Post Category: Armfield News

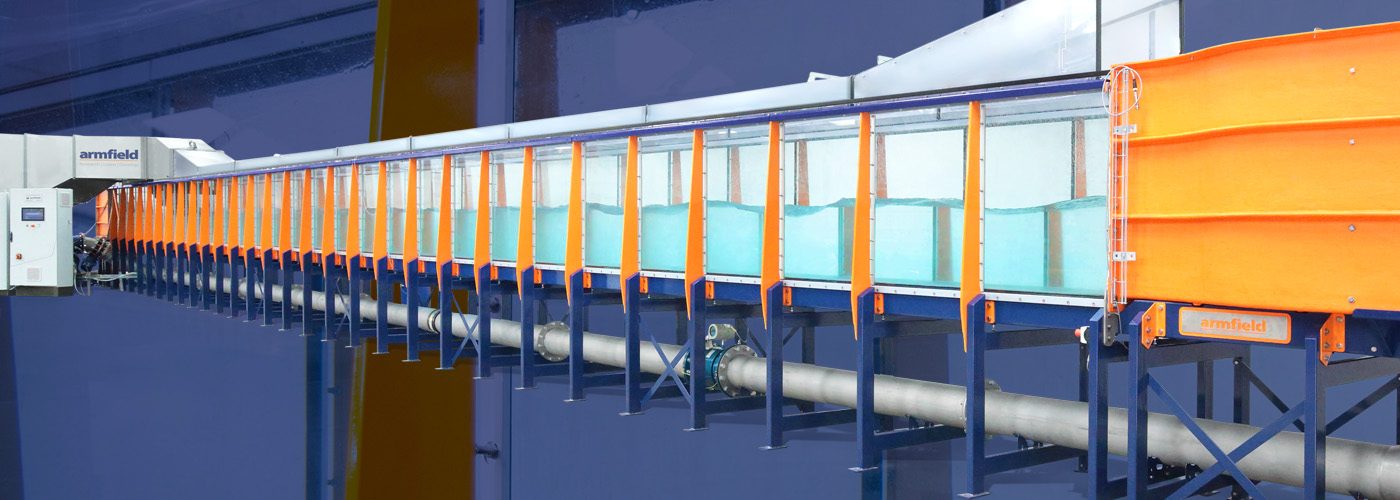

Mini Pilot Systems for product testing

Product testing sits at the heart of modern product development. Before any product reaches mass production, it must be proven in a controlled, repeatable, and measurable way. Across sectors such as food processing, pharmaceuticals, chemicals, education, and advanced manufacturing, organisations rely on structured pilot studies and pilot runs to validate assumptions, reduce risk, and protect product quality.

As an engineer working at Armfield, I see first hand how Mini Pilot Systems for product testing bridge the critical gap between laboratory experiments and full scale production. These systems allow businesses, researchers, and educators to test under real production conditions without the cost, disruption, or safety risks associated with full deployment.

Mini pilot systems are no longer optional extras. They are fundamental tools for informed decisions, risk mitigation, innovation, and increased confidence throughout the development process.

The importance of product testing in modern product development

Product development has become more complex. Markets demand higher quality, shorter time to market, and fewer costly errors. Product testing within a pilot environment allows companies to test specific aspects of a manufacturing process before committing significant resources.

Pilot studies play a vital role during the early stages and first stage of development. By running pilot programs and pilot surveys in a controlled environment, teams can collect live data, assess performance metrics, and gather qualitative feedback from real users where appropriate.

Whether developing high value products or refining existing production systems, product testing helps identify critical issues long before they affect a production line or full rollout.

What are Mini Pilot Systems for product testing?

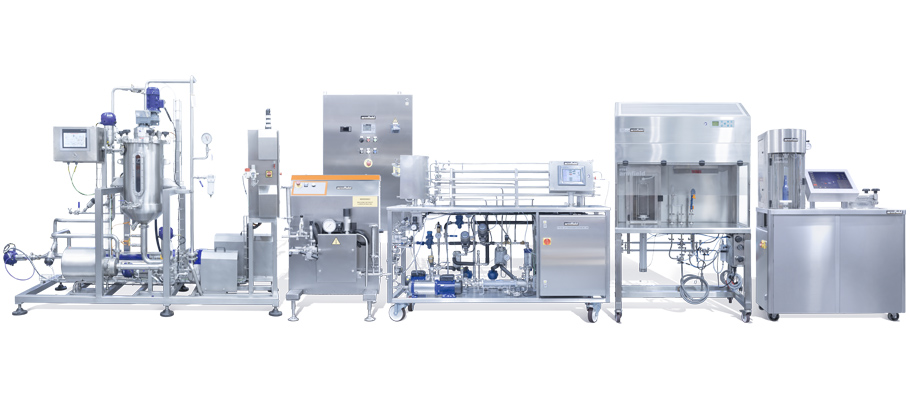

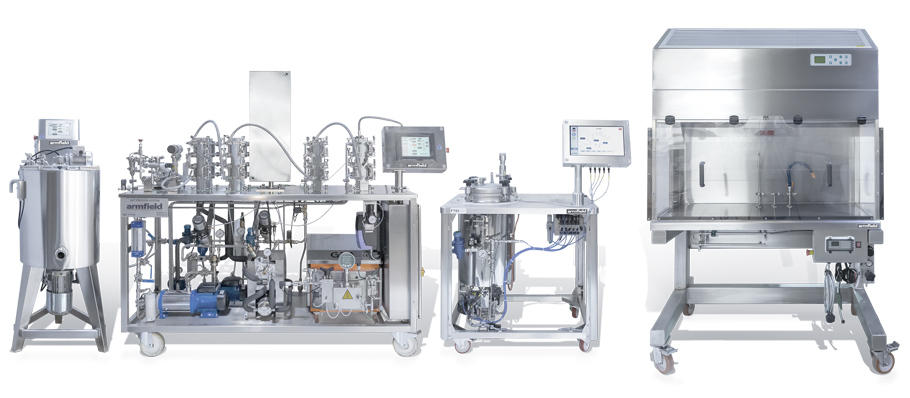

Mini pilot systems are small scale pilot plants designed to replicate real production conditions within a laboratory or controlled environment. They simulate full scale production processes while operating at a smaller scale, making them ideal for pilot stage testing, research findings, and later analysis.

Unlike simple bench tests, mini pilot systems allow continuous operation, live monitoring, and precise control of variables such as heat transfer, flow rates, pressure, and processing time. This enables highly accurate pilot results that inform the next stages of implementation.

At Armfield, our product testing apparatus is designed to support pilot runs, pilot studies, and larger scale study decisions with confidence and repeatability.

Key benefits of using Mini Pilot Systems

Mini pilot systems offer a wide range of advantages over traditional pilot plants or immediate full scale implementation.

One major benefit is cost effectiveness. Operating at a smaller scale reduces material usage, energy consumption, and waste. This is particularly important when working with expensive ingredients or high value products.

Speed is another advantage. Mini pilot systems deliver faster results, allowing development teams to iterate quickly, make necessary improvements, and avoid delays before product launches.

From a safety perspective, testing in a pilot environment significantly reduces potential risks. Safety risks can be identified early, protecting both staff and equipment before any full deployment.

Types of Mini Pilot Systems available

There are several types of mini pilot systems available depending on the testing requirements and production conditions.

Benchtop systems are ideal for laboratory based pilot studies, where space is limited but precision is essential. These systems are commonly used for preliminary tests, proof of concept, and early development process evaluations.

Portable pilot systems allow testing in live environments or multiple locations. These are particularly valuable for educational institutions, public sector research, and organisations seeking flexibility without permanent installation.

Larger mini pilot plants support structured packing, continuous processing, and extended pilot runs under real world operating conditions.

Core components of a Mini Pilot System

A well designed mini pilot system consists of several integrated components working together as a complete production system.

Sensors are used to capture live data including temperature, pressure, flow rate, and product parameters. Controllers manage process variables and ensure stable operation throughout pilot runs.

Data acquisition software plays a critical role by recording pilot results, supporting later analysis, and delivering actionable insights. These systems support informed decisions about scaling, process development, and full scale production.

At Armfield, system architecture is designed for ease of use, reliability, and compatibility with new technology while avoiding dependence on legacy systems.

Industries that rely on Mini Pilot Systems

Mini pilot systems are used across a wide range of industries. In pharmaceuticals, they support controlled pilot studies and quality control before full scale manufacturing.

In food and beverage processing, mini pilot plants help optimise production conditions, packaging approaches, and product quality before mass production. Educational institutions use mini pilot systems to teach real world process development methodologies to engineers and researchers.

Electronics, chemicals, and advanced manufacturing also depend on mini pilot systems to validate production processes and identify key differences between small scale and full scale operations.

Best practices for setting up and operating a Mini Pilot System

Successful pilot testing requires careful planning. Sensors must be calibrated regularly to ensure accurate live data collection. Operators should monitor performance metrics throughout pilot runs to catch usability issues and production flaws early.

