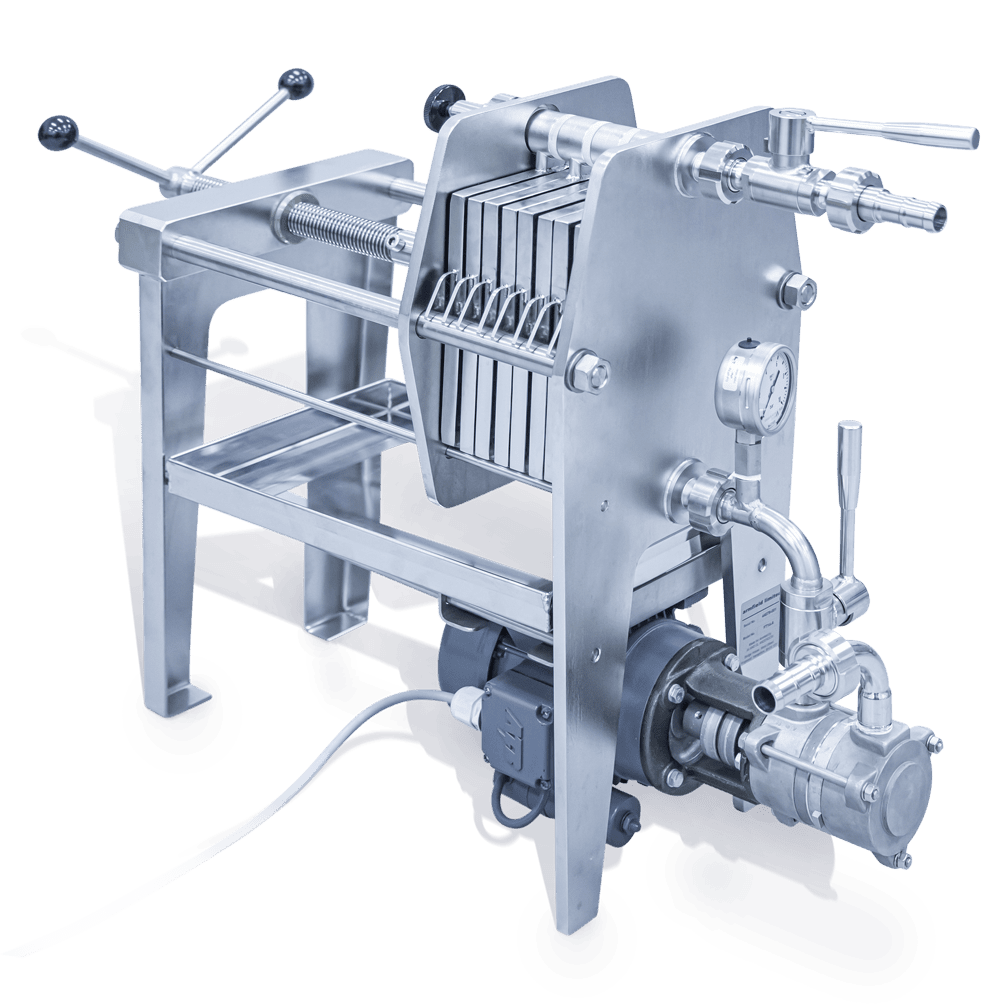

FT14 Plate and Frame Filter Press

A small plate pack mounted on a stainless steel framework, enabling demonstration of filler operation. This type of filter is widely used in the food, pharmaceutical, brewing and distilling industries.

The laboratory size unit is robust and versatile. A high degree of experimentation for scale-up to industrial process including several grades of filter media.

Description

The unit is mounted on a stainless steel, floor standing frame onto which the filter, feed pump and pipework are attached. A stainless steel drip tray is also included.

Four grades of filter media are supplied suitable for: pre-coat filter-aid, coarse clarifying, polishing and sterilisation. The small stainless steel plate pack allows ease of handling. Making teaching demonstrations more convenient.

The filter pack between the end castings is made up of one end and three intermediate thick turbid frames and one end and three intermediate filter plates. The filter will take a dressing of 7 x 200mm x 200mm filter sheets giving a nominal filtering surface area of 0.22m² and a nominal solids holding capacity of 1.5 litres.

Operation

The slurry to be filtered is connected by hose to the pump suction, and the pump is connected to a suitable electricity supply. A hose fitted to the filter outlet takes the clear filtrate to a suitable receiving vessel. The plate pack has been designed to allow washing of the filter cake when filtering is complete. A pressure gauge situated at the filter inlet is used to monitor the filtering process.

Feed/Circulating Pump

Centrifugal pump of all stainless steel construction with polished internals.

Maximum flow rate: 18.0 l/min

Maximum head: 2.0 bar

Motor: 0.25kW @ 2,800rpm

Additional information

| Weight | 120 kg |

|---|---|

| Dimensions | .73 × .3 × .57 m |

Technical Specifications

Feed/Circulating Pump: Centrifugal pump of stainless steel construction with polished internals

Maximum flow rate: 18.0 litres/min

Maximum head: 2.0 bar

Motor: 0.25kW 2800 rpm

Gasket material: Silicone

Features & Benefits

- Accurate for Education and research

- Versatile unit for uses in: Food / Pharmaceutical / Brewing / Distilling Industries

- Simple design enabling easy cleaning

- Four grades of filter media supplied: Pre-coat filter aid / Coarse clarifying / Polish / Sterilisation

- High degree of experimentation for scale-up to industrial processes

The slurry to be filtered is connected by hose to the pump suction, and the pump is connected to a suitable electricity supply.

A hose fitted to the filter outlet takes the clear filtrate to a suitable receiving vessel.

The plate pack has been designed to allow washing of the filter cake when filtering is complete. A pressure gauge situated at the filter inlet is used to monitor the filtering process.

- A fully self-contained plate and frame type filter press constructed entirely in stainless steel

- A centrifugal pump is mounted integrally in the framework and is connected to the filter inlet via a throttle valve and pressure gauge

- The filter pack is made up of four plates and four frames which will accept a dressing of seven filter sheets 200mm x 200mm

- The filter pack and sheets are compressed manually using a hardened steel screw thread

- Filter surface area is 0.22m2 and solids holding capacity is 1.5 litres

- A back pressure valve is located at the filter outlet

- Wine

- Beer

- Low TDS slurry

Electricity supply:

FT14-A: 220-240V/1ph/50Hz

FT14-B: 120V/1ph/60Hz

FT14-G: 220-240V/1ph/60Hz

Packed and created shipping specifications Volume: 0.5m³

Gross Weight: 120Kg

Overall dimensions

Length: 0.73m

Width: 0.30m

Height: 0.57m

- FT14-A

- FT14-B

- FT14-G