HT15X – Extended Surface Heat Exchanger

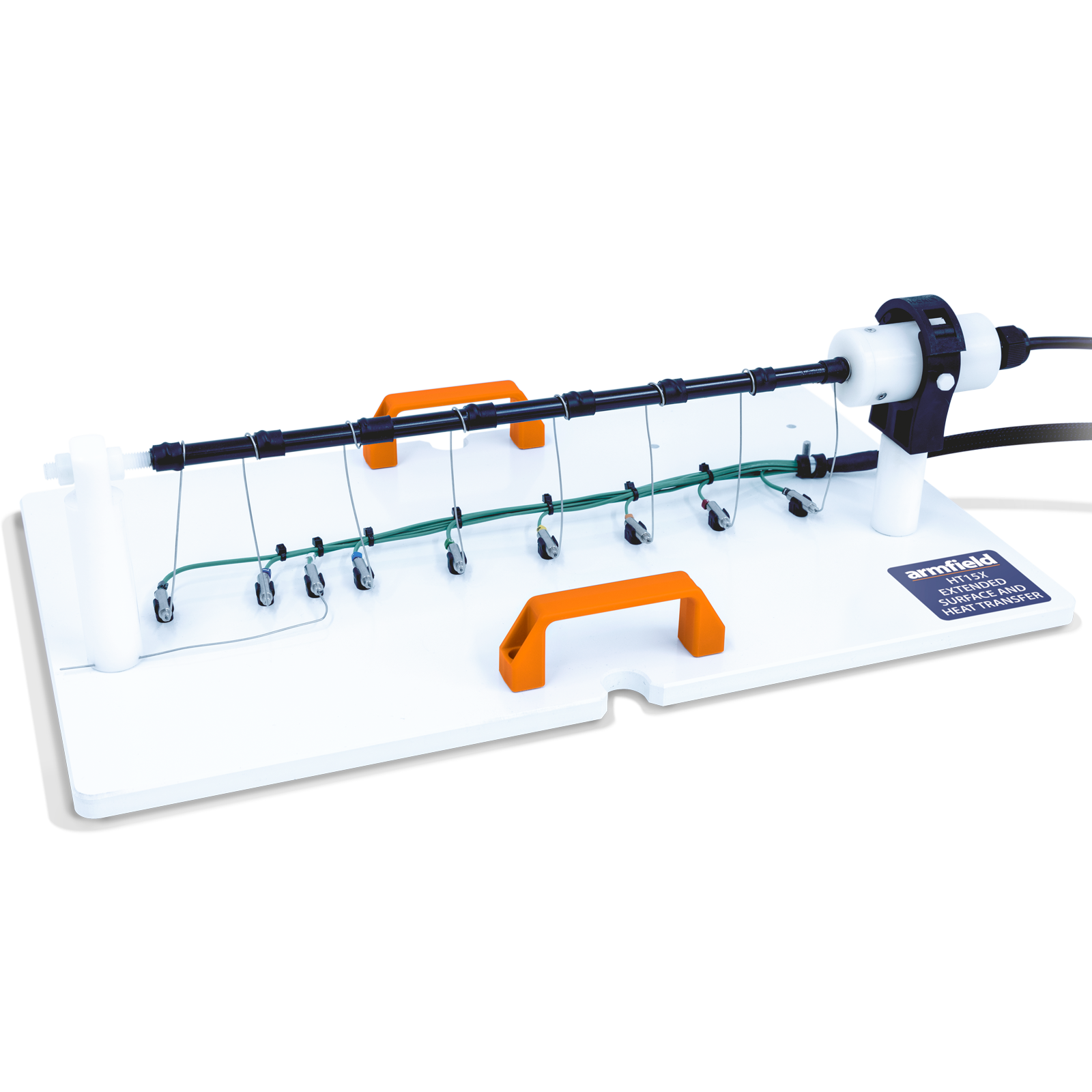

A long horizontal rod, which is heated at one end, provides an extended surface (pin) for heat transfer measurements.

Thermocouples at regular intervals along the rod allow the surface temperature profile to be measured.

Description

The rod is manufactured from brass and coated with a heat-resistant matte black paint, which provides a consistent emissivity close to unity. It is mounted horizontally with support at both ends positioned to avoid the influence of adjacent surfaces.

It is heated by an electric heating element, which operates at low voltage for increased operator safety and is protected by a thermostat to prevent damage from overheating. Eight thermocouples are attached to the surface of the rod at equal intervals of 50mm, giving an overall instrumented length of 350mm.

Another thermocouple is mounted adjacent to the heated rod to measure the ambient air temperature.

The heated end of the rod is mounted coaxially inside a plastic housing, which provides an air gap and insulates the area occupied by the heater, in order to minimise heat loss and prevent burns to the operator.

The measurements obtained can be compared with a theoretical analysis of thermal conduction along the bar combined with heat loss (heat transferred) to the surroundings by the modes of free convection and radiation simultaneously.

Technical Specifications

A small-scale accessory designed to demonstrate the temperature profiles and heat transfer characteristics for an extended surface when heat flows along the rod by conduction and heat is lost along the rod by combined convection and radiation to the surroundings.

