Post Category: Educational

Fluid Dynamics: The Importance of Proper Training

Fluid dynamics is the study of how liquids and gases behave and interact under various forces and in different environments. It is an exciting engineering discipline that lies at the heart of numerous industrial and scientific innovations, from the aviation industry to environmental engineering. As a proud employee of Armfield, a leading provider of Educational Training Equipment for Scientists and Engineers, I can confidently say that our solutions offer everything needed to master the fascinating world of fluid dynamics.

Understanding Fluid Dynamics

At its core, fluid dynamics examines the movement of fluids (both liquids and gases) and the forces acting upon them. Covering key principles such as fluid statics, fluid motion, conservation laws, and thermodynamics, the field offers a comprehensive analysis of behaviours critical to engineering and natural systems alike.

The properties of fluids—such as density, viscosity, and compressibility—determine how they behave under pressure, temperature changes, and external forces. From incompressible flows to turbulent flow, understanding these fundamental concepts is essential for solving complex flow problems in real-world applications.

Types of Fluids: Liquids and Gases

Although both are classified as fluids, liquids and gases exhibit vastly different behaviours. Liquids are generally incompressible, maintaining a constant volume under pressure, while gases are highly compressible and sensitive to temperature and pressure changes. Mastering the fluid kinematics of both types is vital in fields like aerospace, where flow separation and shock waves can have serious consequences on aircraft performance.

Real-World Applications of Fluid Dynamics

Fluid dynamics is everywhere. In aviation, pitot tubes measure airspeed and are crucial for flight safety—a topic we explore further in our article on pitot tubes and their role in aviation. In the automotive sector, fluid mechanics plays a significant role in aerodynamics and thermal management. Environmental engineers rely on multi-phase flow and heat transfer principles to design systems for water treatment and renewable energy applications.

These applications often rely heavily on CFD simulations and CFD software to model and predict outcomes. Mastery of CFD methods and CFD analysis has become a standard expectation for CFD practitioners and industry professionals across multiple sectors.

Fluid Dynamics Training: An Essential Investment

For anyone looking to launch an industrial or research career in engineering, fluid dynamics training is indispensable. Academic programmes, online courses, and hands-on workshops provide invaluable tools for gaining applied expertise.

Armfield offers a range of training solutions, including our F1-29 Fluid Statics and Manometry kit and the F1-38 Hele Shaw Apparatus, each designed to bring theoretical learning to life through hands-on experience.

Our equipment helps students and researchers delve into topics such as fluid statics, dimensional analysis, numerical methods, and even the Navier-Stokes equations. Whether you’re an undergraduate, a postgraduate, or a senior industry professional, the educational base provided by Armfield is second to none.

Choosing the Right Fluid Dynamics Training

When selecting a training programme, it’s essential to consider the course content, instructor expertise, and availability of hands-on learning opportunities. A good programme should offer comprehensive coverage of topics like fluid mechanics and heat transfer, grid generation, boundary conditions, and simulation results interpretation.

It is also wise to investigate whether the programme uses industry-standard software like ANSYS Fluent and offers experience in mesh generation, conservation laws, and the computational analysis sector.

At Armfield, we design our educational training equipment with the goal of meeting a broad range of education needs, ensuring that learners get access to the full breadth of fluid dynamics fundamentals.

Tips for Maximising Your Fluid Dynamics Training

Active participation is key. Ask questions, engage with case studies, and seek to understand the practical applications of what you’re learning. Using our equipment allows students to witness flow patterns and pressure drops first-hand, preparing them for both professional employment and independent study and project work.

Additionally, supplementing coursework with additional resources, like online modules on Applied Computational Fluid Dynamics (CFD applications) and turbulence modelling, can significantly deepen your understanding.

Key Topics in Fluid Dynamics Training

An excellent fluid dynamics course should cover:

- Fluid mechanics and heat transfer

- Fluid-structure interaction problems

- Applied Computational Fluid Dynamics

- CFD fundamentals, CFD codes, and advanced concepts

- Multiphase flow and incompressible flows

- Solution methods and numerical schemes

Training must also highlight modern computational capabilities and provide exposure to simulation results and real-world applications.

FAQS about Fluid Dynamics Training

What is Applied Computational Fluid Dynamics and how is it used in the field of engineering?

Applied CFD uses numerical solutions to solve real-world fluid flow problems. Engineers across various industries use CFD simulations for product design, analysis, and optimisation.

How does heat transfer play a role in fluid dynamics training?

Heat transfer is integral to fluid mechanics. Understanding how fluids move and transfer thermal energy is crucial in fields like HVAC systems, automotive cooling, and environmental engineering.

In what ways can a research career focus on fluid flow problems within the context of fluid dynamics?

A research career might involve investigating turbulent flow, developing new CFD methods, or enhancing simulation accuracy in complex environments like renewable energy systems.

What are some real-world applications for CFD simulations in industries outside of engineering?

Beyond engineering, CFD is used in biomedical flows for healthcare applications, in sports to optimise athlete performance, and even in film and video game graphics for realistic fluid animations.

Why Armfield Is Your Partner in Fluid Dynamics Training

At Armfield, we don’t just provide equipment—we provide comprehensive training solutions that empower future scientists and engineers. Whether you’re exploring fluid statics with our F1-29 module or delving deeper into real-world CFD applications, we support your journey every step of the way.

Our dedication to hands-on experience, educational excellence, and industry-led education sets us apart. Ready to take your understanding of fluid dynamics to the next level?

Contact Armfield today and discover how we can support your educational and professional aspirations!

You may also like:

What is Direct Steam Injection?

Direct Steam Injection (DSI) is a highly efficient method of heating liquids and slurries by injecting steam directly into the product stream. Unlike indirect heating methods, which rely on heat exchangers or coils to transfer heat, DSI allows for the immediate transfer of the steam’s energy directly into the product. This ensures fast, consistent heating with minimal heat loss and enhanced energy efficiency.

In a direct steam injection system, steam is introduced into the product using a steam injector or sparger. The steam condenses instantly upon contact, transferring both sensible and latent heat. This leads to rapid temperature increases and precise temperature control — crucial for industries that require consistent product quality and efficient processing.

How Direct Steam Injection Works

The steam injector introduces high-velocity steam into the product stream. As the steam mixes with the product, it condenses and releases heat. This results in:

- Instantaneous heating – Quick heating minimises processing times.

- Uniform temperature control – Steam is evenly distributed for consistent heating.

- Energy efficiency – Direct contact reduces heat loss, making the process more energy efficient.

Benefits of Direct Steam Injection

- Faster Heating – The direct contact method allows for rapid heat transfer and reduced processing time.

- Precise Temperature Control – Immediate and uniform heat distribution ensures consistent product temperatures.

- Increased Energy Efficiency – Direct heating reduces energy loss, improving overall efficiency.

- Compact Design – DSI systems take up less space than indirect heating setups.

- Improved Product Quality – Rapid and even heating prevents burning, over-processing, or texture loss.

Armfield Equipment Featuring Direct Steam Injection: FT174

The FT174 Modular Miniature Scale HTST/UHT Process System from Armfield is a state-of-the-art solution that utilises direct steam injection to deliver high-performance heating and processing capabilities. Designed for precise high-temperature short-time (HTST) and ultra-high-temperature (UHT) processing, the FT174 is ideal for research and development in the food, beverage, and pharmaceutical industries.

Key Features of the FT174:

- Flexible Flow Rates – Operates at flow rates between 10–60 LPH for UHT and up to 100 LPH for HTST to suit a wide range of process requirements.

- Modular Design – The system allows for quick and easy configuration based on specific process needs

- Indirect Heating Capability – Tubular, plate and scraped surface heat exchangers can be specified

- Direct Steam Injection Capability – Enables rapid heating and precise temperature control.

- PLC-Controlled with Touchscreen Interface – Provides real-time monitoring and process adjustments.

- Aseptic Processing and Homogenisation – Ensures product integrity and consistency.

- Easy Maintenance – Designed for straightforward cleaning and maintenance to minimise downtime.

- Integrated Cooling and Chilling – After heating, the product can be cooled or chilled to specific temperatures using a chilled water supply.

The FT174 offers a comprehensive solution for high-performance processing, making it ideal for product development and small-scale production. Its ability to combine direct steam injection with HTST/UHT processing ensures high product quality and efficiency.

Learn more about the FT174 here

Historical Perspective: Evolution and Significance of Direct Steam Injection

The concept of steam injection dates back to the early 20th century when steam was first used for industrial heating. Early systems relied on heat exchangers and jacketed vessels, which often resulted in uneven heating and high energy costs.

The breakthrough came with the development of direct steam injection technology, which allowed manufacturers to bypass heat exchangers and introduce steam directly into the product. This created a more efficient and effective heating process. Over time, technological improvements, including the development of high-performance steam injectors and spargers, have enhanced the precision and scalability of DSI systems.

Notable Examples of Direct Steam Injection in Key Industries

Food and Beverage Industry

Direct steam injection is widely used for pasteurisation, sterilisation, and cooking. It ensures fast, consistent heating without compromising flavour, texture, or nutritional value. Products such as dairy, soups, and sauces benefit from the rapid heating and precise temperature control offered by DSI.

Pharmaceutical Industry

The pharmaceutical sector relies on DSI for sterilisation and precise temperature regulation during drug production and formulation. The FT174’s ability to handle aseptic processing makes it an ideal choice for pharmaceutical applications.

Chemical Industry

Direct steam injection is used in the chemical industry to heat process fluids, accelerate reaction times, and maintain consistent product quality. The ability to adjust steam pressure and flow rates allows for high levels of process control.

Factors to Consider When Choosing a Direct Steam Injection System

- Flow Rates – The system should handle both low and high flow rates without causing steam hammer.

- Temperature Control – High-performance control valves ensure consistent heating.

- Product Compatibility – The system must be suitable for different product viscosities and process requirements.

- Steam Pressure – The steam pressure should match the process requirements to avoid cavitation or incomplete condensation.

Why Choose Armfield?

At Armfield, we have over 50 years of experience in designing and manufacturing industry-leading direct steam injection systems. The FT174 stands out due to its high-performance capabilities, ease of use, and adaptability for research and production.

Discover the Power of Direct Steam Injection with Armfield

Interested in enhancing your production efficiency with the FT174 Modular Miniature Scale HTST/UHT Process System? Contact Armfield today to learn more about how direct steam injection can benefit your business.

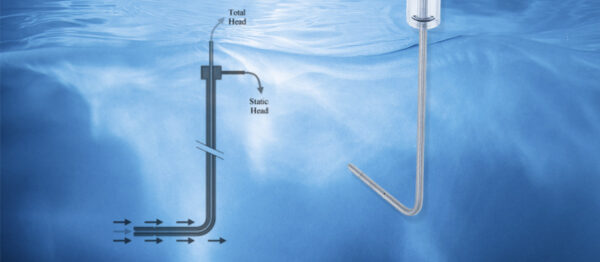

Pitot Tubes and Their Role in Aviation

What Are Pitot Tubes?

Pitot tubes are ingenious devices used to measure fluid flow velocity, particularly in aviation, automotive industries, and meteorological applications. Invented by the French engineer Henri Pitot in the early 18th century, these tubes have become an indispensable tool for calculating airspeed, fluid flow rate, and even dynamic pressure. Their role in flight safety and efficiency cannot be understated, making them a cornerstone of modern aerodynamics.

A Brief History of Pitot Tubes

Henri Pitot’s original invention was designed to measure the velocity of water in rivers. Over time, this simple yet effective design evolved into more sophisticated versions, such as pitot-static tubes, which are now integral to aircraft instrumentation. These advancements have enabled accurate airspeed measurements, contributing to the safety and performance of countless vehicles and systems.

Types of Tubes

There are several types of tubes, each suited to specific applications:

- Traditional Tubes: These measure the stagnation pressure of a fluid and are often paired with a static port to calculate flow velocity.

- Pitot-Static Tubes: These combine both pitot and static pressure measurements, offering greater accuracy in calculating airspeed and other parameters.

- Multi-Port Tubes: These advanced versions are used for more complex measurements, such as determining fluid flow in varying conditions.

Armfield provides a range of H30 pitot tubes to meet diverse requirements, ensuring precision and reliability across all applications.

How A Pitot Tube Works

The tubes operate based on Bernoulli’s equation, which relates the pressure of a fluid to its velocity. The device captures both the total pressure (stagnation pressure) and the static pressure. The difference between these pressures, known as dynamic pressure, is used to calculate the flow velocity. For aviation, pitot-static systems play a crucial role in measuring airspeed, which is displayed as indicated airspeed on an aircraft’s instrumentation panel.

See: F1-33 Demonstrator

Applications of the Tubes

Pitot tubes are incredibly versatile, finding use in:

- Aviation: Measuring airspeed and other flight parameters.

- Automotive Testing: Determining airflow in wind tunnels.

- Weather Instruments: Measuring wind speed and direction.

- HVAC Systems: Monitoring airflow in ducts and vents.

Armfield tubes are expertly designed to study these diverse fields.

Maintaining and Calibrating Pitot Tubes

Regular maintenance and calibration of pitot tubes are essential for reliable performance. Here are some tips:

- Prevent Blockages: Ensure the pitot tube’s openings are free of debris and contaminants.

- Calibrate Regularly: Calibrate the manometer connected to the tubes.

- Inspect for Damage: Check for signs of wear, especially in high-velocity applications.

Armfield offers comprehensive calibration and maintenance services, providing peace of mind to our customers.

Troubleshooting Common Issues

Despite their robust design, pitot tubes can encounter problems, such as:

- Icing: In cold conditions, ice can block the openings, leading to inaccurate readings.

- Pressure Loss: Damage or wear can result in incorrect pressure measurements.

- Misalignment: Improper installation can affect performance.

Our team at Armfield provides expert support and guidance to address these issues, ensuring optimal performance of your pitot systems.

Pitot FAQs

1. Who was Henri Pitot, and what was his contribution?

Henri Pitot was a French engineer who invented these tubes to measure fluid velocity in rivers. His work laid the foundation for modern fluid dynamics.

2. How do pitot tubes measure flow velocity?

The tubes measure flow velocity by capturing total and static pressures. The difference between these pressures, known as dynamic pressure, is used to calculate velocity using Bernoulli’s equation.

3. What is the difference between pitot-static tubes and traditional pitots?

Traditional tubes measure only stagnation pressure, while pitot-static tubes combine this with static pressure measurements, offering greater accuracy in calculating airspeed and other parameters.

4. What are the common applications?

These tubes are used in aviation, automotive testing, meteorology, and HVAC systems to measure airspeed, fluid flow velocity, and dynamic pressure.

The Armfield Advantage

At Armfield, we pride ourselves on providing high-quality solutions for all types of tubes. Our products are designed with precision, reliability, and performance in mind, catering to a wide range of industries. From standard tubes to advanced multi-port designs, we have the expertise and innovation to meet your study needs.

Contact Us Today

Ready to enhance your operations with reliable pitot solutions? Contact Armfield today to learn more about our products and services.

You may also like:

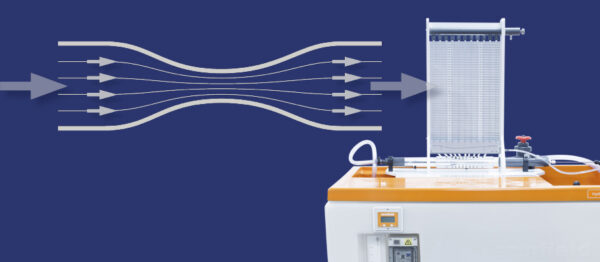

Fans and Compressors: Designed For Engineering Education

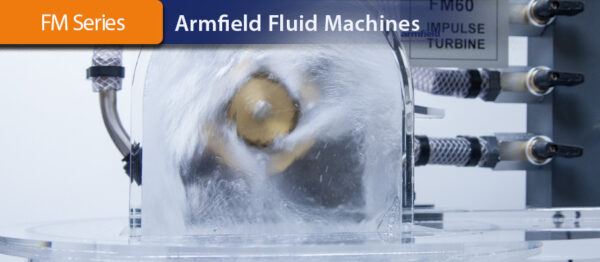

Turbines are essential components in energy engineering, particularly in the study of renewable energy and sustainable technology. At Armfield, we specialise in providing state-of-the-art educational tools that empower universities and colleges to deliver hands-on, real-world training. Our modular range of turbines connects seamlessly with the versatile FM6x Turbine Service Unit, which is designed to meet the diverse needs of engineering courses worldwide.

Joseph Armfield and the Evolution of Turbines

The story of turbines at Armfield began in 1875, when Joseph Armfield founded his engineering company in Ringwood, England. Initially focused on farm and milling machinery, the company quickly expanded its capabilities. By 1887, Armfield produced its first water turbine, marking a significant shift from traditional water wheels to more efficient power generation systems.

Incorporating cutting-edge innovations such as inward radial flow, based on the principles of the Francis turbine, these early designs optimised water flow using curved guide vanes and blades. By the early 20th century, Armfield had sold over 1,000 turbines worldwide, solidifying its role as a pioneer in advancing turbine technology. Today, that innovative legacy lives on in the modern equipment we provide for engineering education.

Understanding Turbines in Training

Turbines are pivotal in various engineering industries, from power generation to water management and beyond. Their primary purpose is to harness the power of fluids. This product range plays a crucial role in demonstrating principles such as torque, power generation, flow rates, and efficiency. Educational institutions require reliable, precise equipment to train students for real-world applications.

Why Choose Armfield for Your Training Needs?

At Armfield, we’ve developed an innovative range of turbines and associated equipment such as compressors and fans, ideal for teaching foundational and advanced engineering principles. Our solutions are tailored to universities and colleges seeking to equip students with the knowledge and skills needed for careers in industries like power generation, HVAC, and renewable energy.

Explore our full range of fans and compressors, where you’ll find a variety of tools designed for in-depth analysis and experimentation.

The FM6x Turbine Service Unit: A Game-Changer

One standout product in our collection is the FM6x Turbine Service Unit. This cutting-edge base unit is fully controlled by software, allowing for the precise testing and analysis of various turbine characteristics. It’s an essential tool for demonstrating key engineering principles such as:

- Torque

- Power usage

- Pump speed

- Braking loads and forces

- Flow rates and inlet pressure

The FM6x is versatile, enabling students to test multiple turbine types, including:

- Impulse turbines

- Reaction turbines

- Pelton wheels

Software Integration for Enhanced Learning

The FM6x Turbine Service Unit is equipped with advanced software that generates detailed datasheets and performance charts. This feature allows students and instructors to monitor loads, benchmark performance, and analyse results with precision. By simulating real-world scenarios, the FM6x prepares students for larger-scale applications, such as those used by electrical power companies in water-driven turbine systems.

How Turbine Demonstration Units Educate Future Engineers

1. Harnessing Energy from Wind and Water

Turbine demonstration units like the FM6x illustrate how energy can be captured and converted into usable power. Reaction turbines, for instance, utilise fluid flow to generate mechanical energy, a principle widely applied in hydroelectric and wind power systems.

2. The Role of Hydraulic Training Systems

Hydraulic training systems are invaluable in demonstrating how water flow impacts turbine operation. With the FM6x, students can adjust water flow rates and observe the effects on power output and efficiency, fostering a deeper understanding of fluid dynamics.

3. Airflow and Efficiency

The efficiency of turbines is closely linked to airflow dynamics. The FM6x allows users to manipulate airflows, showcasing their impact on performance metrics such as speed and torque.

4. Speed and Performance

Speed plays a critical role in turbine efficiency. Students can observe how different loads and braking forces influence energy generation by varying rotational speeds.

Real-World Applications

The FM6x Turbine Service Unit bridges the gap between theory and practice, equipping students with the skills they need to succeed in industries such as:

- Renewable energy production

- Industrial fluid systems

By mastering the operation and analysis of turbine systems, graduates are better prepared for roles in engineering firms, utilities, and manufacturing industries.

FAQs

What is the FM6x Turbine Service Unit used for?

The FM6x is a base unit for testing turbine characteristics. It’s designed for engineering education, helping students understand torque, power usage, flow rates, and more.

How does a reaction turbine work?

Reaction turbines harness fluid flow to generate mechanical energy. They rely on the principle of Newton’s third law, where the reactive force of moving fluid produces rotational motion.

Can the FM6x Turbine Service Unit simulate real-world scenarios?

Yes, the FM6x’s software enables users to replicate various turbine conditions, preparing students for real-world applications in industries such as power generation and renewable energy.

How does the FM6x benefit universities and colleges?

The FM6x provides hands-on training, detailed performance data, and the ability to test multiple turbine types, making it an invaluable resource for engineering courses.

Fans and Compressors for Engineering Education

Armfield’s FM6x Turbine Service Unit is more than just a training tool—it’s a gateway to understanding the intricacies of turbine operation and performance. Combined with our full range of fans and compressors, we offer a comprehensive solution for engineering education.

Contact Us Today

Contact us to enhance your engineering programme. Learn more about our cutting-edge solutions by visiting our contact page. Let Armfield help you shape the engineers of tomorrow.

You May Also Like

- The Science of Carbonation and Armfield’s FT102XA

- Bespoke Flumes by Armfield: Tailored Solutions For Research

- The Ultimate Solution for Teaching and Research Flumes:

- Reducing Energy Consumption in Food Manufacturing

Armfield FT22 & UOP20X Evaporators

Armfield is proud to offer two exceptional evaporators designed specifically for chemical engineering education: the FT22 Rising Film Evaporator and the UOP20X Modular Evaporator Series. These advanced systems provide comprehensive solutions for teaching and research applications, ensuring that students gain practical experience with industry-relevant equipment.

FT22 Rising Film Evaporator

The FT22 is a floor-standing unit engineered to replicate the operations of large-scale industrial evaporators. Despite its compact footprint of only 0.65 m², it delivers robust performance, making it ideal for laboratory settings.

This evaporator processes samples as small as 2 litres under production-like conditions, allowing users to observe the effects of heating on newly introduced ingredients. Such capability is crucial for investigating organoleptic and physico-chemical properties, as well as preparing products for daily taste trials to ensure consistent raw material quality.

Key Features:

- Single-Tube Heat Exchanger: Mimics industrial units with multiple tubes, providing practical training on modern evaporation equipment.

- Integral Clean-In-Place (CIP) System: Facilitates easy cleaning and maintenance, ensuring hygiene and operational efficiency.

- Data Logging and Analysis: Comes with integrated software for process control and data logging, enhancing the educational experience.

The FT22’s design ensures that small quantities of liquid products can be concentrated efficiently, making it suitable for applications involving juices, milk products, extracts, and effluents.

UOP20X Modular Evaporator Series

The UOP20X represents a versatile, computer-controlled modular system tailored for chemical engineering education. It offers a wide range of configurations, including rising or falling film; single or double effect; and forward, backward, or parallel feed.

This flexibility allows educators to demonstrate various evaporation processes within a single system, providing students with a comprehensive understanding of industrial evaporation techniques.

Notable Features:

- Service Unit: Houses one or two evaporator columns, with options for either rising or falling film configurations.

- Heating Options: Available in two variants—one utilizing an internal electric-powered pressurised hot water system and another requiring externally supplied steam as the heating medium.

- High Vacuum Capability: Enables low-temperature evaporation, preserving heat-sensitive materials.

- Comprehensive Instrumentation: Equipped with sensors and controls for monitoring temperatures, conductivity, and vacuum levels, all displayed via an integrated control console.

The UOP20X’s modular design and advanced features make it an invaluable tool for conducting mass and energy balance experiments, comparing economies of different evaporation methods, and performing process control exercises.

Applications in Chemical Engineering Education

Both the FT22 and UOP20X are integral components of Armfield’s evaporation series, designed to enhance chemical engineering teaching. They provide practical, hands-on experience with evaporation processes, allowing students to explore the effects of various parameters on product concentration and quality.

These systems are particularly beneficial for:

- Investigating Heat Effects: Understanding how different heating conditions impact product properties.

- Process Optimization: Exploring methods to improve efficiency in evaporation processes.

- Product Development: Preparing small batches of concentrated products for testing and analysis.

By incorporating the FT22 and UOP20X into their curriculum, educational institutions can provide students with a thorough understanding of evaporation processes, bridging the gap between theoretical knowledge and practical application.

Frequently Asked Questions

- What is the difference between rising film and falling film evaporation?

In rising film evaporation, the liquid feed enters the bottom of the heated tube and rises due to vapour generation, forming a thin film along the tube walls. In contrast, falling film evaporation involves the liquid feed entering at the top of the tube, flowing downward under gravity, and forming a film as it evaporates. Each method has its advantages, with the rising film being suitable for low-viscosity liquids and falling film preferred for heat-sensitive materials.

- Can the FT22 handle different types of products?

Yes, the FT22 is designed to concentrate various liquid products, including fruit and vegetable juices, milk and dairy products, non-flammable extracts, and effluents. Its versatility makes it suitable for a wide range of applications in food technology and chemical engineering.

- How does the UOP20X facilitate process control studies?

The UOP20X is equipped with comprehensive instrumentation and computer-controlled features, allowing users to perform process control exercises. The included educational software provides configurable PID controllers, enabling students to study the dynamics of process control in evaporation systems.

- What are the space requirements for installing these evaporators?

The FT22 requires only 0.65 m² of floor space and is designed to fit easily into rooms of standard height. The UOP20X, being a modular system, has a larger footprint, with overall dimensions of 2.5 m in height, 1.5 m in width, and 0.9 m in depth. It’s advisable to ensure adequate space for installation and operation.

Discover the Armfield Advantage

Armfield’s FT22 Rising Film Evaporator and UOP20X Modular Evaporator exemplify our commitment to high-quality, educational equipment that bridges the gap between academia and industry. These systems provide hands-on experience, allowing students to understand industrial evaporation techniques in a controlled learning environment.

With features that enable process control, data logging, and real-world application, both evaporators are ideal for research, product development, and education in chemical and food engineering fields. Their versatile configurations, compact design, and industrial-grade performance make them essential tools in university and research laboratories worldwide.

Why Choose Armfield?

For over 60 years, Armfield has been a trusted provider of innovative engineering and technology-based educational solutions. Our evaporators are designed, manufactured, and tested to meet the rigorous demands of academic institutions and industrial training programs.

When you invest in an Armfield system, you get:

Comprehensive educational support with process control and data analysis tools

Reliable and robust engineering, ensuring long-term use with minimal maintenance

Scalable configurations, allowing multiple evaporation methods in one unit

Expert technical support and dedicated after-sales service

Whether you need an evaporator for teaching, research, or product development, Armfield provides a proven, industry-leading solution.

Get in Touch

Discover how the FT22 Rising Film Evaporator and UOP20X Modular Evaporator can enhance your chemical engineering teaching and research. Our team is happy to assist with technical specifications, pricing, and product demonstrations.

Contact us today at sales@armfield.co.uk

You may also like:

- Pitot Tubes and Their Role in Aviation

- Exploring Cantilever Span Bridges and How They work

- Fans and Compressors: Designed For Engineering Education

- The Science of Carbonation and Armfield’s FT102XA

GESS Dubai 2021

Middle East and North Africa’s (MENA) energy diversification into the renewable energy has spiked in the early half of 2021, focusing on fuel cell and renewable energy in aid to reduce greenhouse gas emissions. Armfield Ltd, leader in Engineering Teaching Equipment from the UK who will be attending GESS Exhibition (stand R20), will be showcasing methods for students and adults to develop in the field of new energy technology, making a significant contribution to the “green” energy revolution within the education system.

In addition to this, with the increase of coronavirus that led the world to a pandemic, many students, teachers, and staff resorted to remote learning, which has been of paramount importance. With education at forefront, Armfield Ltd is demonstrating remote learning to increase student engagement with online classrooms and home learning in the engineering sector at the GESS exhibition hall.

“Armfield employer of the year award”

Armfield were extremely honoured to be invited to the Annual Brockenhurst Gala awards dinner to receive the Brockenhurst College “employer of the year award” from the Principal, Polly Perkins CBE and Graham Beards, The Chair of Governors.

As part of our continued social responsibility program, the Armfield team has been actively involved in working with our local college by providing work placements, added curriculum support, equipment and an enhanced profile at employability events.

This partnership will prove invaluable to both Armfield and @brockcollege, with the students taking an active role in our new product development and evaluation.

Armfield look forward to strengthening our relationship with Brock college and playing an active role in helping them continue to develop world class engineers.

Armfield is pleased to announce the acquisition of RJ Lewis Ltd

Armfield is pleased to announce the acquisition of RJ Lewis Ltd, a leading high quality plastic machining and manufacturing specialist.

Armfield’s corporate mission is to be the leading manufacturer of engineering teaching and research equipment and industrial research & development equipment. The acquisition of a key supplier such as RJ Lewis Ltd brings us one step closer to accomplishing this goal.

RJ Lewis Ltd is being integrated into Armfield and will be relocated in our new dedicated assembly and inspection facility. This will enable us to meet the increased demands of our growing business, more than double our production capacity, and create new jobs within the company.

Armfield’s laboratory flow channel

Armfield’s laboratory flow channel is one of the most important tools available to the hydraulics or civil engineer whether engaged in teaching basic principles or researching solutions to practical problems.

A comprehensive range of accessories are available for selection, these provide the basis for a large number of practical experiments in open channel flow.

See more at www.armfield.co.uk

Armfield’s History

Armfield Ltd are feeling nostalgic today…..

Take a look at these historical adverts from 120 years ago, the company had several foundry’s producing farm machinery, public works projects such as lamp posts but specialised in water irrigation. In 1898 Armfield started selling the Empire Turbine, a reliable, easy to maintain and operate motor for obtaining power from water, Armfield’s tag line was “Expert Engineers sent anywhere to advise upon ANYTHING to do with WATER”.

By 1938 Armfield had iron work, farm machinery, pumps, hydroelectric generators, water wheels and irrigation gates all over the world.

Happy Earth Day from Armfield!

Current studies in geoscience and earth science include so much more than rocks and volcanoes. It looks at the processes that shape the earth’s surface, natural resources and how water and ecosystems are interconnected. It also looks at the effects these have caused in the past, present and what changes may need to be implemented for the future.

Armfield offers products for both laboratory and field-learning opportunities. It also introduces such diverse topics as crop water requirements, erosion, soil moisture content, ground water flow, plant water need and sprinkler irrigation systems.

Contact us at: armfield.com for more information.

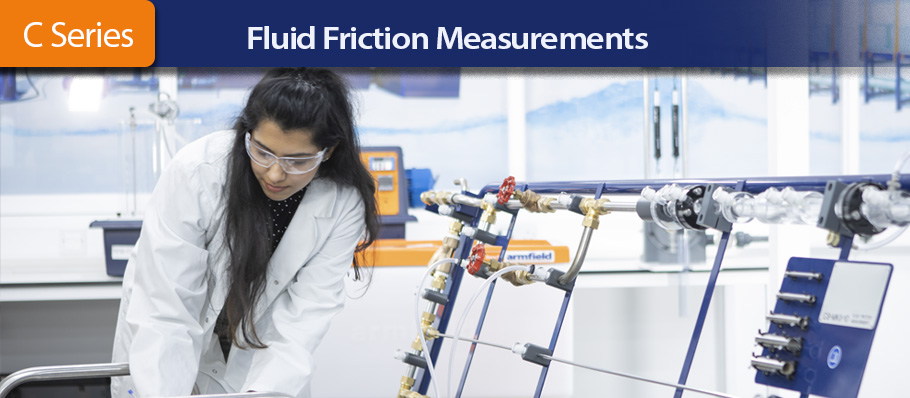

Fluid Friction Measurements

The Armfield C6-MKII-10 Fluid Friction Measurements unit provides facilities for the detailed study of fluid friction head losses, which occur when an incompressible fluid flows through pipes, fittings and flow metering devices.

A wide range of measurements, demonstrations and training exercises are possible with the equipment:

· Confirming the relationship between head loss due to fluid friction and velocity for flow of water

· Determining the head loss associated with flow through a variety of standard pipe fittings

· Determining the relationship between pipe friction coefficients and Reynolds’ number for flow through a pipe with roughened bore

· Demonstrating the application of differential head devices in the measurement of flow rate and velocity

· Providing practical training of pressure measurement techniques

· Enhancing understanding of the hydraulic principles involved through the use of complementary computer software

See more at www.armfield.co.uk

Computer control is so much more than just datalogging a sensor!

Armfield’s range of computer-controlled products, provide not only real time monitoring and datalogging, but additional computer control of multiple variables used when undertaking experimentation.

For example, in our heat exchanger range both the hot and cold-water flow rates can be controlled from the mimic diagram screen in the HT30XC software, which is supplied as standard.

We additionally supply the ability for the pump speed to be controlled via a PID algorithm to achieve a stable flow of hot water through the heat exchanger on test. Changes to the flow that would be caused by effects, such as viscosity reduction due to increasing temperature, are eliminated by automatically adjusting the pump speed.

Contact our sales team to find out more regarding our computer control and remote access options: sales@armfield.co.uk

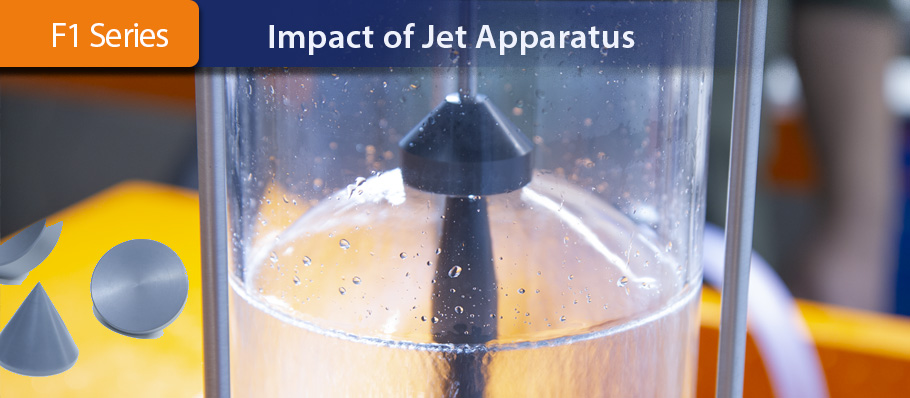

Armfield Impact of Jet Apparatus F1-16

The Armfield F1 Fluid Mechanics products provide a comprehensive range of hydraulic models each of which is designed to demonstrate a particular aspect of hydraulic theory.

The Impact of Jet Apparatus, F1-16. This consists of clear acrylic test cylinder, into which water is fed vertically through a nozzle. The water strikes a target mounted on a stem. A weight pan mounted at the top of the stem allows the force of the water to be counterbalanced by applied masses.

Experimental outcomes include:

* Principle of linear momentum

* To investigate the reaction forces produced by the change in momentum of a fluid flow

* Measurement of the forces produced by a jet impinging on solid surfaces which produce different degrees of flow deflection

Fluid mechanics has developed as an analytical discipline from the application of the classical laws of statics, dynamics and thermodynamics, to situations in which fluids can be treated as continuous media.

The particular laws involved are those of the conservation of mass, energy and momentum and, in each application, these laws may be simplified in an attempt to describe quantitatively the behavior of the fluid.

Armfield Research Flumes

Water engineering research continues to be paramount in areas such as coastal research, environmental modelling, sediment transportation and irrigation studies. For over 50 years, Armfield have been designing and supplying open channel facilities (also referred to as flumes) to hydraulic laboratories throughout the world.

Our brochure presents the standard range of channels/flumes available from Armfield for teaching and research purposes. Bespoke sizes and layouts to suit specific design criteria can be produced and the Armfield engineering team work closely with our customers to make sure the brief, deadline and installation designs are fully met.

All our flumes are supplied under the guidance of the Armfield professional service team who will oversee the transportation, installation, commissioning and training on site.

C3 Multi-Pump Test Rig

The Armfield Multi-Pump Test rig can accommodate both rotodynamic and positive displacement pumps and is supplied with the most common example of each type as standard (ie a centrifugal pump and a gear pump).

A range of other pump types are available as accessories, (including axial, turbine, flexible impeller, diaphragm and plunger, plus a second centrifugal pump for series/parallel demonstrations). Up to four pumps can be accommodated simultaneously within the rig for use within a single laboratory period, and each can be run without disconnecting any pipework or connections. Further, pumps can also be easily interchanged.

Happy Holidays from us all at Armfield

While none of us could have predicted how tough 2020 was going to be, all of us at Armfield want to say a massive thank you for sticking with us throughout the year.

Armfield would not be where it is without our amazing customers and agents, due to your continued support we are able to head into 2021 full of confidence that further success is just around the corner.

Our office will close for the holiday on the 24th of December, returning on the 4th of January.

We will continue our evolution including the opening of the Armfield academy knowledge hub and the release of the new product catalogue early in 2021

The Armfield Sediment Transport Demonstration Channel

Most natural waterways and many canals are subject to bed movements caused by the action of the water transporting the material forming the bed in the downstream direction.

The type and rate of movement of the transported material can vary from large stones moved down fast flowing mountain streams, through sand and gravel sizes, to very fine clay particles moved by slow flowing rivers being deposited in lakes and estuaries to form deltas and bottom clay deposits.

A basic understanding of the processes of sediment transport is essential to scientists, engineers and technologists who may be engaged in geology, hydrology, irrigation and other aspects of civil, marine or environmental engineering.

The Armfield S8-MkII allows a range of experiments to be performed to demonstrate the two principle methods of sediment transport in water: bed load movement & suspended sediment transport.

Additional investigations can be undertaken to demonstrate local scour at channel obstructions such as bridge piers, and the secondary flow in channel beds.

See more here> armfield.co.uk/S8

Remote access to the essentials of Process Control

Introduce students to the fundamentals and principles of process control and provide a thorough understanding in the control of physical processes with Armfield’s Essentials Process Control range.

Level, flow, temperature and pressure as the controlled variable can all be demonstrated via four independent process units. The concepts of closed loop control, including on/off control, proportional control, proportional/integral and proportional/integral/derivative (PID) control can be explored and demonstrated.

All units are computer controlled and can be remotely operated enabling seamless teaching in a distant or remote learning environment.

Contact Us at sales@armfield.com

Armfield welcomes Nancy Manik

Our new Area Sales Manager for Asia, joining the Educational Sales Team.

Nancy brings years of experience working within the academic and pharmaceutical industry within the global market, where she assisted researchers set up their new laboratories and provide core facility systems for a multi user environments.

Nancy is looking forward to supporting and looking after educational sales agents and customers in Asia.

You can reach her on nancy.manik@armfield.com for any enquiries.

RA3 Recirculating Air Conditioning Unit

Armfield’s Recirculating Air Conditioning Unit is a climate control demonstration unit.

Variable louvres within the unit allow investigation of 0 to 100% re-circulation.

