EF-3.1 – Mechanisms – Cam, Crank and Toggle

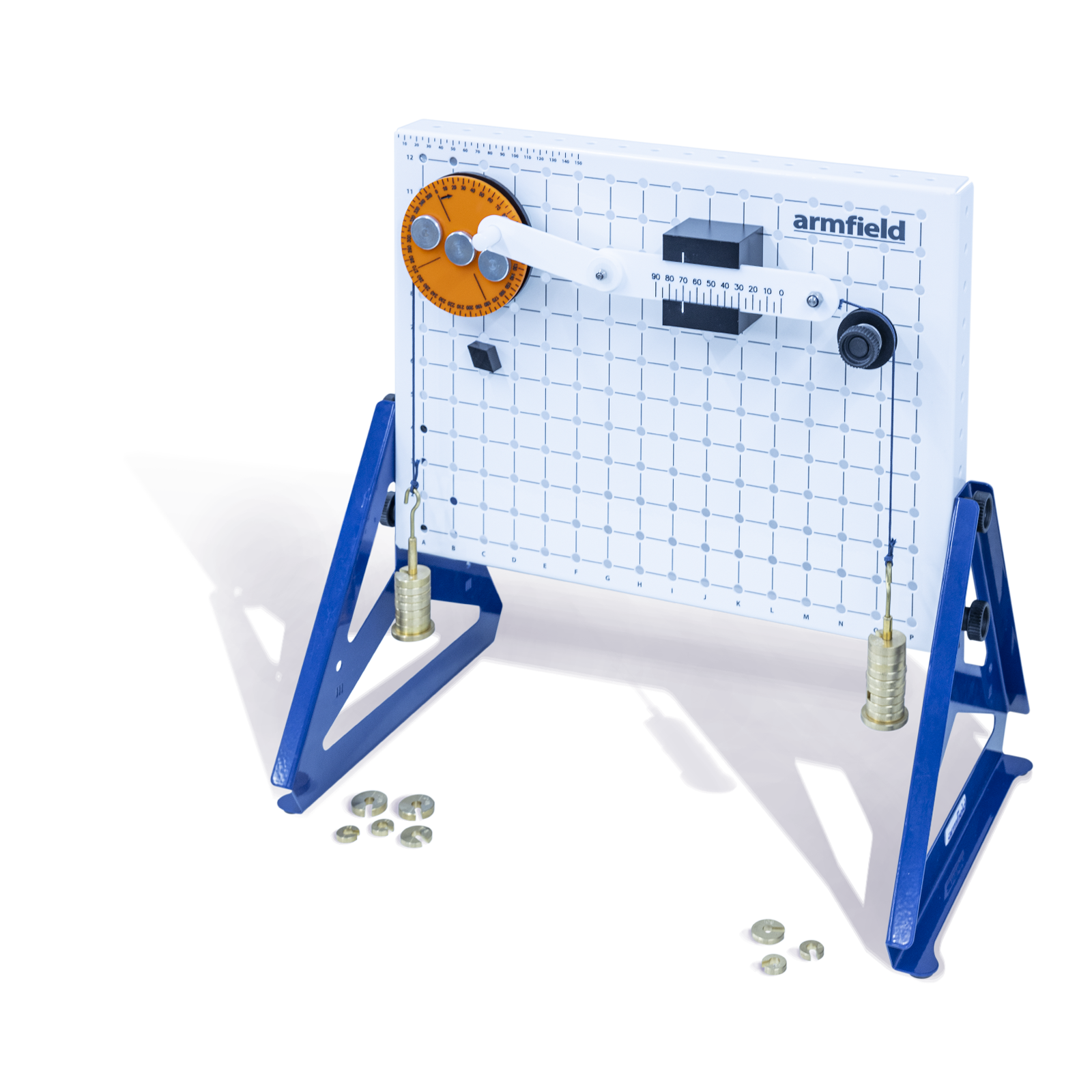

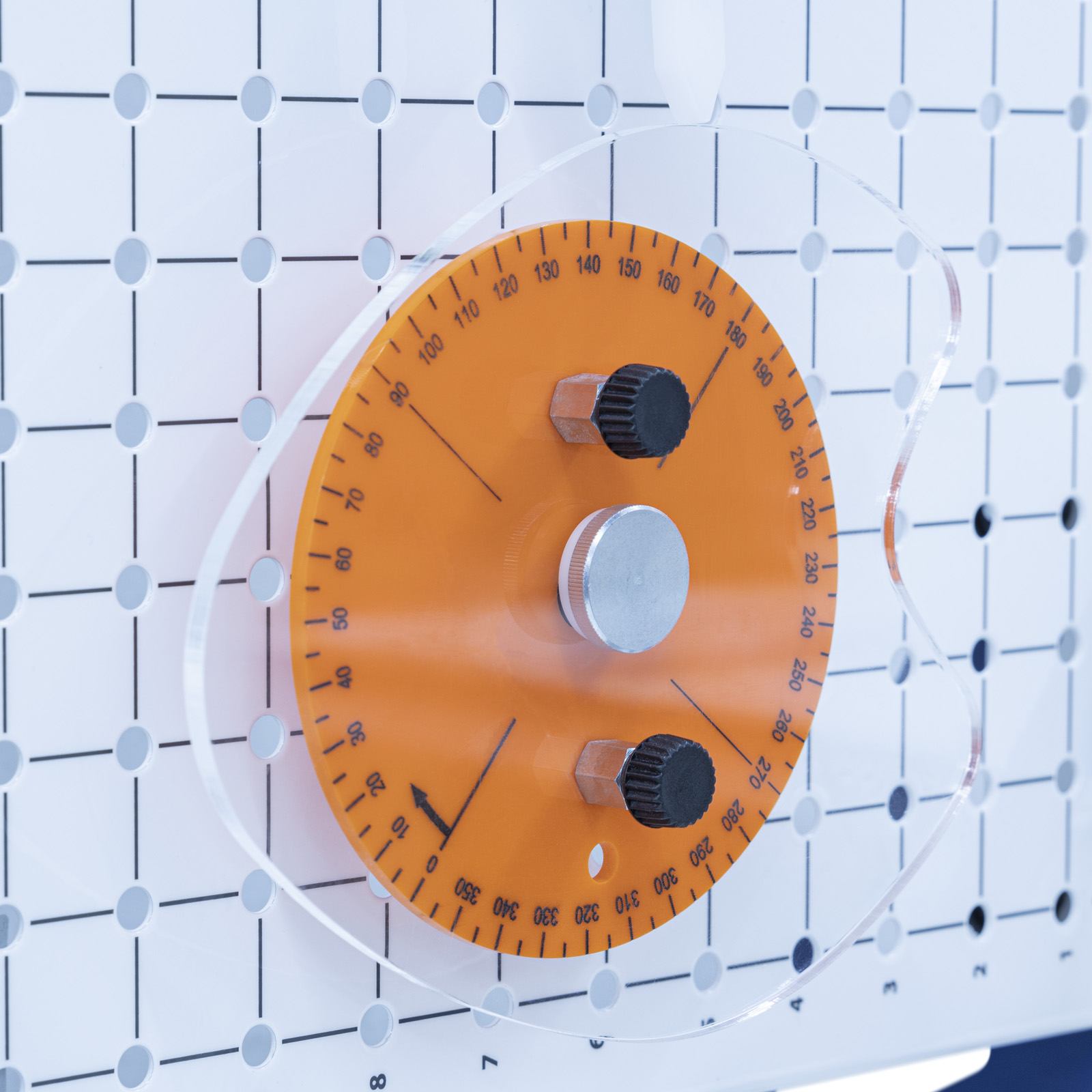

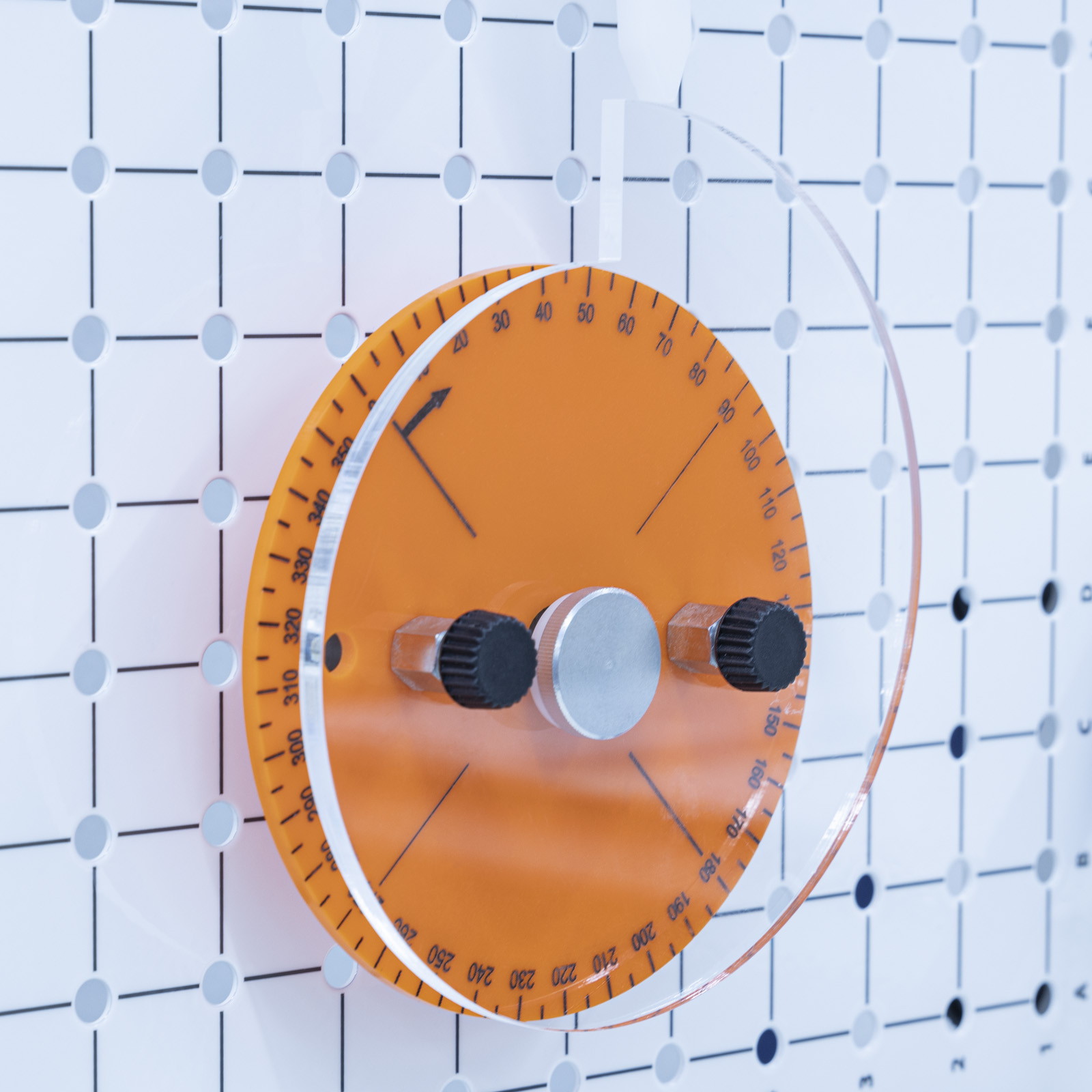

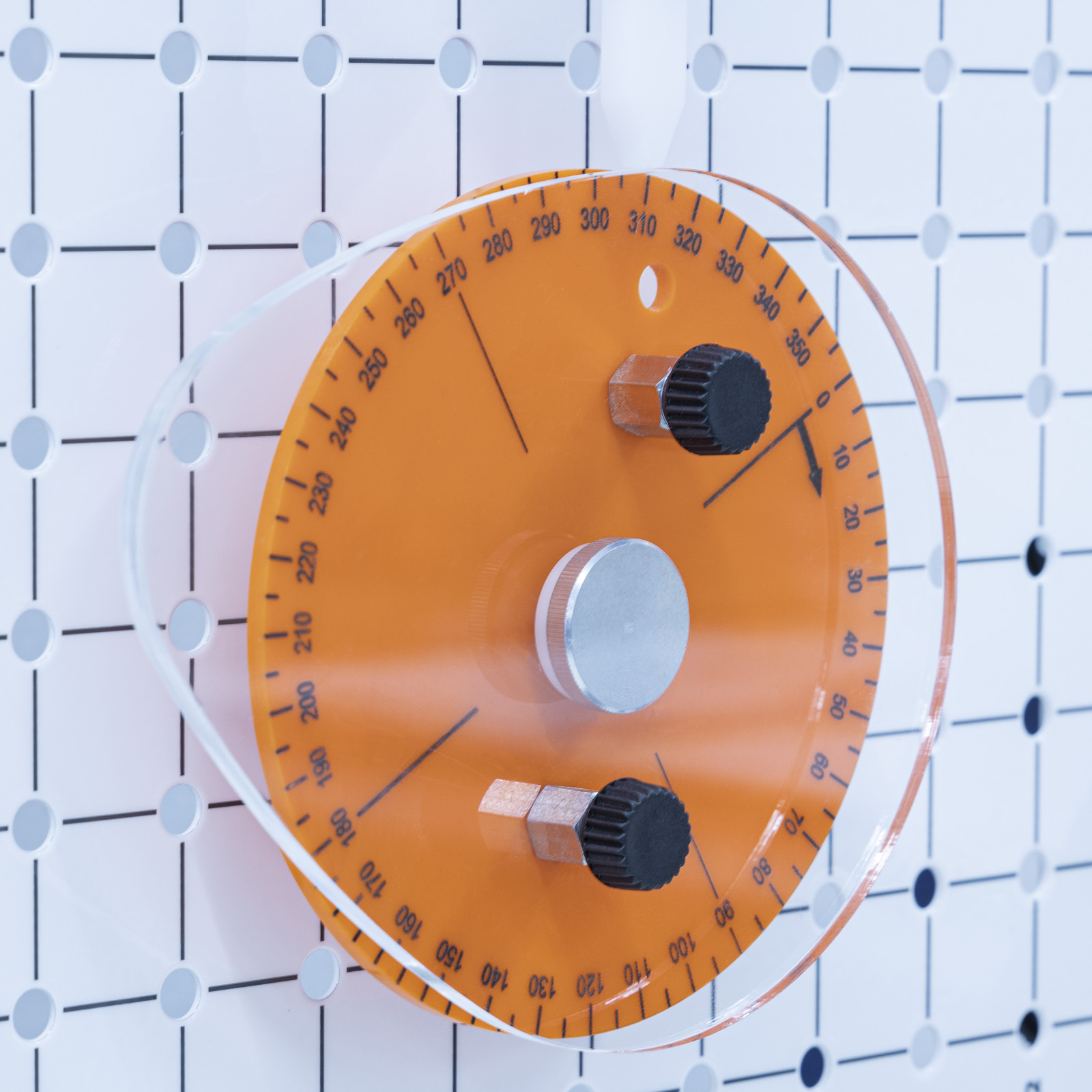

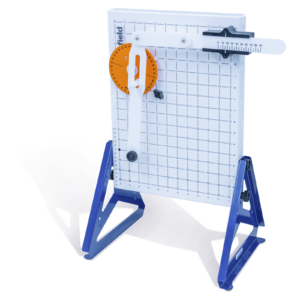

The EF-3.1 Cam, Crank and Toggle experiments kit provides students with an introduction to cams and rollers and additionally crank motion and toggle.

Description

The Engineering Fundamentals range enables students to gain an understanding of the principles of engineering by the process of learning via experimentation.

The EF-3.1 Cam, Crank and Toggle experiments kit provides students with an introduction to cams and rollers and additionally crank motion and toggle.

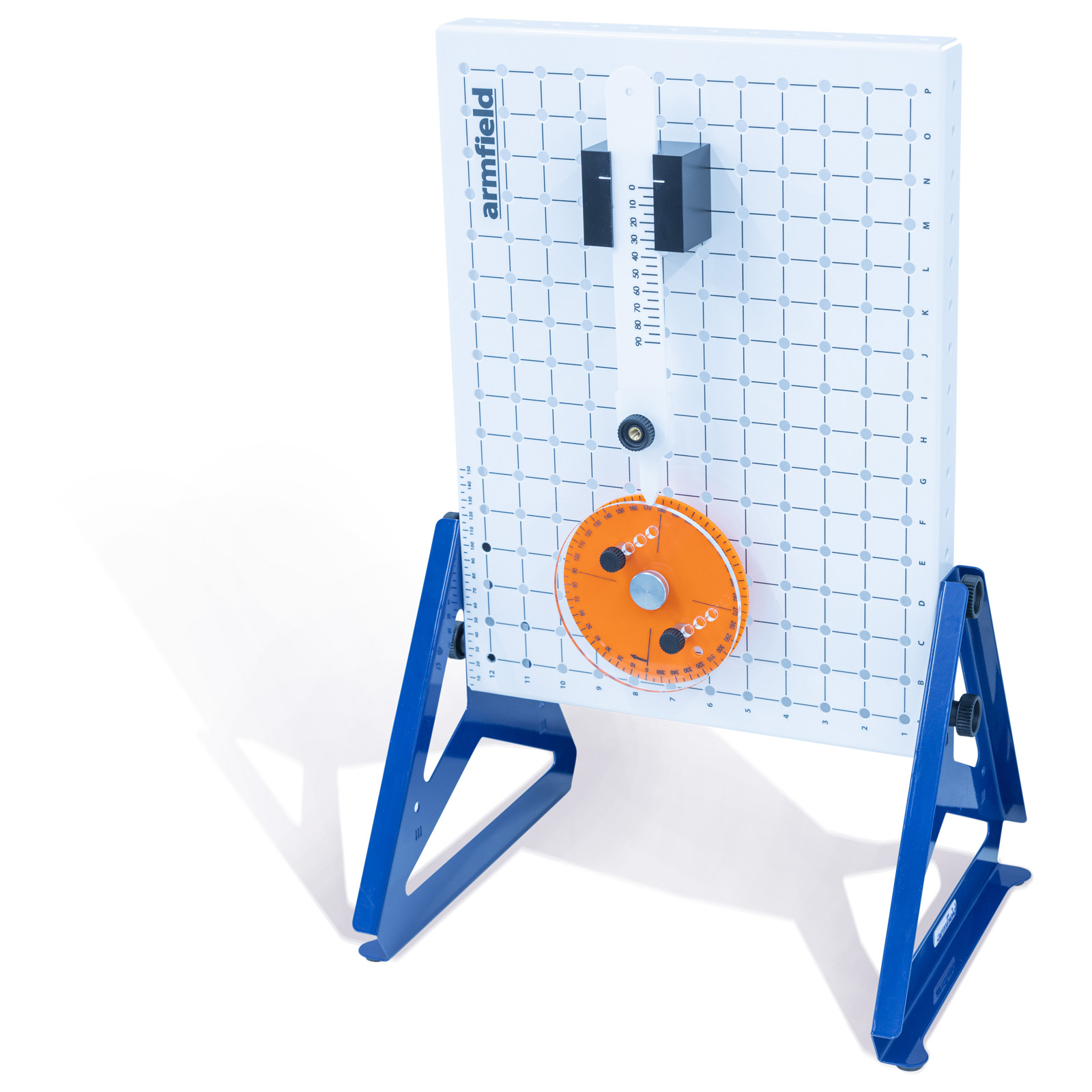

The kit is designed to help students understand how cams are used, to show how the rotational motion of a cam is transmitted to the linear motion of a follower and how different shapes of cam can be used to achieve varying magnitude and duration of linear motion.

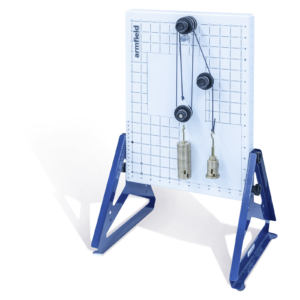

Similar to cams, a crank mechanism can transform rotational motion into linear motion although unlike cams, cranks can also work in the opposite direction, transferring linear motion into rotational motion.

Technical Specifications

Features & Benefits

Features

- Neatly presented in an easily identifiable and durable storage tray

- Trays have clear lids making it easy to see their contents

- Pictorial tray contents list to identify missing components easily

- Accompanied by a detailed manual with various practical exercises

- Clear and concise assembly instructions for each experiment

- Multiple experiments per kit

- Toolless assembly

Benefits

- Hands-on understanding from lessons

- Improve the student’s dexterity by self-assembly with the instructions provided

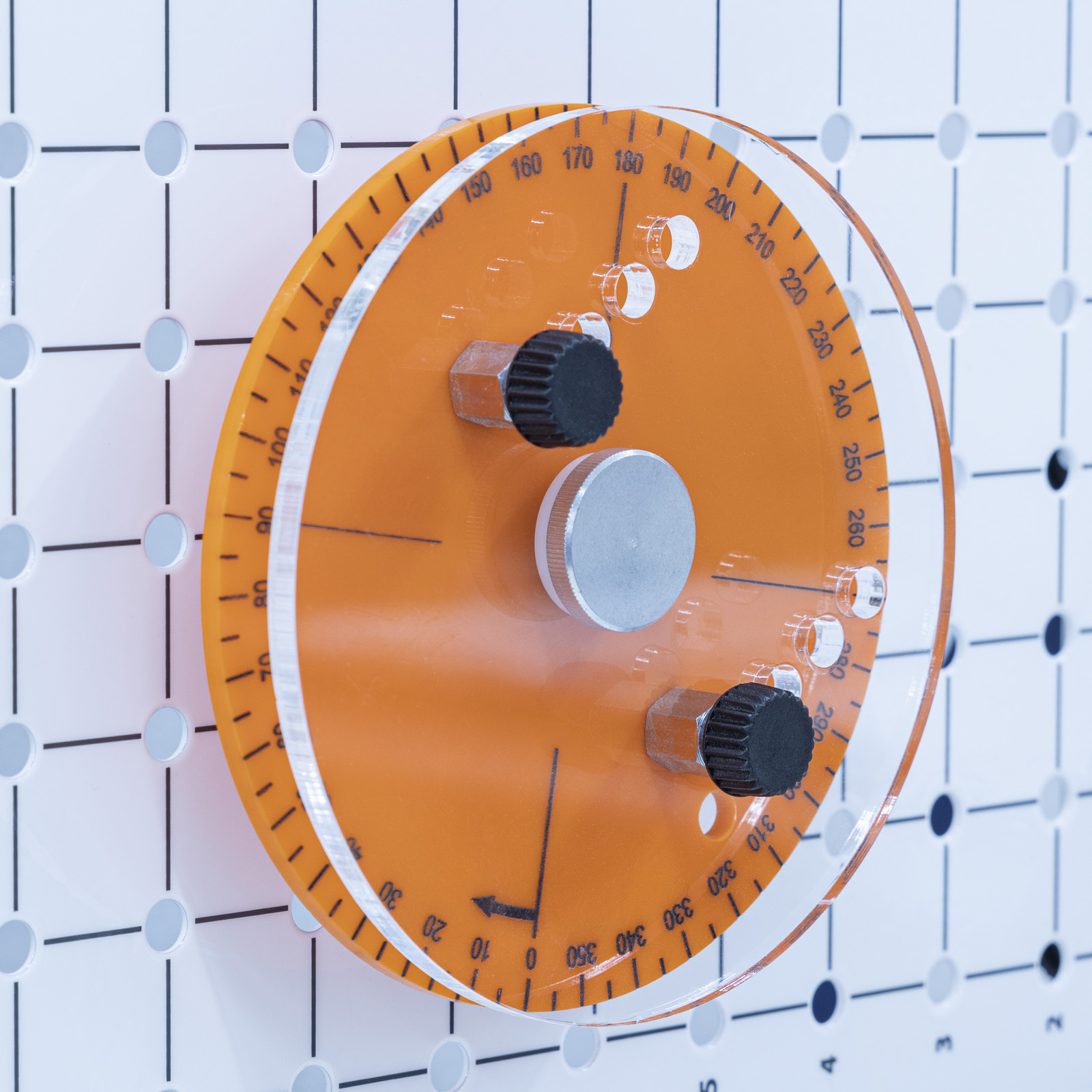

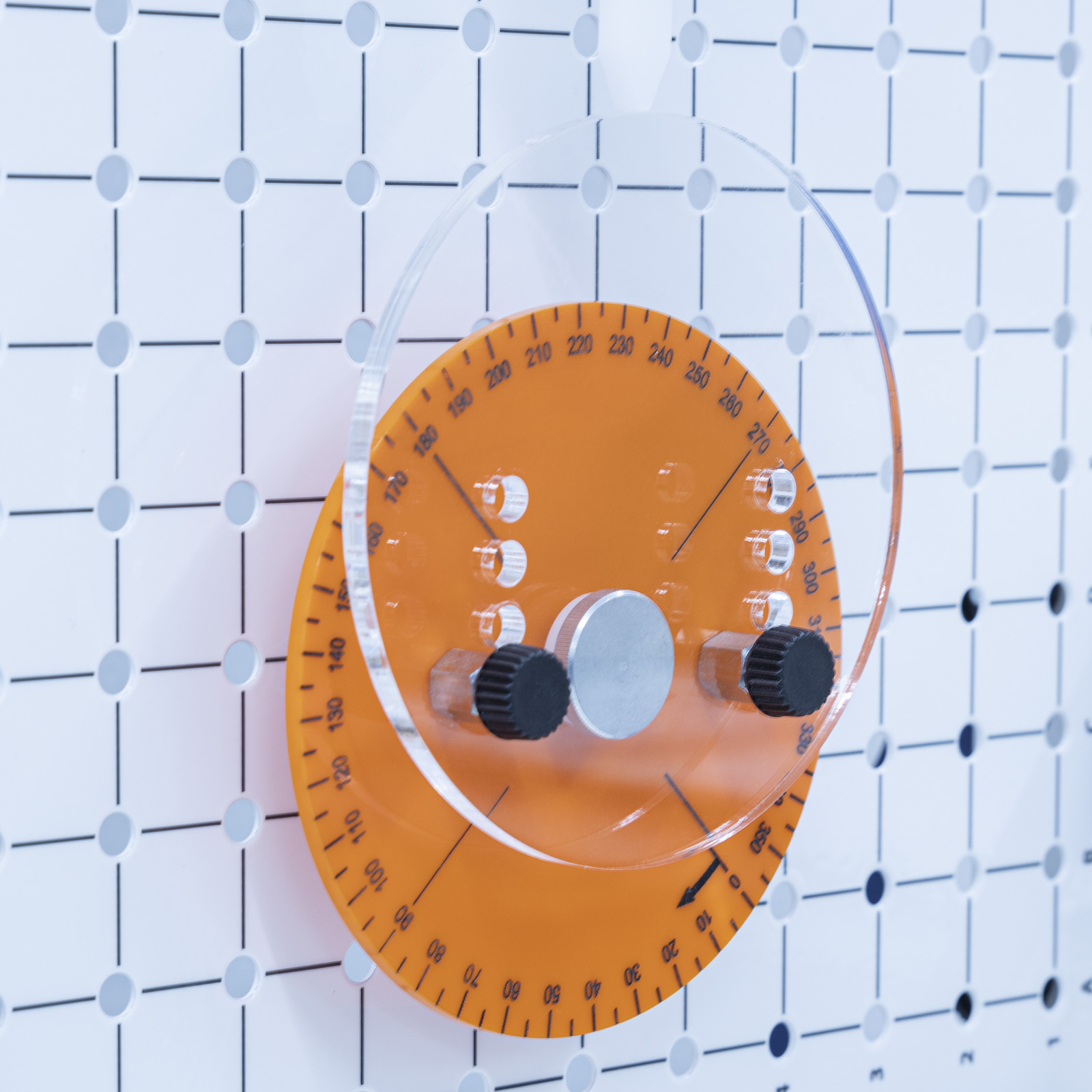

- Relationship between the angular movement of a pear, heart, round and snail cam and the linear movement of the follower

- Characteristics of a pear, heart, round, and snail cam profile

- Show characteristics of a rotating crank assembly by observing the motion of the system and observe the change in turning moment with crank angular position

- Turning moments and forces during crank motion

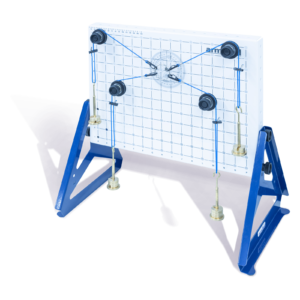

- EF-BU Base Unit

- Statics Experiments

– EF-1.1 Forces

– EF-1.2 Moments

– EF-1.3a Beams

– EF-1.3bTrusses

– EF-1.4 Springs

– EF-1.5 Torsion

- Dynamics Experiments

– EF-2.1 Friction

– EF-2.2 Simple Harmonic Motion

– EF-2.3 Rotational Friction

– EF-2.4 Potential and Kinetic Energy

– EF-2.5 Centrifugal and Centripetal Force

- Mechanisms Experiments

– EF-3.1 Cam, Crank and Toggle

– EF-3.2 Simple Mechanisms

– EF-3.3 Additional Mechanisms

– EF-3.4 Bar Linkages

- Kinematics

– EF-4.1 Pulleys

– EF-4.2 Gears

– EF-4.3 Drive Systems

- Strength of Materials

– EF-5.1 Tensile Tester

- Options

– EF-WS Workstation

- Pear cam

- Heart cam

- Circular cam

- Snail cam

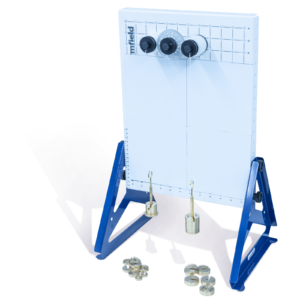

- Knife edge follower

- Flat face follower

- Rotational cam follower

- Offset rotational cam follower

- 2 x 250g Weights set on hanger

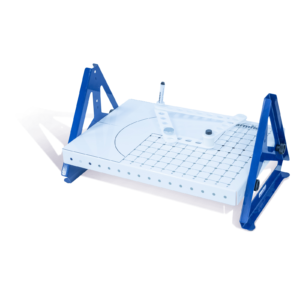

- EF-BU Base Unit

- EF-BU on which to build the experiment from the tray components

- Level and stable work surface to mount the EF-BU upon. The optional EF-WS is ideal for this if no suitable desk or bench is available.

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.02m³ per tray

Gross Weight: 5.0kg per tray

Tray

Length: 0.430m per tray

Width: 0.312m per tray

Height: 0.080m per tray

- EF-3.1 – Cam, Crank and Toggle

- EF-BU – Base Unit

- EF-WS – Workstation (optional)