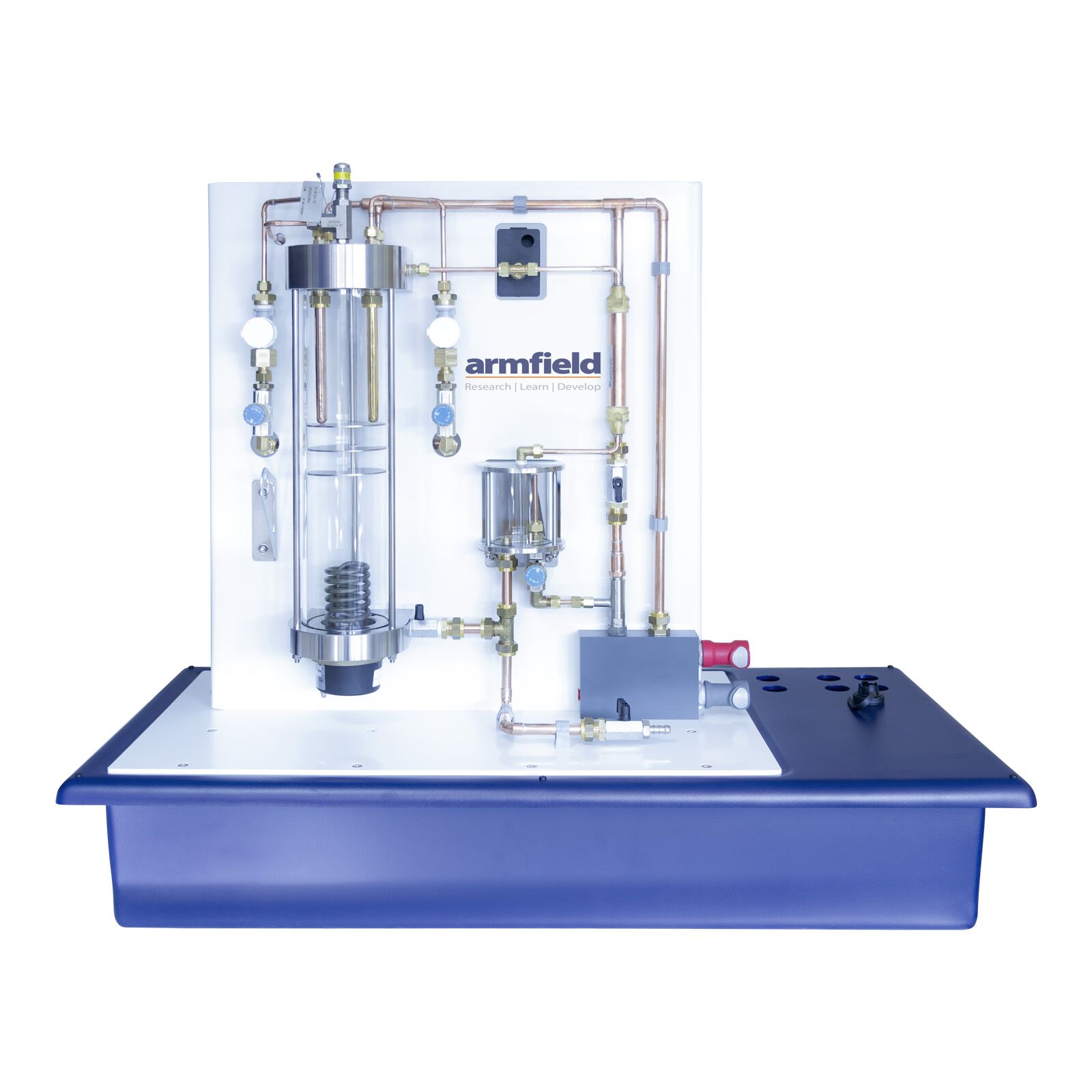

TH6 – Film and Dropwise Condensation Demonstration unit

The TH6 Film and Dropwise Condensation Demonstration unit demonstrates the formation of condensation of water on two differing surfaces with the ability of the operator, to change a variety of parameters and observe the effects and undertake calculations based upon the presented data.

Description

The Armfield TH6 Dropwise and Film Condensation Unit has been designed as a highly visual means for students to observe the two condensation processes and study the effects of varying the vacuum and heat input whilst gathering data concerning temperatures, pressure and flowrates to be able to undertake a variety of calculations involved in the condensation process. Additionally, the unit will allow the operator to understand the influence of air as a non-condensable gas on the condensation processes.

The unit uses the latest ArmBUS technology to collect, display and store data in a clear format as well as control certain parameters. Other parameters can be controlled manually by the student by manipulation of valves on the working face of the unit. Safety features are also designed into both software and hardware to greatly reduce the risk of over-pressurisation and thus safeguard students undertaking experimental work.

Technical Specifications

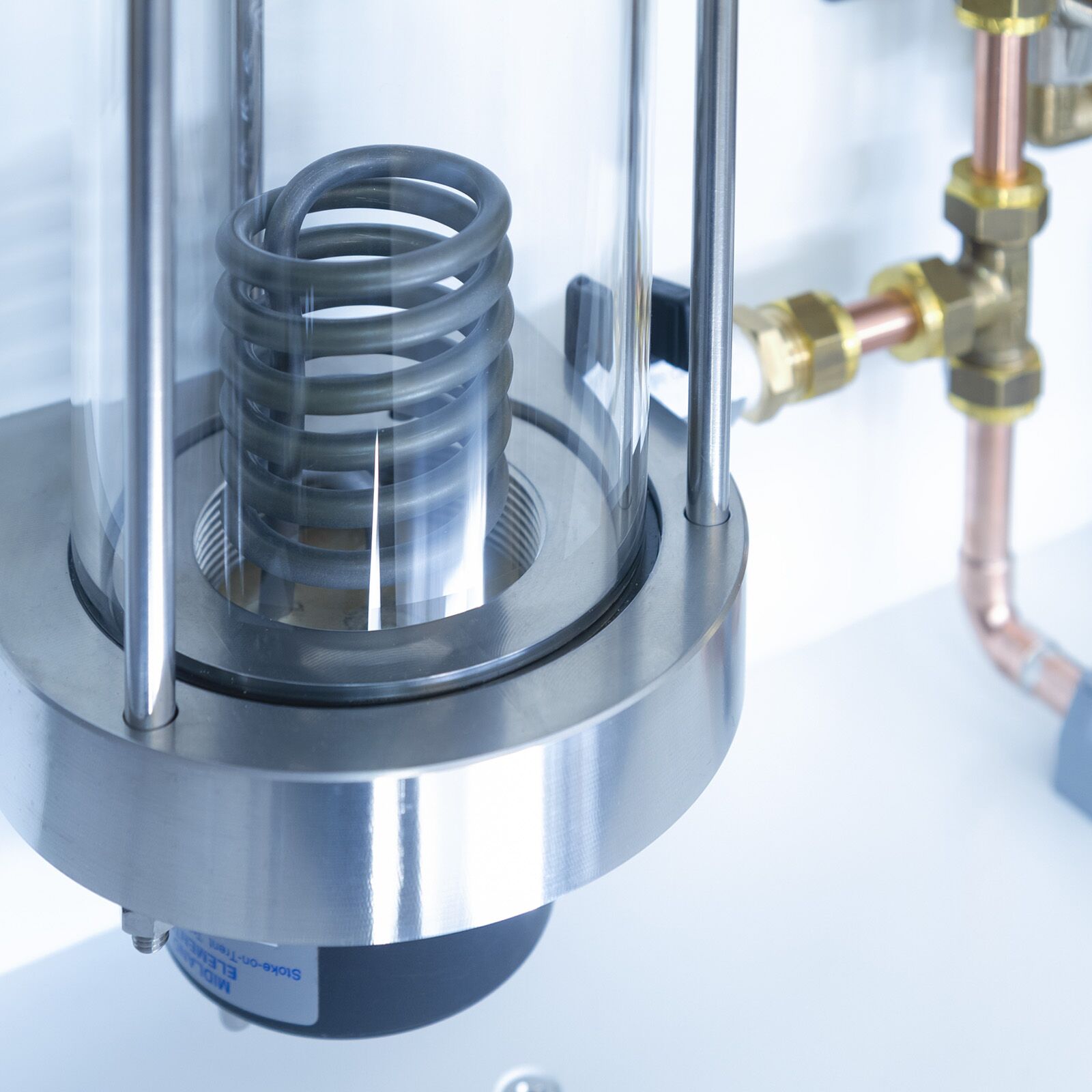

- Matt finished copper cold finger condenser: 90-100mm length 12.7mm OD

- Polished copper cold finger condenser: Gold plated 90-100mm length 12.7mm OD

- Flow rates to each condenser: 0-7.5l/min

- Flow rate to the vacuum educator: 0-15l/min

- Electronic flowmeters: 0-7.5l/min

- Operational pressure: 100-1500 mbara

- 11x PT100 Thermocouples: 1-120 °c

- 1 x electronic pressure sensor: 0-2500 mbar

- Water level: Optical Sensor

Features & Benefits

- Demonstration of film and dropwise condensation

- Determining coefficients of heat transfer and heat flux at constant pressure

- Determine the influence of pressure on the coefficients of heat transfer

- Demonstrate the effect of non-condensable gases (air) on the heat transfer coefficients

- Determine the influence of temperature deltas between the saturated steam and the condenser surfaces on the coefficients of heat transfer

PC – Running Windows 7 or higher

Electrical supply: 100-250vAC, 50-60Hz single phase

Software requires a computer running Windows 7 or above with a USB port (computer not supplied by Armfield)

Cold water supply and drain: 5 Litres/minute at 1bar gauge (min)

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: TBC

Gross Weight: 50Kg

Length: 1.00m

Width: 0.50m

Height: 0.92m

TH6: Film & Dropwise Condensation Demonstration unit