Fans and Compressors: Designed For Engineering Education

Turbines are essential components in energy engineering, particularly in the study of renewable energy and sustainable technology. At Armfield, we specialise in providing state-of-the-art educational tools that empower universities and colleges to deliver hands-on, real-world training. Our modular range of turbines connects seamlessly with the versatile FM6x Turbine Service Unit, which is designed to meet the diverse needs of engineering courses worldwide.

Joseph Armfield and the Evolution of Turbines

The story of turbines at Armfield began in 1875, when Joseph Armfield founded his engineering company in Ringwood, England. Initially focused on farm and milling machinery, the company quickly expanded its capabilities. By 1887, Armfield produced its first water turbine, marking a significant shift from traditional water wheels to more efficient power generation systems.

Incorporating cutting-edge innovations such as inward radial flow, based on the principles of the Francis turbine, these early designs optimised water flow using curved guide vanes and blades. By the early 20th century, Armfield had sold over 1,000 turbines worldwide, solidifying its role as a pioneer in advancing turbine technology. Today, that innovative legacy lives on in the modern equipment we provide for engineering education.

Understanding Turbines in Training

Turbines are pivotal in various engineering industries, from power generation to water management and beyond. Their primary purpose is to harness the power of fluids. This product range plays a crucial role in demonstrating principles such as torque, power generation, flow rates, and efficiency. Educational institutions require reliable, precise equipment to train students for real-world applications.

Why Choose Armfield for Your Training Needs?

At Armfield, we’ve developed an innovative range of turbines and associated equipment such as compressors and fans, ideal for teaching foundational and advanced engineering principles. Our solutions are tailored to universities and colleges seeking to equip students with the knowledge and skills needed for careers in industries like power generation, HVAC, and renewable energy.

Explore our full range of fans and compressors, where you’ll find a variety of tools designed for in-depth analysis and experimentation.

The FM6x Turbine Service Unit: A Game-Changer

One standout product in our collection is the FM6x Turbine Service Unit. This cutting-edge base unit is fully controlled by software, allowing for the precise testing and analysis of various turbine characteristics. It’s an essential tool for demonstrating key engineering principles such as:

- Torque

- Power usage

- Pump speed

- Braking loads and forces

- Flow rates and inlet pressure

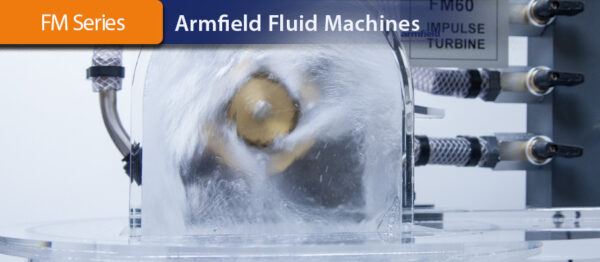

The FM6x is versatile, enabling students to test multiple turbine types, including:

- Impulse turbines

- Reaction turbines

- Pelton wheels

Software Integration for Enhanced Learning

The FM6x Turbine Service Unit is equipped with advanced software that generates detailed datasheets and performance charts. This feature allows students and instructors to monitor loads, benchmark performance, and analyse results with precision. By simulating real-world scenarios, the FM6x prepares students for larger-scale applications, such as those used by electrical power companies in water-driven turbine systems.

How Turbine Demonstration Units Educate Future Engineers

1. Harnessing Energy from Wind and Water

Turbine demonstration units like the FM6x illustrate how energy can be captured and converted into usable power. Reaction turbines, for instance, utilise fluid flow to generate mechanical energy, a principle widely applied in hydroelectric and wind power systems.

2. The Role of Hydraulic Training Systems

Hydraulic training systems are invaluable in demonstrating how water flow impacts turbine operation. With the FM6x, students can adjust water flow rates and observe the effects on power output and efficiency, fostering a deeper understanding of fluid dynamics.

3. Airflow and Efficiency

The efficiency of turbines is closely linked to airflow dynamics. The FM6x allows users to manipulate airflows, showcasing their impact on performance metrics such as speed and torque.

4. Speed and Performance

Speed plays a critical role in turbine efficiency. Students can observe how different loads and braking forces influence energy generation by varying rotational speeds.

Real-World Applications

The FM6x Turbine Service Unit bridges the gap between theory and practice, equipping students with the skills they need to succeed in industries such as:

- Renewable energy production

- Industrial fluid systems

By mastering the operation and analysis of turbine systems, graduates are better prepared for roles in engineering firms, utilities, and manufacturing industries.

FAQs

What is the FM6x Turbine Service Unit used for?

The FM6x is a base unit for testing turbine characteristics. It’s designed for engineering education, helping students understand torque, power usage, flow rates, and more.

How does a reaction turbine work?

Reaction turbines harness fluid flow to generate mechanical energy. They rely on the principle of Newton’s third law, where the reactive force of moving fluid produces rotational motion.

Can the FM6x Turbine Service Unit simulate real-world scenarios?

Yes, the FM6x’s software enables users to replicate various turbine conditions, preparing students for real-world applications in industries such as power generation and renewable energy.

How does the FM6x benefit universities and colleges?

The FM6x provides hands-on training, detailed performance data, and the ability to test multiple turbine types, making it an invaluable resource for engineering courses.

Fans and Compressors for Engineering Education

Armfield’s FM6x Turbine Service Unit is more than just a training tool—it’s a gateway to understanding the intricacies of turbine operation and performance. Combined with our full range of fans and compressors, we offer a comprehensive solution for engineering education.

Contact Us Today

Contact us to enhance your engineering programme. Learn more about our cutting-edge solutions by visiting our contact page. Let Armfield help you shape the engineers of tomorrow.

You May Also Like

- The Science of Carbonation and Armfield’s FT102XA

- Bespoke Flumes by Armfield: Tailored Solutions For Research

- The Ultimate Solution for Teaching and Research Flumes:

- Reducing Energy Consumption in Food Manufacturing

Armfield can trace its history back over 130 years, throughout which, the Company’s policy of quality, innovation and service has helped it to maintain a strong market position and develop a reputation for industry leadership in the field of Engineering teaching.

Education Division

Operating since 1963, the Armfield Education Division designs and manufactures equipment for engineering education and research.

Industrial Division

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries.