TH5 – Expansion Process of a Perfect Gas

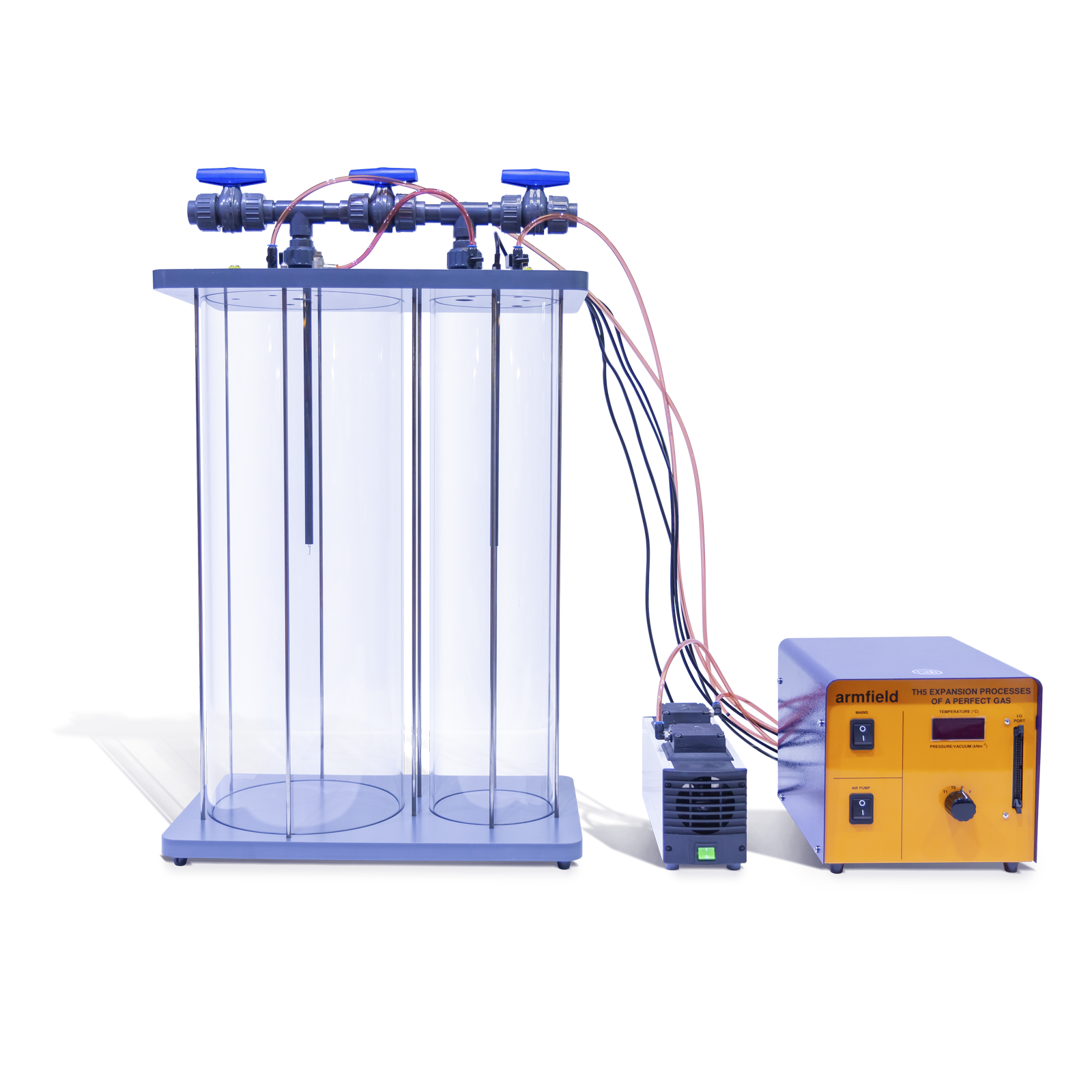

The Armfield Expansion Processes of a Perfect Gas apparatus has been designed to introduce students to a range of basic thermodynamic processes using air as the working fluid.

Description

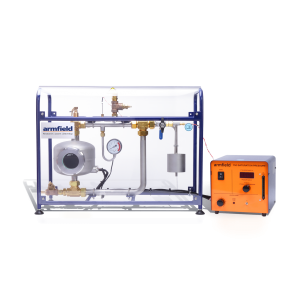

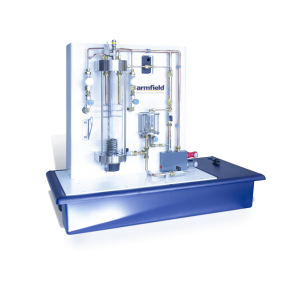

The apparatus consists of two floor-standing interconnected rigid vessels, one equipped for operation under pressure and the second under vacuum.

An electrically operated air pump connected to the top of the vessels, together with valves and tappings enables the appropriate vessel to be pressurised or evacuated as required to suit the teaching exercise.

The vessels can be used independently or together to enable different thermodynamic processes to be evaluated. A pressure sensor connected to each vessel and a temperature sensor inside each vessel permit the changes in the properties of the air contained within the vessels to be monitored continuously.

Both vessels are constructed from clear rigid plastic, which affords light insulation between the air inside the vessel and the surroundings to reduce heating/cooling. This also enables each vessel and its contents to return to ambient temperature reasonably quickly.

The capacity of the pressurised vessel is approximately 23 litres.

The capacity of the evacuated vessel is approximately 9 litres.

Each vessel incorporates the following features:

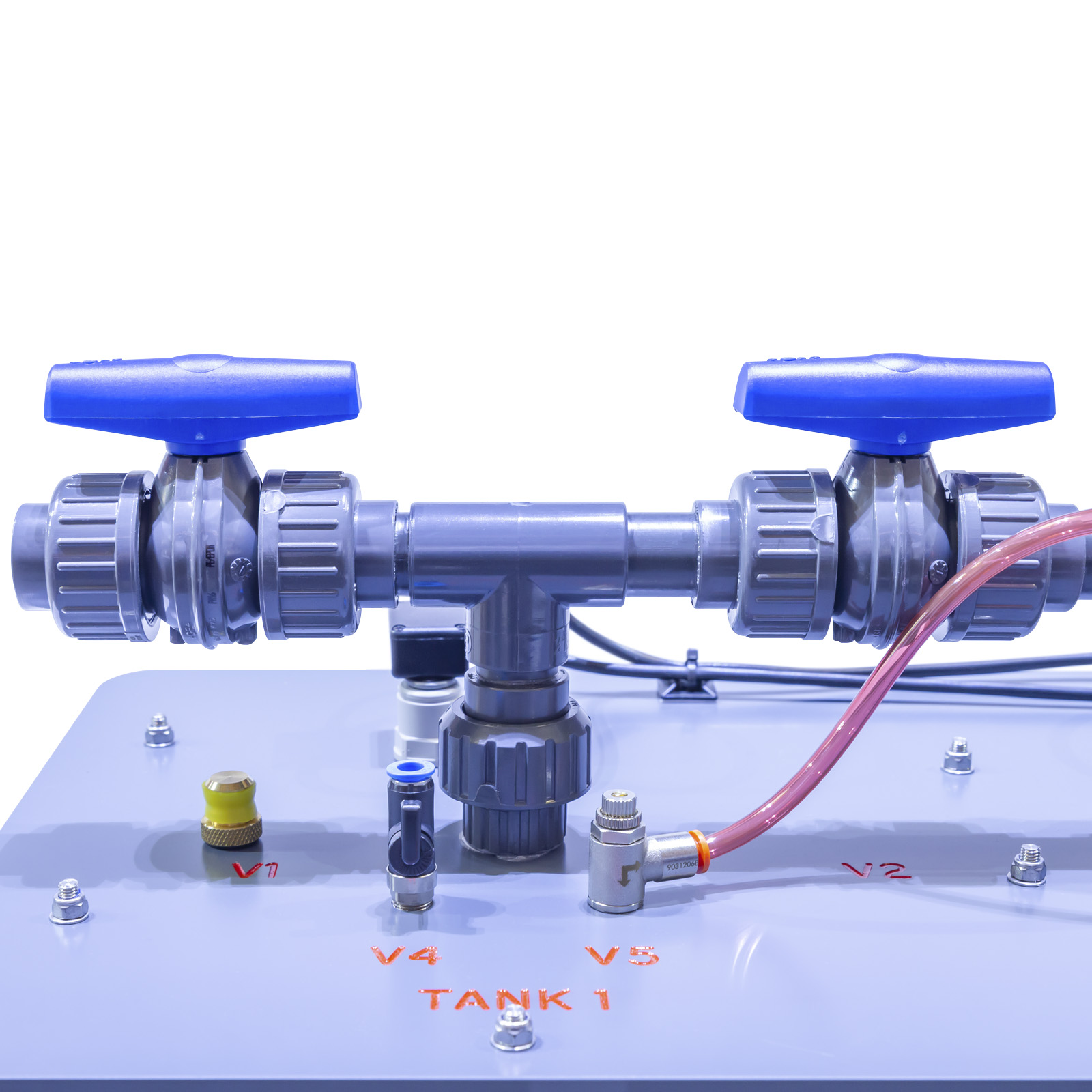

- Connection to the air pump via an isolating valve to enable the vessel to be pressurised/evacuated

- Connection to a piezoresistive sensor to measure the pressure / vacuum inside the vessel (range of both sensors ±34.5kN/m2)

- Connection to a large bore pipe and valve to enable depressurisation / pressurisation of the vessel to / from the atmosphere (the valve is rapidly opened and closed to provide a small step change in pressure)

- Interconnection between the two vessels via a large bore pipe and valve (fast change) and small bore pipe and needle valve (gradual change)

