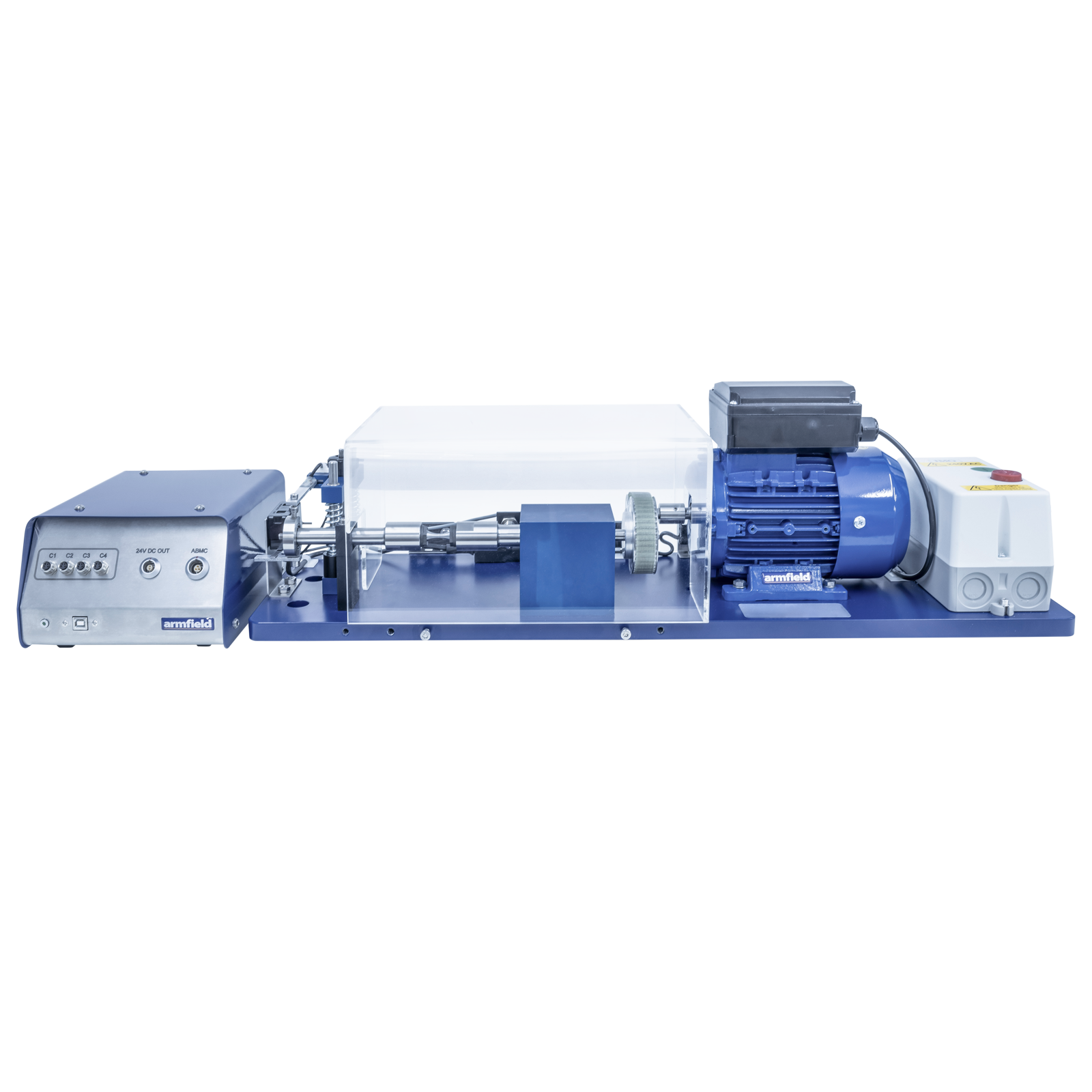

SV800 Rotating Fatigue Machine

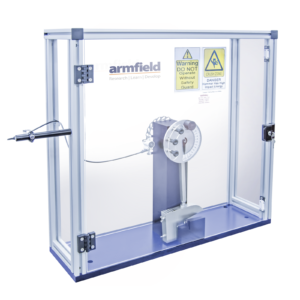

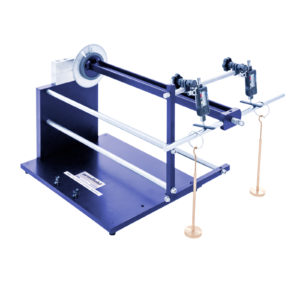

The SV800 rotating fatigue machine has been designed to introduce students to the effects of material fatigue using a sinusoidal variation of bending stress

Description

The SV800 rotating fatigue machine has been designed to introduce students to the effects of material fatigue using a sinusoidal variation of bending stress.

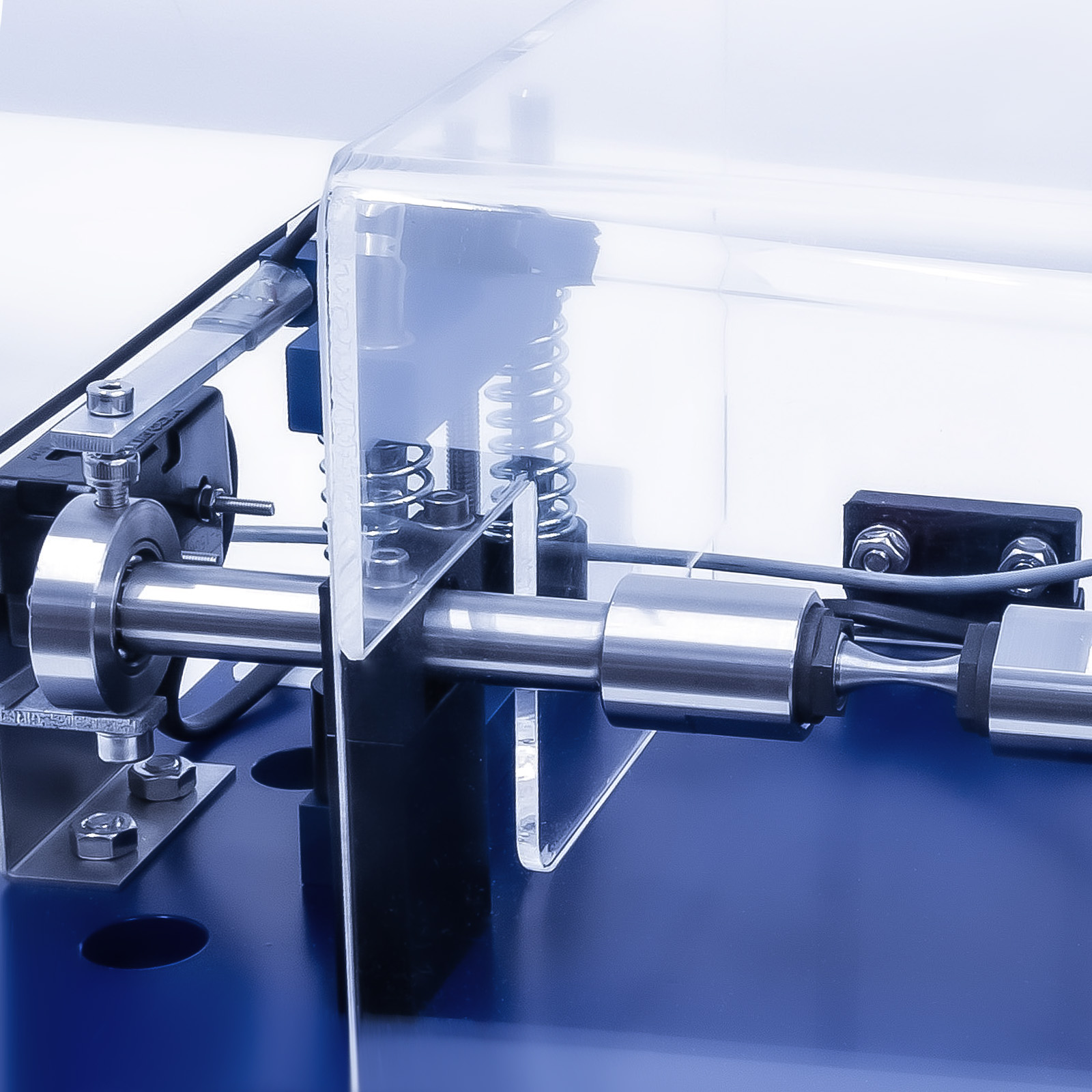

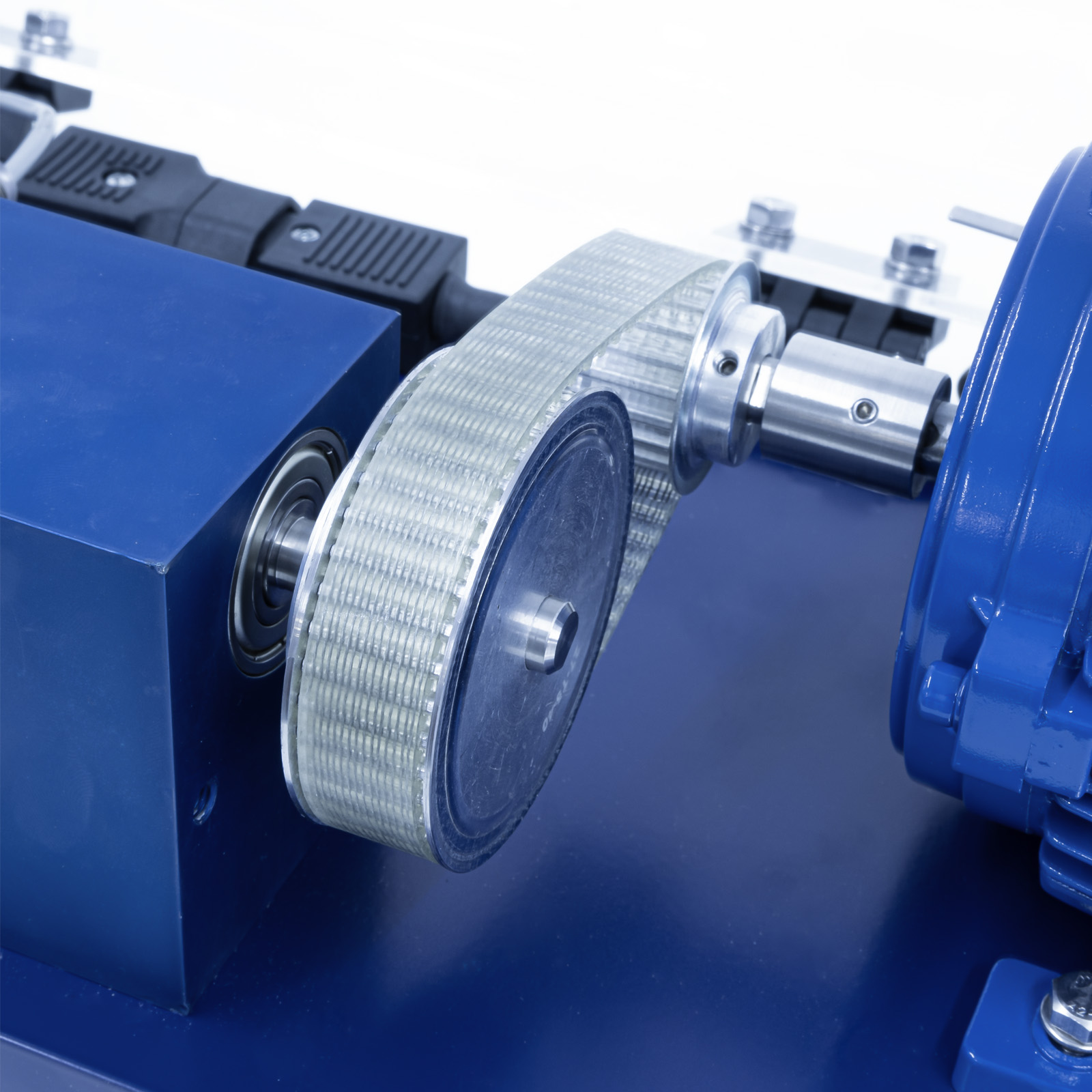

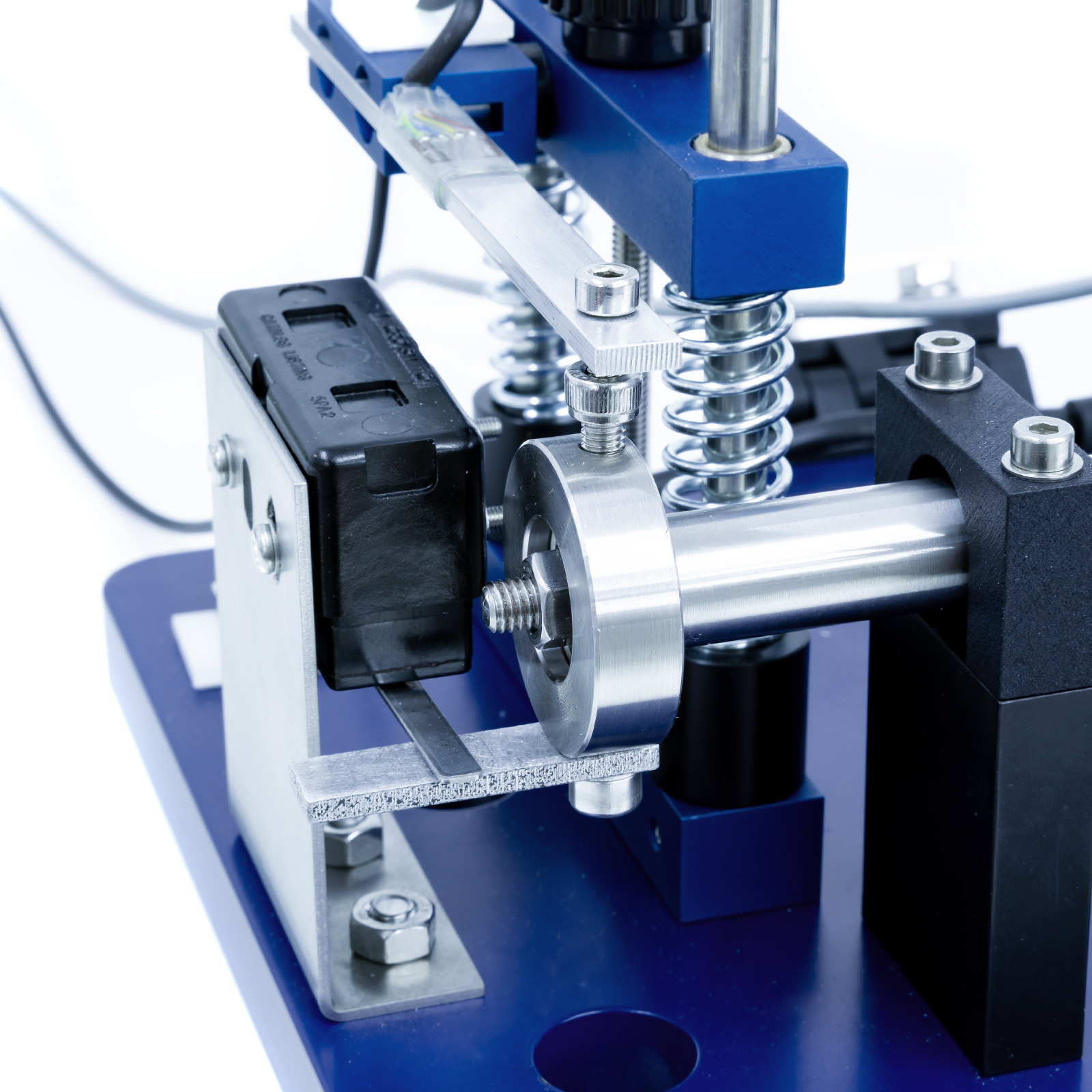

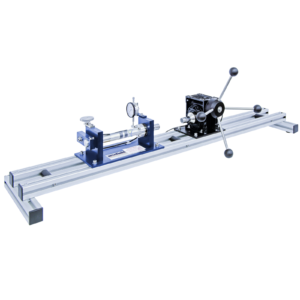

A 2800rpm motor rotates a specimen through a gear and pulley arrangement between 5600 or 1400 rpm. The specimens are held within ‘keyless’ chucks and loaded using a cantilever arrangement, with the load being applied through a screw jack mechanism with integral cantilever load cell.

A digital interface displays the applied force and revolution count of the specimen. Both values can be reset and zeroed (tared) prior to the testing commencing. When specimen failure occurs, a micro switch stops the motor and the cycles to failure are registered on the digital display. The count remains when the motor is not running. A safety guard shields all rotating parts.

The supplied AIU Armfield interface unit allows a host computer (not supplied) to be connected to the SV800. The software supplied allows the capture and reviewing of data.

Technical Specifications

- Motor speeds: 5600 or 1400rpm

- Motor speed: 2800rpm nominal

- On-board starter box

- Timing pulley and belt drive system: 20t and 40t

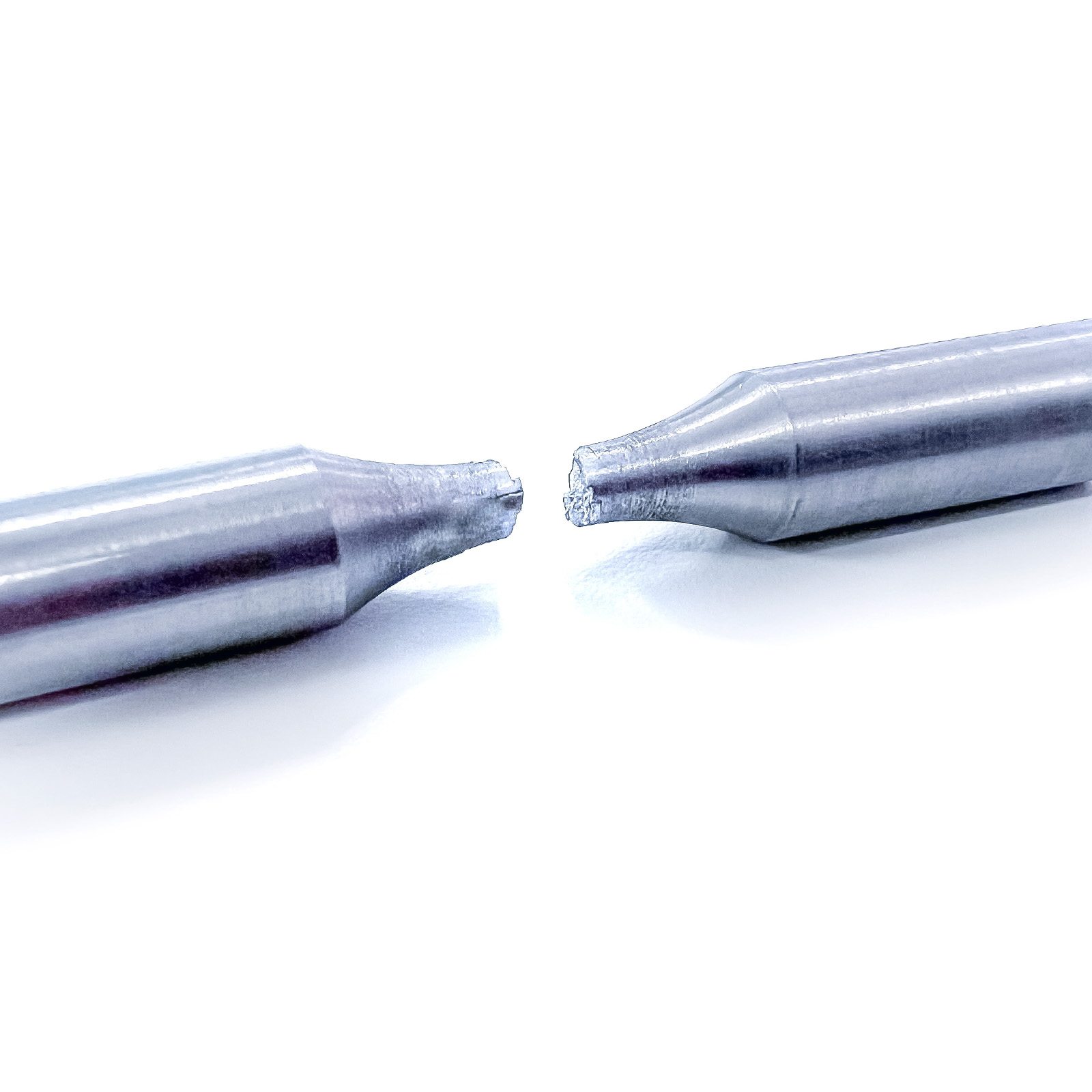

- 10 x Standard specimens: Ø4mm neck diameter x 65(L) mm, steel

- Cantilever loading arrangement

- Clear safety guard

- Safety: Motor will remain inactive with safety guard removed

Features & Benefits

- Fatigue testing based on Wohler

- Fully guarded system

- Variable speed

- Automatic motor cut-off following specimen fracture

- Digital force sensor

- Digital interface and software

- Keyless chucks

- Set of specimens supplied with spares optionally available

- To make an introductory study of fatigue using a Wohler rotating fatigue apparatus, including the time to failure caused by various stress levels and materials

- Introducing students to S-N curves

- Material specification on fatigue limits

- Specimen geometry on fatigue limit

- Fatigue

- Maximum Stress

- Proof, Yield Stress

- Fracture

- Tensile stress

- Endurance Limit Stress

- Stress Variation

- Localised

- Wohler Fatigue

- Sinusoidal Stress

- SV800-1: Additional 10 Mild Steel Specimens

- SV800-2: Additional 10 Brass Specimen

- SV800-3: Additional 10 Aluminium Specimen

- 1 x SV800 Rotating Fatigue Machine

- 2 x Spanner

- 10 x Specimen

- 1 x Hex wrench set

- 1 x Spare belt

- 5 x Spare fuse

- Instruction manual

- Packing list

- Test sheet

Electrical supply: 110/120V, 60Hz or 220/240V, 50Hz

- The user must have a PC with a USB port, running Windows 7 or above

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.05m³

Gross Weight: 35kg

Length: 0.715m

Width: 0.260m

Height: 0.280m

- SV800-A: Rotating Fatigue Machine 230v – 1Ph – 50Hz

- SV800-B: Rotating Fatigue Machine 115v – 1Ph – 60Hz

- SV800-1: Additional 10 Mild Steel Specimens

- SV800-2: Additional 10 Brass Specimens

- SV800-3: Additional 10 Aluminium Specimens

- AIU: Armfield Interface (Supplied with the unit)