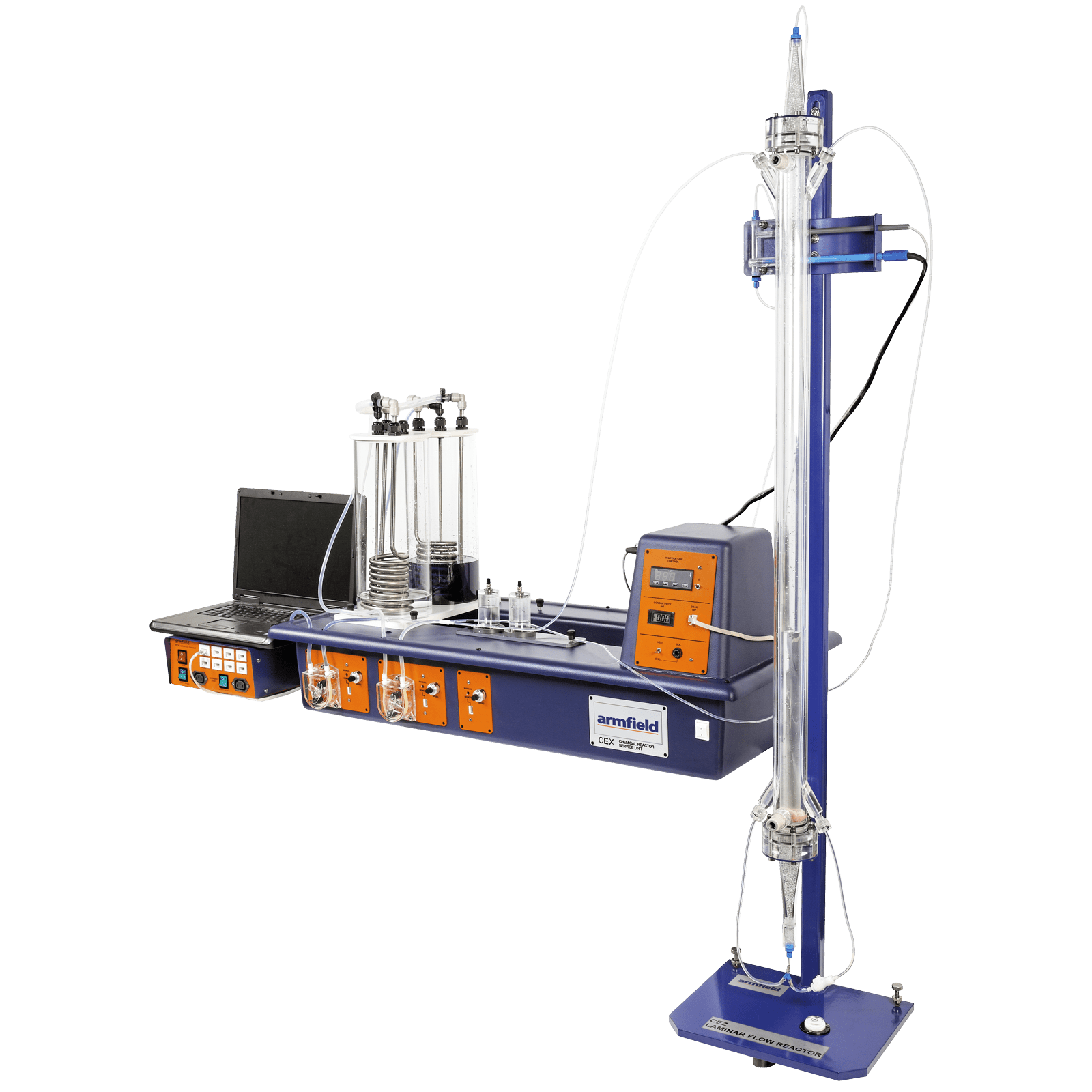

CEZ Laminar flow reactor

The CEZ Laminar flow reactor is a tubular reactor, mounted on a floor standing steel frame with two diffusers packed with glass beads located at the ends.

Description

The CEZ Laminar flow reactor is a tubular reactor made of clear acrylic, mounted on a floor standing steel frame with two diffusers packed with glass beads located at the ends. A static premixer at the bottom of the column provides premixing of the reagents entering the reactor to improve the flow distribution.

It includes two reagent vessels fitted with heat exchangers, mounted on the CEXC plinth. The heat exchangers are used to cool down the reagents before performing the experiment. A cold water jacket keeps the reactor contents at constant temperature in order to maintain the laminar characteristic. A thermostatically controlled supply of chilled water is required for this such as the CW-17.

A clear acrylic sensor block is mounted on the frame for the CEXC conductivity and temperature sensors. The reagents are fed to the reactor by the CEXC peristaltic pumps using PTFE tubing. Pulsation dampers are used to ensure a smooth flow.

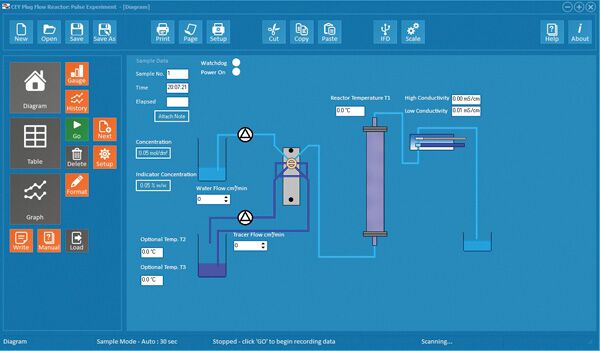

Tracer experiments and conversion experiments may be demonstrated and followed visually. Conductivity data logging allows the student to apply the flow pattern characterisation theory and compare it with the experimental results.

Technical Specifications

Features & Benefits

- Determination of residence time distribution of a Laminar flow reactor

- Flow pattern characterisation – Step change

- Flow pattern characterisation – Pulse change

- Study of the reactor response to inlet perturbations: step change

- Effect of flow rate and feed concentration on the determination of flow pattern

- Effect of temperature on the laminar flow characterisation

- Demonstration of the flow pattern in the reactor and comparison with the theoretical model

- Determination of the steady-state conversion of a second order reaction

- Effect of flow rate and feed concentration on the steady-state conversion

- Visual monitoring of the steady state

- A small scale laminar flow reactor (400ml working volume) designed to demonstrate both flow pattern characterisation and steady-state conversion in a tubular reactor

- The reactor column is 1300mm long including diffusers packed with glass beads

- A static premixer is fitted at the base of the column

- Reactor column is jacketed with easy connections for recirculating cooling system

- A feed assembly is supplied with the reactor which consists of two pulsation dampers mounted on a base plate, special lids for Service Unit reagent vessels and PTFE interconnecting pipe

- Stainless steel coils are mounted on the reagent vessel lids to cool their contents. Quick-release connectors allow easy supply of cold transfer medium to the coil and reagents

- The unit is mounted on a painted frame and includes a sensor block for conductivity and temperature sensors

- Can perform flow visualisation where the progress of the reaction can be monitored visually using colour

- Can also perform true reactions where the progress of the reaction is recorded using the CEXC conductivity sensor and compared with the theory

Requires CEXC Base unit to operate

Consumables:

- 100g Potassium Chloride

- 20mg Indigo Carmine

- 20g NaOH Sodium Hydroxide

- 50ml Ethyl Acetate

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.5m³

Gross Weight: 22Kg

Length: 1.00m

Width: 0.50m

Height: 0.50m

CEZ