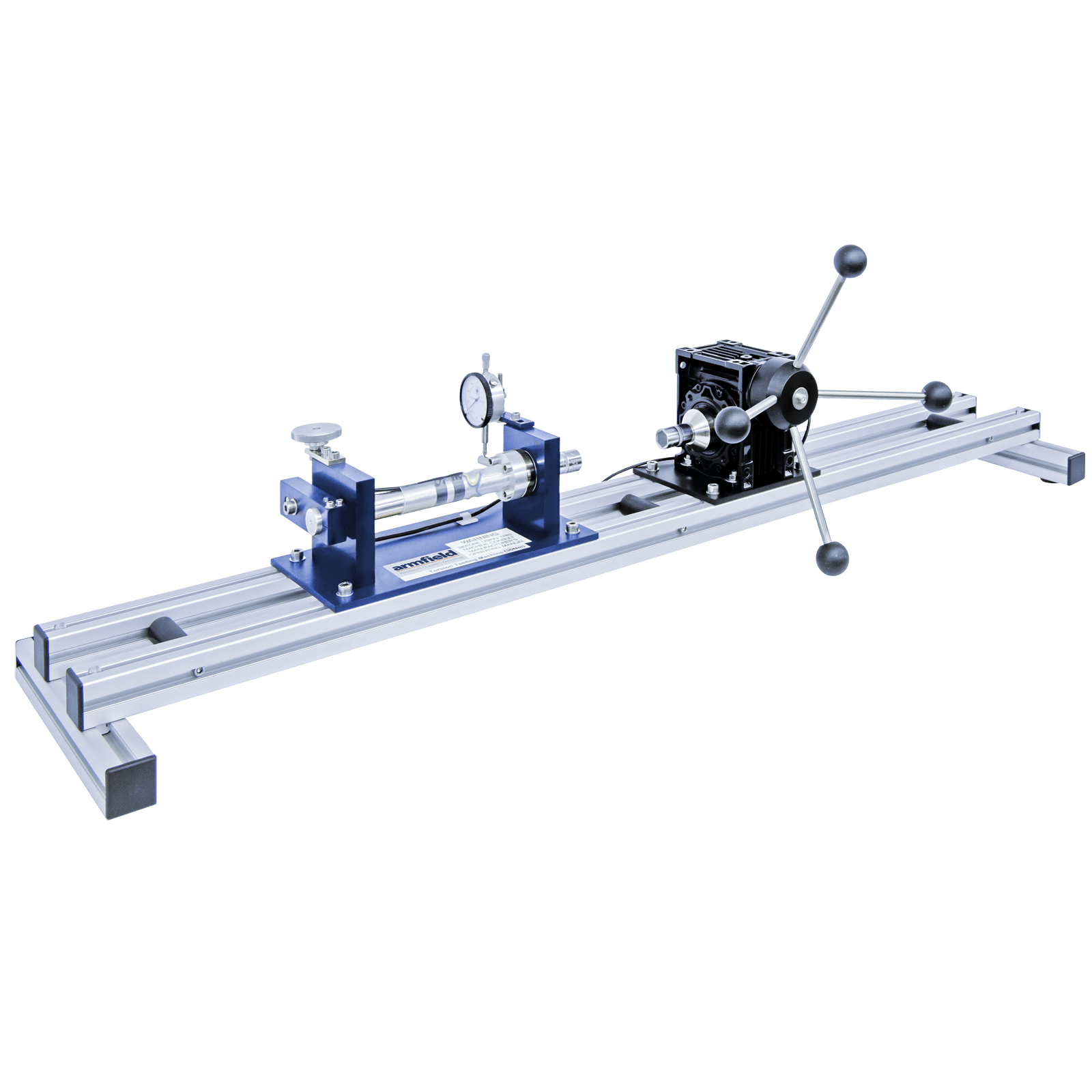

SV802 – Torsion Testing Machine 30Nm

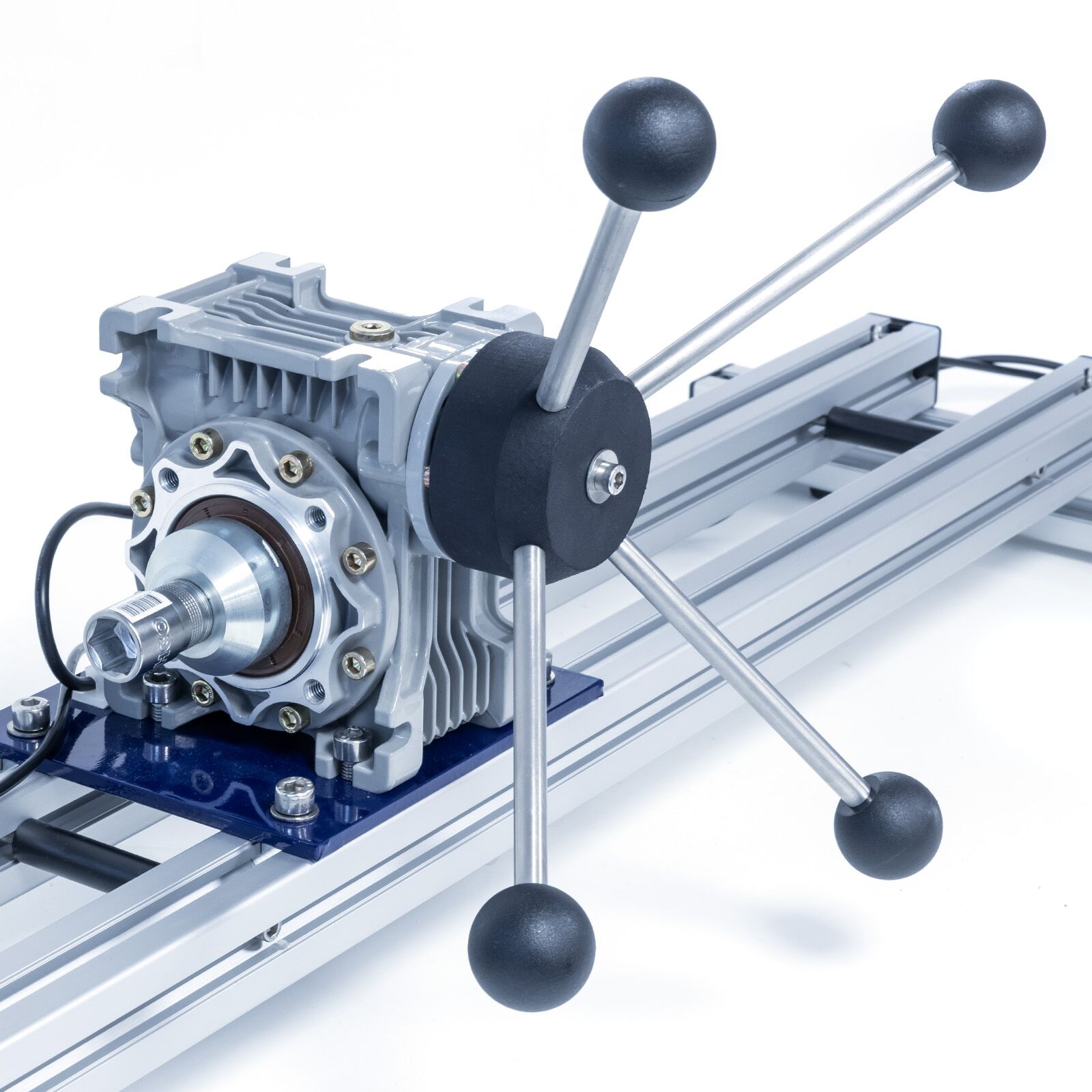

The SV802 can cater for test specimens of up to 750mm between the moment head and torsion head. The moment head is fixed but the torsion head can be moved along the base to allow for the different lengths of specimen.