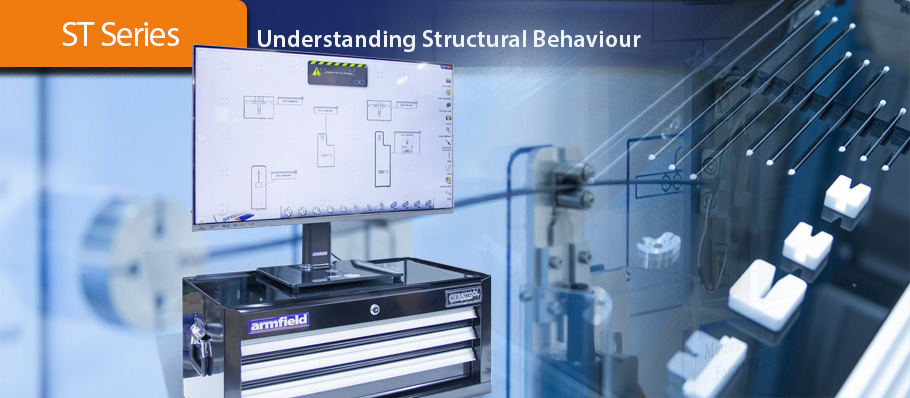

Understanding Structural Behaviour

Armfield have teamed up with Dr David Brohn (who is also working with the Institution of Structural Engineers on this topic) to develop a range of hardware and software specifically to address this issue of understanding structural behaviour. This is a highly modular system with almost an infinite range of possibilities.

To simplify purchasing, the components are available in a number of kits depending on requirements, there are eight standard projects including:

– Cantilever beam

– Simply supported beam

– Two span beam

– Pinned beam

– Rigid right angle joint

– Rigid portal frame

– Portal frame with pinned connection

– Portal frame with pinned support

The equipment provides an unsurpassed and unique learning experience when the display software is coupled with the sensors, actuators and analysis software.

Armfield Fluid Machines

The FM53 Plunger Pump Demonstration Unit replicates those used in industry in a wide variety of applications such as cleaning or process technology in the chemical industry.

The plunger or ram pump is used for pumping small quantities of liquid at high pressure. Electronic sensors measure the instantaneous cylinder pressure within the pump, the pump displacement and the cumulative flow.

Computer controlled with datalogging the FM53 is one of Armfield’s vast range of units with remote access capabilities.

See the extensive range of fluid machine demonstration units at www.armfield.co.uk/fm or contact sales@armfield.co.uk to discuss your remote access needs.

Montana State University

Armfield recently visited Stephanie Wettstein at the chemical engineering department, Montana State University to complete the installation of the UOP3CC Continuous Computer Controlled Distillation Column.

As innovators of educational engineering equipment Armfield have developed this state-of-the-art laboratory based distillation column to enable safe hands on practical training for student engineers and plant operators as well as empowering research in different fields to be conducted.

The UOP3CC enables a range of demonstrations from the introductory stages of a process engineering course through to the more complex demonstrations of modern control strategies.

Armfield’s professional services team offer installation, commissioning and training on site to ensure that laboratories and research centres are able to fully utilise all equipment at the earliest opportunity.

See more at www.armfield.com

Armfield Remote Controlled Equipment

As innovators of engineering educational equipment, it is not new for Armfield Ltd to offer remote access on their products. Self-based learning in the current environment is key and Armfield provide students and lecturers with the access and capability required to continue comprehensive teaching.

Engaging students in their subject is paramount, especially with restrictions on face to face teaching, so by providing access, to a user based system that not only allows you real time data logging but also to remotely control equipment, is a necessity in teaching going forward.

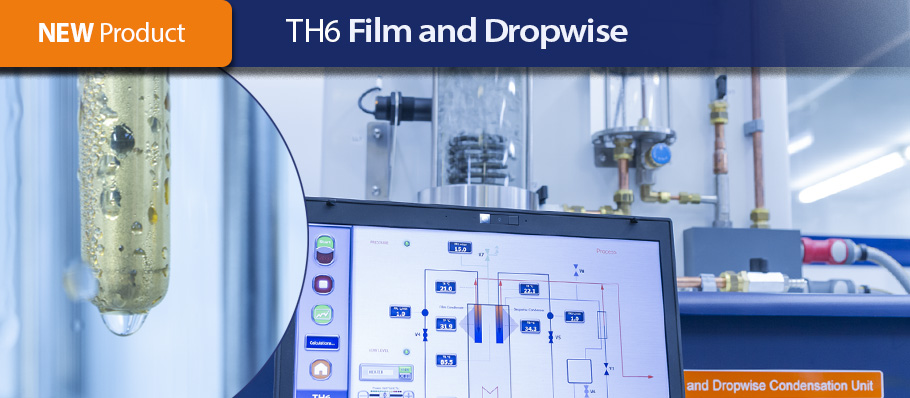

TH6 Film & Dropwise Condensation Unit

The Armfield TH6 Film & Dropwise Condensation Unit enables students to gain a knowledge of two fundamental condensation processes and how they affect efficiencies and heat transfer, found in industries such as steam power plants and distillation operations.

Used to demonstrate dropwise condensation, demonstrated by means of the condenser with a polished gold-plated surface and film condensation which forms on the matt copper surface of the second condenser.

The pressure in the main vessel can be reduced using a water jet pump to allow the student to observe it’s influence. Additionally, boiling point can be varied by a combination of changing the pressure in the system and controlling the heating power or water temperature by simple controls. The TH6 additionally includes the ability to undertake experimentation into the influence of non-condensing gases on the condensation processes.

Sensors record the temperature, pressure (vacuum) and flow rates at all relevant points. These measured values along with heater power are displayed via the unique ArmBUS software system which also includes inbuilt equations and a data export functionality for off-line analysis.

www.armfield.co.uk

Armfield Process Control Teaching System

Introduce students to the fundamentals and principles of process control with Armfield’s Essentials of Process Control range.

A highly visible and easy-to-understand suite of products to demonstrate controlled variables of level, flow, temperature and pressure. ArmSOFT software allows control and data acquisition using a PC including, when testing any of the control loops, the ability to control the process and initiation of step changes as well as response recording through graphing. This real-time data can then be exported for further analysis, See the full range of PCT-related products.

Armfield Updates

Subscribe to our occasional newsletter for the latest product updates from Armfield Engineering.