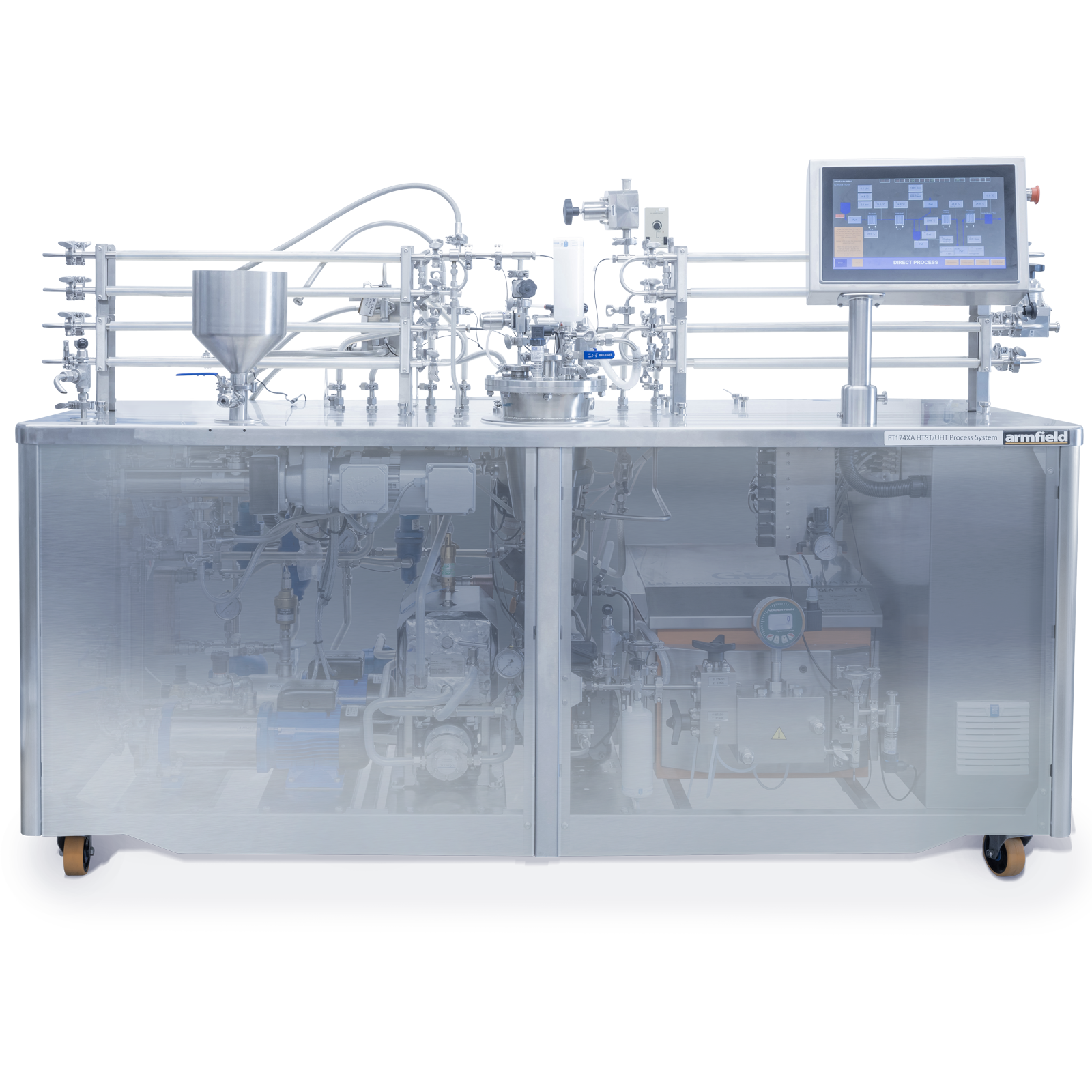

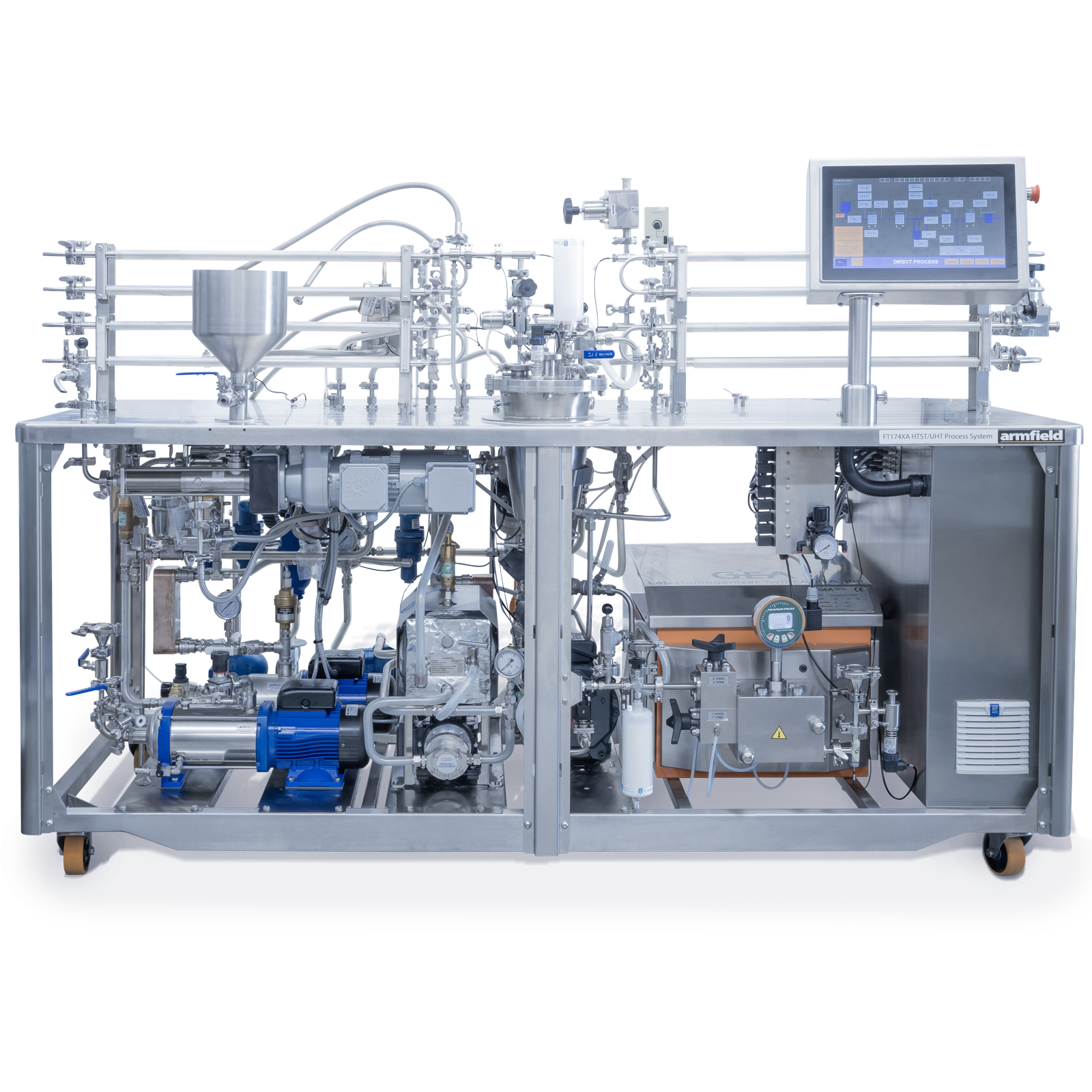

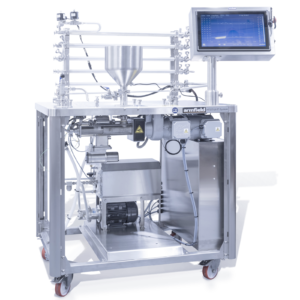

FT174 – Modular Miniature Scale HTST/UHT Process System

The FT174 is a modular HTST/UHT processing system designed to treat products at flow rates of 10-60 l/h.

Interchangeable modules for direct heating (steam injection) or indirect heating (using tubular, plate or scraped surface heat exchangers), aseptic processing, upstream or downstream homogenisation and additional chilling are available.

