Measuring the Invisible: The Fascinating World of Fluid Science Manometers

Fluid science manometers are fundamental tools for measuring pressure in gases and liquids. They are widely used across research laboratories, industrial applications, and education to provide accurate and reliable pressure readings. At Armfield, we specialise in designing and manufacturing advanced manometer solutions, from U-tube and inclined manometers to differential systems, ensuring precision and durability for every application.

What Is a Fluid Science Manometer?

A fluid science manometer is an instrument that measures pressure using a column of liquid. Its design is based on hydrostatics—the principle that pressure in a fluid is proportional to its height and density. By comparing fluid levels in connected columns, manometers provide a direct, visual indication of pressure differences, making them one of the most reliable tools for both fundamental fluid dynamics experiments and industrial processes.

The Fluid Science U-Tube Manometer tray from Armfield, for example, allows for accurate demonstrations of pressure variations caused by differing flow rates and atmospheric conditions, supporting both individual and group experiments.

Armfield uses paraffin (kerosene) in its manometer systems because its lighter density enhances sensitivity, making it ideal for measuring small pressure variations—such as those found in flow channels and Pitot tube experiments. It’s safe, visible, and well-suited for teaching environments. (H12-5: 500mm scale differential kerosene over water manometer – Range 0.213m H2O)

Types of Fluid Science Manometers

U-Tube Manometers

These are the most common type, consisting of a U-shaped glass tube filled with manometric fluid (often water or mercury). They are simple, robust, and effective for measuring gauge pressure and differential pressure in various fluids.

Inclined Manometers

When higher sensitivity is required for small pressure differences, inclined manometers provide enhanced accuracy. Their tilted design magnifies height differences, allowing for precise measurements in laboratory settings.

Differential Manometers

These measure pressure differences between two points in a system, making them ideal for monitoring flow rate changes, filter performance, or pressure drops across components in HVAC or fluid transport systems.

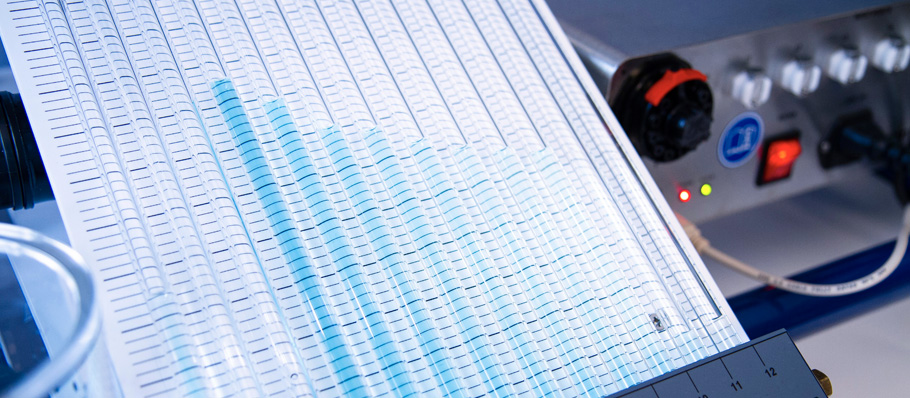

Differential kerosene over water manometer

A differential kerosene over water manometer uses the density difference between kerosene (0.8) and water (1.0) to measure small pressure changes in fluid systems. The immiscible fluids in a U-tube shift under pressure, with the height difference indicating pressure via ΔP = g (ρ_water * h_water – ρ_kerosene * h_kerosene). Ideal for low-pressure applications like HVAC and fluid mechanics, it offers accuracy and stability.

Inverted Differential Manometers

Unlike standard differential devices, inverted types are designed to measure negative pressure differentials. They are especially useful in vacuum systems and specialised industrial processes.

Digital Manometers

By integrating electronic pressure sensors, digital manometers deliver real-time data with high accuracy. They are commonly used in industrial environments where precise, repeatable measurements are essential.

How Fluid Science Manometers Work

The working principle of a manometer is straightforward:

-

A reference fluid (such as water or mercury) is placed in the tube.