Description

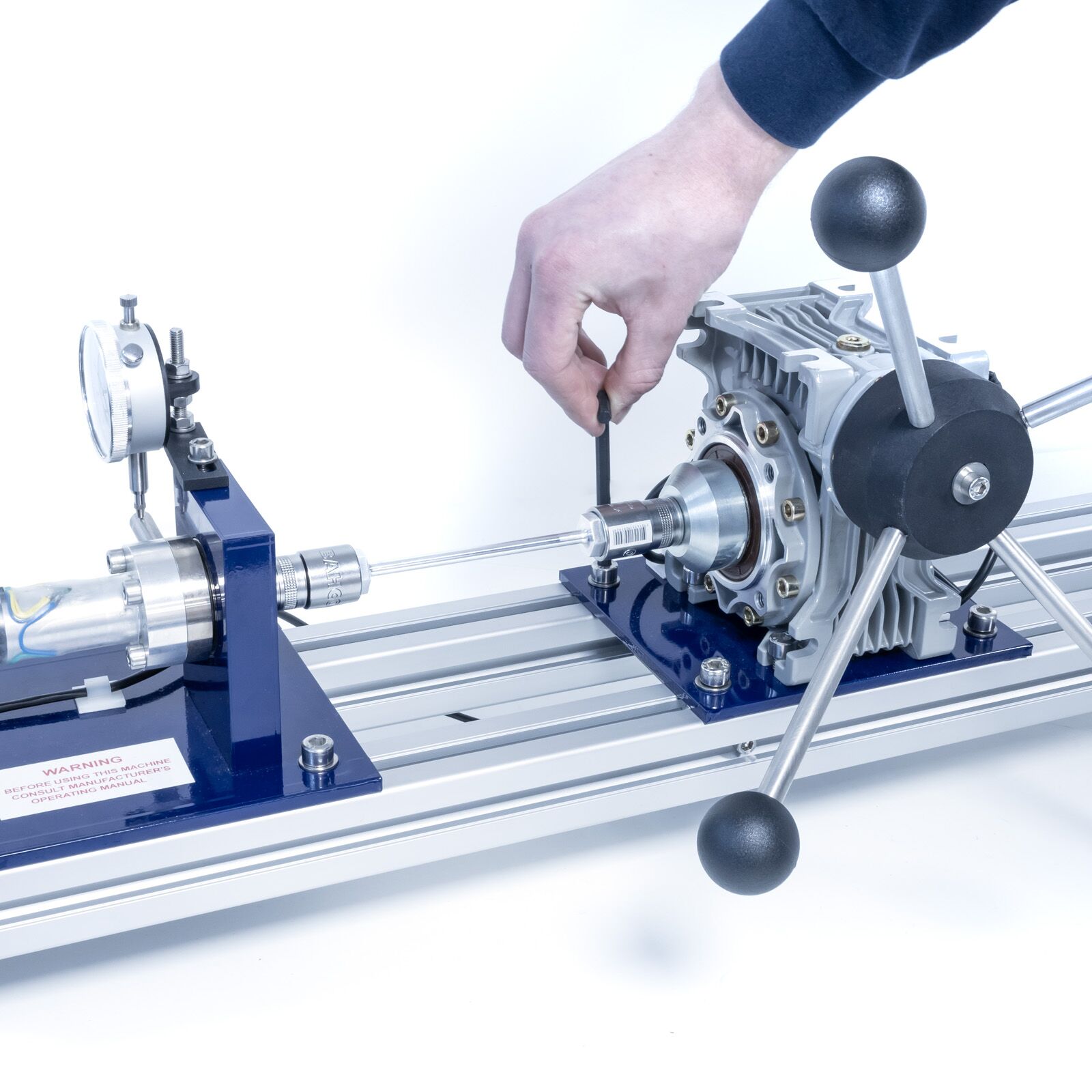

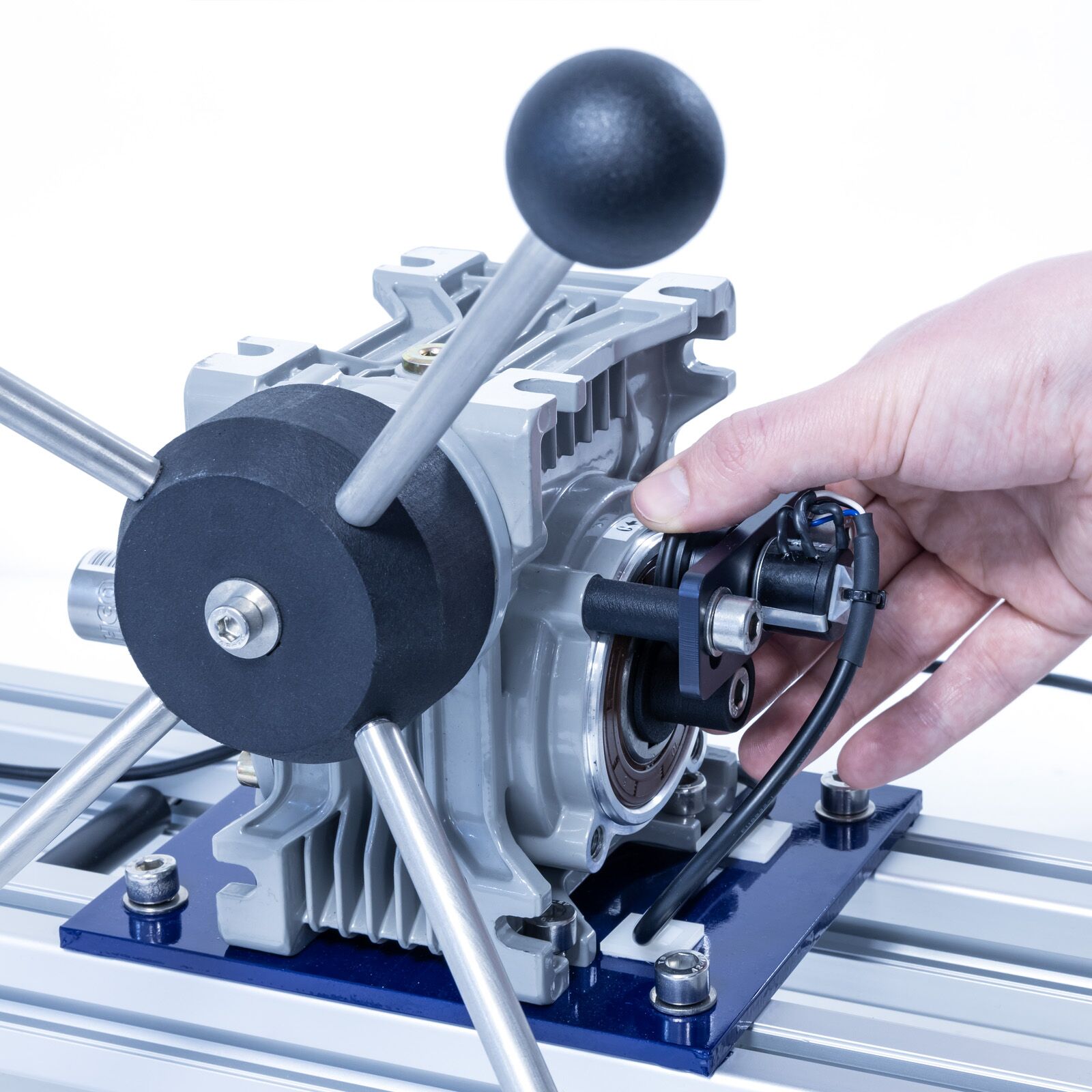

Up to 30Nm torque is applied via the moment head to differing material test specimens using hand operated worm and wheel gearbox (60:1 ratio).

The unit can cater for test specimens of up to 750mm between the moment head and torsion head. The moment head is fixed but the torsion head can be moved along the base to allow for the different lengths of specimen. The change in length of the specimen is not restricted during the experiment. Standard hexagon drives are used for transmitting the torque into the specimens.