Description

FT174 HTST/UHT Base unit

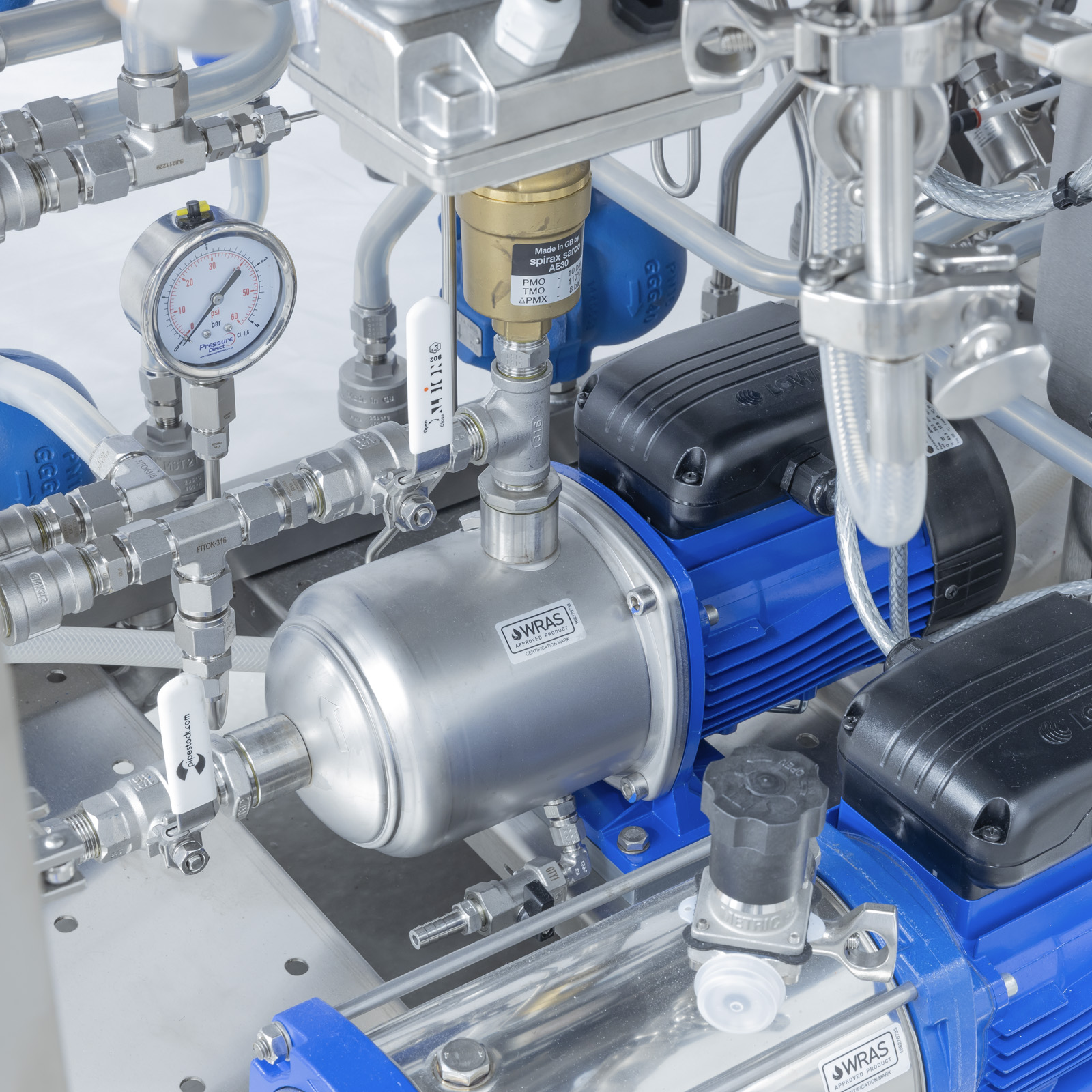

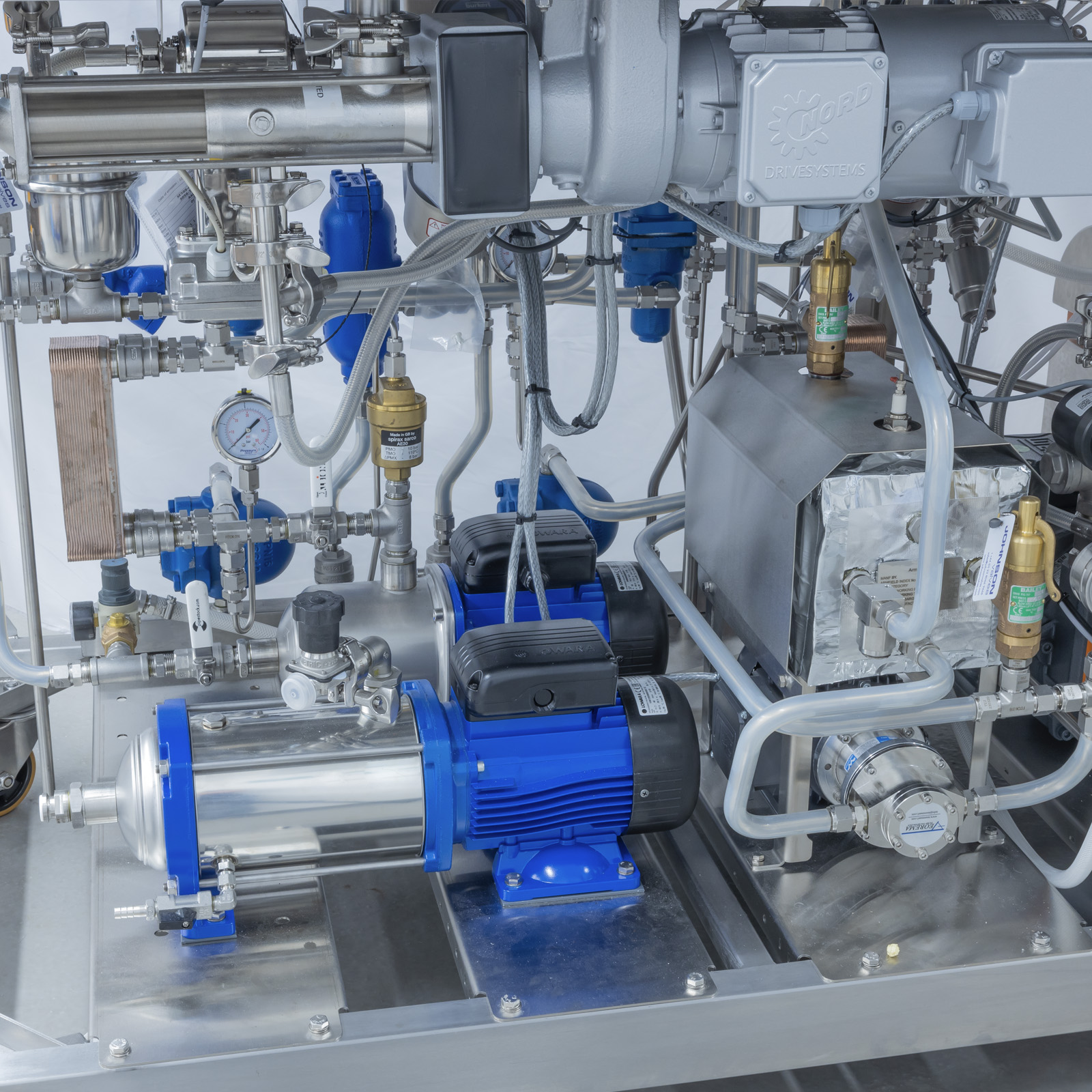

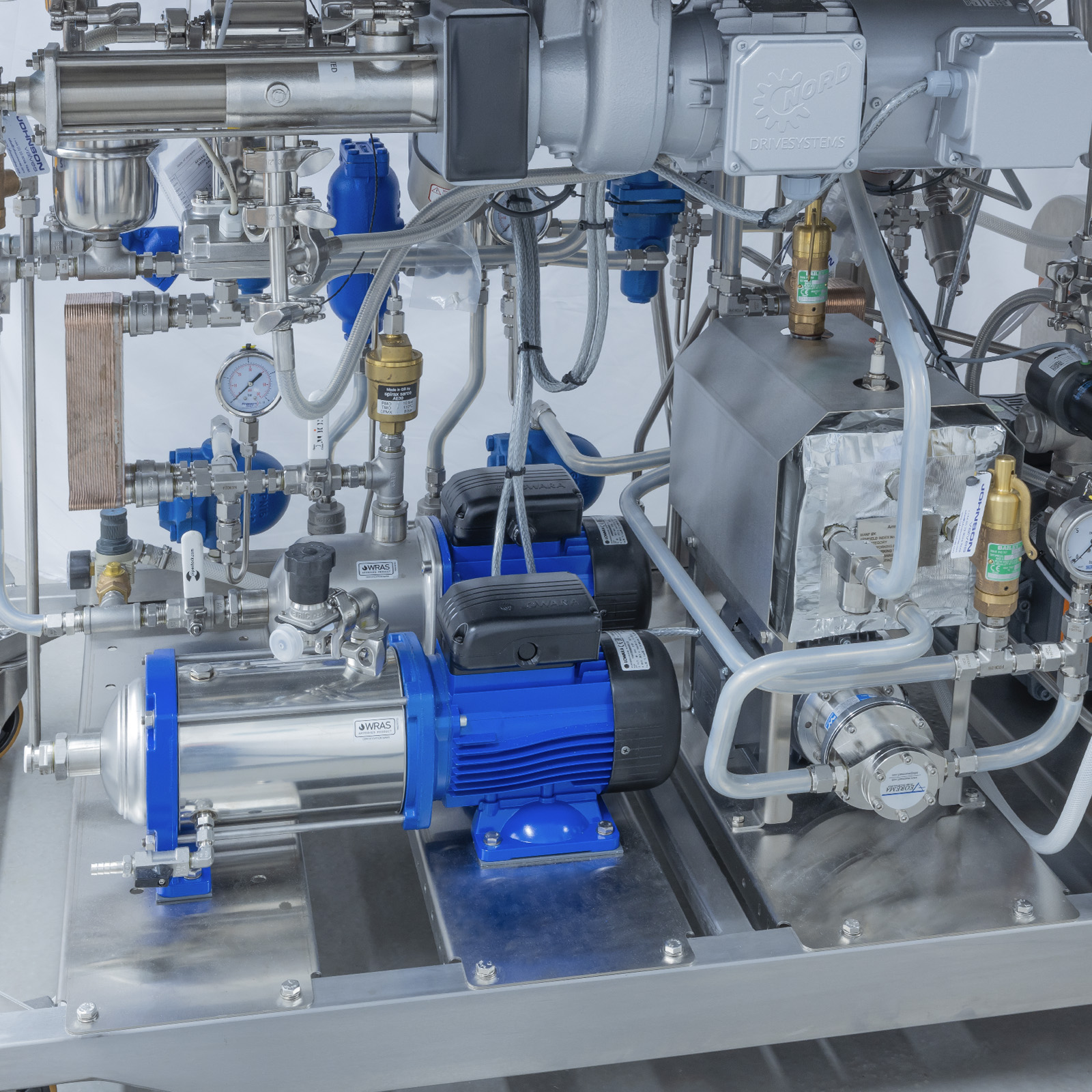

The base unit comprises a stainless-steel table for mounting the process equipment, a feed pump and vessel, the touchscreen control panel, steam line components and all associated electrical controls housed in an IP65 cabinet. The base unit provides the services to the heat exchangers.

