F1-18 Energy Losses in Pipes

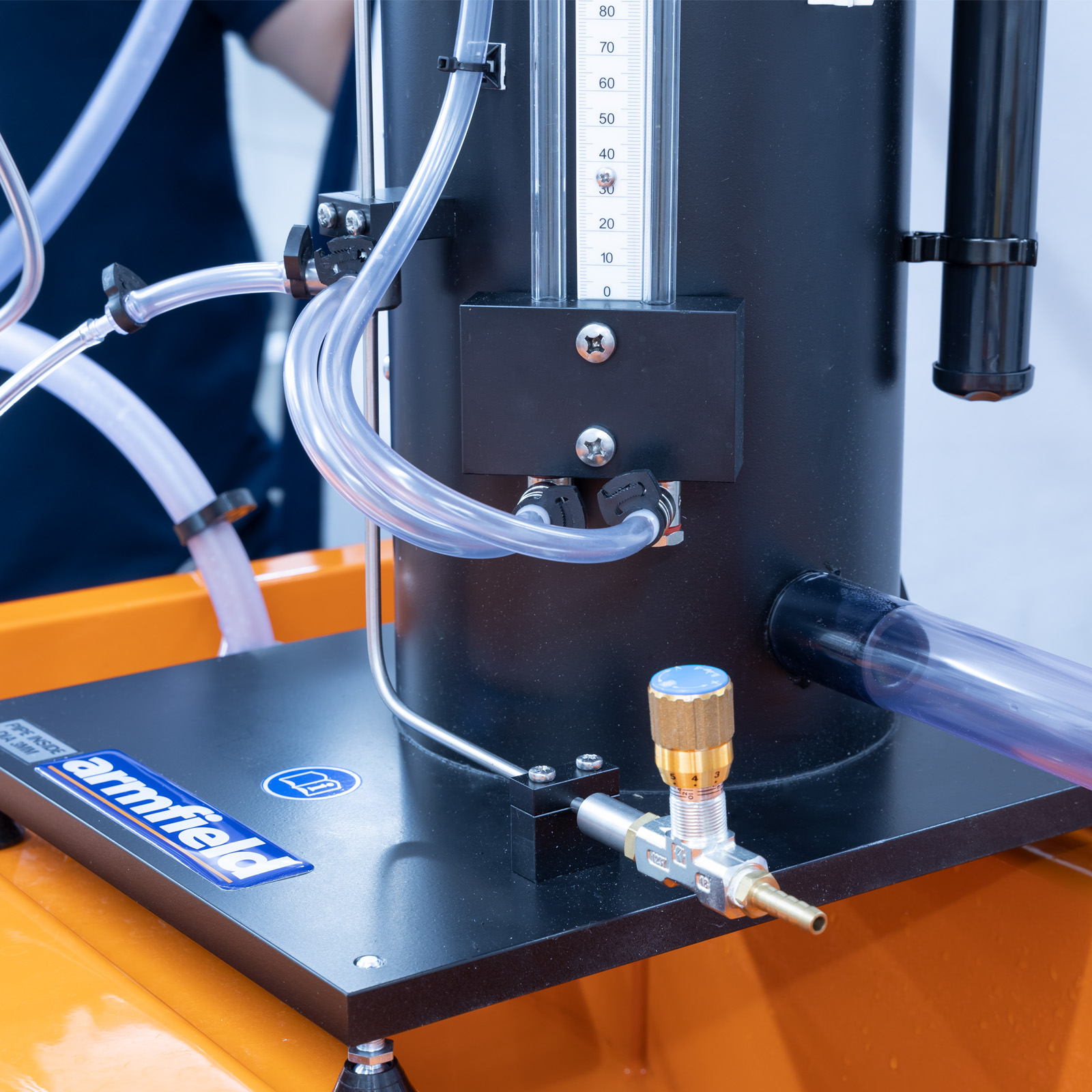

The unit consists of a vertical test pipe on the side of the equipment which can be fed directly from the hydraulics bench supply or, alternatively, from the integral constant head tank above.

For large pressure differentials a digital handheld manometer is used.

Description

The Energy Losses in Pipes accessory consists of a test pipe, orientated vertically on the side of the equipment, which may be fed directly from the hydraulics bench supply or, alternatively, from the integral constant head tank.

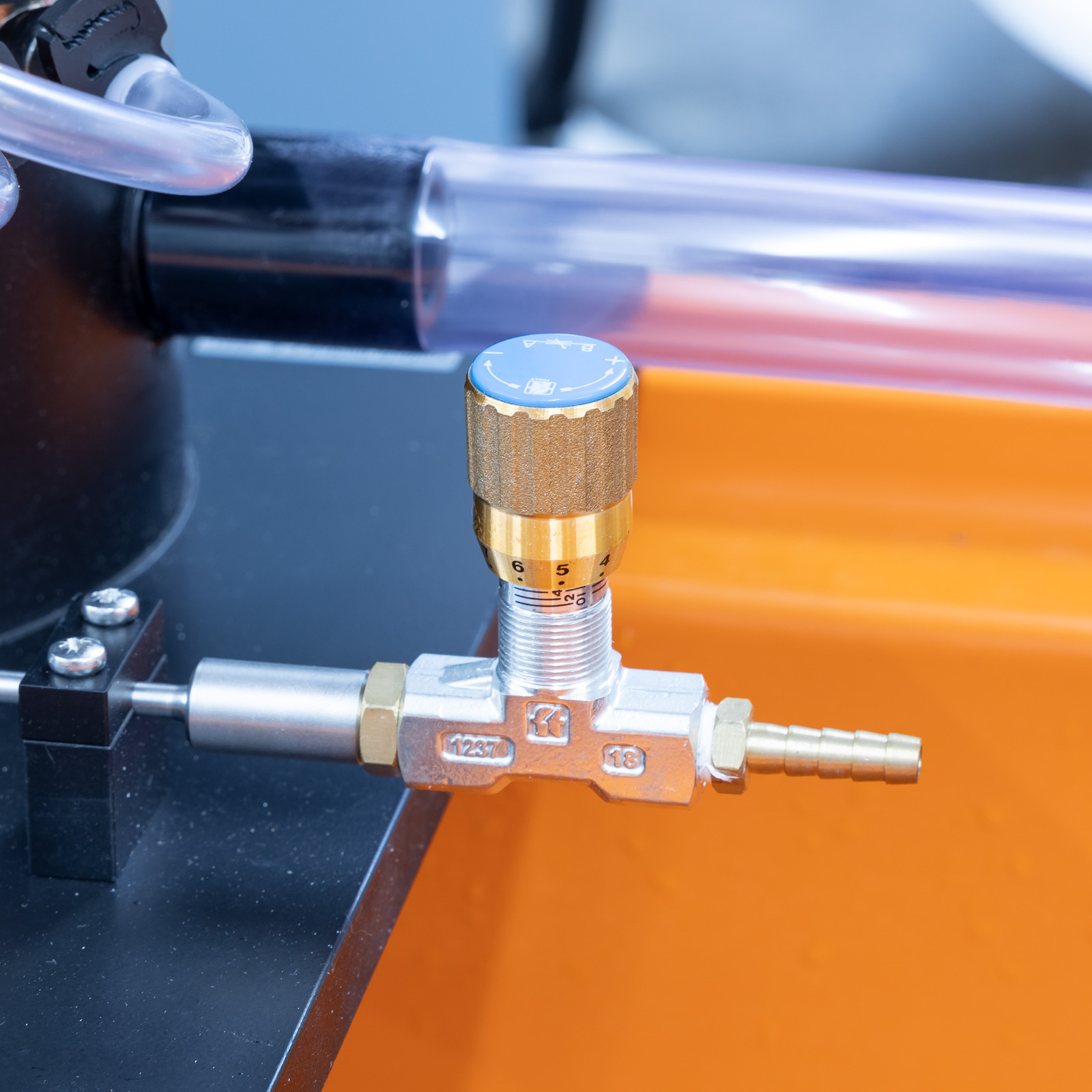

These sources provide high or low flow rates which can be controlled by a valve at the discharge end of the test pipe. Head loss between two tapping points in the test pipe is measured using two manometers, digital hand held manometer for large pressure differentials and a pressurised water manometer for small pressure differentials.

Adjustable feet permit levelling.

Technical Specifications

Diameter of test pipe: 3.0mm

Length of test pipe: 760mm

Distance between pressure tapping points: 500mm

Range of digital manometer: 103 kPa

Range of water manometer: 500mm

Measuring cylinder capacity: 1000mm

Requires Hydraulics Bench Service unit F1-10/F1-10-2

Features & Benefits

- To investigate the head loss due to friction in the flow of water through a pipe and to determine the associated friction factor over a range of flow rates in laminar flow

- To investigate the head loss due to friction in the flow of water through a pipe and to determine the associated friction factor over a range of flow rates in turbulent flow

- Determining the critical Reynolds number

- Vertical test pipe with pressure tapping’s at entry and exit

- Feed either direct from Hydraulics Bench or from constant head tank

- Water and digital manometers supplied as standard

- Quick-release fitting for easy connection to Hydraulics Bench

- Educational software supplied as standard with F1-10 Hydraulics bench

F1-10 Hydraulics Bench

Length: 0.33m

Width: 0.28m

Height: 0.75m

F1-18