RA1- MKII-Computer controlled vapour-compression refrigeration unit

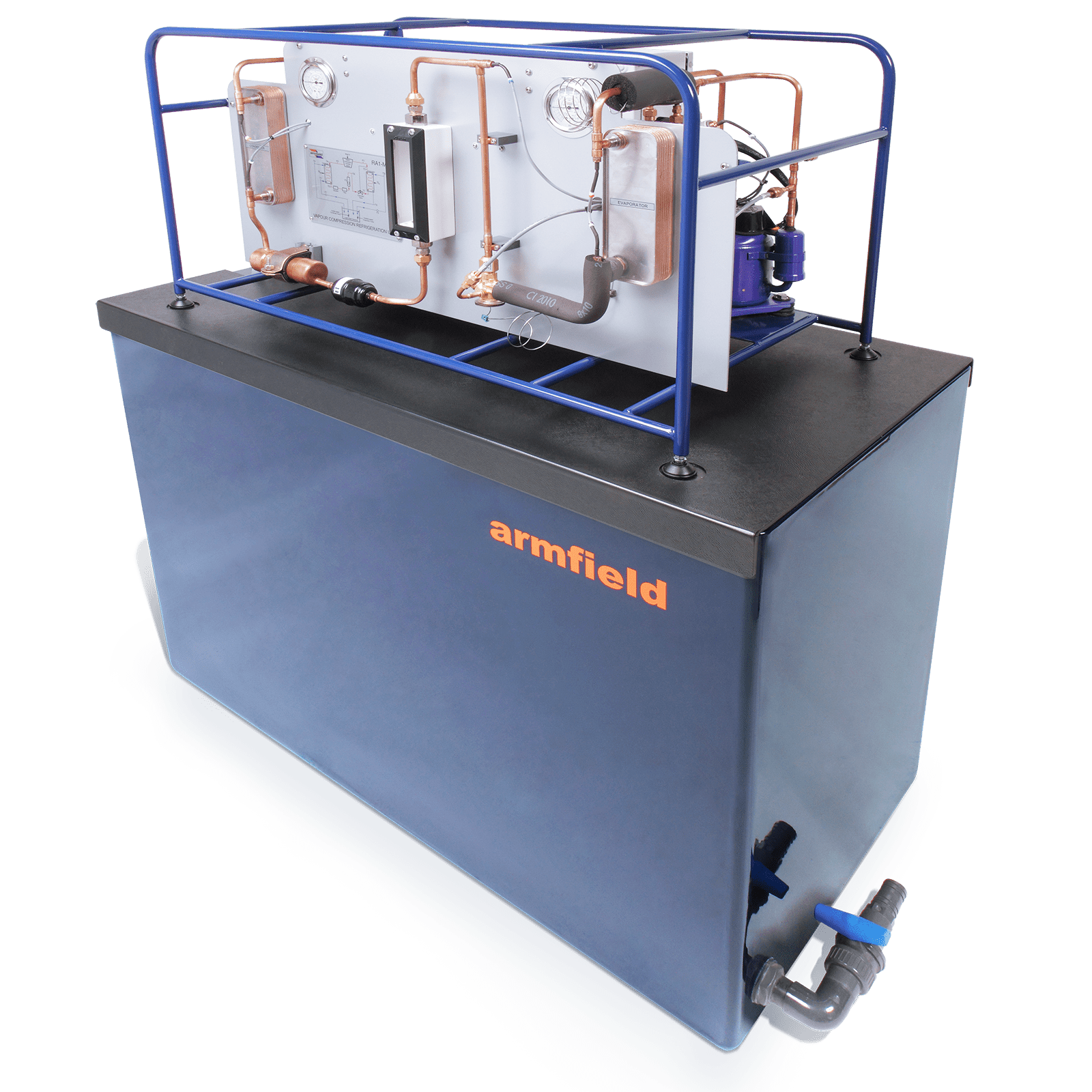

The RA1-MKII is a self contained computer controlled vapour-compression refrigeration system with automatic recording of all important process variables using an integral USB interface device.

Description

The RA1-MKII is a self contained computer controlled vapour-compression refrigeration system with automatic recording of all important process variables using an integral USB interface device.

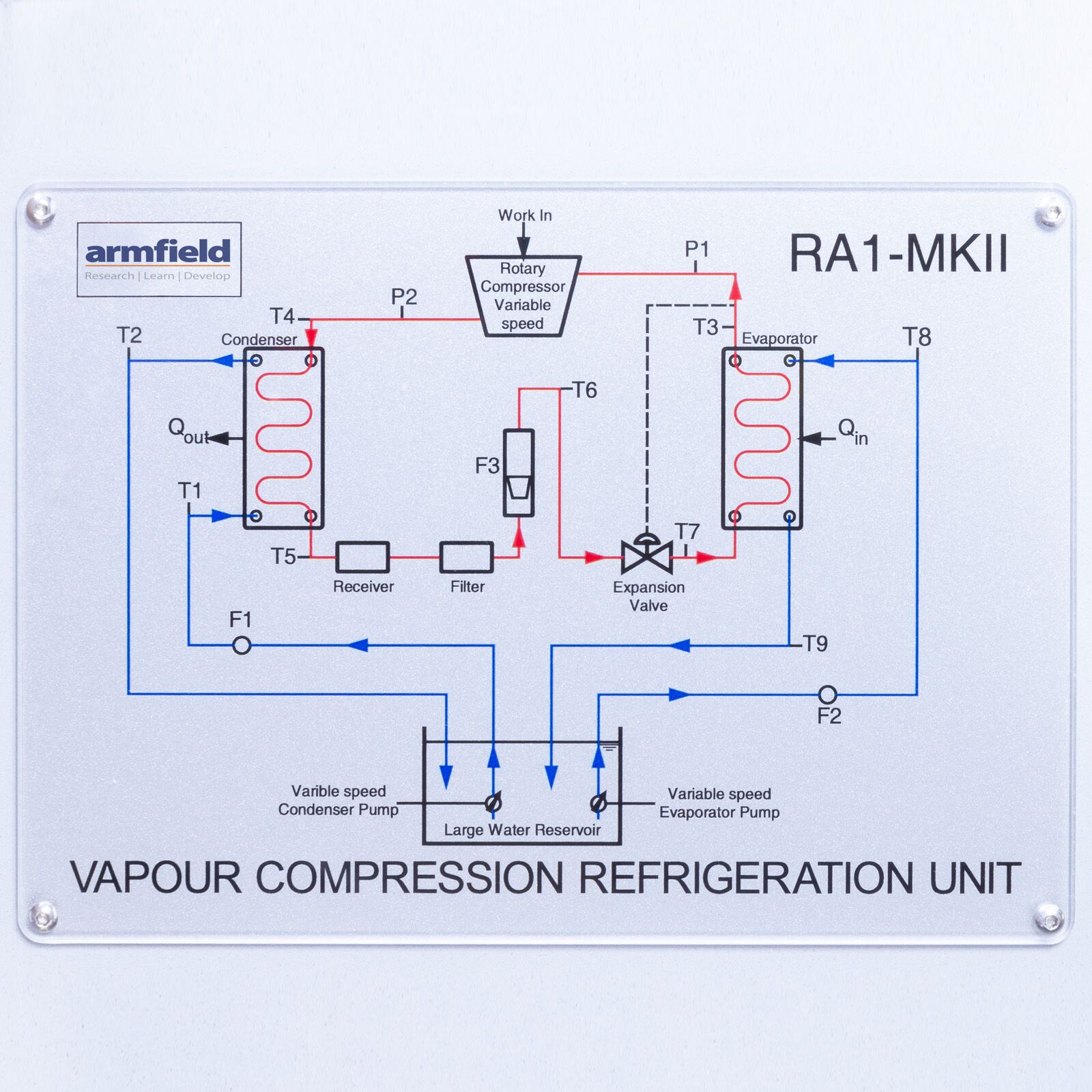

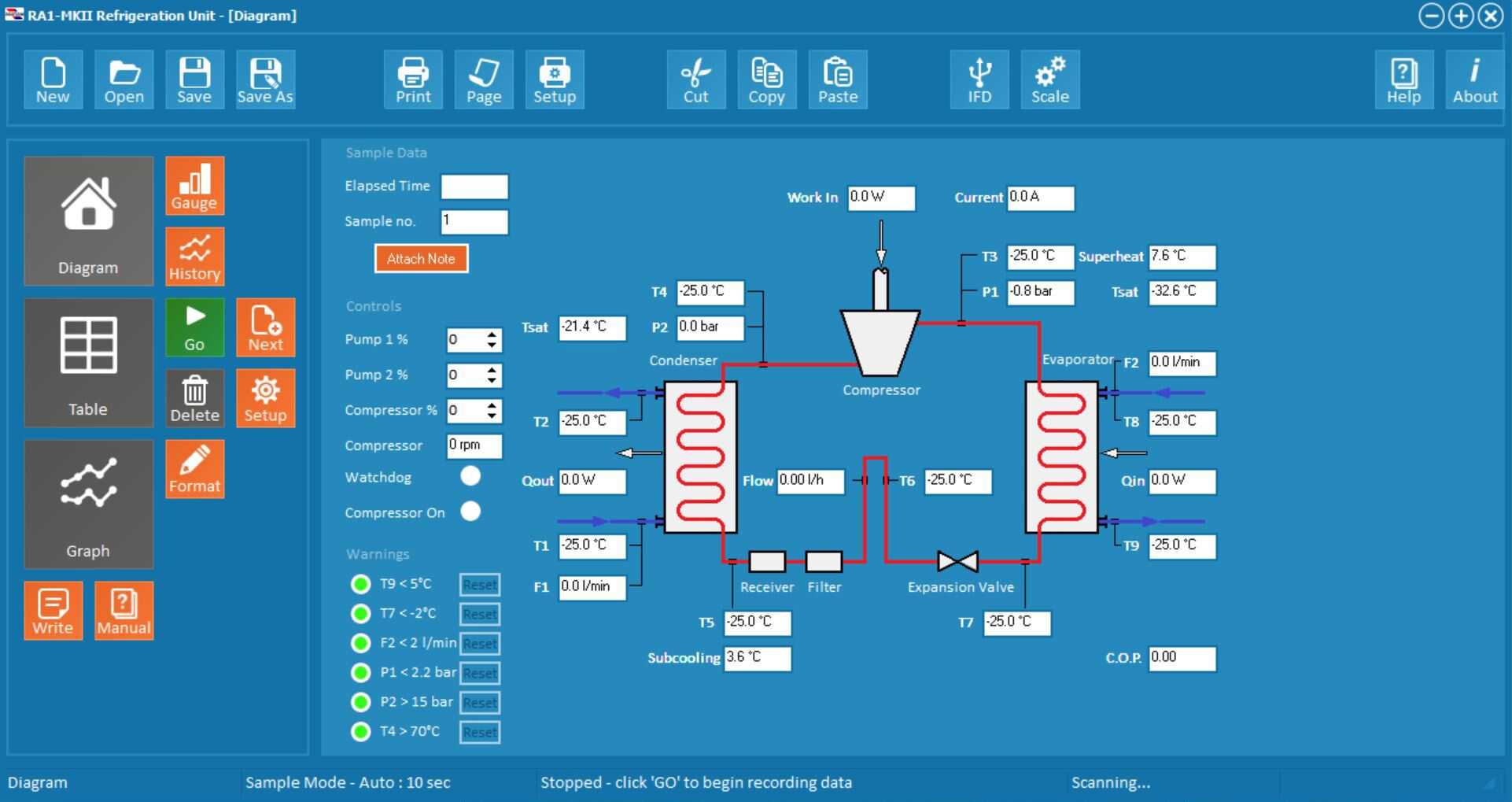

Compressor speed and power supplied are displayed on the PC. The hermetically sealed refrigerant exiting the compressor passes through a condenser, receiver, filter, variable area flowmeter, expansion valve and evaporator before returning to the inlet side of the compressor.

Technical Specifications

Refrigeration system: Vapour-compression type

Refrigerant: R134a

Hermetically sealed compressor speed range: 2000 to 4400 RPM

Hermetically sealed compressor supply: 24V DC to speed controller of brush-less 3 phase DC motor

Hermetically sealed compressor rating: 7.11 cm3 (0.434 cu in) for high evaporator temperature with 7.2°C rating point

Condenser: Brazed plate heat exchanger using water as heat transfer medium

Evaporator: Brazed plate heat exchanger using water as heat transfer medium

Water reservoir: Working capacity 400 litres

Temperature sensors: NTC Thermistor

Refrigerant flowmeter: Variable area flowmeter

Features & Benefits

- Complete system enabling demonstration of the most common refrigeration system used today

- Computer controlled with automatic recording of measured and calculated variables using a PC

- Overall performance of the system is calculated and displayed continuously enabling the effect of changes in the system to be evaluated

- Submersible variable speed pumps supply water at a stable temperature and pressure from the reservoir to the condenser and evaporator eliminating fluctuations

- Condenser and evaporator both use plate heat exchangers enabling a full energy balance to be carried out while varying the operating conditions on both sides of the compressor

- Separation of the refrigerant and water circuits aids understanding of the refrigeration system and the function of the various components

- Real-time superheat conditions in the condenser and evaporator are calculated and displayed

- Real-time display of Coefficient of Performance (COP)

- Expansion valve setting can be varied by the operator to change the operating point (evaporator superheat setting)

- Use of the refrigerant flowmeter as a sight glass enables observation of any vapour bubbles downstream of the compressor when conditions are not optimal

- Alarms protect the equipment from misuse by switching the compressor off if pressures, temperatures, flowrates or pumps drift outside acceptable limits. Advanced warnings enable the operator to take remedial action before the compressor is switched off

- Bourdon type gauges indicate the pressure and corresponding refrigerant saturation temperature on both sides of the compressor independent from the electronic systems

- Gain an in-depth understanding of the vapour-compression process by changing the operation of different parts of the process and recording the response of the complete system

- To operate vapour-compression refrigeration system and understand the relation between the hardware components and the refrigeration cycle

- First Law of Thermodynamics – The law of conservation of energy

- To investigate the effect on the refrigeration system of the flow of water through the condenser and to determine the optimum flow rate for a given load

- To investigate the effect on the refrigeration system of the flow of water through the evaporator and to determine the optimum flow rate for a given system load

- To investigate the effect of the flow of refrigerant through the refrigeration system, and whether there is an optimum flow rate

- To investigate the effect of closing/opening the expansion valve on a refrigeration system, and to determine the optimum setting for a particular application

- Coefficient of Performance (COP)

- Thermodynamic system modelling

- To perform appropriate energy balances and a detailed analysis of the performance of the refrigeration system

- Complete refrigeration system enabling demonstration of the vapour-compression refrigeration cycle

- Computer controlled system with automatic recording of process variables using an integral USB interface

- Measurement sensors include:

- – 9x Thermistor sensors measuring temperatures throughout the system – 2x Turbine type flow meters measuring flow of water through the condenser and evaporator – 2x Electronic sensors measuring pressures before and after the compressor

- – 2x Bourdon type refrigeration pressure gauges (with scale indicating equivalent refrigerant saturation temperature)

- – 1x Variable area flowmeter measuring refrigerant flowrate

- – 1x DC current shunt measuring current to the compressor motor

- Bench mounted refrigeration unit supplied complete with large water reservoir to isolate the process from fluctuations in temperature or pressure in the mains water supply

- Comprehensive instruction manual supplied

- RA2 Air conditioning unit

- RA3 Recirculating air conditioning unit

- RA4 Air conditioning training Unit

- HT Series

- TH Series

Electricity supply: Single phase (see ordering codes below)

Software requires the user to have a PC running Windows 7 or above with a USB port.

Cold Water

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 1.26m³

Gross Weight: 160Kg

Overall dimensions

Bench mounted refrigeration unit with separate floor standing water reservoir

Refrigeration unit:

- Length: 0.95m

- Width: 0.52m

- Height: 0.50m

Water reserve:

- Length:1.09m

- Width: 0.71m

- Height: 0.79m

Note: Refrigeration unit is located on top of the water reservoir when installed

- RA1-MKII-A: 230V/1ph/50Hz 5 Amps

- RA1-MKII-B: 110V/1ph/60Hz 10 Amps

- RA1-MKII-G: 220V/1ph/60Hz 5 Amps