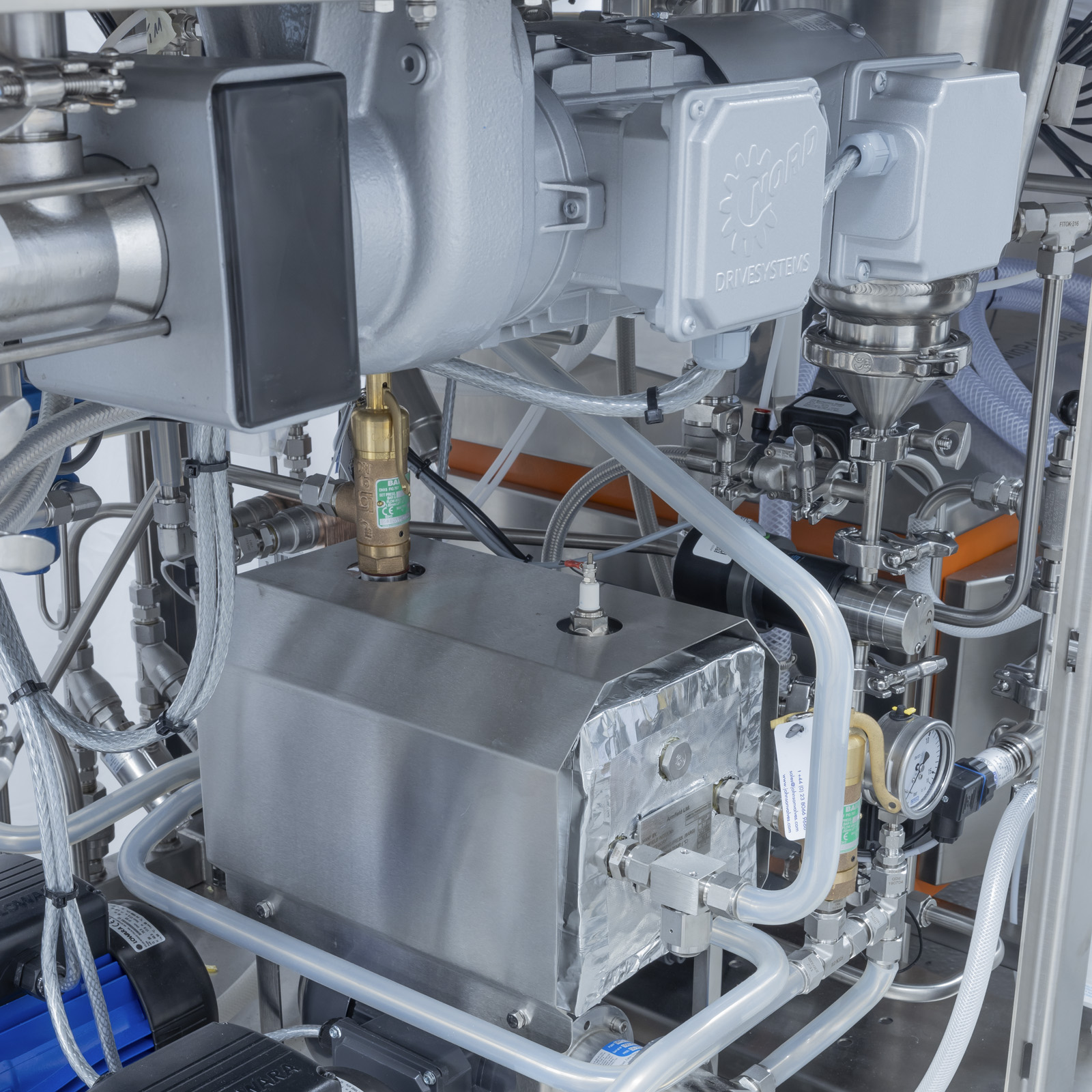

Under the tabletop are positions for multiple options or accessories. These include the vacuum, extraction and CIP pumps, homogeniser, direct steam injection and the hot water circulator options.

The system is PLC controlled, with a 15” full colour touchscreen panel PC (IP65). The touch-screen control panel makes it extremely user friendly to configure and monitor processing parameters.

These, along with many other options, enable multiple modules to be included in the same system, giving high process adaptability by reconfiguration of flexible product hoses, using quick-release connections.

The sterilisation options enable it to be linked to an Armfield sterile filling bench to produce sterile product, even when using long holding tubes and/or downstream homogenisation.

As with all UHT Armfield systems, it comes with hygienic fittings throughout as standard.

Different sets of processing parameters can be edited, stored and quickly recalled using the system’s menu capability.

Similarly, the ancillary items such as the homogeniser and sterile filler are also controlled from this panel. The system can be quickly and easily interfaced to other free-standing Armfield process items, such as a mixing vessel, a chiller (FT63 or FT64) or a sterile filling system (FT83XA).

Technical Specifications

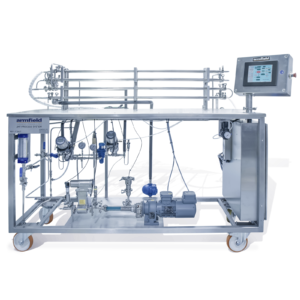

FT174 Heat Exchanger Service Unit

FEED PUMP

Pump type: Progressing cavity variable-speed pump

Particulate handling: 0.8mm

Fibre handling: 25mm

Flowrate: 10-120l/h (max)

PLATE HEAT EXCHANGERS

Used for Preheat, Main heat, Primary Cooling and/or Secondary Cooling

Nominal/Processing Flowrate: 20l/h / 10-60l/h

Plate overall dimensions: 75 x 115mm

Effective diameter: 3.0mm

Plate thickness: 0.5mm

Wetted perimeter: 153.0mm

Working pressure: 10 bar (max)

Materials

Plates: 316 stainless steel

Gaskets: Food-grade silicone

Tubular HEAT EXCHANGERS

Used for Preheat, Main heat, Primary Cooling and Secondary Cooling

Nominal/Processing Flowrate: 20l/h / 10-60l/h

Tube diameter (product side): 8.1mm

Overall diameter: 15.8mm

Material: 316 stainless steel

Assembled test pressure: 15 bar

Working pressure: 10 bar (maximum)

Surface Scraped heat exchanger

Used for Preheat, Main heat, Primary Cooling and/or Secondary Cooling

Nominal/Processing Flowrate: 20l/h / 10-40l/h

Heat transfer area: 0.045m²

Shaft/barrel volume ratio: 1 : 3.5

Scraper blades: 4 PEEK scrapes along stainless steel shaft, 2 pairs with 180° separation

Barrel length: 0.35m

Barrel working pressure: 10 Bar

Utility Requirements

Mains water: 5 l/min @ 2 bar (10 l/min if FT174-49 or FT174-55 are fitted)

Electricity: 400V / 3ph / 50-60Hz / 30 amp

Consult Armfield for the specifics of your system

Compressed air: 6 bar

Steam: 6 bar, estimated consumption 15 kg/h

Features & Benefits

- High degree of user configuration

- Rapid start-up and shut down

- Switch-over between heat exchangers is quick and easy

- Direct and/or indirect heating

- Tubular & plate heat exchangers, scraped surface heat exchangers (SSHE), DSI module options.

- Low product hold-up

- Modular design for your product specific processing

- Full sterile capability options

- 15” Touchscreen HMI with PLC control

- Hygienic fittings as standard

- Integral homogeniser option

- Standard throughputs from 10-60 l/hr

- Maximum product temperature setting of 150˚C

- Controllable preheat and cooling option

- Built-in CIP facility

- Data logging as standard

Preheat

A progressive cavity feed pump is used for consistent volumetric flow rate for a wide range of liquid viscosities.

It consists of a stainless steel rotor within a food-grade rubber stator.

All metal parts of the pump that come into contact with product are made from 316L stainless steel or other food-grade materials.

This pump provides a very wide range of flow capability, from as low as 10 l/h to as much as 120 l/h (used for CIP). The pump is fitted with a feed tank and level sensor, a pressure-relief valve and temperature and pressure sensors.

A gentle preheat action is achieved by using steam at sub-atmospheric pressure. In this way, stable temperatures of 100 – 60°C or less are feasible. Control of the steam pressure/temperature is achieved by a manual steam-control valve or an automatic PID control is an available option.

Hot water preheat to enable control from ambient to sub <100°C is available on request.

Main heat

Steam is applied to the service side of the heating section of the product heat exchanger using an electro-pneumatic steam-control valve.

The product temperature is measured at the end of the heat exchanger (or holding tube) and this value is used by a PID control algorithm to control the steam-regulating valve, ensuring the user defined set point is maintained.

The same steam output and control valve is used to provide the steam injection for the optional Direct Steam Injection module. A pressurised hot water heating system is available on request.

Primary Cooling

Cooling water is applied to the cooling section of the product heat exchanger with the flowrate controllable and measured.

Secondary Cooling (optional)

An additional heat exchanger using an external chilled water or glycol supply. Options available are a recirculating chiller such as the Armfield FT63, FT64 or other chilled/ice water supply.

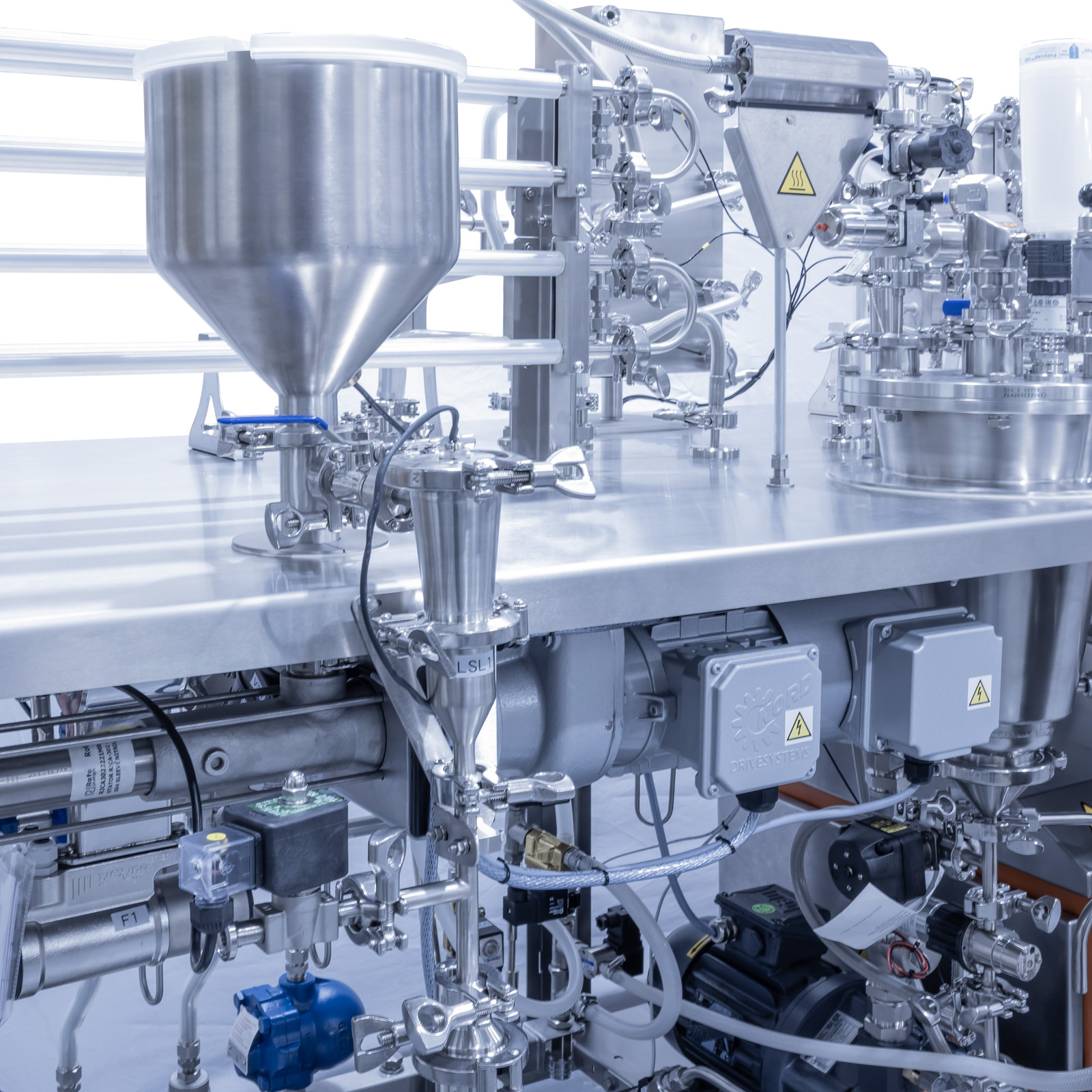

Feed Pump System

A progressive cavity feed pump is used for consistent volumetric flow rate for a wide range of liquid viscosities. It consists of a stainless steel rotor within a food-grade rubber stator.

All metal parts of the pump that come into contact with product are made from 316L stainless steel or other food-grade materials.

This pump provides a very wide range of flow capability, from as low as 10 l/h to as much as 150 l/h (used for CIP). The pump is fitted with a feed tank and level sensor, a pressure-relief valve and temperature and pressure sensors.

- Baby foods

- Beer

- Beverages

- Condiments

- Confectionery

- Milk

- Cream

- Ice-cream

- Yoghurt

- Desserts and puddings

- Fruit and vegetable purées

- Fruit juices and cordials

- Sauces and soups

- Gravies

- Gelatine products

- Pet food

- Health and nutritional products

- Culture media

- Protein drinks

- Pharmaceuticals

- Plant based beverages

Flow Meter (Electromagnetic) (FT174-40)

The standard unit calculates the flow rate from the feed pump. This is accurate for most applications, but where very high accuracy is required e.g. medicinal dosing, an electromagnetic flowmeter is available for measuring the product flow rate.

Product Divert for Indirect Heating (FT174-22)

This enables the product to be diverted away from the downstream process if the maximum temperature drops below a critical value. This enables the downstream process line to maintain its sterility.

Pneumatic Back Pressure Valve (FT174-42)

The FT174-42 is a pneumatic pinch valve, which provides better pressure control for products containing particulates.

Equipment Sterilsation Option (Indirect) (FT174-45)

Sterilisation is achieved by applying steam onto the outside of the cooling tubes instead of cold water. This sterilises the cooling tubes and gives the power to sterilise a downstream homogeniser.

This is only needed for indirect sterilisation of the system.

Digitally Controllable Preheat (FT174-46)

This option adds digital control to the HMI. It replaces the standard manual preheat control valve with a PID controlled electro-pneumatic valve.

Direct Steam Injection Module (Non-Sterile) (FT174-49)

The option comprises:

- Steam-conditioning unit – built into the service unit frame. Includes a culinary grade steam filter to clean any impurities from the steam prior to injection

- Steam-injection port

- Back pressure valve on vessel inlet

- Tubular HE (two tubes) for cooling prior to the extraction pump

- Pressure (vacuum) sensor and temperature sensor

- Vacuum pump assembly with isolator valve and bleed valve

- Extraction pump to extract the contents of the vessel against the vacuum.

When processing with direct steam injection, tubular/plate heat exchangers are for preheat. Product flow rates would be typically 10-30 l/h.

Direct Steam Injection Module (Sterile) (FT174-55)

The divert valve enables product to be diverted away from the vessel until it is fully up to temperature keeping the vessel sterile during processing. This module is an alternative to the non-sterile module above, which is modified to make sterilisation possible. It is designed to be used in conjunction with the FT83 Sterile Filler Cabinet.

It comprises:

- All items in the DSI Module (Non-Sterile)(FT174-49)

- A hygienic divert valve prior to the vacuum chamber

- Cooling heat exchanger for the discharged product

- Sterile breather

- Second valve and steam trap at the filler (FT83)

Steam is used to sterilise the system, injected through the direct injection port.

Controlled Cooling (FT174-51)

This option, used in conjunction with secondary cooling, allows the user to define an outlet product temperature.

CIP System (FT174-52)

A dedicated centrifugal pump to augment the standard capabilities of the standard CIP facility on the FT174. This option is necessary if one of the direct heating methods is chosen.

Suction Feed Assembly with Automatic Changeover (FT174-53)

This option allows product to be drawn from an upstream tank or vessel. In a low level situation, a 10 second warning is given before the system switches the feed to water. This can be reversed on the HMI when desired.

This means the process is not interrupted by the dry-pump safety shutdown and therefore downstream sterility is not broken.

Pressurised Hot Water Heating Circuit (FT174-58/FT174-59)

This option is available for Preheat and Main heat. It is a secondary hot water heating circuit between the steam & product streams. This gives precise control over the temperature of the process temperatures between ambient and 100°C. This is especially useful for sensitive products or those with high protein or sugar contents.

Scraped Surface Heat Exchanger (FT174-75)

The scraped surface heat exchanger can be used for both heating and cooling of your products and can be fitted at any position (preheat, main heat, cooling).

They are especially effective when viscous products are being processed, especially if they are non-Newtonian fluids. Product flow rates would be typically 10-20 l/h.

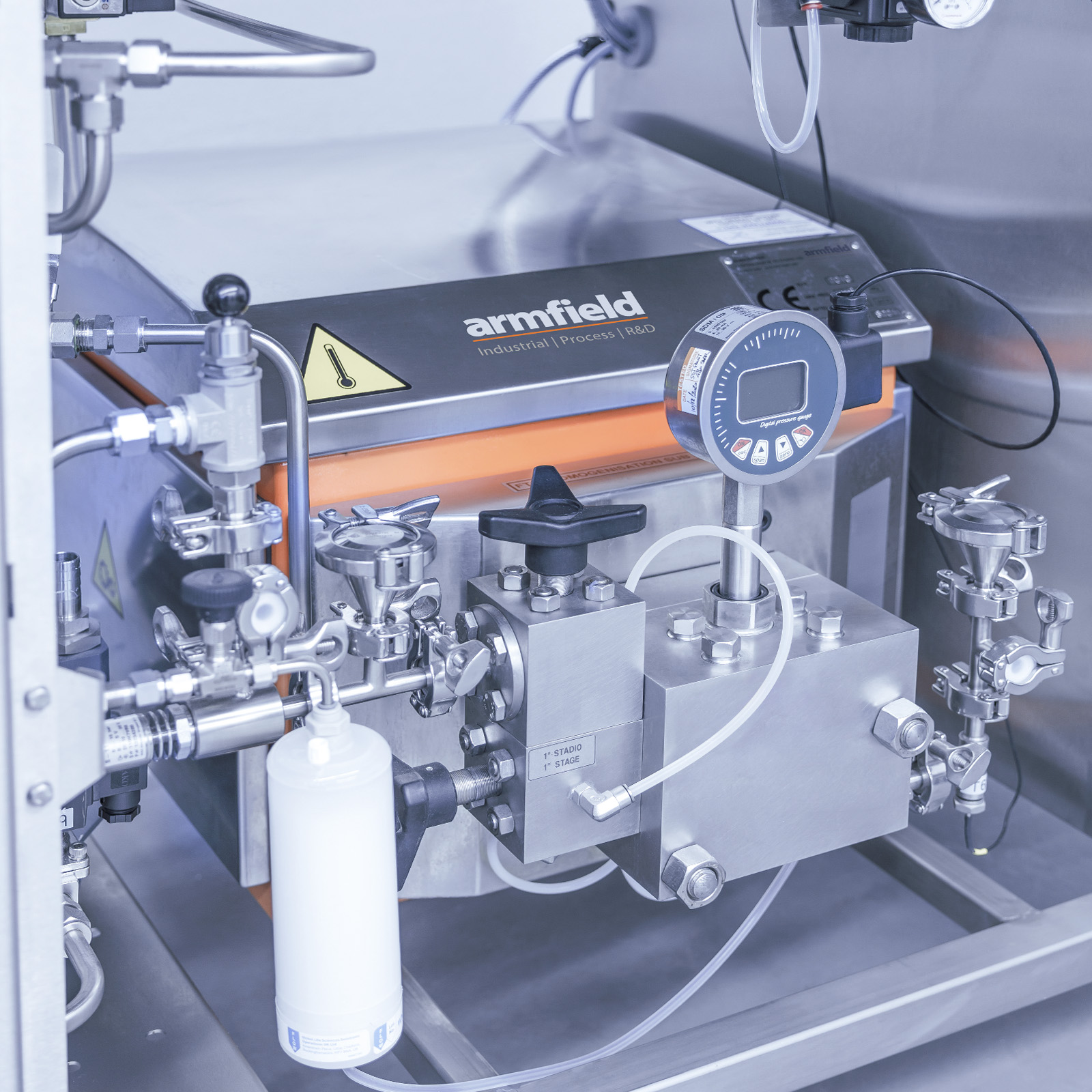

Integrated Homogeniser Assembly (FT174-91)

Integrated within the FT174 frame, this enables upstream or downstream homogenisation. Twin-piston, two-stage variable flow rate homogeniser with pressures up to 400 bar. Included are pulsation damping devices, a bleed valve to control input pressure, plus temperature, product line pressure and homogenisation pressure sensors.

The homogeniser is controlled from the FT174 touchscreen. The pump speed can be automatically controlled to match the product flow rate.

Set of Static Mixers (FT174-21)

Static mixers promote turbulence in the tubes and improve heat transfer. One set provides mixers for one tube.

Product Divert for Indirect Heating (FT174-22)

This enables the product to be diverted away from the downstream process if the maximum temperature drops below a user defined critical value. This enables the downstream process line to maintain its sterility.

Tubular Heat Exchangers (FT174-26)

One set consists of 4 tubes with a temperature sensor. The product flows through the center while the service fluid (heating or cooling fluid) flows through the outer tube (typically up to 60 l/h).

Primary Cooling Tubular Heat Exchanger (FT174-27P)

One set consists of 4 tubes with a temperature sensor. The cooling media is mains water.

Secondary Cooling Tubular Heat Exchanger (FT174-27S)

One set consists of 4 tubes with a temperature sensor. The cooling media is glycol/ice water. Options available are a recirculating chiller such as the Armfield FT63, FT64 or other chilled/ice water supply.

Extended Plate Heat Exchanger (FT174-36)

Single stage plate heat exchanger comprising 18 plates. Can be used for the Preheat, Main heat (indirect) or Primary Cooling.

The FT174-36’s can be mixed and matched with tubular heat exchangers.

Dual Plate Heat Exchanger (FT174-36-DUAL)

For Secondary Cooling, this PHE is required. The cooling media is glycol/ice water. Options available are a recirculating chiller such as the Armfield FT63, FT64 or other chilled/ice water supply. It also includes the plates for Primary Cooling.

(This option is needed when two stages of heating, or two stages of cooling are required.)

Variable Holding Tube (FT174-65)

Provides nominal holding times of 15, 30, 45, 60, 75, 90, 105, and 120s for a flow rate of 20 l/h.

Note: FT174 display shows the actual hold time based on the measured or calculated flow rate used during processing.

Other holding tubes

Other holding tubes can be provided to suit your holding time and flow rate requirements. Please contact us with your specific requirements.

Side Panels (FT174-80) Side panels to shield components inside the frame and provide access for maintenance.

10L Feed Hopper

The base unit comes with a 5L hopper as standard. A 10L hopper is available as an alternative preference.

- Mains water: 5 l/min @ 2 bar

(10 l/min if FT174-49 or FT174-55 are fitted) - Electricity: 400V / 3ph / 50-60Hz / 30 amp

(Consult Armfield for the specifics of your system) - Compressed air: 6 bar

- Steam: 6 bar, estimated consumption 15 kg/h

Note: Armfield can supply a steam boiler if required, order code UOP10

Packed and crated shipping specifications

Volume: 5m3

Gross weight: 567kg

Length: 2.25m

Width: 0.89m

Height: 1.53m

- FT174-C

- FT174-D