FS-1.2 Energy Losses in Straight Pipes

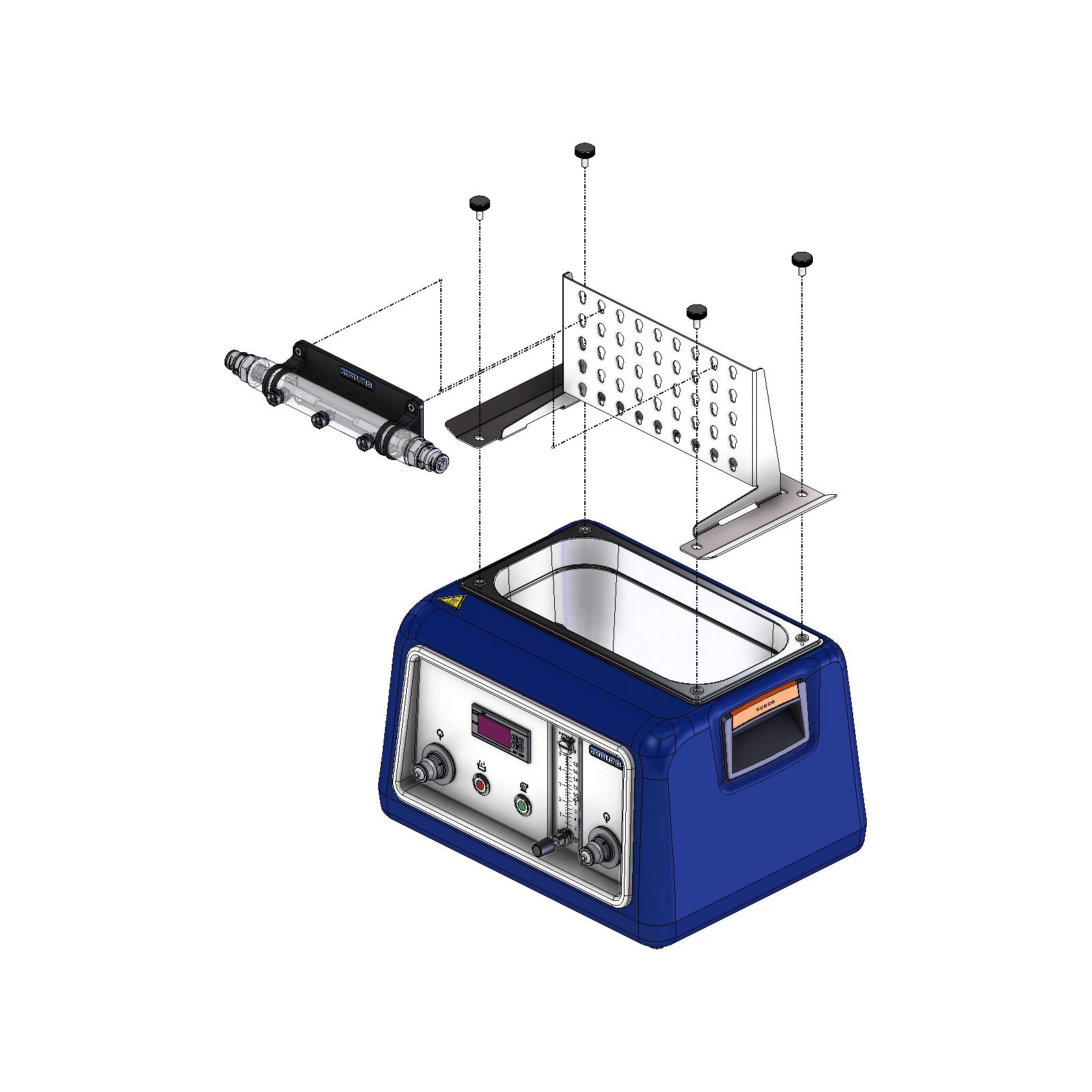

The Fluid Science FS-1.2 Energy Losses in Straight Pipes Tray provides hands on experimentation designed to demonstrate energy losses due to the geometry of the flow path at different flow rates.

Description

The Fluid Science range is an innovative suite of products designed to demonstrate energy losses due to the geometry of the flow path.

This enables students to gain an understanding of the fundamentals of Fluid Mechanics and Thermo Fluids by the process of learning via hands-on experimentation.

The Fluid Science Energy Losses in Straight Pipes Tray includes experiments to measure the pressure drop across an expansion and contraction and an internal artificially roughened pipe. All except the stepped pipe test section are of the same cross section, enabling meaningful comparisons to be made. The additional energy losses due to the geometry of the flow path can be clearly seen at different flow rates and the relationship to theory can be established.

Technical Specifications

Features & Benefits

Features

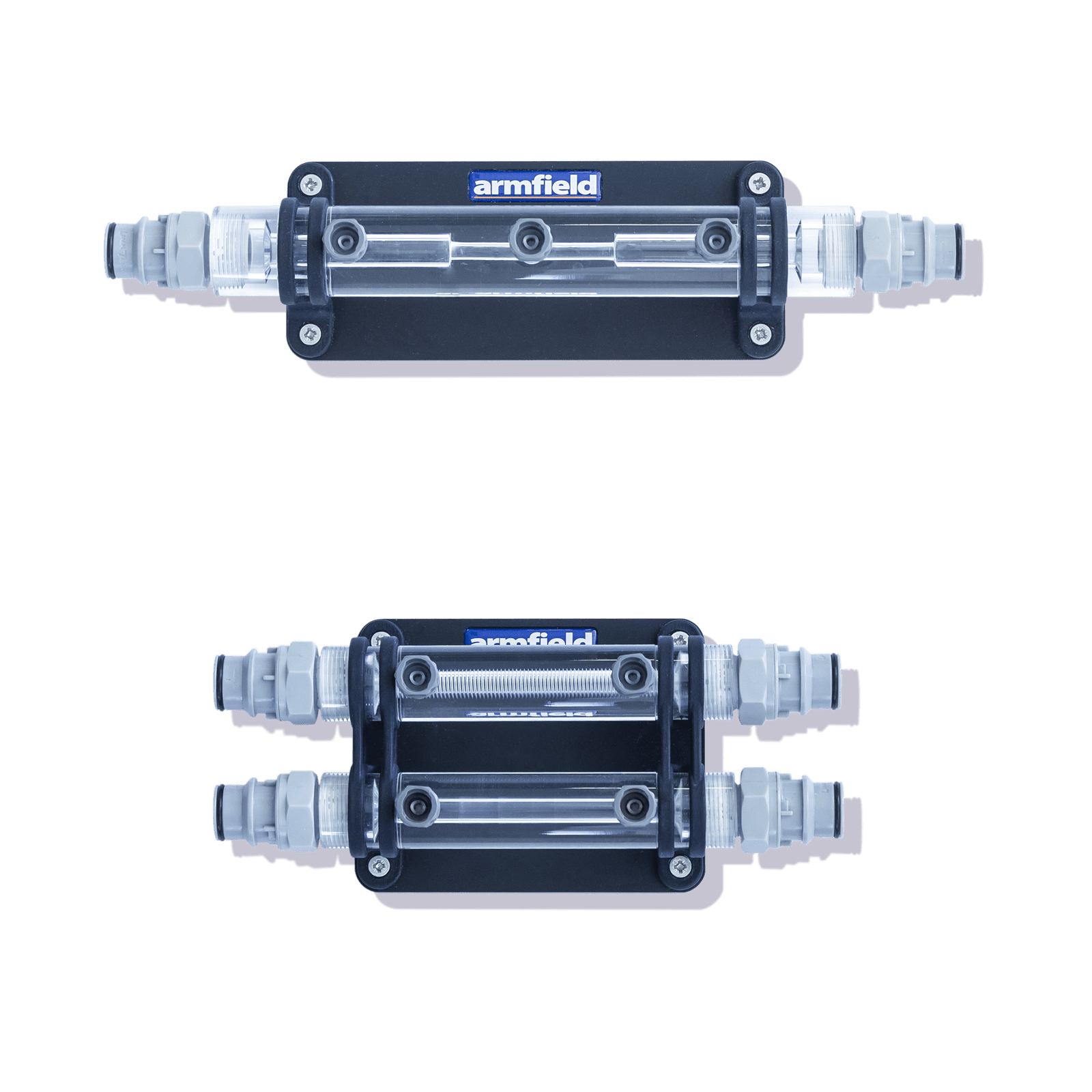

- Smooth and Roughened pipe 6mm diameter

- Contraction and expansion 8mm – 4mm – 8mm diameters

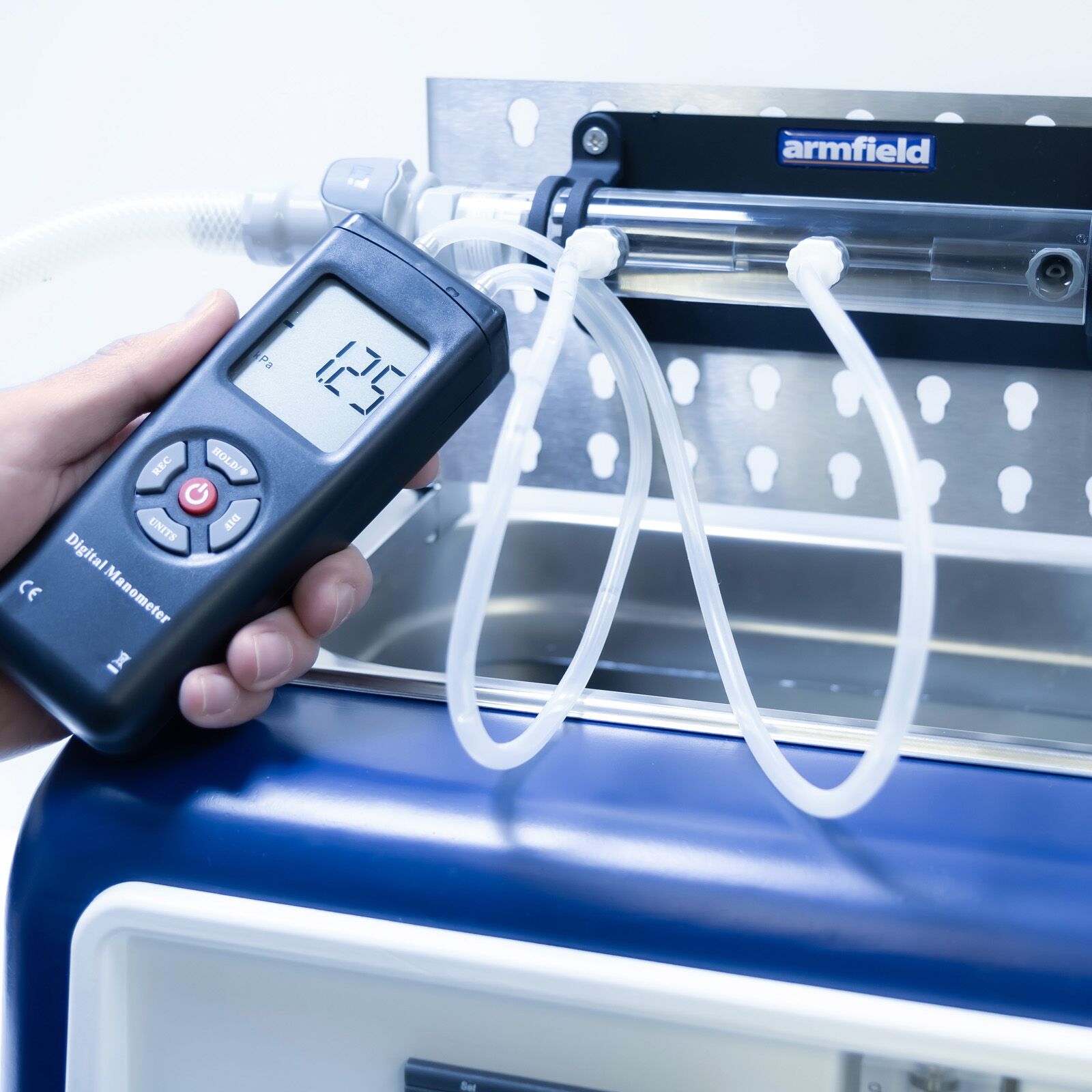

- Differential pressure reading obtained using digital manometer

- Highly visual design

Benefits

- Applied student learning via experimentation

- Common service unit can be used for either hot or cold-water supply

- Tool-less assembly

- Designed to be highly visual and simple to use

- Quick setup

- Suitable for both classroom and laboratory environment

- Explanation of basic principles such as conservation of mass

- Conservation of energy

- Explain energy loss and frictional loss

- Types of flow steady and unsteady flow, uniform and non-uniform flow etc.

- Types of fluid flow regime i.e. laminar, turbulent and transitional flow

- Compare measured pressure drop from 3 different pipe forms, explaining the effect of geometry on pressure drop.

- Using Bernoulli’s equation, calculate the pressures and compare results with experimental values.

- Calculate the frictional head loss and pressure drop using

- Darcy’s equation

Fluid Mechanics Range

- FS-SU – Service Unit

- FS-1.1 – Flow Measurement

- FS-1.3 – Energy Losses – Bends

- FS-2.1 – Manometer – Inclined

- FS-2.2 – Manometer – U tube

- FS-3.1 – Heat Exchanger – Shell and Tube

- FS-3.2 – Heat Exchanger – Tubular

- FS-3.3 – Heat Exchanger – Cross Flow

- FS-3.4 – Heat Exchanger – Plate

- FS-4.1 – Fluidised Bed

FS-SU Fluid Science Service Unit

Electrical supply:

- 100-240V/1 Phase, 50-60Hz

Initial fill of 5ltrs water. Drain to empty water away once experiment is complete. During use, water supply or drainage are not required.

Packed and crated shipping specifications

Net weight: 1.41Kg

Gross weight: (Tray only) 4.02Kg

Dimensions Stowed – Trays measure

Length: 0.43m

Width: 0.312m

Height: 0.080m

Dimensions Set Up for Smooth and Rough bore

Length: 0.21m

Width: 0.092m

Height: 0.064m

Dimensions Set Up for Stepped bore pipe

Length: 0.21m

Width: 0.092m

Height: 0.064m

FS-SU

FS-1.2