Navigating the Waves: The Importance of Testing Ship Stability Apparatus

Ship stability has always been central to safe and efficient maritime operations. From passenger ships and cargo vessels to fishing boats and specialist marine vessels, stability determines how a ship behaves at sea, how it responds to loading conditions, and how it withstands forces such as wind, waves and weight shifts. Testing ship stability apparatus allows naval architects, marine engineers and students to understand these behaviours in a controlled and measurable way.

At Armfield, we specialise in advanced educational and research equipment that bridges theory and practice. Our solutions for testing ship stability apparatus enable precise investigation of hydrostatic pressure and its effects on floating bodies, making complex principles of naval architecture accessible, repeatable and accurate.

This article explores testing ship stability apparatus in depth, covering the methods, components, risks, interpretation of results and long term importance of accurate and regular testing.

Understanding ship stability and why it must be tested

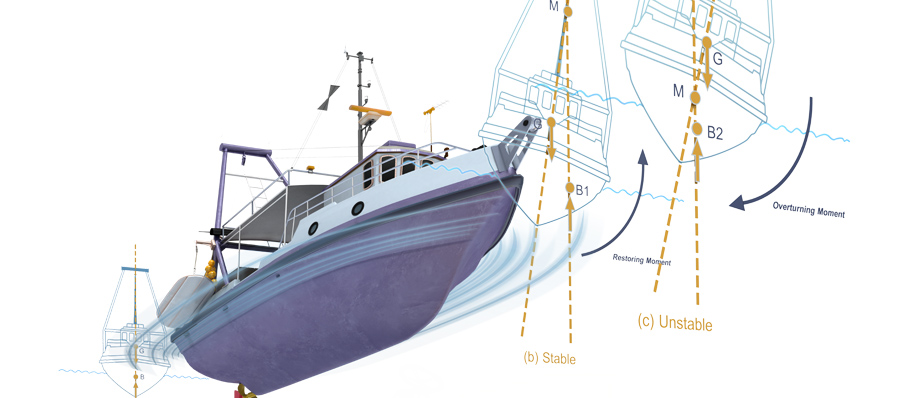

Ship stability describes a vessel’s ability to return to its upright position after being disturbed by external forces. These forces may include waves, wind, cargo movement, passenger distribution or free surface effects within tanks. Stability is governed by the relationship between gravity G, buoyancy B and the metacentric height.

Testing ship stability apparatus enables engineers to study hydrostatic stability in safe laboratory conditions rather than relying only on full scale testing. It allows repeatable experiments using known weights, measured inclining angles and controlled heeling moments. This level of control is essential for understanding ship hydrostatics and stability characteristics across different ship designs and loading conditions.

Types of ship stability tests used in modern maritime engineering

A range of stability tests are carried out when using testing ship stability apparatus. Each test focuses on a different aspect of stability and ship motion.

Inclining experiments are among the most widely used stability tests. Known weights are moved transversely across the ship or model, producing a measurable heel. From this, metacentric height and initial stability can be calculated with high accuracy.

Rolling period tests measure the natural roll frequency of a floating body. These tests provide insight into adequate stability and comfort, particularly for passenger vessels. A longer rolling period often indicates better overall stability characteristics.

Lightship displacement tests assess the ship’s weight when empty of cargo, fuel and passengers. Understanding lightship displacement is essential for calculating intact stability under various loading scenarios.

Large angle stability tests focus on behaviour beyond small inclinations. These tests help engineers understand capsize risks, buoyancy vectors and hydrostatic curves at extreme heel angles.

The purpose of testing ship stability apparatus

The core purpose of testing ship stability apparatus is safety. Accurate stability data ensures that ships comply with international standards and operate within safe limits. Organisations such as the International Maritime Organization rely on stability data to regulate vessel design and operation.

Testing also supports ship design optimisation. Naval architects use stability data to refine hull forms, internal bulkheads, transverse watertight bulkheads and weight distribution. For newly constructed ships, testing confirms that theoretical design values align with real behaviour.

From an educational perspective, testing ship stability apparatus provides practical insight into fluid mechanics, hydrostatic pressure and ship hydrostatics. It transforms abstract curves and equations into observable behaviour.

Key components of a ship stability testing apparatus

A comprehensive testing ship stability apparatus consists of several integrated components working together.

The floating ship model represents real world ship structure and design. Models may include general cargo vessel forms, passenger ships or fishing vessels, allowing comparisons between large ships and small ships.

Inclining mechanisms apply controlled heeling moments using suspended mass or known weights. These movements simulate weight shifts and cargo movement.

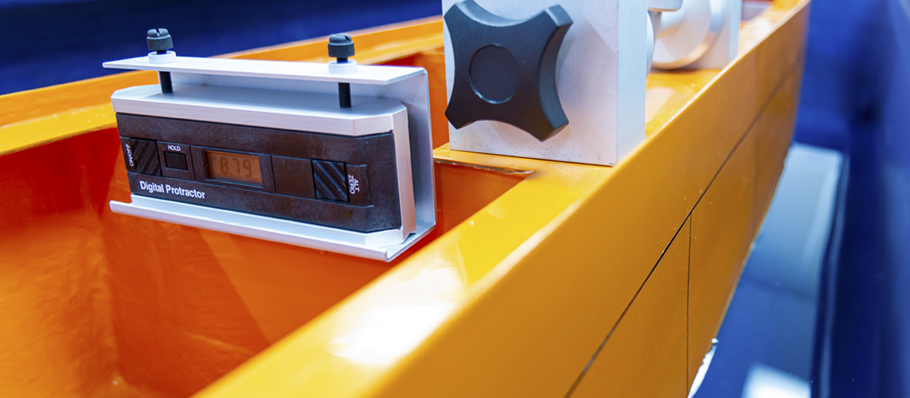

Stability meters and clinometers measure heel angle with high accuracy. These instruments are critical for determining metacentric height and stability characteristics.

