PCT60 – Level Control

PCT60 – Level Control introduces students to fundamental control concepts, such as feedback control, (PID) controllers, and closed-loop control systems.

Description

Level control is a fundamental aspect of process control in various industries, including chemical, petrochemical, food and beverage, water treatment, and more. Understanding level control is essential for students pursuing careers in engineering, process automation, or any field related to these industries.

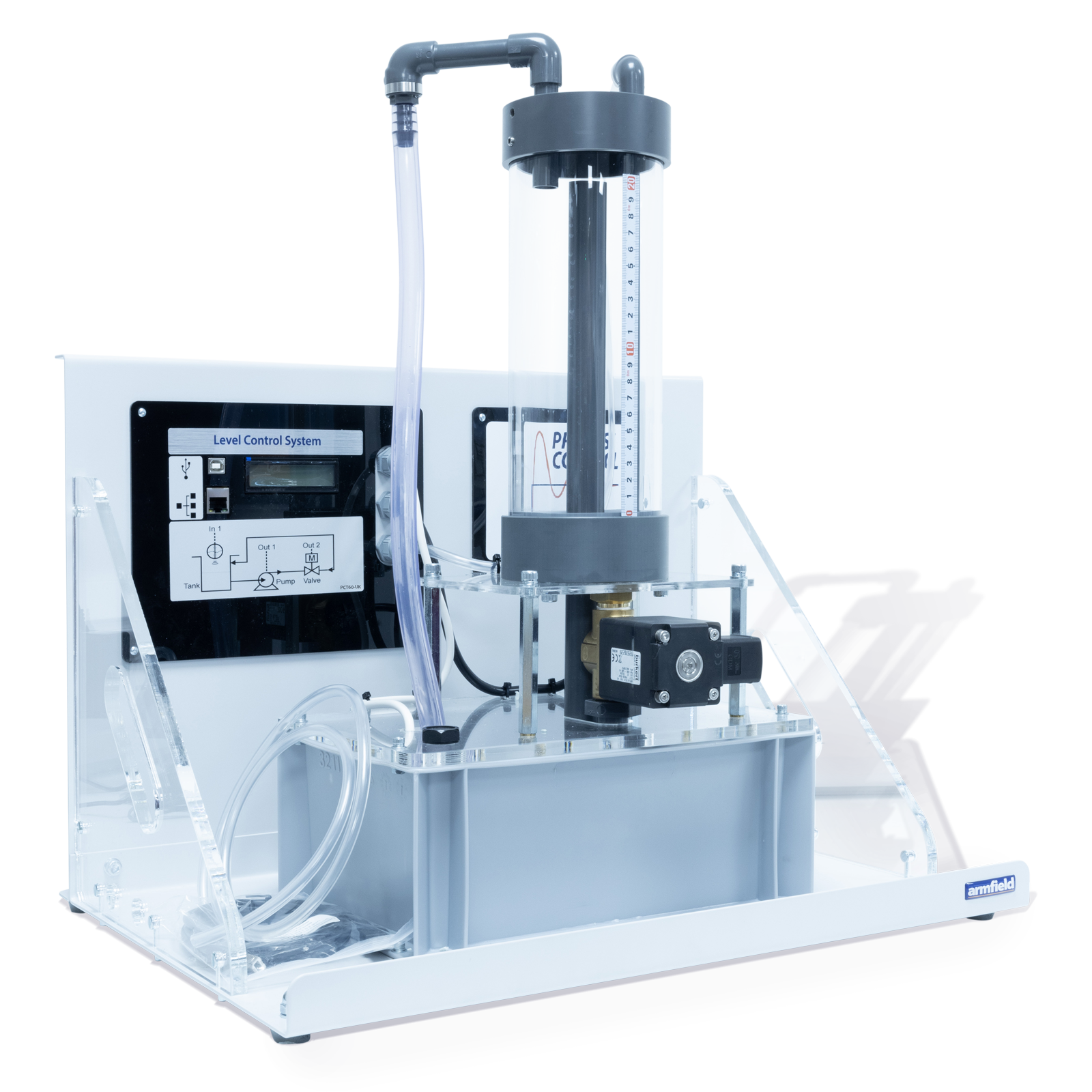

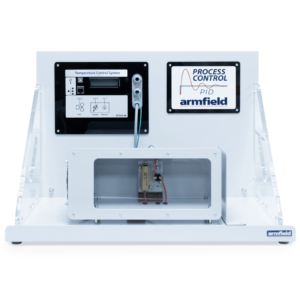

The Armfield PCT60 level control system introduces students to fundamental control concepts, such as feedback control, proportional-integral-derivative (PID) controllers, and closed-loop control systems.

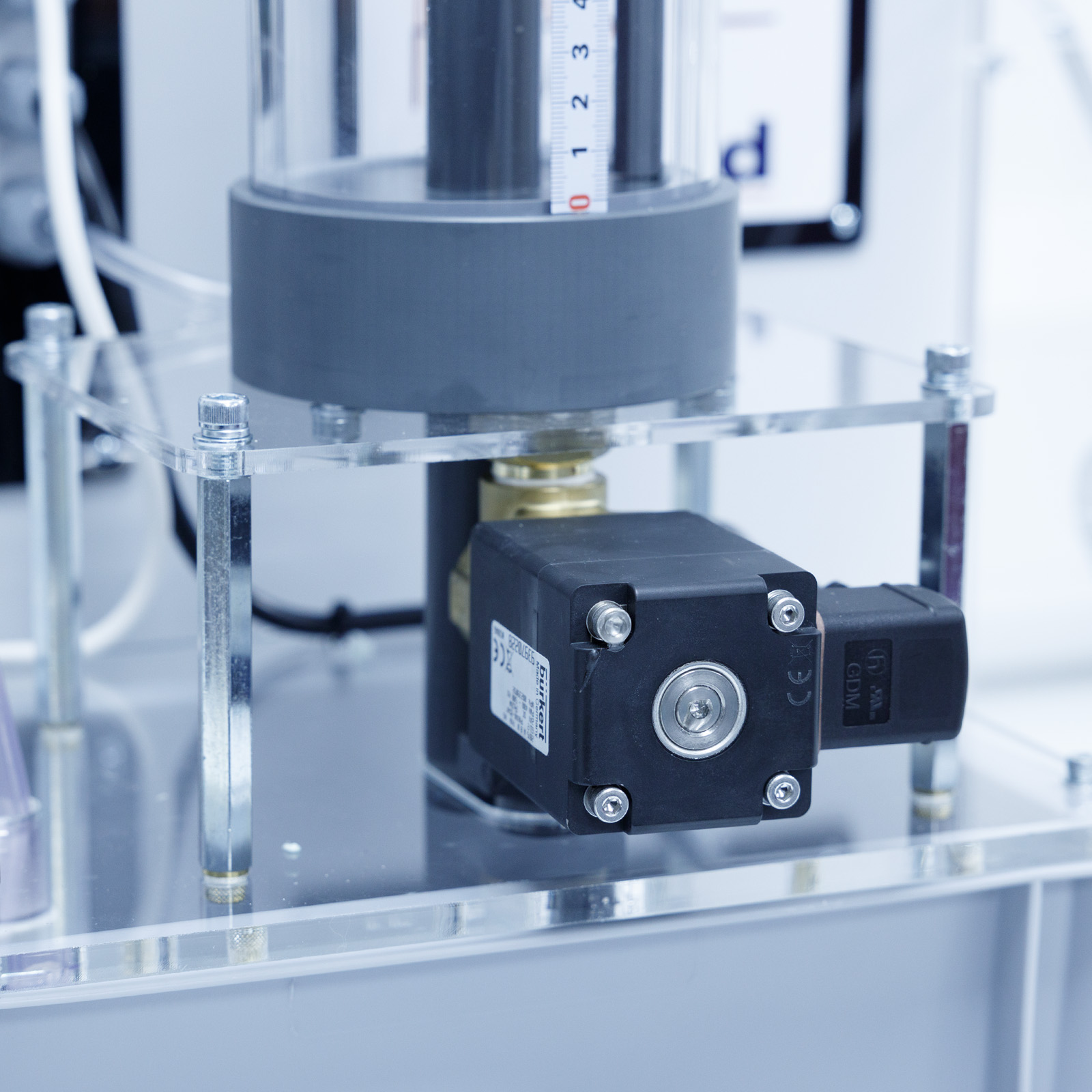

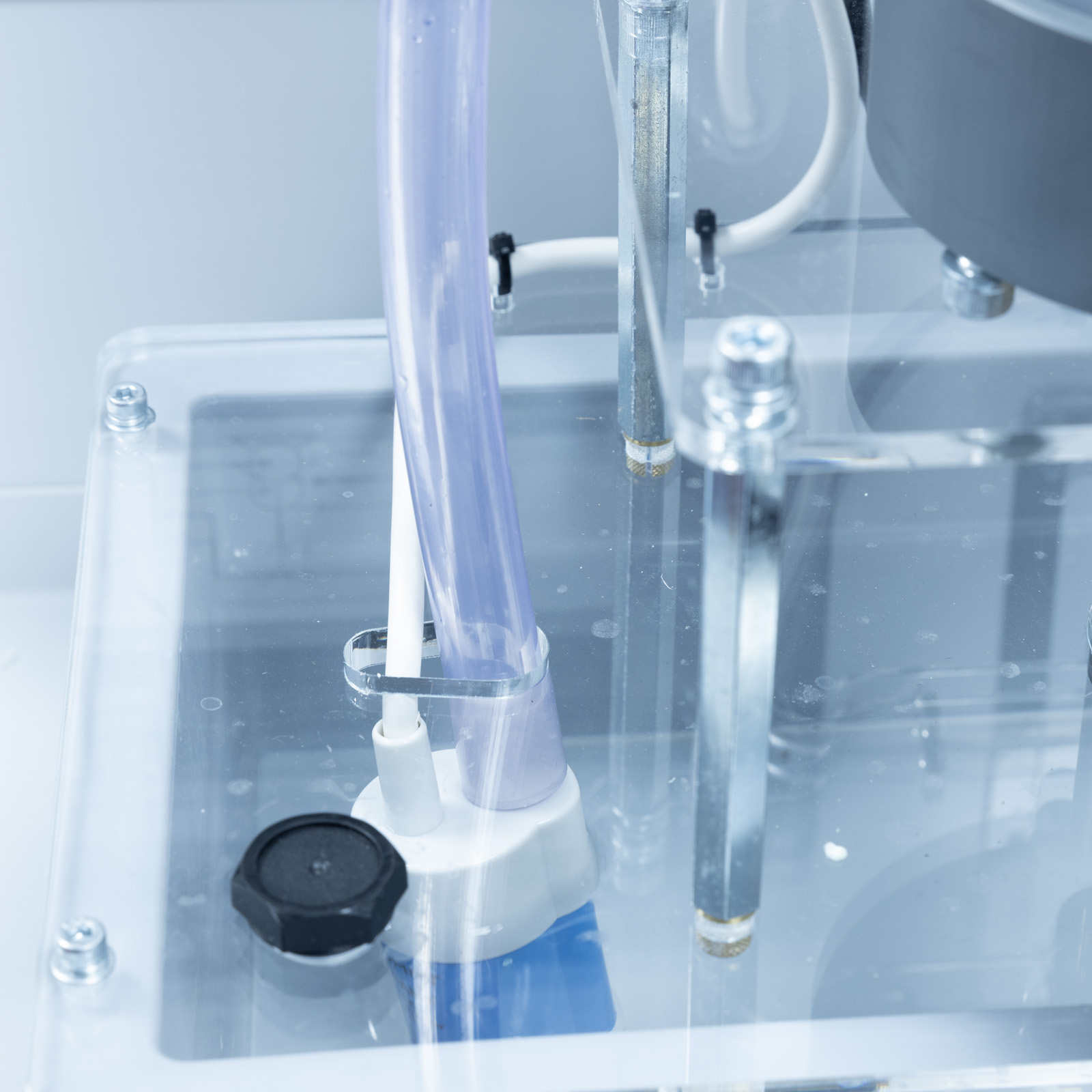

The Level system consists of a reservoir water tank, a variable speed pump, a pressure-based level sensor, and a clear process vessel with a scale. A proportional valve provides the process vessel drain.

An overflow pipe in the process vessel prevents it from being overfilled and the system allows students to adjust the pump speed and valve opening.

Technical Specifications

PCT60 Level Control Process

A level control process trainer, comprising:

- 4mm x 1.5mm wall clear PVC tube (300mm)

- 24V PSU 60w 2.5a

- Level process control system assembly

- Barley pot for process control

- USB lead

- Manual Control software allowing low level access to the Drive and Load in each system allowing calibration of sensors and drive systems

- On/Off Control software allowing control of each system with a simple On/Off algorithm, view software based oscillations and to explore the effects of hysteresis

- PID Control software allowing uses to enter values for Kp, Ki, Kd and see how the system reacts to in-putted values

Features & Benefits

- USB, Wi-Fi, Bluetooth and LAN communications supplied as standard

- Supplied software includes Basic control, On/Off control and PID control

- Software dynamically displays Set point, Process value and Kp, Ki, and Kd

- MATLAB and LabVIEW compatible

- Supplied with full set of manuals and teaching material

- Understanding how to control driving devices

- Understanding the sensors

- On/Off control systems

- System time constant

- P controller

- PI controller

- PID controller

- Zeigler Nichols algorithm

- Integral wind up

- Derivative filter

- Manual tuning

- Interfacing with MATLAB/LabVIEW

PCT60 Level Control Process

A level control process trainer, comprising:

- 4mm x 1.5mm wall clear PVC tube (300mm)

- 24V PSU 60w 2.5a

- Level process control system assembly

- Barley pot for process control

- USB lead

- Manual Control software allowing low level access to the Drive and Load in each system allowing calibration of sensors and drive systems

- On/Off Control software allowing control of each system with a simple On/Off algorithm, view software based oscillations and to explore the effects of hysteresis

- PID Control software allowing uses to enter values for Kp, Ki, Kd and see how the system reacts to in-putted values

Mains electrical supply: 110-230V, AC 50-60 Hz.

PC and Display meeting the following minimum specification:

– Processor: 1Ghz or faster

– RAM: 1Gb or more

– HDD Space: 1Gb

– OS: 32 or 64bit Windows 7, 8, 10 or 11

– Display: Recommended minimum (1920 by 1080) full HD

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.095m³

Gross Weight: 12.1Kg

Length: 0.64m

Width: 0.45m

Height: 0.33m

- PCT60-UK: Level Process Control System

- PCT60-EU: Level Process Control System

- PCT60-USA: Level Process Control System