S60/S80/S100 – Standard teaching and research flumes

Armfield designs and supplies open channel facilities (also referred to as flumes) to hydraulic laboratories throughout the world.

Description

Armfield has been designing and supplying open channel facilities (also referred to as flumes) to hydraulic laboratories throughout the world for over 50 years.

This page presents the standard range of channels/flumes available from Armfield, both for teaching and research purposes. We however can produce other sizes and layouts to suit specific design criteria.

The Armfield engineering team will work with our customers to make sure the brief, deadline and installation design needs are fully met.

All our flumes are supplied under the guidance of the Armfield professional service team who will oversee the transportation, installation, commissioning and training on site.

Technical Specifications

Static & Tilting configuration modular flumes

Working section dimensions

S60 Tilting

Width – 0.6m

Depth – 0.8m

Length – 5-30m (in 2.5m modular increments

S60 Static

Width – 0.6m

Depth – 0.8m

Length – 5-50m (in 2.5m modular increments

S80 Tilting

Width – 0.8m

Depth – 1.0m

Length – 5-30m (in 2.5m modular increments

S80 Static

Width – 0.8m

Depth – 1.0m

Length – 5-50m (in 2.5m modular increments

S100 Tilting

Width – 1.0m

Depth – 1.2m

Length – 5-30m (in 2.5m modular increments

S100 Static

Width – 1.0m

Depth – 1.2m

Length – 5-50m (in 2.5m modular increments

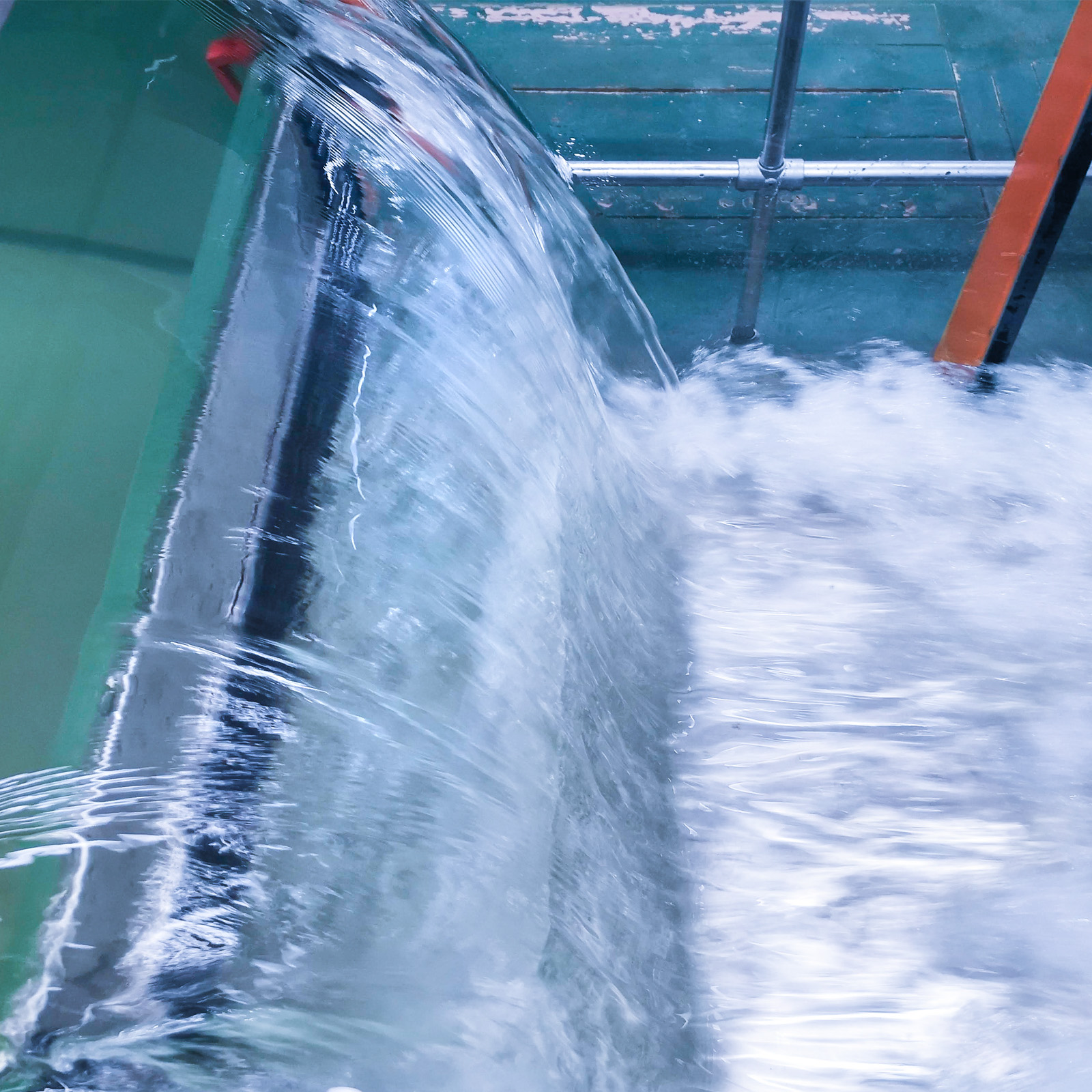

Free discharge verses recirculation flumes

Traditionally hydraulic laboratories were constructed with underfloor sumps and/or elevated header tanks linked with a ring main rarely enjoyed by new facilities. Armfield are able to supply flumes either in a non self-contained configuration, where they can be serviced from an existing header tank and discharge to a laboratory sump, or as fully self-contained system.

Below: Top – Free discharge via underfloor or floor mounted reservoir

Bottom: Recirculation flume via Armfield supplied pipework

Features & Benefits

Armfield Ltd have over 50 years experience in the design and supply of major research flumes worldwide.

Representing innovative product evolution, Armfield’s research flumes can be offered as static or tilting with either free discharge or recirculation modes.

- All our flumes are supplied under the guidance of the Armfield professional service team who will oversee the transportation, installation, commissioning and training on site as part of our scope of supply

- Single or multiple pump options to suit user requirements

- The flume is constructed in a modular format allowing extension in multiples of 2.5m at a later stage if required

- Standard lengths of up to 30m can be accommodated for tilting flumes. Tilting flumes greater than 30m are available on request. Static flumes are available at any length

- Armfield have extensive experience in design and delivery of large tilting flumes and understand the operational requirements upon the jacks and the pivot. Both the pedestals and the jacking mechanism are designed to ensure stability in all operating conditions

Standard Supply

- Inlet tank complete with inlet manifold

- Discharge tank

- Precision working section topped by load bearing instrument rails

- Control console

- Service system

- Software package

Options

- Recirculation

- Top-up pump for recirculation mode

- Sediment recirculation

- Jacking system

- Reservoir tanks

- Sediment weighing

- Sediment transfer

- Sediment feed

- Instrument carriage

- Powered instrument carriage

- Walkway

- Wavemaker

- Bed profiling

- Wind generation

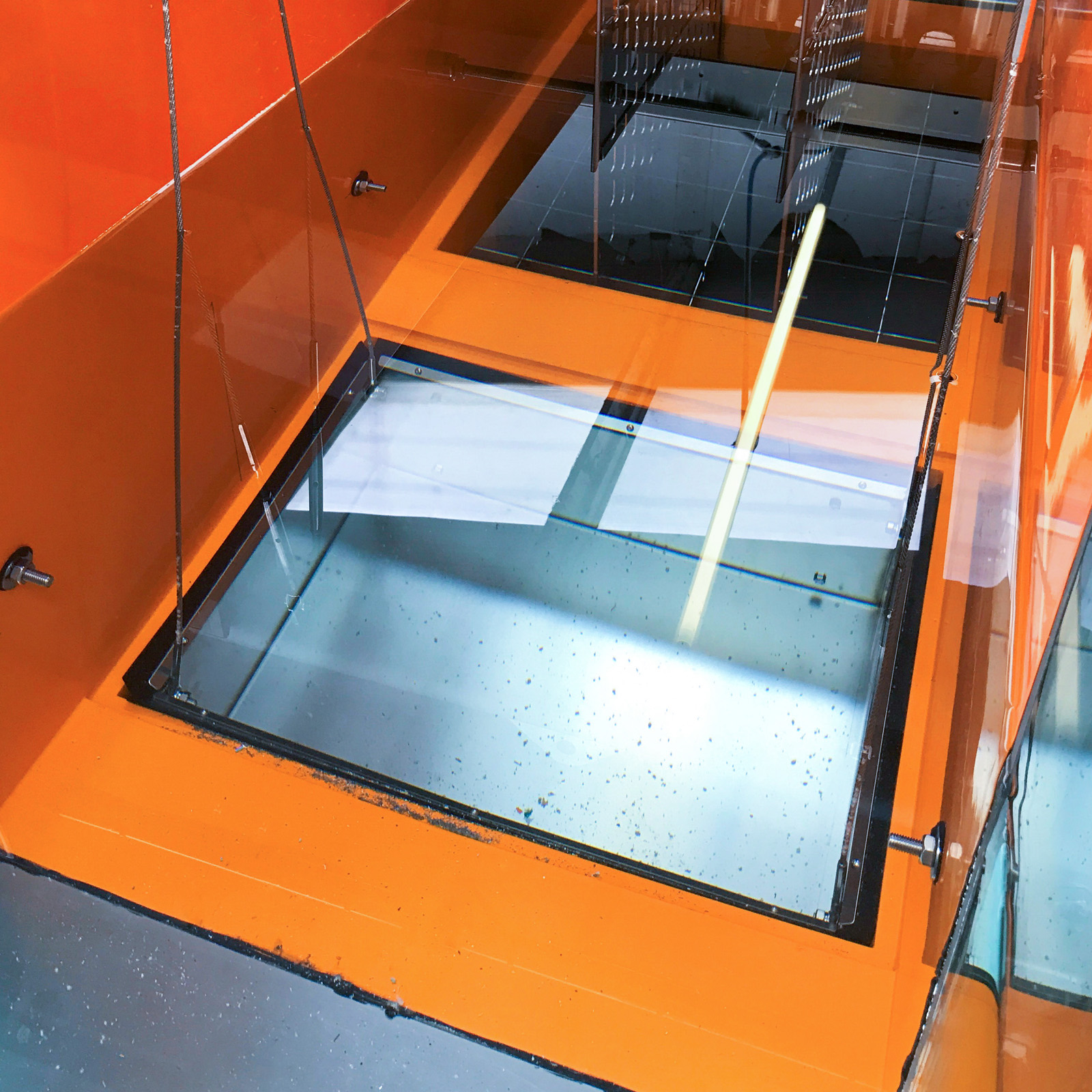

- Base glass viewing window

- Undershot/overshot weir

- Venetian blind weir option

- Dam release option

3 Standard sizes available

The critical dimensions of a flume are the working length and cross-section (width and depth).

Working length also means usable length. Often the turbulent entry conditions require a substantial portion of what can be described as the ‘working section’ before suitable flow conditions prevail.

Armfield flumes are designed to maximise the working length. The overall dimensions of the flume are minimised through careful design of the inlet and outlet conditions and sensible use of the space underneath the flume and surrounding area.

The key features of an open channel facility

The glass panels are sealed using a rubber “U” section compressed by an aluminium alloy clamping strip.

The flume bed is manufactured to high tolerances and the overall strength and rigidity of the design allows excellent stability figures to be achieved.

Instrument rails are provided along the entire working length of the flume and a continuous scale calibrated in millimetres is provided along the length of one of the rails.

Adjustable screws allow the track to be set level and true.

Tilting or static flume bed

Armfield can offer both static and fully automated tilting flumes. Both flume types are available in standard 2.5m lengths. Armfield can offer a range of options and enhancements to create a versatile piece of equipment for a broad range of experimental capabilities.

Static

The static flume sections have an integrated supporting structure and can be supplied with a stainless steel or glass base panel. There are no restrictions on available lengths and can be extended at any stage.

Tilting

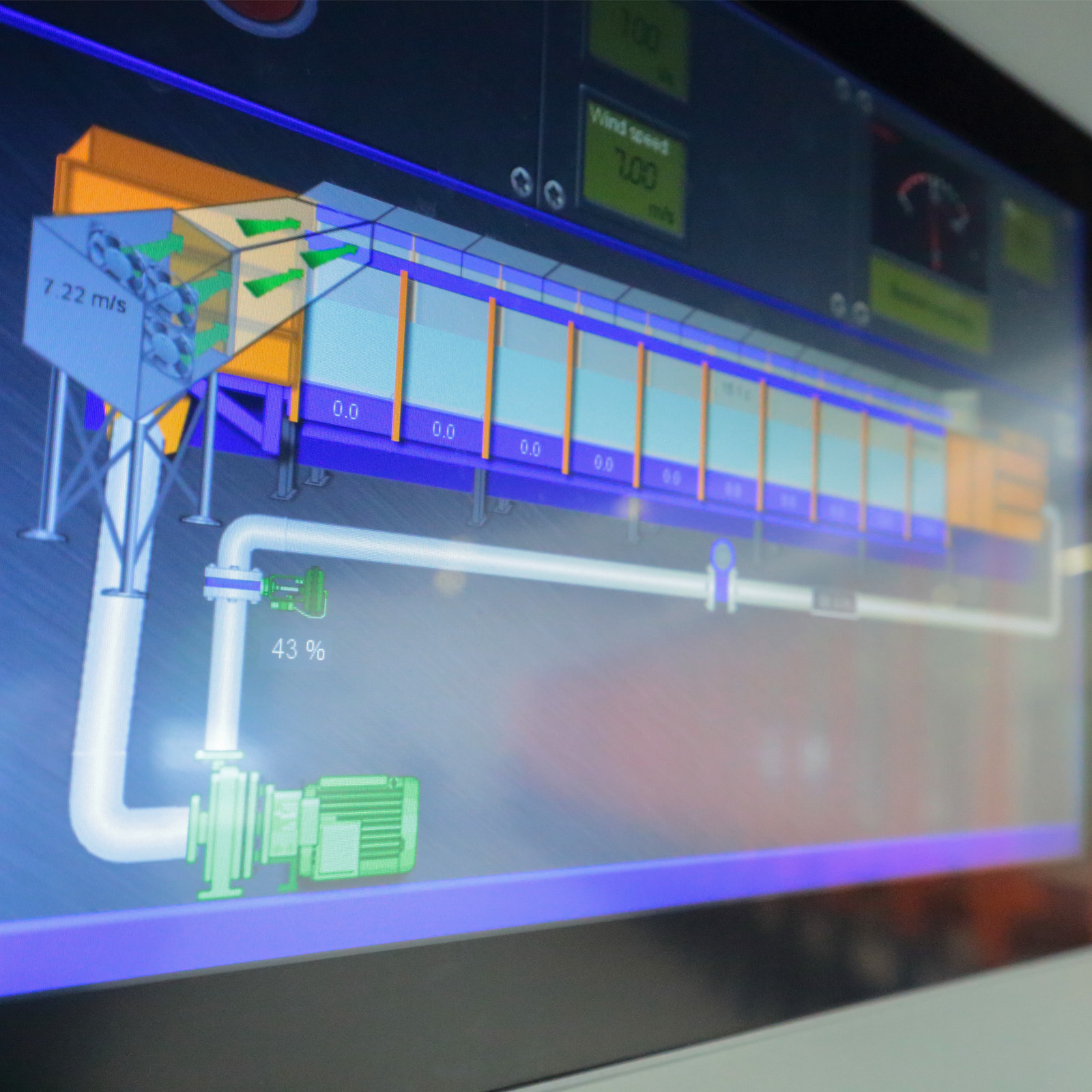

The standard tilting flumes can be supplied in lengths up to 30m and with both positive and negative tilt.** The tilting system is fully automated via the main PLC touch screen and enables users to set desired height or a height profile in conjunction with flow and test conditions. **maximum and minimum tilt subject to overall length of flume.

Wavemaking

Types: Single and multi paddle, piston or wind generated

Description: Wave generation and the effects of waves are significant areas of research.

Wave generator options can range from simple paddle systems, through to multi-paddle computer controlled wave generating systems. For many applications, particularly coastal models and flume studies, long crested and directional random waves are sufficient to model the sea state. For offshore studies and some shallow water problems multi-directional components are required.

Flumes may be used to study breakwaters, sea walls and beach behaviour or for fundamental research.

Whatever the application Armfield can supply a complete system designed to suit your particular requirements.

Wind simulation

Description: Integrated wind simulation systems can be provided offering mono or bi-direction wind

The wind generation system is integrated into the Armfield flume. Computer operated, it lets you set different wind profiles in conjunction with flow and wave generation as required.

Armfield can offer the addition of wind simulation with a variable speed fan system connected to a clear cowling running over the flume.

Variable wind simulation speeds up to and in excess of 25 metres per second are available.

- Wave makers available for all flumes including C4 Flume

- Computer controlled via our bespoke software

- Wind generated wave achievable

Sediment transfer

Types: Recirculation through dedicated transfer or through main pump system or deposit and collection via vibration feed and extraction point

Armfield can offer options for running sediment transfer experimentation within the flumes.

The flume is fitted with an expansion ‘drop out’ section which collects all mobile bed sediment and a baffle to encourage lighter suspended particles to be deposited and/or weighed.

Dedicated transfer – A separate solids handling pump is installed and connected to the drop out section. The pump can be used with sedimentation up to 10mm in size, which is then pumped to the start of the working section for redistribution. This system can be operated continuously.

Sediment transfer through the main circulation pump – This is particularly suitable for experimentation of fine suspended sediment. The pumps are lined and are designed to handle sedimentation up to 4mm in size. The suspended sediment is pumped through the main pipework. This system can be operated continuously.

Sediment collection and extraction – Where sediment needs to be collected and not automatically recirculated a series of valves are fitted to the drop out section enabling periodic extraction of deposited sediment.

- Recirculation or non recirculation options available

Sediment weighing

Description: Basket weighing system and sediment sampling

The need to gather data regarding the erosion and or deposition of sediment in relevant experiments always presents a challenge.

Armfield offer a weighing system that is efficient and easy to use. The system can be integrated into the software package and allows the logging of weight against time. A removable diverter plate assists to ‘drop out’ fast moving particulate.

- Sensor control

- Add PIV to illuminate and record partials in the flow, build up a picture of the changes in the sediment profile

PLC control system and tilting/incline control option

Types: Touch screen or analogue

The system will be supplied with a floor standing control panel. The cabinet houses the frequency inverters which control the tilt and pump motor speeds.

As standard, the Armfield flume is supplied with a PLC control system with HMI touch screen interface.

Automatic control

When the system is set in automatic mode the desired water depth, tilt/incline and flow rate can be selected. The system will then monitor the settings and using PID control data to maintain the desired output.

- In the main overview there is the function to start/stop the whole process

- The required flow rate can be set

- The required depth can be set

- The required tilt/incline can be set, not visible if option disabled. To disable set the max incline in the settings page to zero

- The required sediment feed can be set, not visible if option disabled. To disable set the max sediment in the settings page to zero

- An information window displays the system state

- The speed on the selected pump is displayed

- The selected pump number is displayed

- The pump valve position is displayed

- The weir position is displayed

- The flow rate is displayed

- The tank levels are displayed

- The running state of the pump is displayed

- The 10 pressure sensors are displayed (optional)

Weir options

Types: Base hinge, undershot/overshot weir, stop log, Venetian blind weir

Venetian blind weir –

To control the water height in the flow channel, advantages are a significantly reduced drawdown upstream of the weir, reduced turbulence at the discharge, no impediment to sediment transport, extends the working section

Undershot/overshot weir –

To control the water height in the flow channel

Base hinge weir –

The standard option to control the water height in the flow channel

Stop log weir –

To control the water height in the flow channel

Flood Gate

Description: Flood event research

With a computer controlled release system, this option will open up environmental experimentation.

Our engineers have designed an option to carry out flood event studies, leaky barriers, dam research, effect on structures and more. This flume furthers our involvement in creating equipment for environmental erosion studies.

Please contact us for more information or talk to us about your requirements. www.armfield.co.uk

- Control and acquisition for flow, velocity, level etc.

- Sediment transport / feeding / weighing / extraction

- Random and mono wave generation systems

- Walkways, gantries and jacking systems

- Bespoke pumping solutions from single to multiple pumps with flow rates ranging from 1-1000 l/sec

- Weir types including: Venetian weir; base hinge; stop log; gate & sluice

- Integrated touchscreen PLC control and logging systems

- Optional glass base sections for full particle image velocimetry (PIV) analysis

- Standard lengths from 5m – 50m

- Models & instrumentation

- Tilting up to 30 meters

- Static bed up to 50 meters

- Free discharge or recirculation configurations

- Fixed bed or variable slope

- Self-contained or laboratory supplied water

Accessories and model option list

Bed Profiling

The profiler uses a single laser, operable underwater, to determine changes in sediment depth over time. Being able to move the laser along a set path allows the user to build up a picture of the changes in the sediment profile.

3D Volumetric PIV System

The 3D PIV system is based on tomographic PIV which extends the stereoscopic approach to the third dimension.

Beach

Wave absorption beach to reduce the effect of reflected waves, other options available

Vibrating Pile

To investigate the effects of resonance on the pile, flow rate and patterns

Set of plate weirs, adjustable undershot weir + 6 plate weirs

Investigations on various plate weirs

– flow over sharp-crested weirs

– flow beneath an undershot weir

– typical measuring weirs

Broad Crested Weirs (GRP)

Investigations on underwater weirs

Venturi Flume

Flow rate measurement in rivers and channels

Parshall Flume

A standing-wave flume and incorporating a clear acrylic viewing window and clear acrylic stilling wells for level measurements

Ogee Weir

Overflow weir with manometer board for displaying the pressure characteristic

Syphon Spillway

A part width Syphon spillway, incorporating adjustable breather tube.

Self Regulation Spillway

Determine the relationship between upstream head and flow-rate through a self-regulating (air regulated) siphon.

Instrument options

Pitot Tube and Manometer Board

A Pitot static tube for measuring water velocity in the working section of the flume, mounted on a traversing carriage and incorporating Vernier height adjustment.

Bespoke customer designs

The engineering team are used to designing equipment for specific customer needs, contact us for more details: sales@armfield.co.uk

Standard Instrument Carriage

The standard instrument carriage comprises of a wheeled trolley capable of manual movement with provision to position and lock to the instrument rails using the scale on the rail and the Vernier on the carriage. It can support loads up to 250kg.

Automated Instrument Carriage

The automated instrument carriage will be supplied with a drive rail along the length of the flume with a flexible cable guide system. A powered carriage assembly and control panel with HMI which allows the user to select the desired position in the X, Y and Z direction. This will be repeatable with a precision of +/- 2mm.

A selection of instruments are available for use in flumes, channels and basins:

- Vernier hook & point gauges

- Manometers including water, pressurised, water-mercury

- Portable pressure meters

- Pitot tubes

- Turbulence/velocity meter

- Velocity probes, digital indicator and data logger

- Wave probe systems

Armfield has a long history in providing a complete design, build and installation service, to suit customer requirements.

As demand increases for research flumes in ever changing areas of enviromental and hydraulic analysis Armfield creates systems to study the new sciences. Armfield are experts in design, bespoke systems and lead the way in service, build, shipping, installation and commissioning of the flume.

Technical specialists provide training, ongoing assistance and support, both on site and via remote systems.

Partnering with industry and research institutions we have successfully executed some very challenging and exciting projects to enable ground-breaking studies and are proud of all our achievements.

Armfield combine the traditions of value, service and workmanship with innovation to meet the ultimate needs of our customers. We are an ISO9001:2015 company and our equipment is supplied with CE and UI certification.

TEST & BUILD from initial client meeting to handover

Armfield’s long history in fabrication, skill sets and dedicated manufacturing facilities supports our ever evolving range or products.

Working on projects across the globe including China, USA and Australia our dedicated and highly skilled team can assist you from design to final assembly, installation and testing.

Capabilities

At Armfield, accountability is foremost and our exacting standards and strict quality management processes mean we are continually striving to achieve the very highest quality in every detail. With our vast experience, highly skilled team, state of the art machinery and facilities we ensure the finished product meets and exceeds our customer expectations.

Environmental

Armfield are fully committed to reducing our environmental impact across the scope of our operations and through the products and services we deliver to our customers. We aim to continually reduce our environmental impact and improve environmental efficiency through our objectives, targets, systems and programs.

Health & Safety

Occupational health and safety is of paramount importance to us at Armfield and as we aim to be leaders in our field we are fully committed to the responsibilities in ensuring the health, safety and welfare of all employees and others is maintained. We pride ourselves on delivering a positive safety culture throughout Armfield for all our employees and affiliates.

S60

- S60t – Tiling

- S60s – Static

S80

- S80t – Tiling

- S80s – Static

S100

- S100t – Tiling

- S100s – Static