Hydrostatics benches and water tanks allow study of hydrostatic pressure, buoyancy B and waterplane area. These benches are essential for understanding pressure distribution and hydrostatic curves.

Advanced systems incorporate data capture and analysis, producing technical data that supports detailed interpretation and reporting.

How hydrostatic pressure testing supports ship stability studies

Hydrostatic pressure plays a direct role in buoyancy and stability. Apparatus that tests hydrostatic pressure and its effects allows engineers to visualise how pressure varies with depth, hull shape and immersion.

Using hydrostatic testing alongside stability testing provides a deeper understanding of buoyancy vectors, pressure curves and the vertical centre of force. This integrated approach is particularly valuable in naval engineering education, where linking fluid properties to real ship motion strengthens comprehension.

Best practice for conducting successful stability tests

Accuracy and repeatability are essential when using testing ship stability apparatus. Proper procedures must be followed at all times.

The apparatus should be levelled and calibrated before testing begins. Baseline measurements ensure that all subsequent data is reliable.

Known weights must be accurately measured and positioned along the transverse direction or longitudinal axis as required. Even small errors can affect calculated metacentric height.

Mooring restraints should be correctly fitted but not restrictive. Mooring lines must prevent drift while allowing free rolling motion.

Environmental factors such as water temperature and vibration should be controlled to maintain consistent results.

Consequences of inadequate ship stability testing

Failure to properly test ship stability apparatus can lead to serious consequences. Inaccurate data may result in unsafe ship design, increased risk of capsize, excessive listing or poor seakeeping performance.

Cargo vessels affected by incorrect weight assumptions may experience dangerous free surface effects. Passenger ships with inaccurate stability data may suffer discomfort or safety risks during rolling motion.

In extreme cases, lack of adequate testing contributes to structural stress, compromised bulkheads and increased risk during heavy weather.

Interpreting stability test results and applying them to ship design

Interpreting stability test data requires understanding of naval architecture principles. Inclining experiment results are used to calculate metacentric height and assess initial stability.

Hydrostatic curves reveal how buoyancy and stability change with draft and heel angle. These curves guide design decisions such as bilge keel sizing, internal layout and centre of gravity positioning.

When results indicate marginal stability, adjustments may include redistributing weight, modifying internal compartments or altering hull geometry. Testing enables these changes to be assessed before real world implementation.

Maintaining and regularly testing ship stability apparatus

Regular testing ensures that ship stability apparatus maintains high accuracy over time. Mechanical components, sensors and measuring instruments should be inspected and calibrated routinely.

Comprehensive manuals and testing records support long term reliability and traceability. In educational environments, regular maintenance ensures consistent results for students and researchers.

By maintaining testing ship stability apparatus, institutions ensure that stability data remains accurate, repeatable and aligned with current international codes and standards.

Frequently asked questions about testing ship stability apparatus

What is the purpose of the NA8 Ships Stability Apparatus in ship stability testing?

The NA8 Ships Stability Apparatus is designed to study ship hydrostatics and stability using floating ship models, inclining tests and stability measurement instruments. It allows investigation of hydrostatic pressure and stability characteristics in a controlled laboratory environment.

How does a floating ship model differ from a crane ship model during stability testing?

A floating ship model represents general ship behaviour and buoyancy, while a crane ship model introduces suspended masses and dynamic loading effects. This allows engineers to study additional heeling moments and complex weight movements.

What role does a stability meter play in determining ship stability?

The stability meter measures heel angle with precision during inclining and rolling tests. Accurate angle measurement is essential for calculating metacentric height and assessing adequate stability.

Can changes in lightship displacement affect intact stability?

Yes, changes in lightship displacement directly affect the centre of gravity and metacentric height. Even small alterations in lightship condition can significantly influence intact stability and must be accurately measured.

Why regular stability testing is essential for modern ships

Regular stability testing ensures that stability data remains current as ships age, are modified or experience changes in operating conditions. It supports compliance with international regulations and enhances long term safety at sea.

Speak to Armfield about advanced ship stability testing solutions

If you are looking to enhance your laboratory, teaching or research capability, Armfield provides proven solutions for testing ship stability apparatus and apparatus that tests hydrostatic pressure and its effects. Our equipment supports accurate experimentation, deep understanding and real world relevance. Visit our contact page today to discuss your requirements and discover how our naval architecture systems can support your work.

Armfield can trace its history back over 130 years, throughout which, the Company’s policy of quality, innovation and service has helped it to maintain a strong market position and develop a reputation for industry leadership in the field of Engineering teaching.

Education Division

Operating since 1963, the Armfield Education Division designs and manufactures equipment for engineering education and research.

Industrial Division

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries.