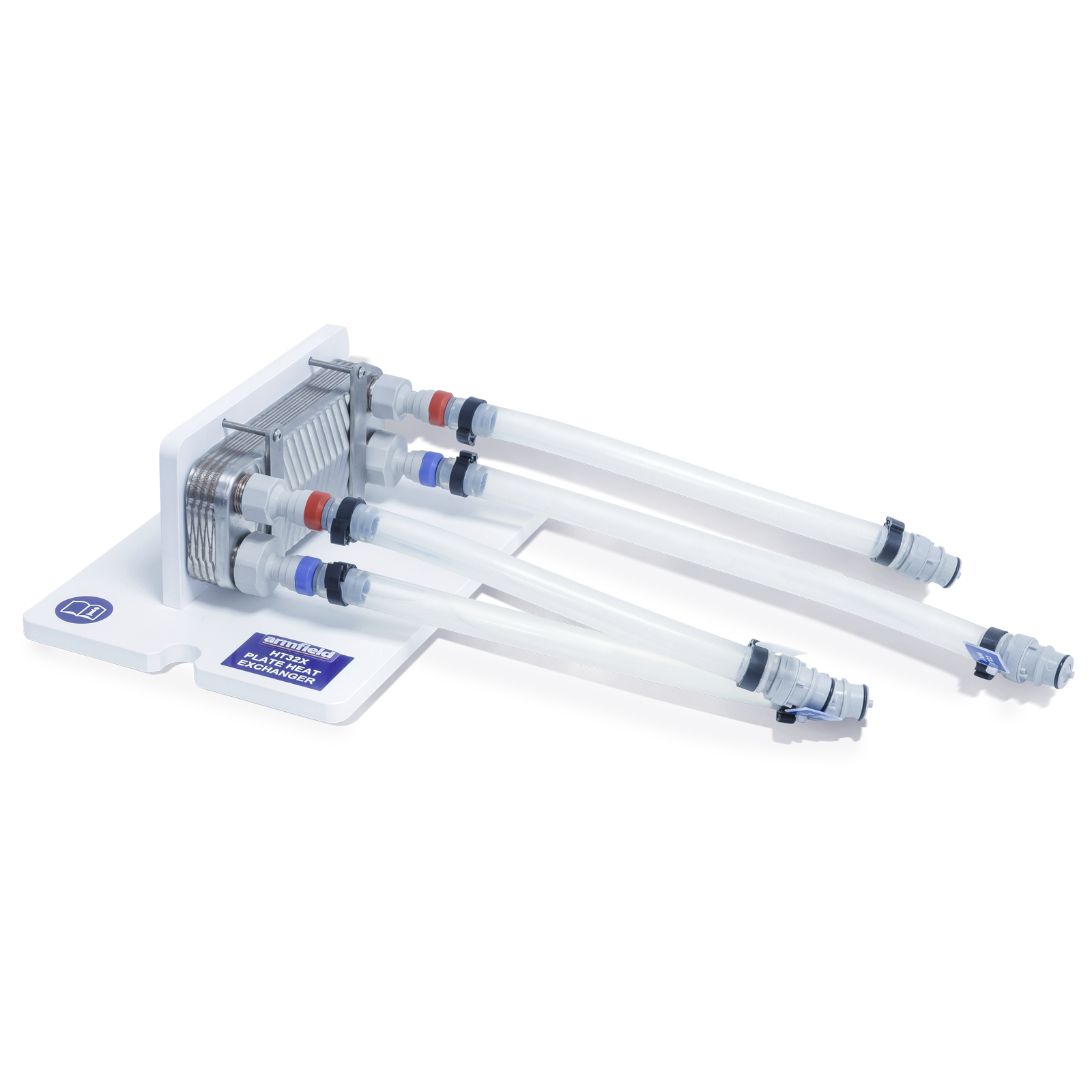

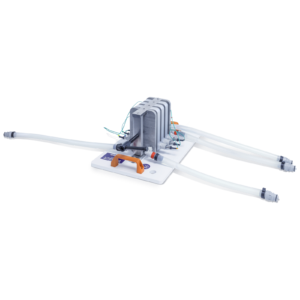

HT32X – Plate Heat Exchanger

The plate heat exchanger is extremely versatile and commonly used in the food and chemical processing industries.

Description

The plate heat exchanger is extremely versatile and commonly used in the food and chemical processing industries.

The HT32X has a single heating section configured for multi-pass operation with passes in series.

It comprises 10 individual plates. When being assembled, each second plate is rotated by 180°, thus forming two separately rotated flow chambers by the means of which the mediums being involved in the heat transfer are conducted in counter flow.

Technical Specifications

As suggested by its name, the plate heat exchanger consists of wave-shaped panels that are assembled in a unique way. There are interspaces between the plates.

The plates are manufactured from thin sheets of stainless steel, embossed with corrugations that promote turbulent mixing even at low Reynolds numbers. This turbulent mixing has the advantages of creating very high heat transfer coefficients and reduce fouling that may occur.

Hot and cold fluid flows may be configured for either cocurrent or countercurrent operation.

Plate details:

Plate overall dimensions: 191mm x 73mm

Effective heat transfer area: 0.12m2

Projected heat transmission area: 0.015m2

Number of plates: 10

Conductive panel (Plate thickness): 0.26mm

Distance between plates: 2.1mm

Material: Stainless steel, copper

Features & Benefits

- A small scale plate heat exchanger system for use with an Armfield Computer Controlled Heat Exchange Service Unit to teach the fundamental concepts of heat exchangers

- Comprises a number of stainless steel plates, each with a pressed chevron pattern, soldered with copper using a vacuum soldering procedure

