FS-3.1 – Fluid Science Shell and Tube Heat Exchanger

The tray introduces students to concepts such as heat transfer coefficients, thermal resistances, controlling resistance and heat transfer driving forces. The heat exchanger can be used in a co-current or countercurrent configuration.

Description

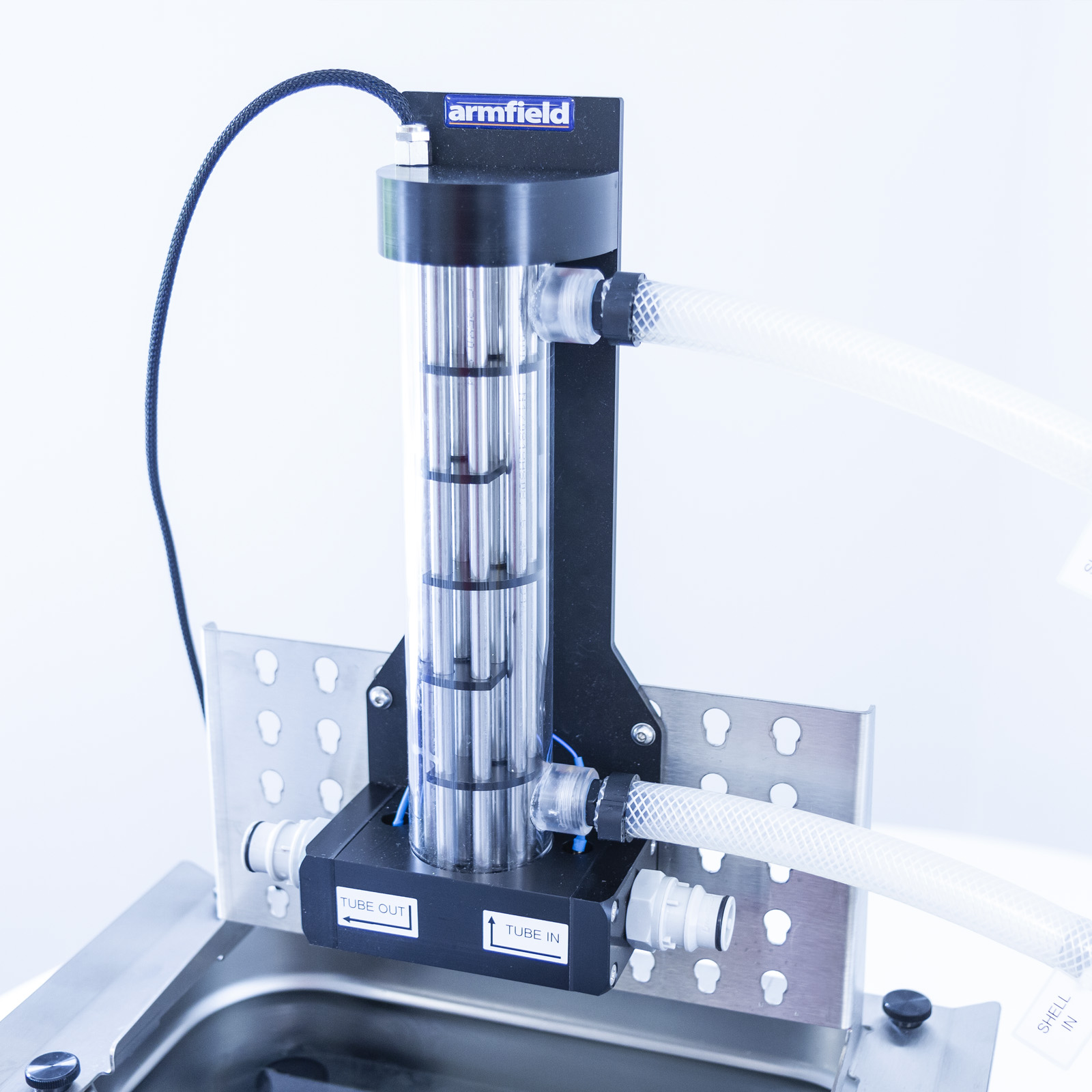

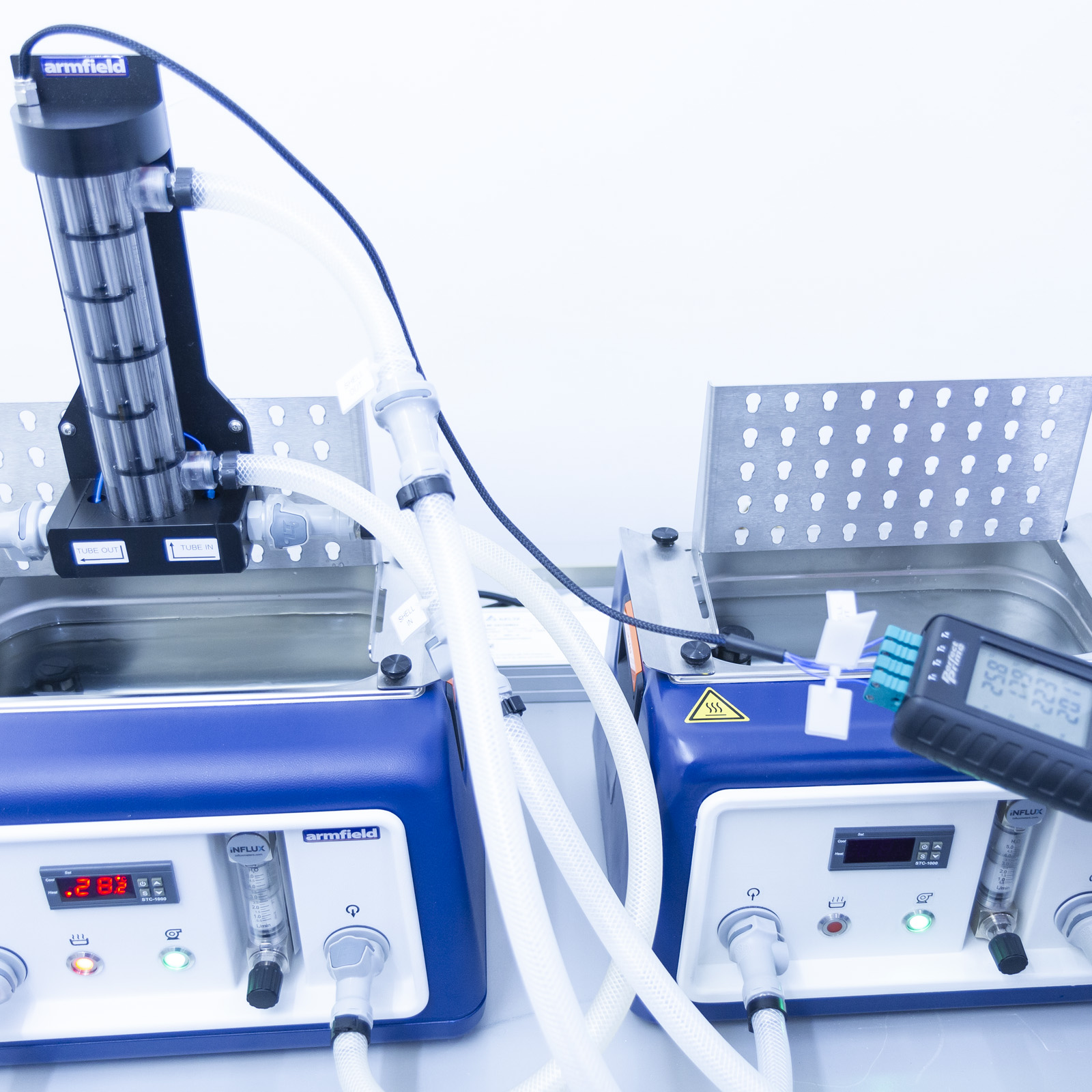

The Fluid Science range is an innovative suite of products designed to enable students to gain an understanding of the fundamentals of Fluid Mechanics and Thermo Fluids by the process of learning via hands-on experimentation.

