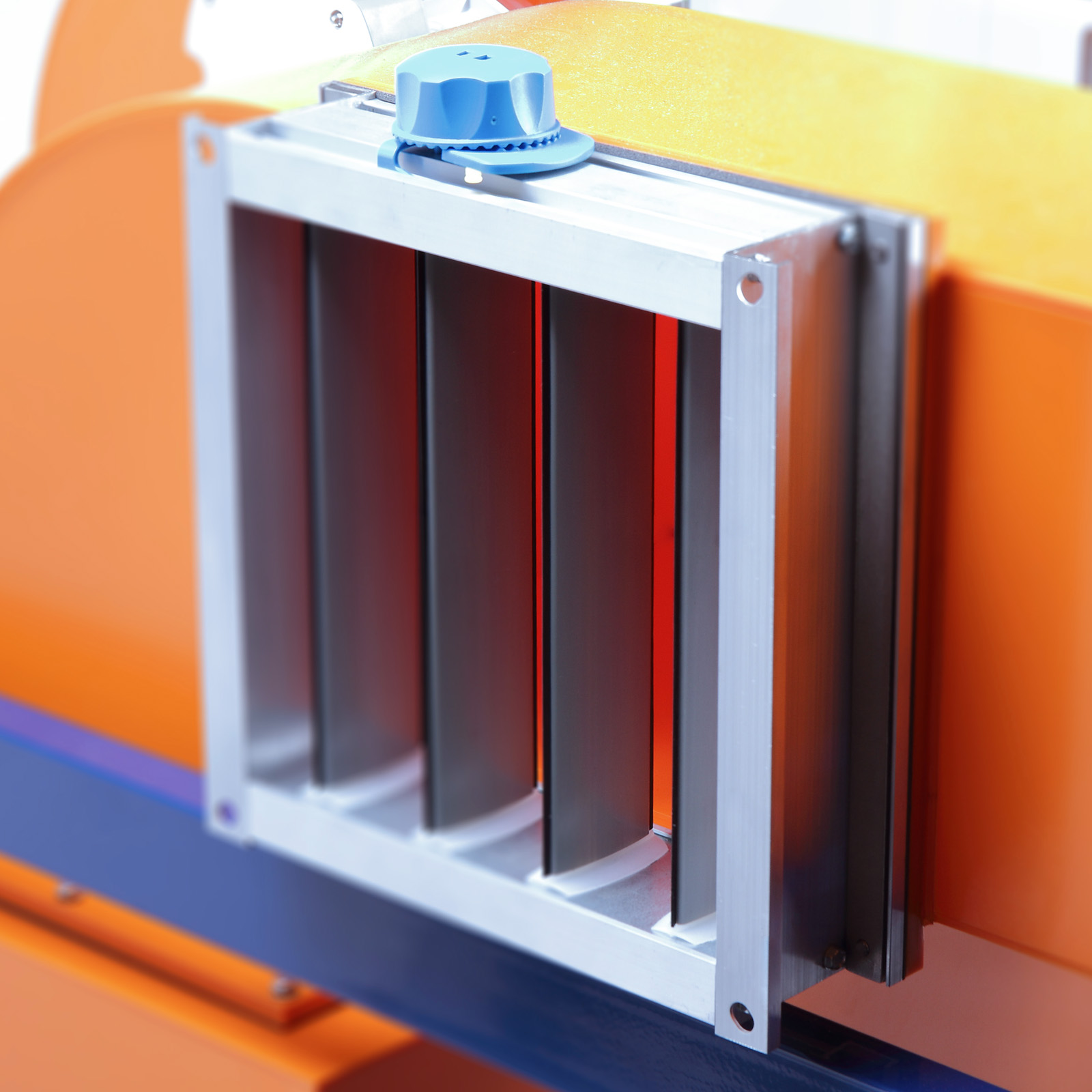

The air out of the duct is passed into a chamber to demonstrate climate control. The exit duct from the chamber is fitted with adjustable vents allowing some of the air to be recirculated back to the duct inlet.

Additional sensors measure the temperature and RH at the chamber outlet and after the recirculated air is mixed with the inlet air as well as the flow rate of the recirculated air.

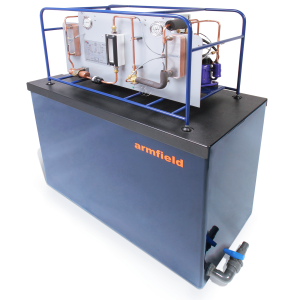

Pressure gauges and temperature sensors allow the refrigerant temperature change across the condenser and evaporator to be established.

The refrigerant flow rate is measured using a variable area flow-meter.

Technical Specifications

Features & Benefits

- Enclosed climate control chamber

- Adjustable recirculation of air leaving the chamber back into the conditioning duct

- Additional sensors, including refrigerant pressures and flow

- Transparent duct for visibility of the process and the components

- Pre-heaters, humidifier, chiller/dehumidifier and re-heaters

- Temperature and relative humidity (RH) sensors at every stage of the process, plus an air flow sensor

- RH sensors calibrated for maximum accuracy

- Suitable for both vocational training and for rigorous academic analysis of the thermodynamic principles involved

- Computer controlled with real time data logging of results (requires a PC not supplied by Armfield)

- Capability of using PID control for preheat, humidity and reheat allows stable conditions to be set up for investigations

- To investigate and understand the use of psychrometric charts, understand relative humidity (RH) measurements and the effect of temperature on RH and understand the Humidity Ratio

- To investigate sensible heating of air in a duct

- To investigate the humidification of air. To investigate the effect of vapor content and temperature on relative humidity

- To investigate dehumidification of air by cooling

- To investigate and understand the effect on enthalpy, understand relative humidity (RH) measurements and the effect of temperature on RH and understand the Humidity Ratio

- To investigate and understand recirculation and the effect on the system efficiency

- To investigate and understand recirculation and the effect on various aspects of the air conditioning cycle

- Heat transfer across the evaporator

Comprehensive data logging and graph plotting facilities, together with sensor calibrations and a wide variety of display and data export options.

RA3-Powerful software is supplied with detailed mimic diagram and instructional help texts.

Comprehensive data logging and graph plotting facilities, together with sensor calibrations and a wide variety of display and data export options.

- Recirculating air conditioning teaching system, complete with initial heating stage, humidifier, chiller/dehumidifier, final heating stage, climatic chamber with window, return duct and adjustable recirculation

- Transparent conditioning duct (200mm x 200mm) for process visibility

- Computer controlled via USB interface

- Educational software including real-time data logging, graphics and data export

- Educational software, replicating the psychrometric chart calculations

- 6 sets of temperature and relative humidity measurements at the various stages throughout process

- RH sensors come with calibration values which can be entered into the software for best accuracy

- 2 Electronic flowmeters measure the flow in each duct

- Dual control of boiler setting with a fast heat up setting and a gentle setting for control

Personal Computer (PC), running Windows XP or above, with spare USB port (not supplied).

- Electricity supply: Single phase (see ordering codes)

- Distilled water required

- Minimum space for ventilation of 50m³

- PC computer with spare USB port (not supplied by Armfield Ltd)

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 4.5m³

Gross Weight: 250Kg

Length: 2.45m

Width: 0.71m

Height: 1.2m

- RA3-MKII-A 220-240V/1ph/50Hz 13 Amps

- RA3-MKII-B 110V/1ph/60Hz 25 Amps

- RA3-MKII-G 220V/1ph/60Hz 13 Amps