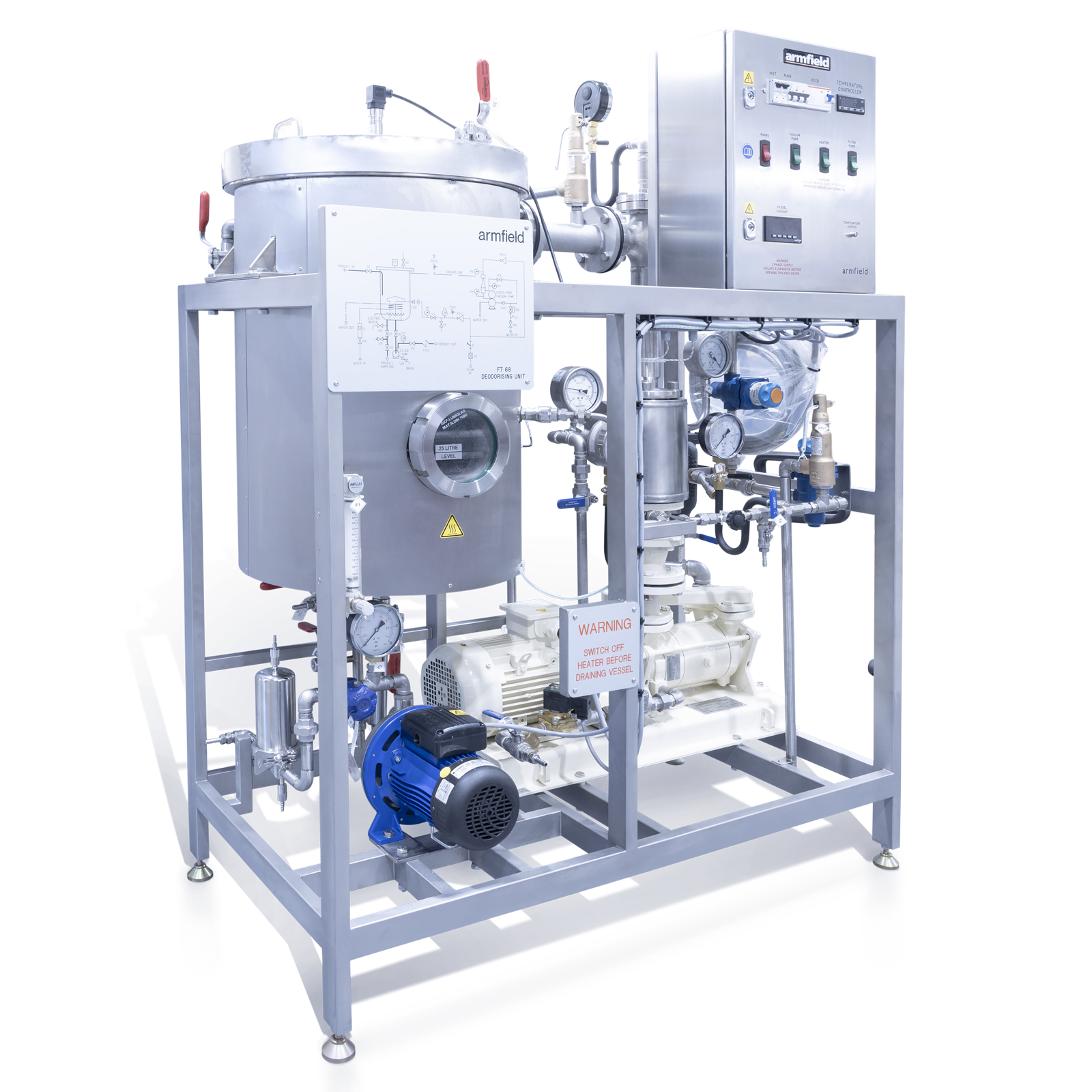

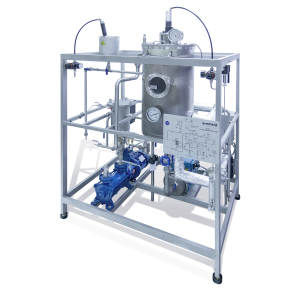

FT68 Deodorising Unit

A vacuum steam distillation unit, suitable for demonstrating the removal of free fatty acids from edible oils.

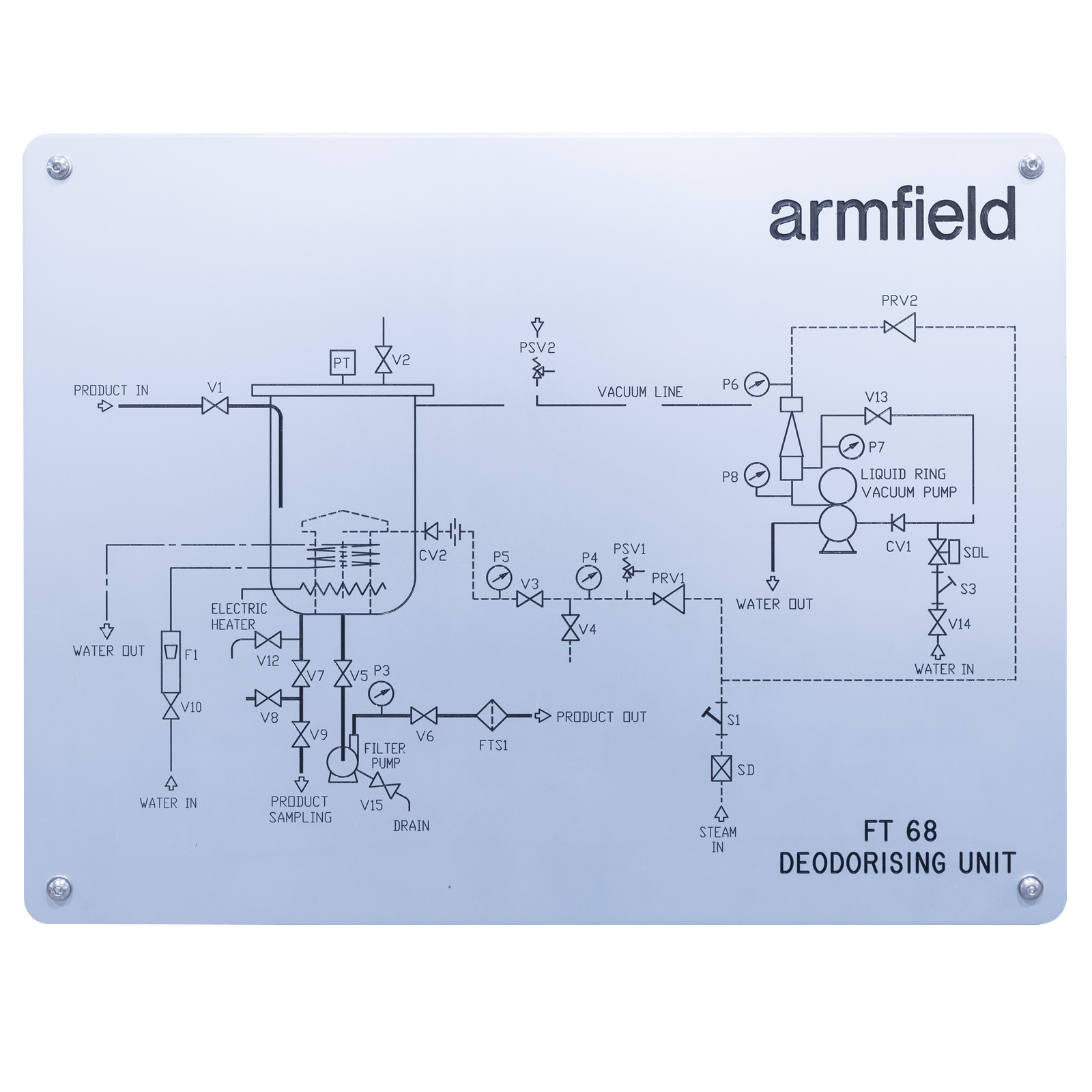

The deodorising process vessel has a batch size of 25 litres and is mounted in a floor-standing stainless steel framework, which also houses the highvacuum equipment, control console, discharge pump and polishing filter.

Description

The deodorising process vessel has a batch size of 25 litres and is mounted in a floor-standing stainless steel framework, which also houses the high vacuum equipment, control console, discharge pump and polishing filter.

A 3.0kW electrical heating element is incorporated in the vessel to heat the oil to temperatures of up to 250°C. The vessel also contains a special steam distribution tube, which enables the thorough steam/oil mixing required.

Operating temperature is selected on an electronic temperature controller and is recorded on a continuous chart recorder both of which are housed in the control console.

An immersed cooling water coil provides a means of reducing the oil temperature on completion of the process.

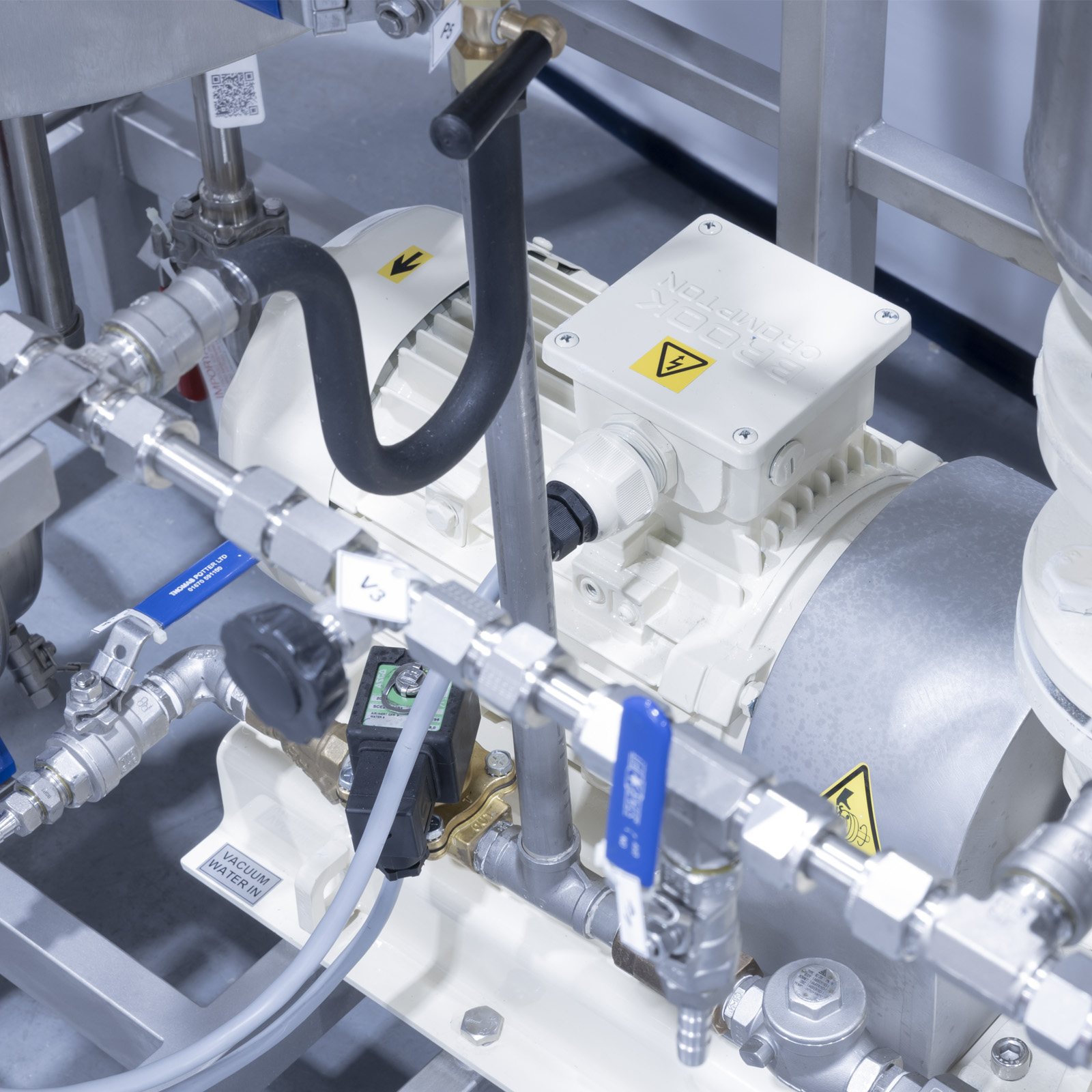

A multi-stage vacuum system incorporates a steam ejector, condenser and liquid ring vacuum pump to achieve vacuum levels less than 5mm Hg (ABS), 6.5 mbar in the process vessel. Accurate indication of the vessel pressure is achieved using an electronic pressure transmitter, which indicates the vacuum level on a digital display in the control panel.

Fatty acids and other compounds carried over with the steam are condensed in a spray type condenser and they pass to drain with the sealing water of the liquid ring vacuum pump.

On completion of the deodorising process, the oil is pumped out of the vessel through a ‘polishing’ filter, which removes any remaining particles in the finished oil.

The deodoriser vessel is designed in accordance with the BS 5500 code for pressure vessels.

All materials in contact with process fluid are of stainless steel.

Technical Specifications

Deodoriser vessel

Overall volume: 60 litres

Working volume: 25 litres

Product temperature

Maximum: 250°C

Working pressure: Less than 5.0mm Hg (ABS), 6.5mbar

Heating element: 3.0kW

Cooling coil area: 0.1m2

Direct steam

Flow rate: 0-1kg/h

Vacuum system

Ejector steam: 4.1 bar, 4kg/h

Vacuum pump

Type: Liquid Ring

Number of stages: Two

Motor power: 2.0kW

Sealant: Water

Sealant flow rate: 10.0lpm

Polishing filter

Type replaceable: cartridge

Filter element size: 6.0 micro

Features & Benefits

- Only 25 litres of oil to be processed

- Safe and easy to use

- Economical

- Stainless steel pressure vessel

- Comprehensive control panel and instructions

- Liquid ring vacum pump

- Steam ejector

- Condenser

- Electrical heating of the oil

- Vacuum in the processing vessel down to 6.5 mbar absolute

- Internal cooling coil

- Extraction pump

- Polishing filter

- Temperatures to 250°C

- Internal steam sparge

Heating, deodorising, cooling, filtering

Removal of free fatty acid, ketone and acetaldehyde traces in edible oils is an important stage in the refining procedure as it is these compounds that impart an unpleasant odour to the oils. The method used for this removal is vacuum steam distillation under very high temperature and vacuum conditions.

The Armfield Deodoriser achieves this using a unique steam mixing/contactor and multi-stage vacuum system.

Deodorising:

The oil is heated under vacuum using direct steam to provide the agitation for good heat transfer. When the desired temperature and pressure are achieved, the direct steam injection is adjusted to impart a high degree of turbulence to the oil, which ensures good physical contact of the steam with the oil.

The impurities are carried over in the vapour and condensed in the vacuum condenser, the resulting condensate blending with the liquid ring vacuum pump sealant to be discharged to drain.

Polishing:

After deodorisation, the oil refining process is complete and the oil can be consumed or used in the manufacture of other products. It must therefore be free of any trace of contaminants and, to achieve this, it is pumped through a fine ‘polishing’ filter, which removes particles down to 6.0 micron giving a bright oil as product.

- Operation of small-scale version of the industrial process

- Determination of optimum process conditions for different oil types

- Effect of variation of process temperature

- Effect of variation of process pressure

- Effect of variation of quantity of direct steam added

- Effect of variation of overall process time

Independent deodorisation tests carried out by: Manchester Metropolitan University, Department of Food and Consumer Technology, using refined and bleached rapeseed oil gave the following analytical results.

Refined bleach oil Deodorised oil

Free fatty acid 0.1% 0.04%

Soap in oil nil nil

Colour 20 Yellow 10 Yellow

0.5 Red 0.4 Red

- Electricity supply: Three phase (see ordering codes)

- Water supply: For cooling and vacuum 20 l/min @ 3 bar min/5 bar max pressure @15°C

- Steam supply: 4 bar minimum; 10kg/h

Packed and crated shipping specifications

Volume: 2.5m³

Gross weight: 500Kg

Length: 1.28m

Width: 0.68m

Height: 1.58m

FT68-C: 415V/3ph/50Hz, (11kW)

FT68-D: 208V/3ph/60Hz, (7kW)

FT68-E: 380V/3ph/50Hz, (11kW)

FT68-F: 220V/3ph/60Hz, (7kW)