-

When a pressure difference occurs between two points, the liquid column shifts.

-

The height difference (h) between the two fluid levels corresponds to the pressure difference, calculated using:

P = ρ × g × h

Where:

-

P = pressure difference

-

ρ = density of the fluid

-

g = gravitational acceleration

-

h = height difference

This fundamental principle is used across fluid dynamics experiments, industrial processes, and research applications.

Applications of Fluid Science Manometers

Manometers have a wide range of applications:

-

HVAC systems: Measuring airflow and differential pressure changes for proper ventilation and performance.

-

Medical equipment: Used in devices such as blood pressure monitors for precise pressure readings.

-

Aerospace engineering: Monitoring airspeed and cabin pressure using high-accuracy systems.

-

Environmental monitoring: Measuring barometric pressure and water levels for weather forecasting.

-

Laboratory research: Essential in teaching fluid mechanics, including experiments on Bernoulli’s principle and fluid velocity.

-

Industrial processes: Ensuring optimal pressure control in chemical engineering, processing plants, and hydraulic systems.

Armfield’s Fluid Science Service Units support these applications by providing modular tray-based systems for experimentation and training.

Choosing the Right Manometer

When selecting a manometer, consider:

-

Pressure range: Match the instrument to the required measurement level (e.g. small pressure differences require inclined manometers).

-

Fluid compatibility: Ensure the manometric fluid is suitable for the working environment.

-

Accuracy and sensitivity: Laboratory experiments often require high sensitivity, while industrial applications demand durability.

-

Environmental conditions: Factors such as temperature and humidity can influence readings.

-

Maintenance needs: Some designs require calibration for long-term accuracy.

At Armfield, our engineering team helps clients choose the best solution for their specific fluid science manometer requirements.

Common Problems and Troubleshooting

-

Inconsistent readings: Often caused by air bubbles in the fluid column—purging the system usually resolves this.

-

Temperature-related errors: Use fluids with stable density across temperature ranges to maintain accuracy.

-

Fluid evaporation: Sealed or digital manometers prevent this issue in long-term applications.

-

Leaks in tubing or connections: Regular inspection prevents errors and protects against performance loss.

Maintenance Tips

To ensure optimal performance:

-

Clean the manometer tube regularly to avoid contamination.

-

Verify fluid levels and top up if required.

-

Calibrate periodically to maintain high-accuracy measurements.

-

Inspect connections and seals to prevent leaks.

-

Store the instrument in a controlled environment to avoid damage.

FAQs About Fluid Science Manometers

1. What is the purpose of a Fluid Science U-Tube Manometer tray?

It is used to measure pressure differences in fluids, enabling students and engineers to observe fluid behaviour and perform hands-on experimentation.

2. How accurate are gauge pressure measurements?

When properly calibrated, manometers provide precise measurements, especially for small and moderate pressure ranges, making them highly reliable in laboratories and industrial environments.

3. How do blood pressure monitors relate to fluid science manometers?

They use the same principle of pressure measurement, adapted to medical devices with electronic sensors for accurate and non-invasive monitoring.

4. How does the choice of manometer fluid impact accuracy?

The density of the fluid directly affects the scale of measurement. For example, mercury is suited to high-pressure applications, while water or low-density fluids are used for sensitive, small-magnitude pressure differences.

Why Choose Armfield?

At Armfield, we have decades of expertise in creating fluid science manometers that deliver reliability, precision, and long-term value. Our modular systems, such as the Fluid Science Service Unit, are designed for both industrial use and practical experimentation in research and education.

Ready to Measure with Precision?

Contact Armfield today to find out how our fluid science manometers can improve your experiments, processes, and training programmes.

Armfield can trace its history back over 130 years, throughout which, the Company’s policy of quality, innovation and service has helped it to maintain a strong market position and develop a reputation for industry leadership in the field of Engineering teaching.

Education Division

Operating since 1963, the Armfield Education Division designs and manufactures equipment for engineering education and research.

Industrial Division

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries.