W8 Anaerobic Digester

The Armfield Anaerobic Digester is designed as a benchtop training facility and as a means of providing operational process data for plant design purposes.

Description

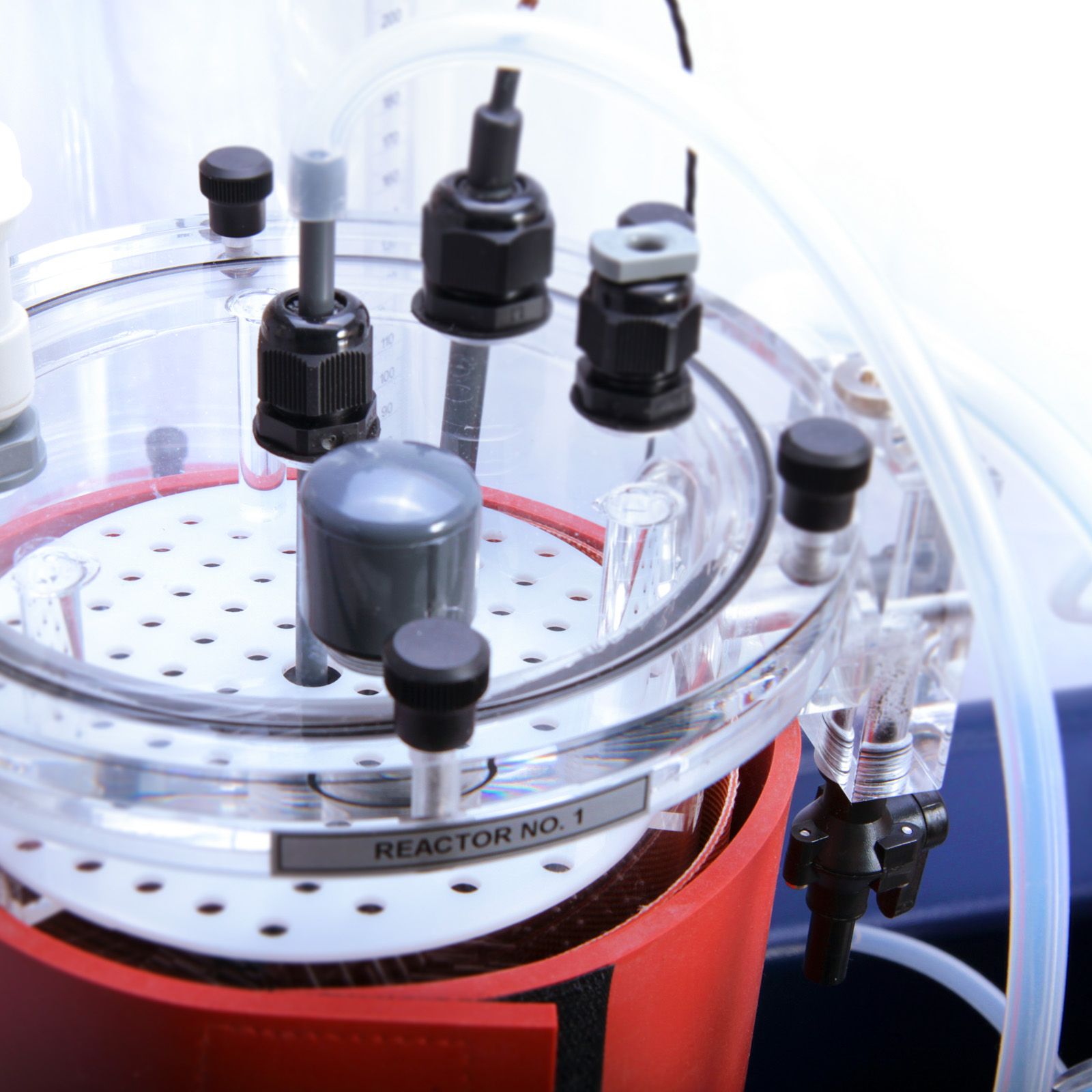

The anaerobic digester comprises two five-litre upward-flow packed bed reactors with feed rate and temperature control facilities. This allows steady, continuous operation at up to seven litres per day over periods of several days.

The reactors may be operated in series or parallel. A buffer vessel between the reactors permits discharge of excess flow from the first reactor when the second reactor is operated in series but at a lower flow rate. The flow rates to the vessels are set and controlled by calibrated peristaltic pumps.

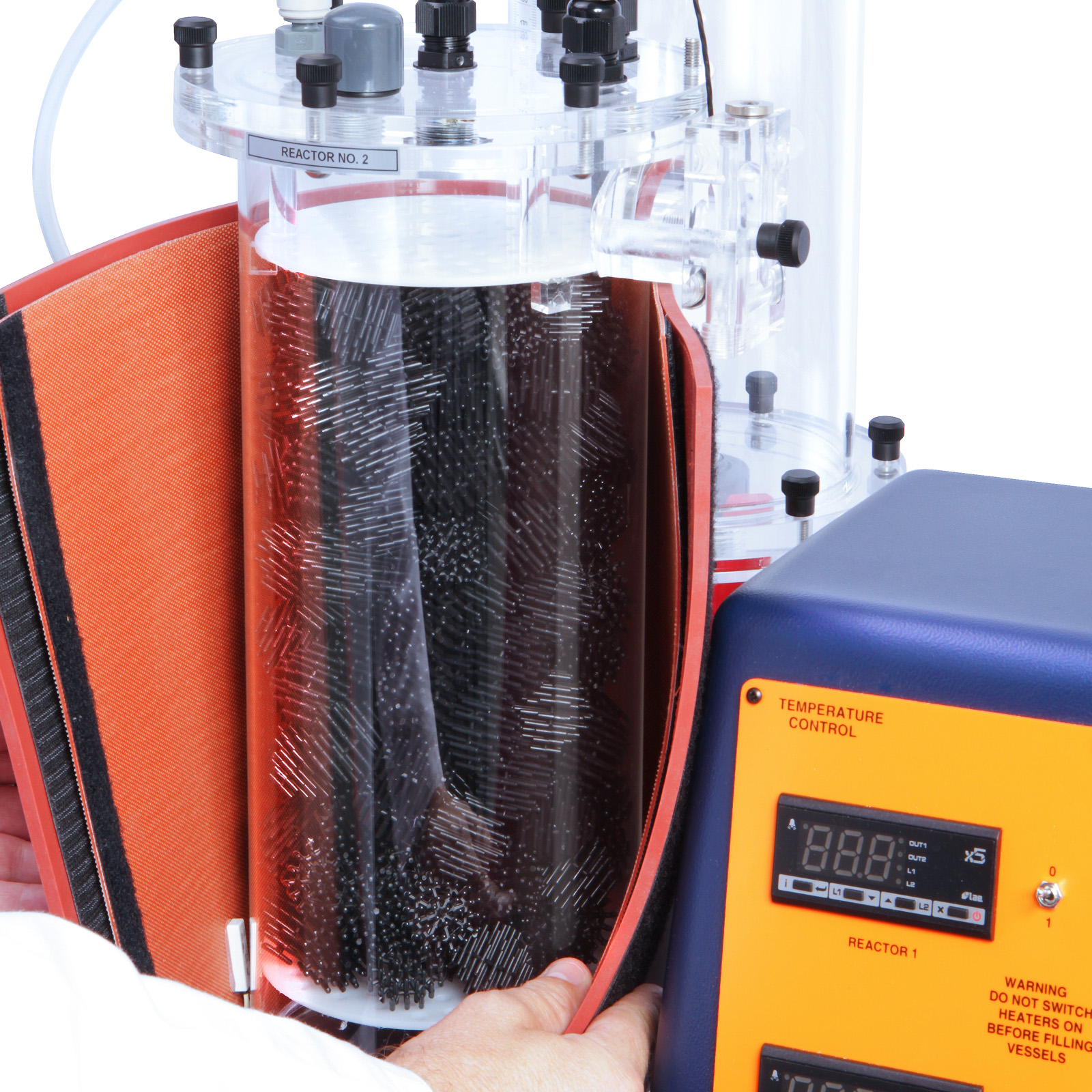

The temperature of each reactor is controlled by an electric heating mat wrapped around the external wall. The temperature distribution within each reactor is maintained to ±0.5°C. Reactor temperatures may be separately set at any desired value in the range ambient to 55°C.

The gas off-take from each reactor is taken to a volumetrically calibrated collector vessel operating by water displacement. A constant head, liquid seal device ensures the gas pressure in the reactor is maintained at a constant value throughout the test run.

The collected gas can be exhausted from the vessel and the volume refilled with water during a run without breaking the liquid seal.

Liquid and gas sampling points are located at all strategic points around the reactors. Non-return valves and liquid seal syphon breaks are included in the process pipework to ensure each reactor operates at a constant volume without the ingress of air or the danger of accidental syphonic action.

The equipment is mounted on a vacuum-formed plastic base with an integral drain channel to cope with spillages and wash down.

Technical Specifications

Reactors:

Two identical reactors

Nominal capacity: 5L

Packed volume: 4L

150mm dia x 250mm high

Reactor packing:

25mm diameter Bio-balls

Temperature control:

For each reactor 200W heating jacket with PID control from a temperature sensor positioned inside the reactor,

set point within range ambient to 55°C,

the jacket is thermostatically protected by a cut-out set at 85°C

Feed pumps:

Two identical peristaltic pumps variable speed using 10 turn potentiometer to 4rpm supplied with three tube diameters, 1.6, 3.2 and 4.0mm,

flow rates from 0.2 to 5.8 l/day

Reactor vessel: 2 x 5L (4.3L packed sestion)

Gas collecting vessel: 2 x 5L

Heat jacket: 2

Temperature sensor: 2

Pump: 2 x 0-40mL, supplied with 4.0, 3.2 and 1.6mm tubes

Features & Benefits

- Small Scales bench mounted design

- A major feature of the digester is that results obtained from tests can be scaled up precisely to industrial throughputs.

- Includes PID control

- Series and Parallel operation

The anaerobic process may be divided into two distinct stages: first the hydrolysis of large molecular species into acetic acid, and then the conversion of the acetic acid into methane and carbon dioxide.

This two-stage process can be demonstrated by operating the two reactors in series, one to produce volatile acids from the initial substrate – acidogenesis – and the second to convert the volatile acids into methane and carbon dioxide – methanogenesis.

In addition, the following basic differences of the two stages of the process can be demonstrated:

(a) the low level of methanogenic activity during acidogenesis compared to methanogenesis

(b) the low level of COD remowed with the methanogenic stage.

- A benchtop anaerobic digester for waste water treatment studies

- Equipped with two 5l packed bed, upward-flow reactors

- Each reactor has gas sampling & collection facilities

- Reactors may be operated in series or parallel flow arrangement, using variable-speed peristaltic pumps

- Feed flow rate to each reactor can be accurately & independently controlled to any temperature between ambient and 55°C, using 200W heating jackets

- Thermostatic cut-out set to 110°C

- Operational manual with teaching exercises including details of a proven feedstock (synthetic waste water) included

Electrical supply:

W8-A: 220-240V / 1ph / 50Hz

W8-B: 120V / 1ph / 60Hz

W8-G: 220V / 1ph / 60Hz

- Plastic feed and product tanks typically 30-50L, floor standing (not supplied)

- pH meter (not supplied)

- Synthetic waste water (not supplied)

- Analytical equipment as exists in most water quality laboratories for measurement of pH, BOD, COD, alkalinity, total volatile acids and suspended solids. (not supplied)

Packed and crated shipping specifications

Volume: 1m³

Gross weight: 150Kg

Length: 1.00m

Width: 0.50m

Height: 0.76m

- W8-A

- W8-B

- W8-G