- The extended surface comprises a 10mm-diameter long solid brass rod mounted horizontally and heated at one end with a 20W, 24V DC heater

- Eight thermocouples mounted at 50mm intervals along the rod provide the temperature distribution

- PID controller allowing for a rapid heat temperature set-point achievement and controlled within 0.1°C

- The temperature of the ambient air is measured by an independent thermocouple

- The accessory is mounted on a PVC baseplate, which is designed to sit on and connect to the HT10X Heat Transfer Service Unit without the need for tools

- A comprehensive instruction manual is included

Features & Benefits

- Measuring the temperature distribution along an extended surface (pin) and comparing the result with a theoretical analysis

- Calculating the heat transfer from an extended surface resulting from the combined modes of free convection and radiation heat transfer and comparing the result with a theoretical analysis

- Determining the constant of proportionality of the rod material (Thermal Conductivity K)

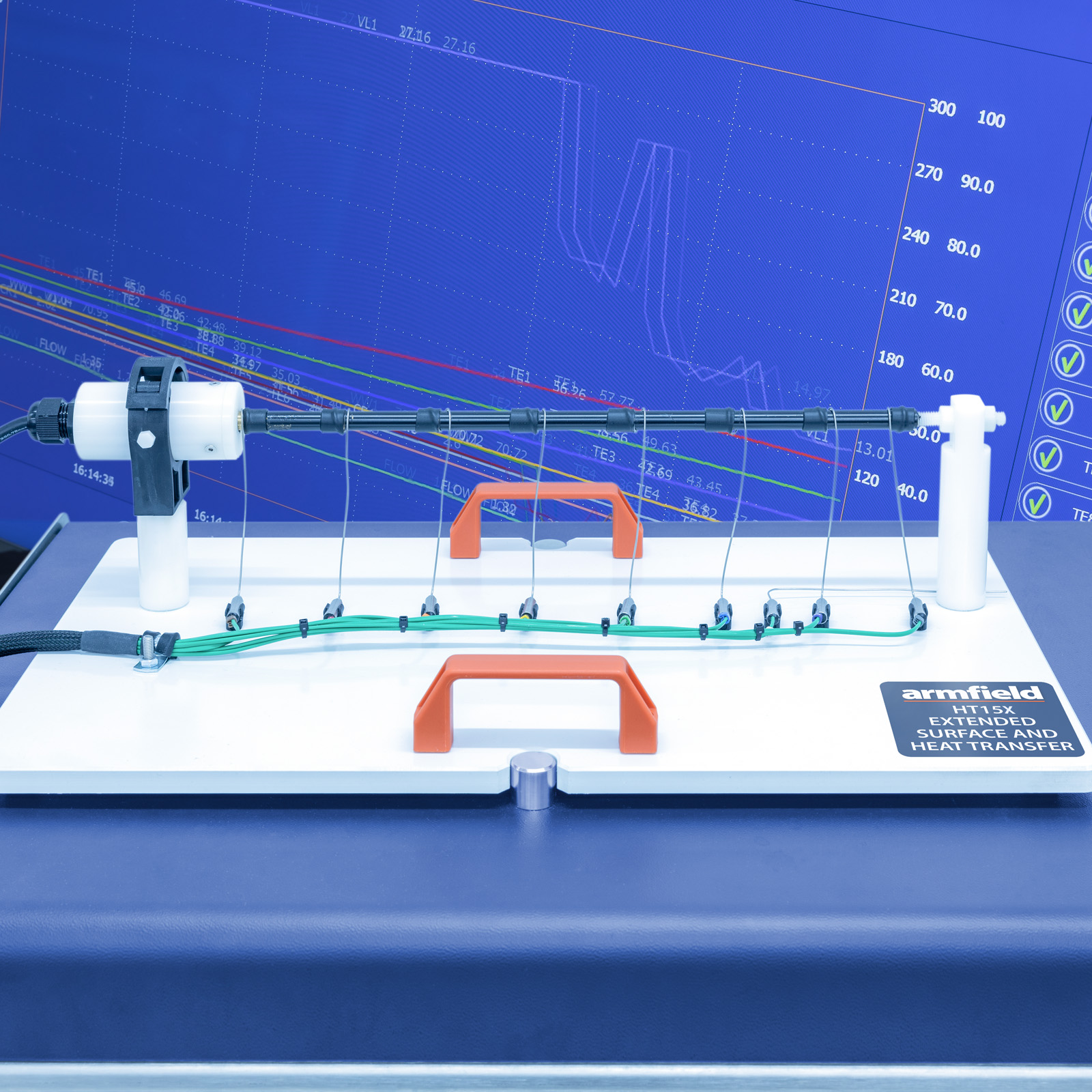

A full armBus educational software suite is provided with the HT10X for all the Armfield heat transfer accessories.

Individual experiment interfaces and displayed data types vary to match selected experiment accessories, common examples are listed below:

- Temperatures and other signals such as flow rates, heater voltage and current are displayed on a diagrammatic representation of the equipment

- Control outputs are operated by a control slider or typing in a value between 0 and 100%. Sensor values are read directly in engineering units

- PID automatic control option is available, permitting the temperature set-point to be achieved quickly and precisely, coping with disturbance rejection

- A maintenance screen allows for PID parameter adjustment and thermocouple calibration

- Data from the sensors are logged into a spreadsheet format, with operator control over the sampling intervals (or ‘single-shot’)

- Sophisticated graph-plotting facilities are provided, including plotting of both measured and calculated values

- Graphs update in real-time as the samples are being taken

- Processing of measured values to obtain calculated values is linked to the questions and answers to ensure student understanding

- Experiment data samples are saved, or exported in Microsoft Excel format

- Real-time sensor data is displayed independently from the data logging. It is possible to check the recent history graphical display to inspect the temperature stability prior to taking a sample

- HT10X Computer-Controlled Heat Transfer Service Unit

- HT10X Computer-Controlled Heat Transfer Service Unit

(All electrical requirements are obtained from the service unit)

Packed and crated shipping specifications

Volume: 0.05m3

Gross weight: 5kg

Length: 0.50m

Width: 0.15m

Height: 0.15m

HT15X