The high precision elements are supplied as modular tray-based systems which operate in conjunction with the Fluid Science service unit, multifunctional work panel and instrumentation enabling the student to conduct their own individual or group experiments.

The experiments are supplied with a highly visual user-friendly operational guide, allowing the students to understand the theory of the subject by the application of practical experimentation.

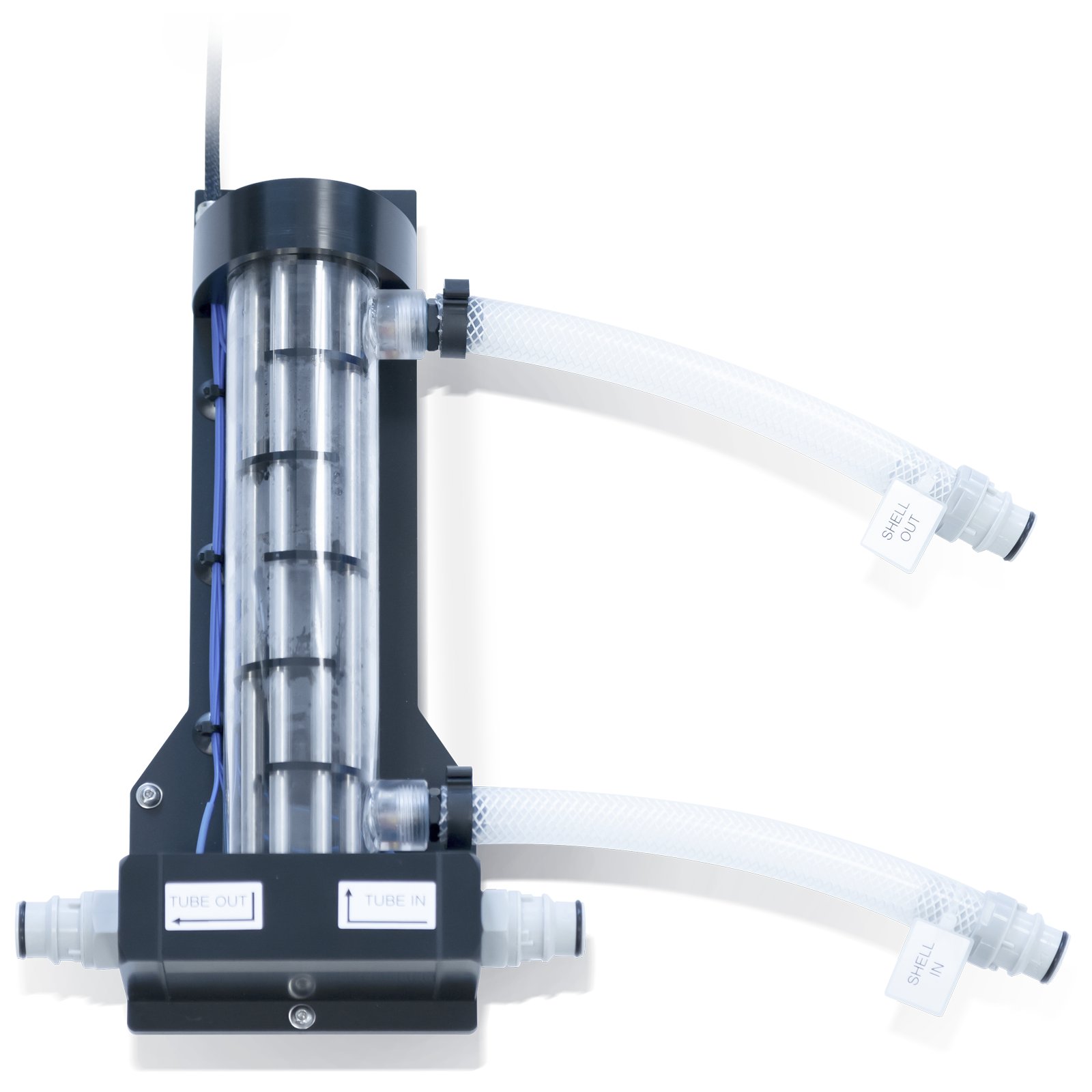

The FS-3.1 Fluid Science Shell and Tube Heat Exchanger tray includes experimentation to demonstrate indirect heating or cooling by transfer of heat from one fluid stream to another when separated by a solid wall (fluid to fluid heat transfer) in a shell and tube heat exchanger.

The tray introduces students to concepts such as heat transfer coefficients, thermal resistances, controlling resistance and heat transfer driving forces.

The heat exchanger can be used in a co-current or counter-current configuration.

Technical Specifications

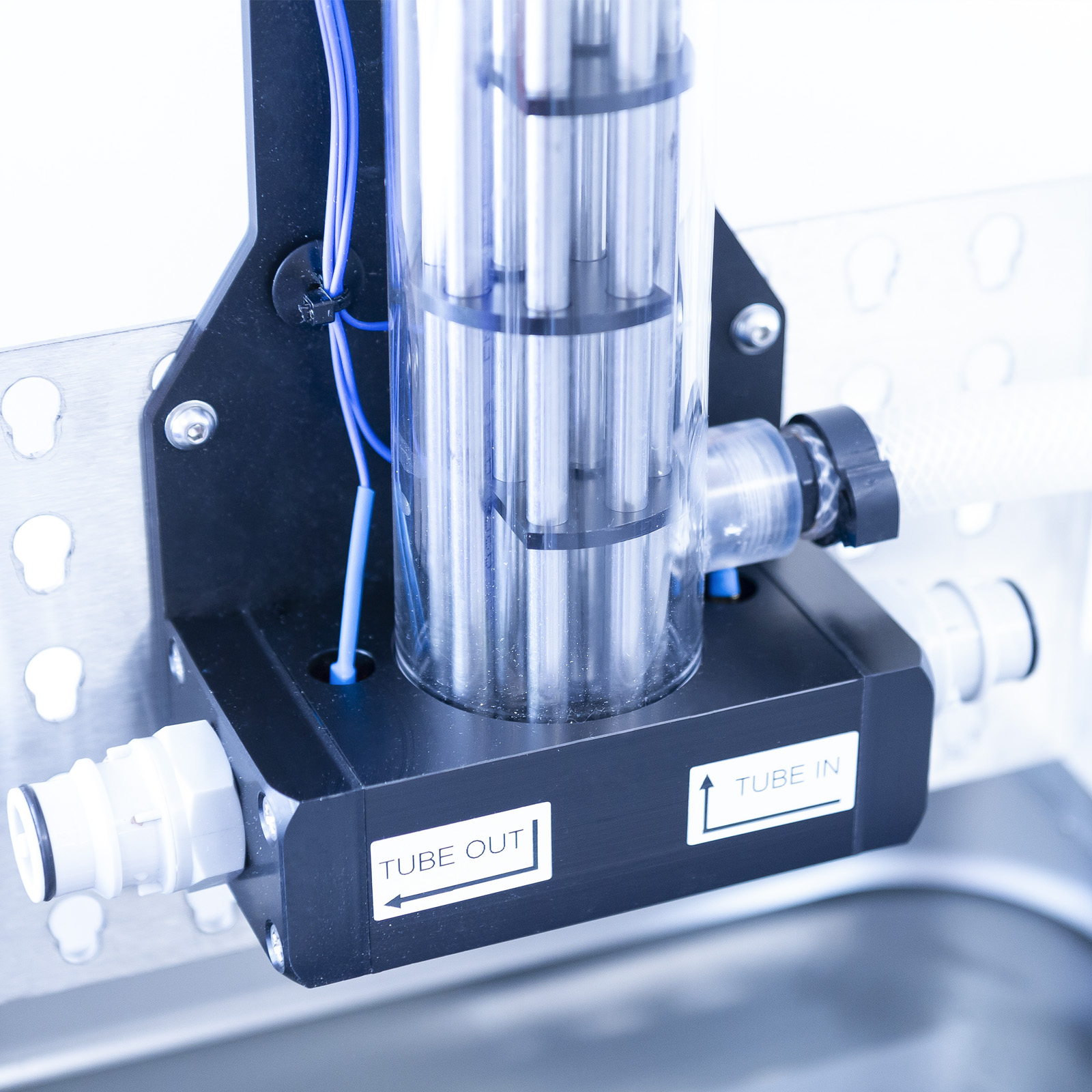

Outer shell diameter ID: 44mm OD: 50mm.

Number of Tubes:10

Tube length: 246mm

Outside diameter of tubes: 1/4 inch / 6.35mm

Inside diameter of tubes: 4.57mm (20 B.W.G tube)

Tube material: stainless steel 316

Thermocouples 4 x K-Type:

- Cold water in

- Cold water out

- Hot water in

- Hot water out

Features & Benefits

FEATURES

- Fully mobile solution

- Each service unit can be used as either a hot or cold-water supply

- Quick connect couplings for easy connection to experiment modules, self-sealing on supply unit to minimise water loss

- Digital manometer and thermometer provided with service unit

- Low voltage within the supply unit to protect users

BENEFITS

- Applied student learning via experimentation

- Common service unit can be used for either hot or cold-water supply

- Toolless assembly

- Designed to be highly visual and simple to use

- Quick setup

- Suitable for both classroom, laboratory and mobile environments

- To demonstrate indirect heating or cooling by transfer of heat from one fluid stream to another when separated by a solid wall (fluid to fluid heat transfer)

- To perform an energy balance across a shell and tube heat exchanger

- To calculate the overall efficiency at different fluid flowrates

- To demonstrate the differences between co-current flow (flows in same direction) and countercurrent flow (flows in the opposite direction) and the effect on heat transferred and temperature efficiencies

- To determine the overall heat transfer coefficient for a tubular heat exchanger

- To investigate the effect of changes in hot and cold fluid flowrate on the temperature efficiencies and overall heat transfer coefficient

Fluid Mechanics Range

- FS-1.1 Flow Measurement

- FS-1.2 Energy Losses – Straight pipes

- FS-1.3 Energy Losses – Bends

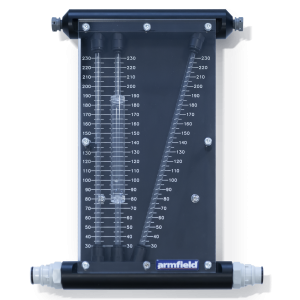

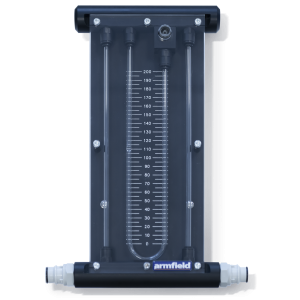

- FS-2.1 Manometer – Inclined

- FS-2.2 Manometer – U tube

- FS-3.2 Heat Exchanger – Tubular

- FS-3.3 Heat Exchanger – Cross flow

- FS-3.4 Heat Exchanger – Plate

- FS-4.1 Fluidised bed

Electrical supply:

- 100-240V/1 Phase, 50-60Hz

Level surface

FS experiment trays

Initial fill of 5ltrs water.

Drain to empty water away once experiment is complete.

During use, water supply or drainage are not required.

PACKED AND CRATED SHIPPING SPECIFICATIONS

Net weight: 2.10kg

Gross Weight: TBC

DIMENSIONS TRAY

Length: 0.43m

Width: 0.312m

Height: 0.080m

DIMENSIONS SET UP

Length: 0.300m

Width: 0.071m

Height: 0.185m

- FS-SU

- FS-3.1