- A comprehensive instruction manual is included

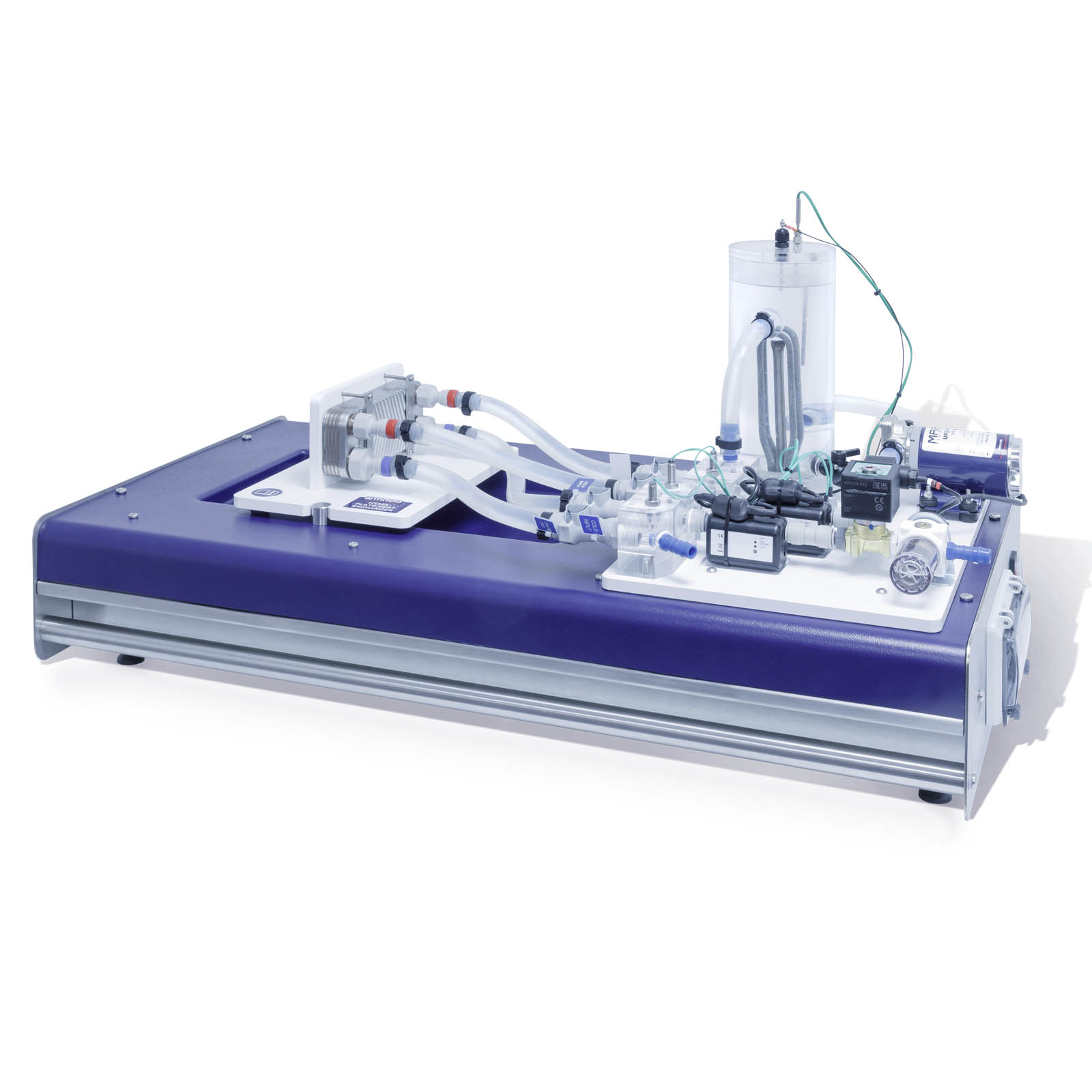

ArmBUS software is provided as standard with the HT30X for all the Armfield heat exchanger accessories. Individual programs are provided for each exchanger, and each program contains a selection of separate exercises that can be performed.

The actual details are exercise specific, but typically the following interfaces are available:

- Full Graphical User Interface (GUI) for each experiment with display screens tailored for each exercise

- All the temperatures and flow rates are displayed on a diagrammatic representation of the equipment

- Student questions and equations can be accessed individually for each exercise

- The hot-water flow rate utilises optional Manual/Automatic control to control the pump output. Manual control allows the user to select a percentage of the total power to supply to the pump. Automatic control allows the user to input the desired set point which the PID control will reach and maintain. The use of automatic control ensures the flow is stable despite changes in the viscosity of the water due to heating

- Real-time flow rate readings are displayed in L/min Sensor data is collated and calculations are displayed in a data-log, a tabulation function provided with the armBUS software. The data is in tabulated format and can be saved and accessed through a .csv file compatible with software such as Microsoft Excel

- The cold-water flow control valve utilises optional Manual/Automatic settings to control water flow from the mains. Manual control allows the user to open/close the valve between 0 and 100%. Automatic control allows the user to input the desired set point which the PID control will reach and maintain so long as the input pressure is adequate.

- The heater utilises optional Manual/Automatic control to supply power to the heater element in the boiler. Manual control allows the user to select a percentage of the total power to supply to the heater. Automatic control allows the user to select a set point (°C), and then PID control software heats the water to and maintains a set temperature

- The data from the sensors is plotted and displayed in a user-configurable graphing function of the software. It can be displayed separately from the data logging and each sensor output can be viewed independently

- Processing of measured values to obtain calculated results (this can be linked to the questions and answers to ensure student understanding, answers to equation calculations can be found as part of the datalogger output)

- HT30X Computer Controlled Heat Exchanger Service Unit

Packed and crated shipping specifications

Volume: 0.03m3

Gross weight: 6kg

Length: 0.07m

Width: 0.19m

Height: 0.40m

HT32X – Plate Heat Exchanger

See HT30X for power options

You may also like…

-

HT36X – Extended Tubular Heat Exchanger

Read more -

HT35X – Cross Flow Heat Exchanger

Read more -

HT31X – Tubular Heat Exchanger

Read more -

HT33X – Shell and Tube Heat Exchanger

Read more -

HT34X – Jacketed Vessel With Coil And Stirrer

Read more -

HT37X – Extended Reconfigurable Plate Heat Exchanger

Read more