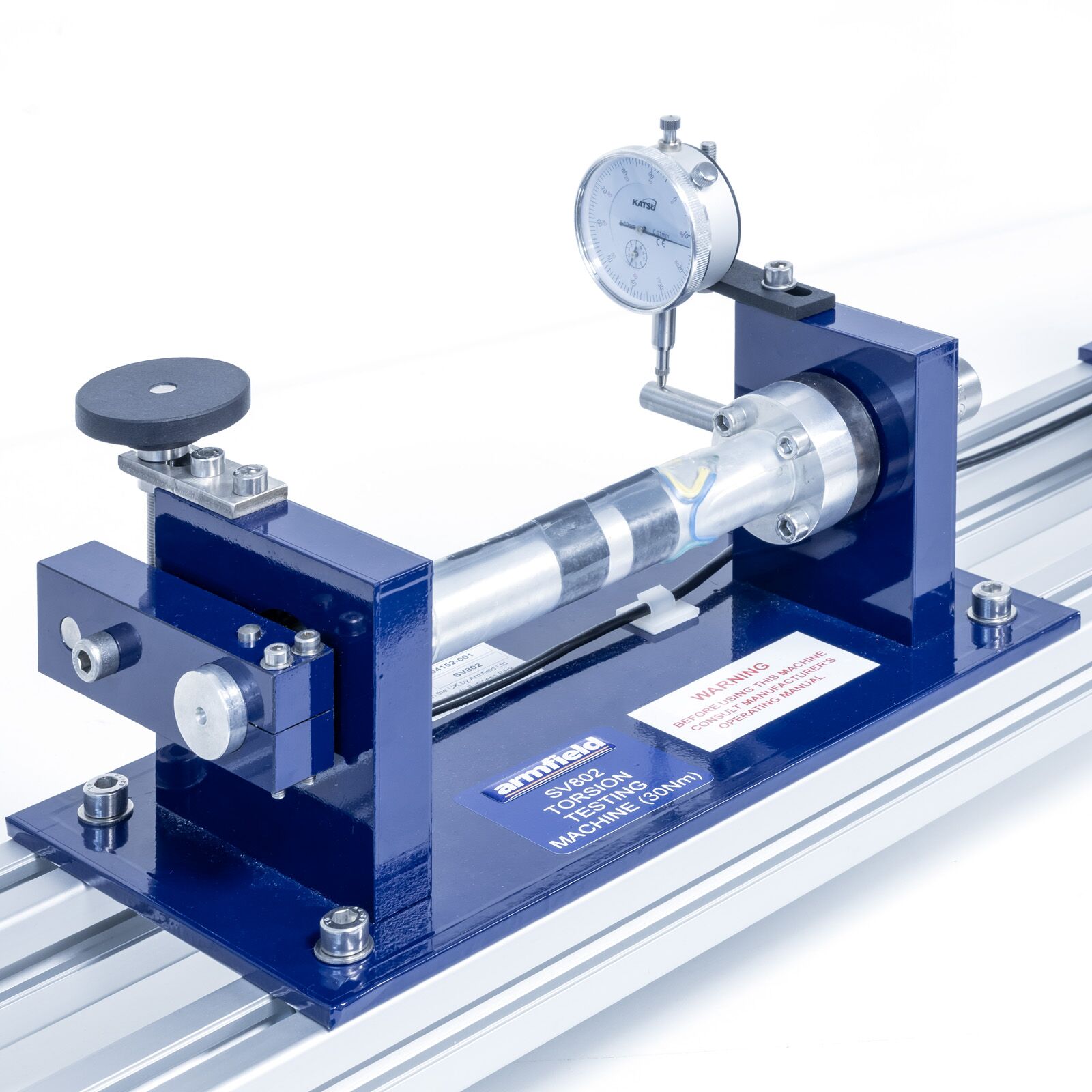

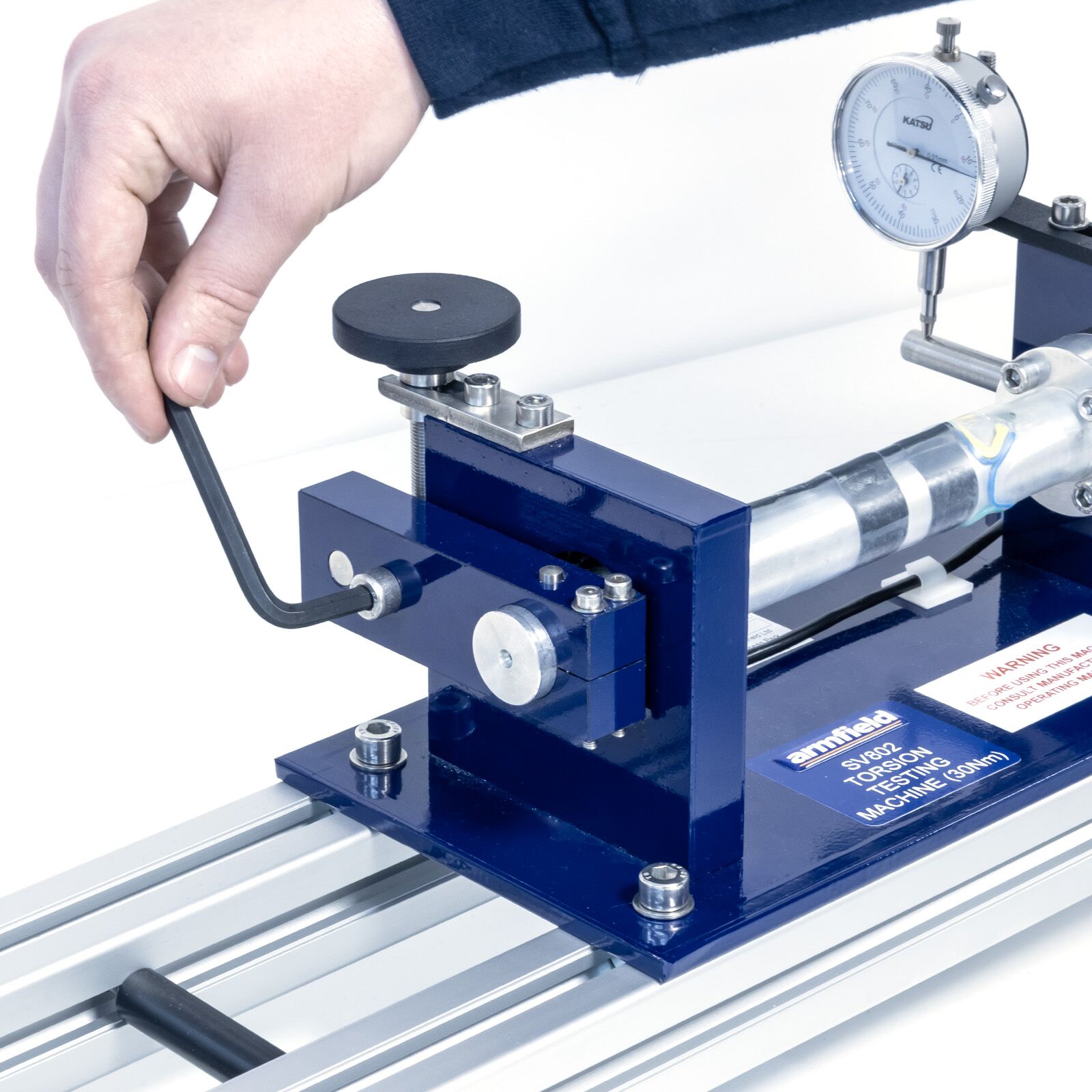

The angular position of one end of the test specimen can be adjusted before and during the experiment to either compensate for twist or to set known twist. This is done using the adjustment mechanism on the torsion head and the reference dial gauge mounted on the torsion head also.

Strain gauge technology is used within the torsion head and the output from these strain gauges is fed directly into the AIU Armfield interface units. The software supplied with the AIU captures and stores the data to allow further data manipulation and processing.

Technical Specifications

- 30Nm torsion ability

- Bench top unit, with sturdy extruded base frame

- 18 test specimens supplied in steel (x6), aluminium (x6) and brass (x6)

- 17mm A/F hexagon ends on specimens

- Test diameter on specimens: Ø6mm nominal

- Can cater for specimen lengths up to 750mm

- Specimen loading through 60:1 worm/wheel gearbox operated by hand

- Digital display of torque (resolution of 0.1Nm) and angle (resolution of 0.1°)

- Analogue dial gauge: 10 or 25mm range, 0.01mm resolution

Features & Benefits

- High quality, visual apparatus

- Sturdy bench frame for up to 750mm specimen lengths

- Digital Interface and software option

- Steel, aluminium, brass test specimens supplied

- Vernier, ear defenders, safety glasses supplied

- Pen supplied to visibly show angle of twist of specimens

- Torsional loading to failure of varying material specimens

- Torsional variation due to material, cross sectional area

- Comparison between actual and theoretical results

- Determination of the Modulus of Rigidity and Yield Shear Stress

- Working with the elastic torsion equation

- Hardness testing

- 1 x Power supply

- 18 x Specimens

- 1 x Safety glasses

- 1 x Ear defender

- 1 x Hex wrench set

- 1 x Vernier caliper

- Instruction manual

- Packing list

- Test sheet

Electrical supply: 110/120V, 60Hz or 220/240V, 50Hz

- The user must have a PC with a USB port, running Windows 7 or above

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.77m³

Gross Weight: 85kg

Length: 1450m

Width: 0.360m

Height: 0.320m

- SV802 Torsion Testing Machine (30Nm)

- SV802-1: Additional Set of Specimens

- AIU: Armfield Interface Unit (Supplied with the unit)