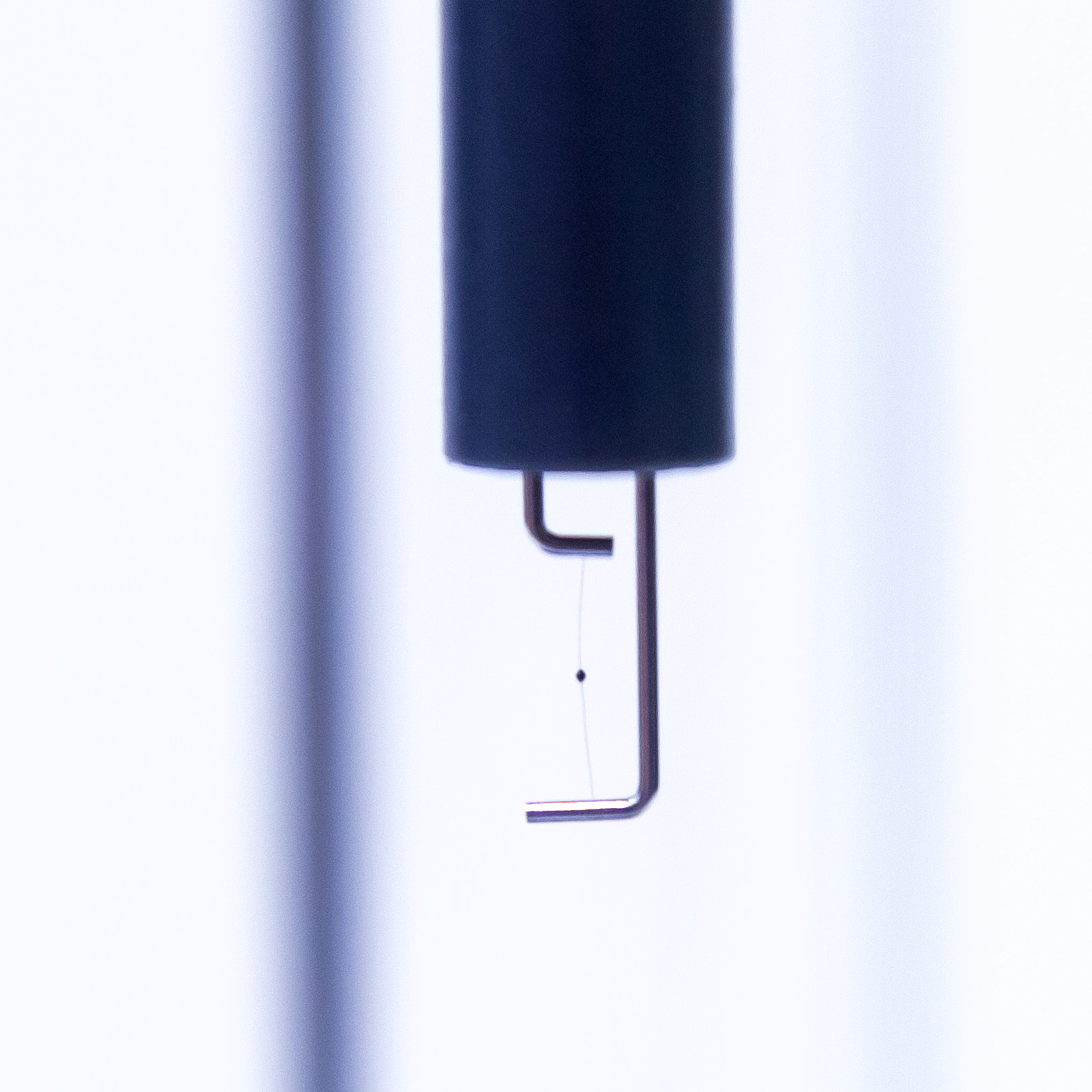

- Fast response thermistor to monitor air temperature inside relief valve to prevent overpressurisation

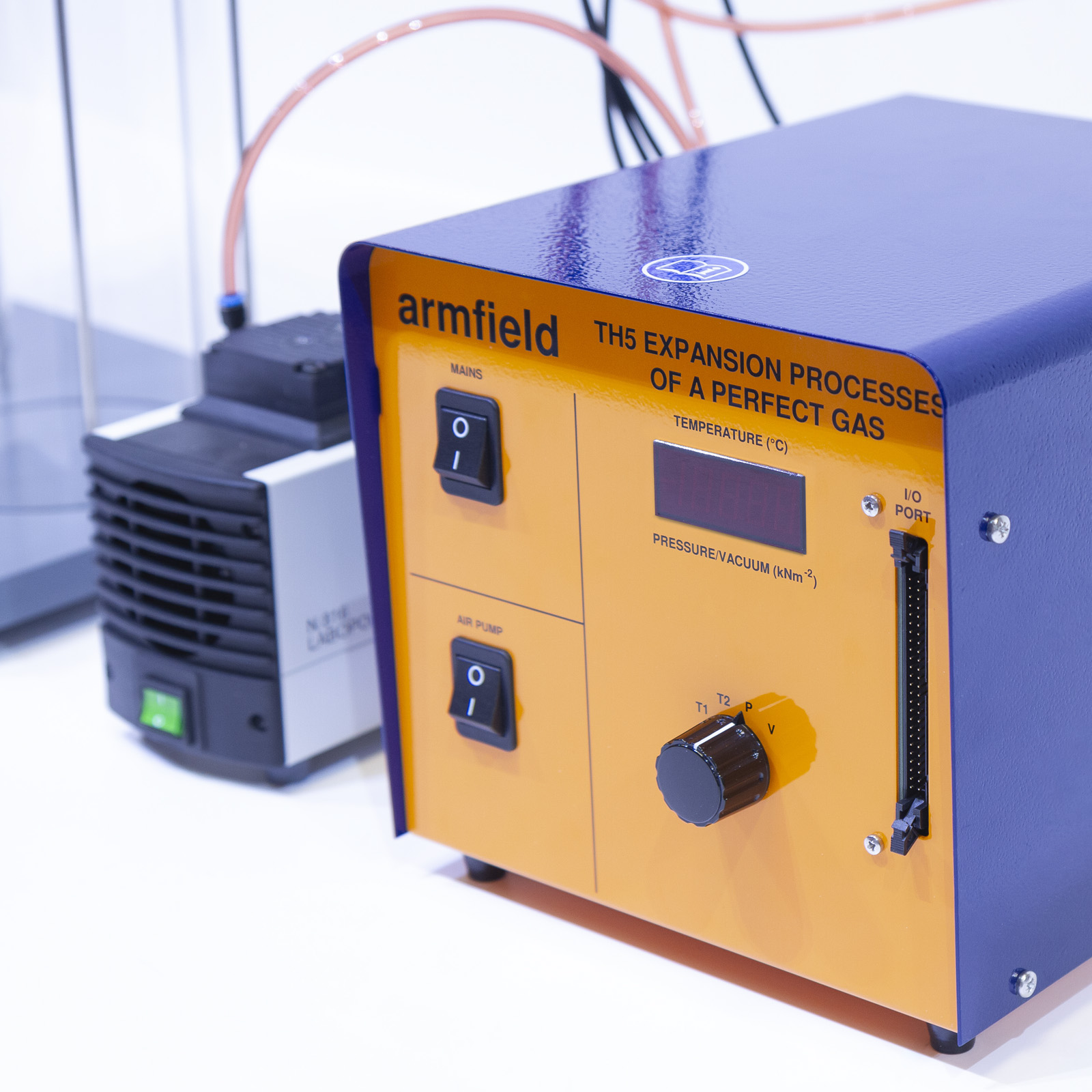

All power supplies, signal conditioning circuitry etc. are contained in a simple electrical console with appropriate current protection devices and an RCD for operator protection. The console is designed to stand on a bench top above the pressure and vacuum vessels and incorporates electrical connections for the air pump and sensors.

Readings from the pressure sensors and thermistors are displayed on a common digital meter with selector switch on the front of the console.

All important electronic sensors used on the unit provide outputs for data logging and analysis. The data logger, provided with the unit, interfaces between the unit and the user’s computer using a USB port.

The optional educational software package enables data recording, graph plotting and provides full instructions for setting up the equipment and performing the experiments.

All related theory and help texts are provided. The software requires a computer (not supplied) running Windows 7 or later with a USB port.

A user supplied chart recorder can also be utilised.

As the teaching exercises require the transient pressure and temperature responses to be observed and recorded one of these recording options is necessary.

Technical Specifications

Features & Benefits

Key features

- Analysis of the pressure changes in the processes involves the First Law of Thermodynamics

- The exercises assist the student in understanding the Second Law of Thermodynamics and its corollaries

- The relationship between pressure, volume and temperature can be explored and used to determine other thermodynamic properties

- The different responses resulting from fast or slow changes in a process and the relationship between the pressure and temperature of air can be observed

Teaching exercises will enable students to become familiar with the following topics:

- The nonflow energy equation

- The behaviour of a perfect gas and its describing equations

- An adiabatic reversible process (isentropic expansion)

- A constant volume process

- An adiabatic irreversible process

- Conversion of pressure units

- A constant internal energy process

- Polytropic processes, with the limiting case of n = Gamma

- Conversion of pressure units

- Gauge and absolute pressures

- The unsteady flow energy equation (in vacuum mode)

- Interconnected vessels operating under pressure and under vacuum are supplied complete with an electric air pump and appropriate instrumentation ready for use

- This modern version of a classic experiment (attributed to Clément and Désormes) enables pressure and temperature changes to be monitored continuously using a PC (not supplied). Optional teaching software is available for data logging

- The vessels can be operated singly or in combination enabling processes whereby air flows from a pressurised vessel to atmosphere, from atmosphere to an evacuated vessel or from a pressurised vessel to an evacuated vessel

- A small-scale unit designed to introduce students to the properties of a perfect gas using air to demonstrate basic thermodynamic processes

- The hardware consists of two floor-standing interconnected rigid vessels, one equipped for operation under pressure and the second under vacuum. Appropriate valves and tappings are fitted to enable different thermodynamic processes to be evaluated. An electric air pump is supplied to enable pressurisation or evacuation of the vessels as required for the different exercises. Each vessel incorporates a fast response thermistor sensor to monitor the temperature of the air and connection to a piezoelectric pressure sensor

- All power supplies, signal conditioning circuitry etc. are contained in a simple electrical console with appropriate current protection devices and an RCD for operator protection. Readings from the pressure sensors and thermistors are displayed on a common digital meter with selector switch. A port on the console can be used to connect to a PC using an optional interface device included with the educational software package . Alternatively the signals can be connected to a user supplied chart recorder

- A comprehensive instruction booklet describing how to carry out the laboratory teaching exercises is included

TH-DTA-ALITE:

Educational software for TH1-TH5 on a USB key complete with data logger (a PC running Windows 7 or later, with a USB port is required)

Electrical supply: Single phase

- TH5-A: 220-240V/1ph/50Hz, 1A

- TH5-B: 120V/1ph/60Hz, 2A

- TH5-G: 220-240V/1ph/60Hz, 1A

Water

Drain

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.34m³

Gross Weight: 22Kg

Vessel assembly

Length: 0.46m

Width: 0.28m

Height: 0.80m

Electrical console

Length: 0.30m

Width: 0.22m

Height: 0.22m

- TH5-A

- TH5-B

- TH5-G