Documentation is essential. Recording pilot results, development process changes, and insights ensures teams maintain clarity throughout the pilot stage and larger study phases.

Working in a controlled environment helps deliver reliable results while minimising business disruption.

Advantages over traditional pilot systems

Compared with traditional pilot plants, mini pilot systems are easier to maintain, require fewer resources, and offer greater flexibility. Their smaller size allows installation in laboratories without major infrastructure changes.

Maintenance demands are lower, and deployment is faster. This supports phased rollouts and small group testing before committing to full scale production lines.

How to choose the right Mini Pilot System

Choosing the right system depends on several factors. Organisations must consider the type of product, required testing parameters, production conditions, and expected scale up requirements.

A clear understanding of the manufacturing process and desired outputs ensures the system delivers business value rather than unnecessary complexity.

Frequently Asked Questions about Mini Pilot Systems

What are pilot studies and how do they support product development?

Pilot studies allow testing within a pilot environment to validate processes, reduce risk, and gather insights before full scale production.

Can mini pilot systems identify flaws before full implementation?

Yes. Mini pilot systems are highly effective at identifying critical issues, usability problems, and performance limitations early.

How does scaling impact product quality?

Data from mini pilot studies informs informed decisions about scaling while maintaining product quality and consistency.

Are mini pilot systems suitable for all products?

While not mandatory for every product, they are strongly recommended for complex processes, new technology, and high value products.

The role of Mini Pilot Systems in successful product launches

Mini Pilot Systems for product testing are essential tools in modern development processes. They help teams move confidently from laboratory concepts to full deployment while managing risk, cost, and quality.

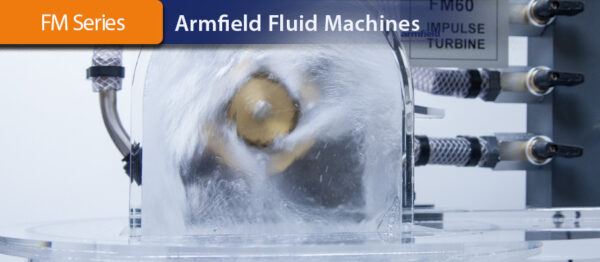

At Armfield, our product testing apparatus supports pilot plants, pilot runs, and pilot stage testing with precision and reliability, helping organisations achieve overall success in product development.

Ready to improve your product testing process?

Discover how Armfield mini pilot systems can support your development process and reduce risk. Visit our contact page today to discuss the right product testing apparatus for your application.

Navigating the Waves: The Importance of Testing Ship Stability Apparatus

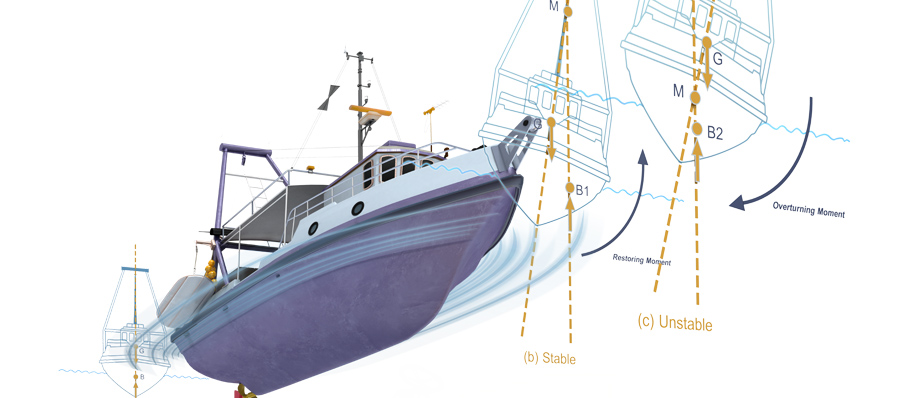

Ship stability has always been central to safe and efficient maritime operations. From passenger ships and cargo vessels to fishing boats and specialist marine vessels, stability determines how a ship behaves at sea, how it responds to loading conditions, and how it withstands forces such as wind, waves and weight shifts. Testing ship stability apparatus allows naval architects, marine engineers and students to understand these behaviours in a controlled and measurable way.

At Armfield, we specialise in advanced educational and research equipment that bridges theory and practice. Our solutions for testing ship stability apparatus enable precise investigation of hydrostatic pressure and its effects on floating bodies, making complex principles of naval architecture accessible, repeatable and accurate.

This article explores testing ship stability apparatus in depth, covering the methods, components, risks, interpretation of results and long term importance of accurate and regular testing.

Understanding ship stability and why it must be tested

Ship stability describes a vessel’s ability to return to its upright position after being disturbed by external forces. These forces may include waves, wind, cargo movement, passenger distribution or free surface effects within tanks. Stability is governed by the relationship between gravity G, buoyancy B and the metacentric height.

Testing ship stability apparatus enables engineers to study hydrostatic stability in safe laboratory conditions rather than relying only on full scale testing. It allows repeatable experiments using known weights, measured inclining angles and controlled heeling moments. This level of control is essential for understanding ship hydrostatics and stability characteristics across different ship designs and loading conditions.

Types of ship stability tests used in modern maritime engineering

A range of stability tests are carried out when using testing ship stability apparatus. Each test focuses on a different aspect of stability and ship motion.

Inclining experiments are among the most widely used stability tests. Known weights are moved transversely across the ship or model, producing a measurable heel. From this, metacentric height and initial stability can be calculated with high accuracy.

Rolling period tests measure the natural roll frequency of a floating body. These tests provide insight into adequate stability and comfort, particularly for passenger vessels. A longer rolling period often indicates better overall stability characteristics.

Lightship displacement tests assess the ship’s weight when empty of cargo, fuel and passengers. Understanding lightship displacement is essential for calculating intact stability under various loading scenarios.

Large angle stability tests focus on behaviour beyond small inclinations. These tests help engineers understand capsize risks, buoyancy vectors and hydrostatic curves at extreme heel angles.

The purpose of testing ship stability apparatus

The core purpose of testing ship stability apparatus is safety. Accurate stability data ensures that ships comply with international standards and operate within safe limits. Organisations such as the International Maritime Organization rely on stability data to regulate vessel design and operation.

Testing also supports ship design optimisation. Naval architects use stability data to refine hull forms, internal bulkheads, transverse watertight bulkheads and weight distribution. For newly constructed ships, testing confirms that theoretical design values align with real behaviour.

From an educational perspective, testing ship stability apparatus provides practical insight into fluid mechanics, hydrostatic pressure and ship hydrostatics. It transforms abstract curves and equations into observable behaviour.

Key components of a ship stability testing apparatus

A comprehensive testing ship stability apparatus consists of several integrated components working together.

The floating ship model represents real world ship structure and design. Models may include general cargo vessel forms, passenger ships or fishing vessels, allowing comparisons between large ships and small ships.

Inclining mechanisms apply controlled heeling moments using suspended mass or known weights. These movements simulate weight shifts and cargo movement.

Stability meters and clinometers measure heel angle with high accuracy. These instruments are critical for determining metacentric height and stability characteristics.

Hydrostatics benches and water tanks allow study of hydrostatic pressure, buoyancy B and waterplane area. These benches are essential for understanding pressure distribution and hydrostatic curves.

Advanced systems incorporate data capture and analysis, producing technical data that supports detailed interpretation and reporting.

How hydrostatic pressure testing supports ship stability studies

Hydrostatic pressure plays a direct role in buoyancy and stability. Apparatus that tests hydrostatic pressure and its effects allows engineers to visualise how pressure varies with depth, hull shape and immersion.

Using hydrostatic testing alongside stability testing provides a deeper understanding of buoyancy vectors, pressure curves and the vertical centre of force. This integrated approach is particularly valuable in naval engineering education, where linking fluid properties to real ship motion strengthens comprehension.

Best practice for conducting successful stability tests

Accuracy and repeatability are essential when using testing ship stability apparatus. Proper procedures must be followed at all times.

The apparatus should be levelled and calibrated before testing begins. Baseline measurements ensure that all subsequent data is reliable.

Known weights must be accurately measured and positioned along the transverse direction or longitudinal axis as required. Even small errors can affect calculated metacentric height.

Mooring restraints should be correctly fitted but not restrictive. Mooring lines must prevent drift while allowing free rolling motion.

Environmental factors such as water temperature and vibration should be controlled to maintain consistent results.

Consequences of inadequate ship stability testing

Failure to properly test ship stability apparatus can lead to serious consequences. Inaccurate data may result in unsafe ship design, increased risk of capsize, excessive listing or poor seakeeping performance.

Cargo vessels affected by incorrect weight assumptions may experience dangerous free surface effects. Passenger ships with inaccurate stability data may suffer discomfort or safety risks during rolling motion.

In extreme cases, lack of adequate testing contributes to structural stress, compromised bulkheads and increased risk during heavy weather.

Interpreting stability test results and applying them to ship design

Interpreting stability test data requires understanding of naval architecture principles. Inclining experiment results are used to calculate metacentric height and assess initial stability.

Hydrostatic curves reveal how buoyancy and stability change with draft and heel angle. These curves guide design decisions such as bilge keel sizing, internal layout and centre of gravity positioning.

When results indicate marginal stability, adjustments may include redistributing weight, modifying internal compartments or altering hull geometry. Testing enables these changes to be assessed before real world implementation.

Maintaining and regularly testing ship stability apparatus

Regular testing ensures that ship stability apparatus maintains high accuracy over time. Mechanical components, sensors and measuring instruments should be inspected and calibrated routinely.

Comprehensive manuals and testing records support long term reliability and traceability. In educational environments, regular maintenance ensures consistent results for students and researchers.

By maintaining testing ship stability apparatus, institutions ensure that stability data remains accurate, repeatable and aligned with current international codes and standards.

Frequently asked questions about testing ship stability apparatus

What is the purpose of the NA8 Ships Stability Apparatus in ship stability testing?

The NA8 Ships Stability Apparatus is designed to study ship hydrostatics and stability using floating ship models, inclining tests and stability measurement instruments. It allows investigation of hydrostatic pressure and stability characteristics in a controlled laboratory environment.

How does a floating ship model differ from a crane ship model during stability testing?

A floating ship model represents general ship behaviour and buoyancy, while a crane ship model introduces suspended masses and dynamic loading effects. This allows engineers to study additional heeling moments and complex weight movements.

What role does a stability meter play in determining ship stability?

The stability meter measures heel angle with precision during inclining and rolling tests. Accurate angle measurement is essential for calculating metacentric height and assessing adequate stability.

Can changes in lightship displacement affect intact stability?

Yes, changes in lightship displacement directly affect the centre of gravity and metacentric height. Even small alterations in lightship condition can significantly influence intact stability and must be accurately measured.

Why regular stability testing is essential for modern ships

Regular stability testing ensures that stability data remains current as ships age, are modified or experience changes in operating conditions. It supports compliance with international regulations and enhances long term safety at sea.

Speak to Armfield about advanced ship stability testing solutions

If you are looking to enhance your laboratory, teaching or research capability, Armfield provides proven solutions for testing ship stability apparatus and apparatus that tests hydrostatic pressure and its effects. Our equipment supports accurate experimentation, deep understanding and real world relevance. Visit our contact page today to discuss your requirements and discover how our naval architecture systems can support your work.

Distillation: Unlocking the Secrets of Efficient Systems

Distillation systems are among the oldest and most effective separation methods in chemical engineering. Used across industries ranging from pharmaceuticals to petroleum refining, these systems exploit differences in boiling points to separate mixtures into their pure components. Whether in a laboratory, an industrial plant, or even for home water treatment, distillation equipment continues to be the ideal solution for producing purified products with precision and reliability.

What is a Distillation System?

A distillation system is a unit operation designed to separate liquids based on their vapour pressure and boiling points. By applying heat to a liquid mixture in a boiling chamber, components are vaporised and then condensed back into liquid form in a condenser. The distillate collected represents the purified fraction. From producing distilled water to refining crude oil into usable fuels, distillation units play a critical role in modern industrial applications.

Different Types of Distillation Systems

Distillation types vary according to the mixture being separated and the efficiency required:

-

Batch distillation – Common in smaller operations such as distilleries for alcoholic beverages.

-

Continuous distillation – Widely used in industrial processes like petroleum refining, where distillation towers operate non-stop.

-

Fractional distillation – Involves fractionating columns to separate multiple components from a liquid mixture, ideal for crude oil and chemical feedstocks.

-

Steam distillation – Applied to heat-sensitive liquids such as essential oils.

-

Vacuum distillation systems – Reduce pressure to allow separation at lower temperatures, protecting heat-sensitive solvents.

-

Extractive and azeotropic distillation – Used when components have very similar boiling points, requiring solvents or pressure-swing designs for effective separation.

Each system has tailored solutions depending on the specific needs of the industry.

Key Components of Distillation Units

Most distillation equipment includes:

-

Boiling chamber or still – Where the original mixture is heated by a heating element.

-

Condenser and coils – To cool vapour into liquid, often aided by heat exchangers.

-

Collection vessel or storage containers – To store the final purified product.

-

Control systems – In modern designs, computer-controlled modules ensure selective boiling, accurate temperature monitoring, and reduced contamination risks.

How the Distillation Process Works

The process begins by heating the liquid mixture until the component with the lowest boiling point enters the gas phase. Vapour rises through the column, undergoes physical separation, and is condensed back into the liquid phase. The condensate is collected as distilled water, purified solvents, or refined fuels depending on the application. Remaining liquid may undergo further evaporation and treatment to maximise yield.

Applications of Distillation Systems

Distillation applications span a wide range of industries:

-

Water treatment – A water distiller can remove contaminants, dissolved solids, and volatile organic compounds (VOCs) to deliver pure water.

-

Pharmaceutical industry – Produces high-purity solvents and fine chemicals.

-

Petroleum refining – Fractional distillation towers separate crude oil into petrol, diesel, and kerosene.

-

Food and beverages – Essential oils, flavourings, and ethyl alcohol production.

-

Laboratory and pilot plants – For water testing, chemical analysis, and process development.

Benefits of Distillation Systems

-

Reliable separation of complex mixtures.

-

Production of purified water, solvents, and chemicals meeting performance standards.

-

Versatility across organic and inorganic compounds.

-

Ability to remove contaminants and target specific compounds.

-

Long-term durability with stainless steel or all-glass construction.

Industrial Sectors That Rely on Distillation

-

Pharmaceuticals – For active ingredients and high-grade solvents.

-

Chemical engineering – Inorganic compounds, sulphuric acid, hydrochloric acid production.

-

Energy sector – Petroleum and renewable fuels.

-

Environmental – Wastewater treatment and recovery of trace metals.

Maintenance and Troubleshooting Tips

Regular maintenance ensures long service life and high performance:

-

Clean boiling chambers and fractionating columns to avoid contamination.

-

Conduct water testing and analysis to verify distillate quality.

-

Inspect storage tanks for leaks.

-

Ensure vacuum pumps and condensers are operating correctly.

-

Follow National Sanitation Foundation guidelines for water distillers in private water systems.

Advancements in Distillation Technology

Modern designs have improved efficiency through:

-

Computer-controlled systems for automated operation.

-

Energy-efficient designs reducing waste heat.

-

Pilot plants allowing scalable testing before full industrial deployment.

-

Compact modular units tailored to laboratory and small-scale industrial use.

FAQs About Distillation Systems

What are the benefits and drawbacks of vacuum distillation systems for water treatment?

Vacuum distillation allows distillation at reduced pressure, protecting heat-sensitive liquids. However, it requires vacuum pumps and adds operational costs.

How does a water distiller remove impurities?

A water distiller heats water in a chamber, vapourises it, and condenses it into distilled water, leaving dissolved solids, contaminants, and VOCs behind.

Can one distillation type be used for all substances?

No. Heat-sensitive liquids need steam distillation, while crude oil requires fractional distillation. Tailored solutions are key.

Why is targeting volatile organic compounds important?

During the boiling process, VOCs can evaporate with water. Advanced distillation equipment is designed to capture and remove them, ensuring purified water.

Contact Us for Tailored Distillation Solutions

At Armfield, we provide advanced distillation units and pilot plants tailored for education, research, and industry. Our systems cover every need, from water distillers for laboratories to continuous distillation towers for industrial applications.

Get in touch with our team today to explore the right system for your specific needs.

Exploring Distillation Columns : The Art of Separation

Distillation columns stand as one of the most critical unit operations in chemical engineering, enabling efficient separation of liquid mixtures based on differences in boiling points. From oil refineries and natural gas processing plants to pharmaceutical laboratories and beverage production, distillation processes remain indispensable.

At Armfield, we specialise in creating world-class solutions for all types of unit operations, including advanced distillation columns that help researchers, engineers, and industrial professionals achieve precise separation and high-purity products.

What Is a Distillation Column?

A distillation column is a vessel designed to separate liquid mixtures into individual components or fractions. The process relies on the principle that different liquid components within a mixture have different boiling points. By providing repeated cycles of vaporisation and condensation, distillation columns allow one to extract a distillate or top product of higher purity, while the less volatile bottom product stream collects at the base.

These distillation systems are found in a wide range of industries:

-

Petrochemicals – for separating crude oil into fuels and lubricants.

-

Pharmaceuticals – to purify solvents or active ingredients.

-

Beverages – such as producing distilled water or alcoholic beverages.

-

Biofuels – for refining ethanol and other renewable fuels.

Principles of Distillation

The separation process in a distillation unit works by heating a liquid mixture until it vaporises. The rising vapour travels up the column, contacting descending liquid, which creates a dynamic vapour-liquid equilibrium. The more volatile component enriches in the vapour phase, while the less volatile component concentrates in the liquid phase.

Fractional distillation, extractive distillation, differential distillation, and azeotropic distillation are variations of this principle, each used for particular separation challenges.

Types of Distillation Columns

There are several designs used across various industrial applications:

-

Batch Columns – operate on a fixed charge until the separation is complete.

-

Continuous Columns – handle a constant input and output stream, widely used in oil refineries.

-

Fractionating Columns – equipped with trays or packing to maximise vapour-liquid contact.

-

Packed Columns – filled with structured or random packing materials, ideal for high-purity requirements and low pressure drop.

-

Tray Columns – employing valve trays, sieve trays, or bubble caps for large-scale separation.

Each type of column serves different distillation processes, from laboratory experiments using borosilicate glass vessels to industrial-scale distillation towers built with high-strength alloys.

Components of a Distillation Column

A typical distillation column comprises several major components:

-

Column Shell – the main vertical vessel, designed with precise column height and diameter.

-

Internals (Trays or Packing) – providing vapour-liquid contact through tray design or structured/random packing.

-

Reboiler – supplies the necessary vaporisation by heating the mixture at the bottom.

-

Condenser – cools rising vapour into condensed liquid for collection or reflux.

-

Reflux Drum – stores condensed liquid and regulates reflux ratio for higher purity.

Armfield designs incorporate durable materials, from borosilicate glass for laboratory applications to corrosion-resistant alloys for industrial vessels.

Design Considerations

Distillation column design must account for:

-

Properties of the feed mixture (boiling points, vapour pressures).

-

Desired product purity and flow rates.

-

Column performance parameters such as pressure drop and reflux ratio.

-

Mechanical design and material transfer efficiency.

A well-designed column balances enriching and stripping sections, ensuring both the distillate composition and bottom product stream meet specifications.

Factors Affecting Column Performance

Several factors influence efficiency in distillation systems:

-

Temperature and Pressure – governing vapour-liquid equilibrium.

-

Reflux Ratio – a higher reflux ratio enhances separation but increases energy use.

-

Column Internals – poor tray design can lead to flooding or weeping.

-

Heat Input – too much or too little heat disrupts proper separation.

Research published in Chemical Engineering Science continues to refine design specifications and column internals to improve performance.

Troubleshooting and Optimisation

Common issues in distillation columns include:

-

Flooding – caused by excessive vapour flow leading to liquid buildup.

-

Weeping – when liquid leaks through tray perforations due to low vapour rates.

-

Foaming – disrupting mass transfer efficiency.

Preventive measures include careful monitoring of vapour pressures, flow rates, and pressure drops. Regular inspection of packing materials and cleaning of equipment ensures long-term reliability.

Applications Across Industries

Distillation towers play a critical role in diverse industries:

-

Natural Gas Processing – separating gas components for fuel and feedstock.

-

Oil Refineries – fractionating crude oil into petrol, diesel, and kerosene.

-

Pharmaceuticals – isolating high-purity ingredients.

-

Beverages – distilling spirits and producing distilled water.

-

Biofuels – refining renewable energy resources.

The ability to achieve efficient separation and high throughputs makes distillation columns one of the most vital unit operations in engineering.

FAQs

What is the role of a distillation unit in industrial processes?

A distillation unit separates liquid mixtures into purified fractions, enabling production of fuels, pharmaceuticals, chemicals, and beverages.

How does a tray column differ from a packed column?

A tray column uses valve trays or sieve trays for vapour-liquid contact, while a packed column employs packing materials for lower pressure drop and higher efficiency in specific applications.

How does adjusting reflux ratio impact column efficiency?

A higher reflux ratio increases separation efficiency but also raises energy consumption. The minimum reflux ratio defines the least energy required for effective operation.

Why is the bottom product stream important?

The bottom product stream contains the less volatile components. Its quality is crucial for downstream processes and depends on factors such as heat input, reflux ratio, and design specifications.

Armfield for Distillation Columns

Distillation columns remain at the heart of modern separation process principles. Their ability to deliver precise separation of liquid mixtures supports industries from petrochemicals to pharmaceuticals. At Armfield, we are proud to provide innovative solutions for all types of unit operations, ensuring our clients benefit from reliable, high-performance distillation equipment tailored to their needs.

Ready to optimise your distillation processes?

Discover how Armfield’s distillation columns and unit operations solutions can enhance your laboratory or industrial setup. Contact us today to learn more.

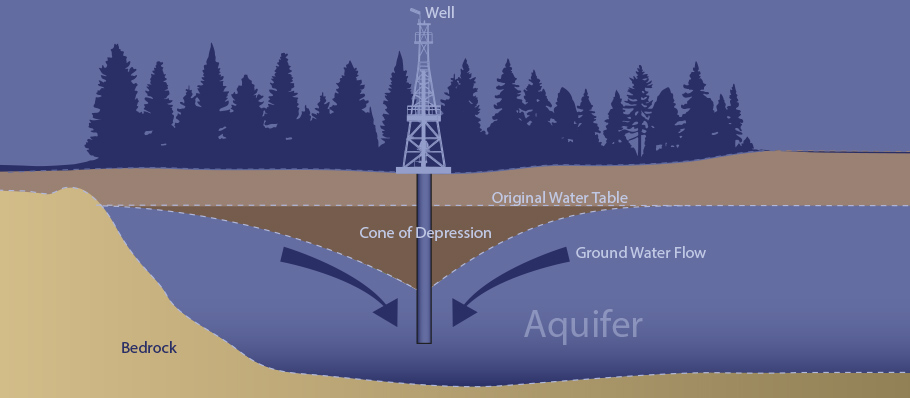

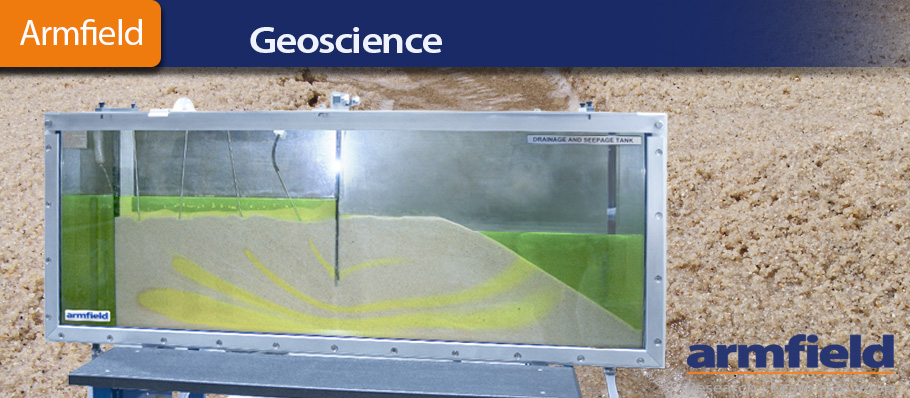

Beneath the Surface: Deciphering Ground Water Flow Patterns

Understanding ground water flow is central to effective water resource management, environmental science, and engineering practice. While water above the ground in rivers, lakes, and wetlands is easy to observe, the silent and steady movement of underground water remains less visible but no less important. At Armfield, we provide leading Hydraulics and Hydrology apparatus that allows researchers, educators, and engineers to study, simulate, and manage ground water systems with precision.

What is Ground Water and Why is it Important?

Ground water refers to the water stored within the pore spaces of soils, sediments, and geological formations beneath the ground surface. Unlike surface water, which collects in rivers and lakes, ground water is often hidden below the land surface, existing in aquifers that can serve as essential water supplies for drinking, irrigation, and industry. Globally, ground water provides nearly half of the world’s drinking water and plays a key role in maintaining flow in surface water bodies.

Understanding ground water flow helps scientists and hydrogeologists ensure water quality, predict contaminant transport, and safeguard long-term water resources.

Sources and Recharge of Ground Water

Ground water originates primarily from precipitation, such as rainfall and snowmelt, which infiltrates the soil and percolates through subsurface layers. This process is known as ground water recharge. Infiltration occurs when water molecules move downward through porous medium until they reach the zone of saturation. Recharge is critical in maintaining the balance of water table aquifers and deeper confined aquifers.

Human activities such as paving and deforestation often reduce natural infiltration, highlighting the need for careful groundwater management strategies.

Factors Influencing Ground Water Flow

Several elements determine the speed and direction of groundwater movement:

-

Topography: Water generally flows from areas of higher hydraulic head to areas of lower hydraulic head, often following elevations and gradients in the land surface.

-

Soil and Rock Type: Granular sediments and permeable materials such as sand and limestone allow rapid flow rates, whereas shale and clay form low permeability barriers.

-

Porosity: The amount of void spaces within subsurface materials dictates how much water can be stored and transmitted.

-

Human Activities: Excessive pumping of well water, contamination from underground storage tanks, or land use changes can disrupt natural flow patterns.

Aquifers and Flow Systems

Ground water exists in different aquifer types:

-

Unconfined aquifers: Directly connected to the surface, their water levels fluctuate with precipitation and surface runoff.

-

Confined aquifers: Protected by impermeable layers, these are often under pressure differences and may produce artesian water.

-

Perched aquifers: Small, localised systems where water sits above impermeable rock within the unsaturated zone.

Each aquifer type influences groundwater flow direction, flow velocities, and the availability of water resources.

Ground Water and the Hydrologic Cycle

Ground water is a crucial part of the water cycle, also known as the hydrologic cycle. It interacts continuously with surface water bodies, contributing to stream flow, wetlands, and lakes. Recharge, storage, and discharge areas create a dynamic balance where ground water and surface water are interconnected.

Hydrogeologists often apply Darcy’s Law to quantify flow rates in a groundwater system, using measures of hydraulic conductivity and significant hydraulic gradients to model flow nets and predict contaminant transport.

Human Impacts on Ground Water Flow

Ground water systems are highly sensitive to human intervention. Excessive pumping can lower the water table, leading to declining water supplies and even land subsidence. Poorly managed industrial activity may lead to contaminated groundwater, which is difficult and costly to remediate. Urbanisation also alters flow lines by reducing natural infiltration and increasing surface runoff.

Sustainable groundwater management requires monitoring water levels, testing water quality, and implementing permeability tests to assess subsurface layers.

Tools for Studying Ground Water Flow

Modern groundwater studies rely on advanced groundwater flow models to simulate flow paths, predict flow patterns, and evaluate the spread of contaminants. At Armfield, our Hydraulics and Hydrology apparatus is designed to support these studies by replicating complex subsurface materials and flow velocities in controlled laboratory conditions. This enables researchers and educators to apply theoretical principles like Darcy’s formula to practical experiments, building a deeper understanding of groundwater systems.

FAQs on Ground Water Flow

What is ground water and how does it differ from surface water?

Ground water is stored beneath the land surface in aquifers, while surface water is found in rivers, lakes, and wetlands. Ground water often moves more slowly, through porous formations and subsurface layers.

How can groundwater flow direction be determined?

It can be identified by mapping equipotential lines and measuring hydraulic head differences. Water flows from higher to lower hydraulic head, often towards the nearest stream or discharge area.

What role does porosity play in groundwater movement?

Porosity refers to the percentage of void spaces in rock formations or granular sediments. Higher porosity means greater potential for water storage and movement, while lower porosity restricts flow.

What methods are used in modern groundwater studies?

Hydrogeologists use Darcy’s equation, flow nets, and groundwater flow models, alongside permeability tests and monitoring wells, to analyse groundwater levels and predict future flow patterns.

Sustainable Ground Water Management

Sustainable management of underground water resources requires an integrated approach: protecting aquifers from pollution, reducing over-extraction, and ensuring continuous monitoring of water quality. As population pressures and climate change impact water resources, a deeper understanding of groundwater flow is essential.

Discover How Armfield Can Help

At Armfield, we offer a wide range of Hydraulics and Hydrology apparatus designed to support groundwater studies, teaching, and applied research. Whether you’re modelling flow velocities in a porous medium or demonstrating Darcy’s Law to students, our solutions provide the accuracy and reliability you need.

Contact us today to learn more about how our apparatus can advance your understanding of ground water flow.

You may also like

(to be added when all new posts are approved)

CSTR Reactors: A Guide to Optimal Chemical Reactions

In chemical engineering, precision, efficiency, and scalability are paramount. Among the various types of reactors used across industries, the Continuous Stirred Tank Reactor (CSTR) stands out as a cornerstone for continuous production processes. At Armfield, we specialise in engineering advanced CSTR reactor systems that are built for research, education, and industrial applications.

What Is a CSTR Reactor?

A CSTR reactor is a type of vessel in which reactants are continuously introduced and products are simultaneously removed while maintaining constant agitation. It’s one of the most widely used reactor types for homogeneous liquid-phase flow reactions, particularly when consistent composition and temperature control are essential.

Designed to operate under steady-state conditions, the CSTR offers continuous operation and perfect back mixing, making it suitable for both laboratory use and scaled industrial processes.

Explore our CEM-MKII CSTR Reactor →

Key Design Elements of a CSTR

A typical CSTR consists of:

-

A tank reactor or vessel, often made from stainless steel to handle a variety of chemicals

-

An impeller that ensures constant agitation for efficient mixing

-

A heat exchanger for temperature control, critical for highly exothermic reactions

The reactor volume, shape of the vessel, and volumetric flow rate of the inlet stream and outlet stream all affect reactor performance and residence time distribution.

Types of CSTRs

CSTRs are highly adaptable and can be operated:

-

Individually – as a single unit for basic applications

-

In series, as a cascade of several CSTRs to approximate plug flow behaviour

-

In parallel, to manage throughput and high viscosity reactions

Each configuration has distinct advantages depending on process requirements, such as product yield, heat flow management, and reaction efficiency.

Operating Principles and Chemical Kinetics

CSTRs operate under the principle of perfect mixing. This means the output composition matches the reactor contents at any given time. The continuous feed of reactants and constant stirring allows for uniform substrate concentration, minimising variations in reaction conditions.

This uniformity is essential in analysing reaction kinetics, determining the rate constant, and maintaining desired stoichiometric coefficients.

Real-World Applications

Industries benefiting from CSTR technology include:

-

Pharmaceutical manufacturing – for precise control of reaction mixtures

-

Food and beverage processing – particularly fermentation and mixing of high-viscosity substances

-

Petrochemicals and biomass processing – for continuous conversion reactions

-

Wastewater treatment – where CSTRs help maximise biomass digestion

Armfield’s BE4 Anaerobic Column Reactor demonstrates how continuous stirred reactors are instrumental in education and real-world industrial processing.

Controlling Conditions: Temperature and Concentration

Maintaining a constant temperature and stable concentration of reactants is crucial in CSTR operation. Armfield CSTRs feature integrated heat exchangers, sensors, and control panels that ensure accurate data logging and reactor temperature regulation.

For complex reactions, the balance between mass transfer and heat transfer is closely monitored to avoid side reactions and to preserve reaction efficiency.

Challenges and Limitations

While CSTRs are ideal for many applications, they are not without limitations:

-

Scaling up from lab-scale to industrial units can be complex due to changes in reaction kinetics

-

Side reactions may occur due to long residence times

-

Assumptions of perfect mixing may not always hold, especially in high-viscosity or multi-phase reactions

Nonetheless, with proper reactor design and control systems, these limitations can be mitigated effectively.

Optimising CSTR Performance

Enhancing CSTR performance involves:

-

Adjusting flow rates for optimal residence time

-

Selecting the correct reactor volume for the specific reaction

-

Using a series of CSTRs to replicate plug flow reactor characteristics

-

Incorporating advanced control techniques for better process monitoring

With Armfield’s modular reactor systems, researchers and engineers can tweak and tailor configurations to fit their exact process needs.

Summary: The Value of CSTRs

To summarise:

-

CSTRs are ideal for continuous reactions, offering a uniform and scalable environment

-

Their versatility spans chemical engineering, food processing, pharmaceuticals, and waste treatment

-

Control over temperature, mixing, and concentration is vital to maximise efficiency

-

With proper design and operation, CSTRs deliver consistent results and are highly valuable for industrial production

Whether you’re looking to develop advanced teaching equipment or streamline an industrial chemical process, CSTRs remain one of the most reliable and versatile reactor types available.

Frequently Asked Questions

What are the advantages of using continuous stirred tank reactors (CSTRs)?

CSTRs allow for continuous production with consistent output, ideal for homogeneous liquid-phase reactions. They provide precise control over conditions and are easier to scale in series.

How does a perfectly mixed reactor differ from a real CSTR?

In theory, a perfectly mixed reactor assumes immediate and complete mixing, whereas real CSTRs may experience mixing limits, particularly with high viscosity or multi-phase materials.

Can all types of continuous reactions be carried out in a CSTR?

Not all. Reactions requiring plug flow behaviour or highly sensitive to residence time distribution may benefit more from plug flow reactors (PFRs) or batch systems.

What are key considerations when scaling up a lab-scale CSTR?

When scaling, it’s crucial to consider changes in mass transfer, heat flow, viscosity, and reactant concentrations. Lab-scale assumptions may not always translate directly.

Get in Touch for Expert Guidance

At Armfield, we provide world-leading equipment for chemical reaction engineering, including advanced CSTR systems. Whether you’re in academia or industry, our modular and robust reactors can be tailored to your specific application.

Contact us today to learn more →

Armfield CSTR Products

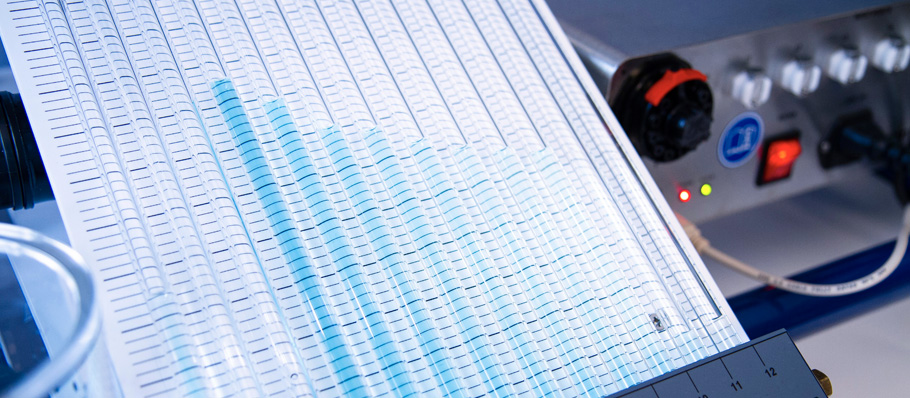

Measuring the Invisible: The Fascinating World of Fluid Science Manometers

Fluid science manometers are fundamental tools for measuring pressure in gases and liquids. They are widely used across research laboratories, industrial applications, and education to provide accurate and reliable pressure readings. At Armfield, we specialise in designing and manufacturing advanced manometer solutions, from U-tube and inclined manometers to differential systems, ensuring precision and durability for every application.

What Is a Fluid Science Manometer?

A fluid science manometer is an instrument that measures pressure using a column of liquid. Its design is based on hydrostatics—the principle that pressure in a fluid is proportional to its height and density. By comparing fluid levels in connected columns, manometers provide a direct, visual indication of pressure differences, making them one of the most reliable tools for both fundamental fluid dynamics experiments and industrial processes.

The Fluid Science U-Tube Manometer tray from Armfield, for example, allows for accurate demonstrations of pressure variations caused by differing flow rates and atmospheric conditions, supporting both individual and group experiments.

Armfield uses paraffin (kerosene) in its manometer systems because its lighter density enhances sensitivity, making it ideal for measuring small pressure variations—such as those found in flow channels and Pitot tube experiments. It’s safe, visible, and well-suited for teaching environments. (H12-5: 500mm scale differential kerosene over water manometer – Range 0.213m H2O)

Types of Fluid Science Manometers

U-Tube Manometers

These are the most common type, consisting of a U-shaped glass tube filled with manometric fluid (often water or mercury). They are simple, robust, and effective for measuring gauge pressure and differential pressure in various fluids.

Inclined Manometers

When higher sensitivity is required for small pressure differences, inclined manometers provide enhanced accuracy. Their tilted design magnifies height differences, allowing for precise measurements in laboratory settings.

Differential Manometers

These measure pressure differences between two points in a system, making them ideal for monitoring flow rate changes, filter performance, or pressure drops across components in HVAC or fluid transport systems.

Differential kerosene over water manometer

A differential kerosene over water manometer uses the density difference between kerosene (0.8) and water (1.0) to measure small pressure changes in fluid systems. The immiscible fluids in a U-tube shift under pressure, with the height difference indicating pressure via ΔP = g (ρ_water * h_water – ρ_kerosene * h_kerosene). Ideal for low-pressure applications like HVAC and fluid mechanics, it offers accuracy and stability.

Inverted Differential Manometers

Unlike standard differential devices, inverted types are designed to measure negative pressure differentials. They are especially useful in vacuum systems and specialised industrial processes.

Digital Manometers

By integrating electronic pressure sensors, digital manometers deliver real-time data with high accuracy. They are commonly used in industrial environments where precise, repeatable measurements are essential.

How Fluid Science Manometers Work

The working principle of a manometer is straightforward:

-

A reference fluid (such as water or mercury) is placed in the tube.

-

When a pressure difference occurs between two points, the liquid column shifts.

-

The height difference (h) between the two fluid levels corresponds to the pressure difference, calculated using:

P = ρ × g × h

Where:

-

P = pressure difference

-

ρ = density of the fluid

-

g = gravitational acceleration

-

h = height difference

This fundamental principle is used across fluid dynamics experiments, industrial processes, and research applications.

Applications of Fluid Science Manometers

Manometers have a wide range of applications:

-

HVAC systems: Measuring airflow and differential pressure changes for proper ventilation and performance.

-

Medical equipment: Used in devices such as blood pressure monitors for precise pressure readings.

-

Aerospace engineering: Monitoring airspeed and cabin pressure using high-accuracy systems.

-

Environmental monitoring: Measuring barometric pressure and water levels for weather forecasting.

-

Laboratory research: Essential in teaching fluid mechanics, including experiments on Bernoulli’s principle and fluid velocity.

-

Industrial processes: Ensuring optimal pressure control in chemical engineering, processing plants, and hydraulic systems.

Armfield’s Fluid Science Service Units support these applications by providing modular tray-based systems for experimentation and training.

Choosing the Right Manometer

When selecting a manometer, consider:

-

Pressure range: Match the instrument to the required measurement level (e.g. small pressure differences require inclined manometers).

-

Fluid compatibility: Ensure the manometric fluid is suitable for the working environment.

-

Accuracy and sensitivity: Laboratory experiments often require high sensitivity, while industrial applications demand durability.

-

Environmental conditions: Factors such as temperature and humidity can influence readings.

-

Maintenance needs: Some designs require calibration for long-term accuracy.

At Armfield, our engineering team helps clients choose the best solution for their specific fluid science manometer requirements.

Common Problems and Troubleshooting

-

Inconsistent readings: Often caused by air bubbles in the fluid column—purging the system usually resolves this.

-

Temperature-related errors: Use fluids with stable density across temperature ranges to maintain accuracy.

-

Fluid evaporation: Sealed or digital manometers prevent this issue in long-term applications.

-

Leaks in tubing or connections: Regular inspection prevents errors and protects against performance loss.

Maintenance Tips

To ensure optimal performance:

-

Clean the manometer tube regularly to avoid contamination.

-

Verify fluid levels and top up if required.

-

Calibrate periodically to maintain high-accuracy measurements.

-

Inspect connections and seals to prevent leaks.

-

Store the instrument in a controlled environment to avoid damage.

FAQs About Fluid Science Manometers

1. What is the purpose of a Fluid Science U-Tube Manometer tray?

It is used to measure pressure differences in fluids, enabling students and engineers to observe fluid behaviour and perform hands-on experimentation.

2. How accurate are gauge pressure measurements?

When properly calibrated, manometers provide precise measurements, especially for small and moderate pressure ranges, making them highly reliable in laboratories and industrial environments.

3. How do blood pressure monitors relate to fluid science manometers?

They use the same principle of pressure measurement, adapted to medical devices with electronic sensors for accurate and non-invasive monitoring.

4. How does the choice of manometer fluid impact accuracy?

The density of the fluid directly affects the scale of measurement. For example, mercury is suited to high-pressure applications, while water or low-density fluids are used for sensitive, small-magnitude pressure differences.

Why Choose Armfield?

At Armfield, we have decades of expertise in creating fluid science manometers that deliver reliability, precision, and long-term value. Our modular systems, such as the Fluid Science Service Unit, are designed for both industrial use and practical experimentation in research and education.

Ready to Measure with Precision?

Contact Armfield today to find out how our fluid science manometers can improve your experiments, processes, and training programmes.

The Impact of Steam Generators in Modern Laboratories

Steam generators for laboratory use are essential tools that ensure consistent performance, precise control, and safe operations. At Armfield, we’re proud to provide world-class laboratory steam generators designed to deliver contaminant-free, high-quality steam for a wide range of applications—from sterilisation to pharmaceutical product development.

Our innovative systems support cutting-edge laboratory work with precision, reliability, and flexibility. But what exactly are steam generators, and why are they so crucial?

What Is a Laboratory Steam Generator?

A steam generator is a specialised device that heats water to produce saturated steam, typically at high temperatures and operating pressure, to serve a variety of laboratory needs. Unlike traditional industrial boilers, laboratory steam generators are purpose-built to offer compactness, energy efficiency, and a cleaner output, commonly referred to as pure steam or clean steam.

At Armfield, our units are trusted by researchers across scientific disciplines for their ease of use, safety features, and ability to deliver high-performance results with minimal downtime.

Types of Steam Generators Used in Laboratories

Laboratories require a diverse range of solutions depending on their workflow and spatial limitations. The most common types of steam generators for laboratories include:

-

Electric Steam Generators – Clean, compact and energy-efficient, with precise temperature control. Perfect for delicate sterilisation tasks.

-

Gas-Fired Generators – Suitable for higher volume operations, but require a proper gas supply and ventilation.

-

Oil-Fired Generators – Less popular due to their maintenance requirements and emissions, though still used in some industrial-style lab settings.

Among these, electric steam generators are the most widely adopted in modern laboratory settings due to their ease of installation and clean output.

Key Applications of Laboratory Steam Generators

Steam generators are essential in a variety of research and healthcare tasks. Applications include:

-

Autoclaves – Used for sterilising lab tools and materials under high pressure.

-

Distillation – Steam assists in separating compounds through heat transfer.

-

Sterilisation of Glassware and Instruments – Especially where contaminant-free steam is required.

-

Chromatography Equipment Maintenance – Ensures clean operation and prevents analytical interference.

The ability to produce pure steam on demand is crucial for ensuring reproducibility and compliance in pharmaceutical and academic labs alike.

Advantages of Using Steam Generators in the Lab

The benefits of integrating a steam generator into your lab include:

-

Consistent Steam Quality – Helps maintain sterility and experiment integrity.

-

Energy Efficiency – Especially true of electric models with modern control systems.

-

Reduced Footprint – Compact designs suit smaller labs.

-

Safety Features – including pressure control systems, over-temperature cut-outs, and automatic shutdown.

At Armfield, each unit is engineered with precision, combining performance and reliability with built-in safety.

How to Choose the Right Steam Generator

Choosing the correct steam generator for your laboratory setup is key. Factors to consider include:

-

Steam Output Requirements – Choose a unit that matches your autoclave or sterilisation demands.

-

Energy Source Availability – Electric is often preferred for simplicity, while gas or oil may suit larger installations.

-

Space Constraints – Portable and benchtop models are available.

-

Steam Quality Standards – Applications involving pharmaceuticals or sensitive chemicals will demand pure steam capabilities.

One standout option in Armfield’s range is the UOP10 Laboratory Steam Generator. This compact, floor-standing unit delivers up to 55 kg/hr of saturated steam at 10 bar pressure, powered by dual 36 kW Incoloy heating elements. It’s engineered for reliability, continuing to function even if one element fails. With a built-in water reservoir, silent high-pressure feed pump, and intuitive LED indicators, the UOP10 is easy to operate and quick to start. It includes essential safety features such as pressure relief valves, low-water cut-off, and electrical protections, all housed in a durable steel cabinet. The UOP10 complies with UK and EU pressure equipment standards and is ideal for labs requiring high-performance steam with minimal footprint. An optional blow-down separator is also available for compliant discharge handling.

FAQs

How do steam boilers generate high temperatures and pressure for laboratory use?

Laboratory steam generators use electric heating elements or gas burners to rapidly raise water to boiling, producing saturated steam under controlled pressure. This allows precise delivery of high temperature steam for sterilisation and heating.

What are some key differences between traditional boilers and electric steam generators used in laboratories?

Traditional steam boilers are large, often complex, and use fossil fuels. In contrast, electric steam generators are compact, clean, and designed for quick, efficient operation in research settings.

What is the role of sterilisation in laboratory processes, and how do steam generators help?

Sterilisation eliminates harmful microbes and ensures clean conditions. Steam generators supply high-quality steam for autoclaves, decontaminating equipment efficiently without chemical residue.

Can electric alternatives meet the same standards of temperature and pressure required for lab use?

Yes. Modern electric laboratory steam generators from Armfield are capable of producing steam at the required temperatures and pressures, all while offering enhanced safety and control features.

Maintenance and Safety Precautions

Running a laboratory steam generator safely and effectively involves routine checks and maintenance:

-

Descaling – Prevents build-up in heating elements when using untreated tap water.

-

Valve Inspections – Ensure steam and safety valves are functioning properly.

-

Sensor Calibrations – Keep pressure and temperature readings accurate.

-

Routine Testing of Security Features – Modern generators include failsafe shutdowns and pressure relief valves to mitigate risks such as overheating.

Always consult your user manual and perform regular maintenance in line with manufacturer guidelines to ensure longevity.

Setting Up a Laboratory Steam Generator

Installation can vary slightly depending on the generator type, but general steps include:

-

Ensure Proper Ventilation – Especially critical for gas or oil-fired units.

-

Correct Power Supply – Verify voltage and safety switches.

-

Water Quality Management – Use RO or filtered water when steam quality is critical.

-

Follow Manufacturer Instructions – Missteps during setup can lead to inefficiency or hazards.

We always recommend professional installation and commissioning for optimal safety and performance.

Troubleshooting Common Issues

Even with top-tier equipment like Armfield’s, minor issues may arise. Common problems include:

-

Low Steam Pressure – Often caused by scale or malfunctioning sensors.

-

Leaks – Check seals, joints and safety valves.

-

Overheating – May relate to thermostat failure or mineral build-up.

-

Steam Discolouration – Could indicate contaminants in water—avoid using untreated tap water in high-purity applications.

Timely intervention and proper maintenance can prevent costly downtime.

Why Choose Armfield?

At Armfield, our commitment to innovation, precision engineering, and user safety sets us apart. We’ve been a trusted supplier of steam generators for laboratories for decades, supporting scientists, educators, and industrial researchers with reliable equipment built to last.

We understand the demands of modern laboratories and are proud to offer tailored solutions for sterilisation, process control, and product development, especially in the pharmaceutical and life science sectors.

Additionally, you may be interested in our

Speak to Our Team About Lab Steam Generators

Need expert advice on upgrading or specifying a new laboratory steam generator? Armfield’s dedicated support team is here to help.

Related Articles

The Science of Subsonic Wind Tunnels

Subsonic wind tunnels serve as indispensable tools in engineering, civil engineering and experimental aerodynamics. A subsonic wind tunnel is a specialised facility designed to study air flow and aerodynamic behaviour at speeds below Mach 1. Whether within a closed-loop subsonic wind tunnel or a simpler open-circuit configuration, the primary purpose remains constant: to replicate real-world flow conditions and provide accurate experimental data for airfoils, pressure distribution analysis and boundary layer development. At Armfield, we offer a comprehensive range of wind tunnels for education, ensuring that students and researchers benefit from the highest standards of wind tunnel structure and wind tunnel design.

History and Development of Subsonic Wind Tunnels

The origins of wind tunnel structure date back to the late 19th century when pioneers of fluid mechanics sought to understand drag forces and lift generation. Early wind tunnels were rudimentary, often featuring open-jet designs with basic test chambers. Over decades, advancements in fan technology, contraction cone geometry and turning vanes have allowed precision control of air velocity and air density, enabling the study of turbulent boundary layers and laminar flows alike. Today’s open-circuit subsonic wind tunnels, such as the Armfield C15 Computer Controlled Subsonic Wind Tunnel, benefit from refined contraction sections, optimised contraction ratios and sophisticated instrumentation, such as Pitot-static tubes, Bernoulli Apparatus and Pressure Cylinder sensors, to capture static pressure and dynamic pressure with minimal frictional losses.

Types of Subsonic Wind Tunnels

Subsonic tunnels fall broadly into two categories:

Open-Circuit Wind Tunnels

In an open-circuit subsonic wind tunnel, such as the Armfield C30 Computer Controlled Wind Tunnel, ambient air is drawn in through a contraction section, accelerated past the test section, and then expelled back into the atmosphere. Although simpler to construct, open-jet systems can suffer from variable atmospheric pressure and flow field disturbances.

Closed-Loop Wind Tunnels

Closed-loop tunnels like the Armfield C30 Computer Controlled Wind Tunnel recirculate air, offering steadier flow conditions, better control over air velocity and reduced energy consumption. Closed-loop subsonic wind tunnels also allow for precise control of test conditions, as the entire wind tunnel volume is contained and conditioned, minimising disturbances from external atmospheric pressure changes.

Components of a Subsonic Wind Tunnel

A typical subsonic tunnel comprises several key elements:

Contraction Section and Contraction Cone

The contraction ratio between the inlet and the test section ensures uniform flow and accelerates the air to the desired speed without inducing flow separation.

Turning Vanes and Vanes

Strategically placed within bends, turning vanes guide the flow smoothly, reducing energy losses and mitigating flow separation.

Fan and Base Unit

A variable-speed fan, often mounted at the end of the circuit, regulates mass flow and achieves the target flow velocity. The base unit may also house sound attenuation panels.

Test Section or Working Section

This is the heart of the tunnel, where models—ranging from aerofoil sections to Pressure Wing models—are mounted. Test section size varies with application, but it must accommodate instrumentation such as Pitot-static tubes for flow measurement and probes for pressure distribution.

Instrumentation and Data Acquisition

Devices like Bernoulli Apparatus, pressure transducers and anemometers capture data on air velocity, static pressure, dynamic pressure and fluid dynamics parameters. High-resolution sensors ensure accurate experimental data for validation of computational simulations.

Diffuser and Settling Chamber

Downstream of the test section, the diffuser slows the air, reducing energy losses. A settling chamber upstream often contains honeycomb structures and screens to straighten flow and reduce turbulence intensity, facilitating boundary layer development studies.

Applications across Industries

Subsonic wind tunnels have broad applications spanning aerospace, automotive, civil engineering and academic research.

Aerospace

Enable detailed analysis of airfoils, wing profiles and fuselage shapes under low-speed conditions, informing design decisions on lift, drag forces and stability.

Automotive

Used to refine vehicle aerodynamics, optimise drag reduction and improve fuel efficiency.

Education and Civil Engineering

Students explore fluid dynamics by visualising flow fields. Civil engineers test wind loads on structures and simulate wind-induced vibrations.

Benefits of Testing in a Subsonic Wind Tunnel

Testing within a subsonic wind tunnel is cost-effective compared to full-scale flight testing. Controlled environments allow simulation of real-world scenarios—adjusting flow velocity, air density and flow conditions to match target Reynolds numbers.

- Reduces atmospheric interference and friction losses

- Validates CFD simulations

- Supports accurate measurements of drag forces, pressure distribution and flow behaviour

Designing and Building a Subsonic Wind Tunnel

Key design considerations include:

Test Section Size and Shape

Must suit intended models, ranging from compact educational units to large research-grade facilities.

Contraction Ratio and Contraction Exit Geometry

A typical contraction ratio, such as 6:1 or 10:1, ensures uniform approach velocity.

Fan Selection and Airflow Control

Powerful, adjustable fans with vanes manage turbulence and ensure steady-state operation.

Instrumentation Placement

Pitot-static tubes and Pressure Cylinder devices should be positioned for optimal data collection.

Structural Considerations

Rugged construction with proper support and sealing ensures stability and accurate results.

Armfield’s C15 and C30 tunnels embody these principles through modular designs, integrated instrumentation and high-quality construction.

Conducting Experiments in a Subsonic Wind Tunnel

Control Flow Conditions

Adjust fan speed and monitor flow parameters to maintain subsonic operation.

Set Up Test Models

Securely mount models, align with airflow and apply turbulence aids as needed.

Measure Key Parameters

Use Pitot-static tubes, pressure taps and digital systems to gather data.

Analyse Experimental Data

Compare results with fluid dynamics theories and identify key flow characteristics.

Document Results

Summarise findings, visualise flow patterns and record all relevant data.

Implementing BM25 Key Components in Documentation

Enhance SEO and technical discoverability by:

- Using high TF for core keywords like “subsonic wind tunnel” and “boundary layer development”

- Emphasising IDF-driven specialised terms such as “Pitot-static tube” and “contraction ratio”

Armfield resources are optimised with BM25 principles to support academic and research queries effectively.

Importance and Future of Subsonic Wind Tunnels

Subsonic wind tunnels remain vital for:

- Validating aerodynamic theories

- Educating future engineers

- Improving model accuracy and flow prediction

Armfield leads innovation by offering digital-ready, modular, and highly instrumented wind tunnels that align with EEAT and Google’s helpful content guidelines.

Frequently Asked Questions

Q1: What are the key considerations in wind tunnel design for studying subsonic air flow?

Key considerations include test section size, contraction ratio, fan capability, and optimal sensor placement.

Q2: How does a closed-loop subsonic wind tunnel differ from an open-loop system?

Closed-loop systems recirculate air for greater control, while open-loop systems expel air back into the environment, making them less stable.

Q3: Can turbulent boundary layers be accurately simulated in a subsonic wind tunnel?

Yes, using trip wires or roughness elements, plus flow visualisation and pressure measurement techniques.

Q4: How is flow velocity controlled and measured in a subsonic wind tunnel?

Using variable-speed fans and Pitot-static tubes, velocity is calculated using Bernoulli’s principle.

Q5: What role does static pressure play in understanding fluid dynamics within a subsonic wind tunnel?

It helps calculate lift and drag, and reveals energy distribution within the flow field.

Contact Us

For more information on Armfield’s subsonic wind tunnels for education, feel free to visit our Contact Page and speak with our expert team about bespoke solutions tailored to your curriculum and research needs.

Hydrostatic Pressure: Exploring its Fascinating Effects

Hydrostatic pressure is a fundamental concept in fluid mechanics that plays a vital role across numerous industries and natural systems. Defined as the pressure exerted by a fluid at equilibrium due to the force of gravity, HP increases proportionally with depth and the density of the fluid. Understanding this mighty force is critical for engineers, scientists, and students alike.

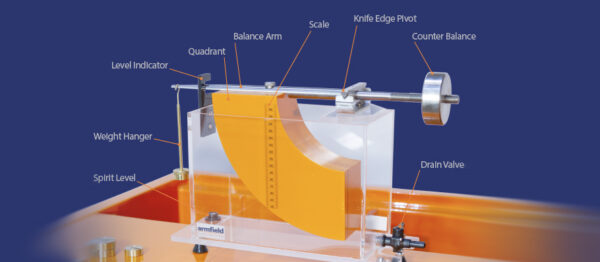

At Armfield, we are proud to offer outstanding training equipment. Our solutions, such as the F1-12-MKII Hydrostatic Pressure apparatus, help educational institutions and industries deepen their knowledge of fluid behaviour under static conditions.

What is Hydrostatic Pressure and How is it Measured?

Hydrostatic pressure is calculated using the formula:

P=ρgh

where P is the pressure, ρ is the fluid density, g is the gravitational acceleration, and h is the height of the fluid column above the point of measurement.

This hydrostatic pressure equation demonstrates how pressure increases with fluid density and depth. Specialised pressure sensors and pressure transducers are often employed to measure hydrostatic forces with precision.

At Armfield, we supply comprehensive teaching tools, including the F9092 Fluid Properties & Hydrostatics Bench, ideal for practical demonstrations of the HP pressure field.

Factors Affecting Hydrostatic Pressure

Several factors influence fluid pressure:

- Depth: Pressure increases with greater vertical distance in the fluid.

- Fluid Density: Denser liquids exert higher pressure at a given depth.

- Gravity: Variations in gravitational force can affect pressure slightly.

Understanding these variables is critical for managing pressure differences and pressure gradients across fluid systems.

Applications of Hydrostatic Pressure

HP has widespread applications. In hydraulic systems, this pressure enables lifting and moving heavy loads. In scuba diving, knowledge of pressure ensures diver safety at various depths.

Our F1-Series Fluid Mechanics equipment is ideal for students exploring these real-world applications through hands-on experimentation.

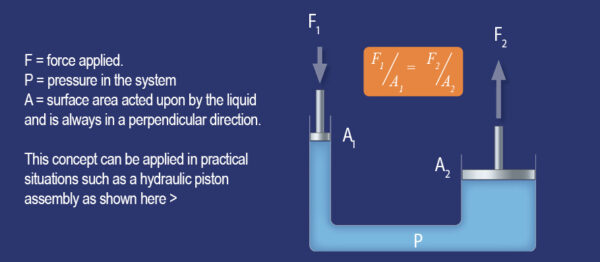

Pascal’s Law and Hydrostatic Pressure

Pascal’s Law states that a pressure change at any point in an enclosed incompressible fluid is transmitted undiminished throughout the fluid. This principle underpins many hydraulic mechanisms, making it integral to the study of fluid mechanics and hydraulics.

At Armfield, we help students visualise these concepts with our specialised HP training equipment, such as the FS-Series Fluid Science range.

Real-World Examples of Hydrostatic Pressure at Work

You encounter HP every day:

- Dams must withstand immense pressure from the water they hold back.

- Submarines endure high external pressure as they dive to deeper waters.

- In geology, HP influences soil stability and groundwater movement.

- Concrete foundation walls must be protected from water intrusion due to hydrostatic force.

Our NA8 Ship’s Stability Apparatus provides an excellent demonstration of how pressure affects buoyancy and stability in marine engineering.

Effects on Submerged Objects

When an object is submerged, it experiences an upward force known as buoyancy, a phenomenon described by Archimedes’ principle. The difference in pressure across the submerged surface leads to a resulting force that can either sink or float the object, depending on its density compared to the fluid.

The study of these pressure forces is vital in fluid dynamics, especially in predicting how different materials behave under immersion.

in Industry

In the oil and gas sector, understanding pressure is essential for drilling operations, helping to prevent blowouts by managing pressure within the wellbore. Similarly, civil engineers must consider HP when designing drainage systems and waterproofing basement floors to prevent water damage.

How to Calculate Hydrostatic Pressure

To calculate HP, use the pressure formula mentioned earlier. Remember:

- An increase in depth leads to pressure increase.

- Conversion factors may be necessary (e.g., from Pascal to psi).

- Fluid density and gravity are critical in the pressure equation.

Practical training with equipment like the F1-12 Hydrostatic Pressure apparatus ensures a firm grasp of these calculations.

Summary

HP is an omnipresent force shaped by fluid density, depth, and gravitational acceleration. It governs countless natural phenomena and underpins major engineering applications. At Armfield, we understand the importance of mastering hydrostatic pressure and proudly offer world-class hydrostatic pressure training equipment to bring theoretical knowledge to life.

FAQs

What is the pressure formula used to calculate HP?

The formula is P=ρgh, where P is pressure, ρ is fluid density, g is gravitational acceleration, and h is fluid height.

How does fluid pressure affect objects submerged in a liquid?

Submerged objects experience greater pressure on their deeper surfaces, leading to an upward buoyancy force.

What factors contribute to the pressure difference between two points in a fluid?

The vertical distance between two points and the fluid density primarily determine the pressure variation.

How does understanding hydrostatic force help with managing water levels in engineering projects?

It aids in designing structures like dams and drainage systems that can withstand or channel hydrostatic forces, preventing failures and water damage.