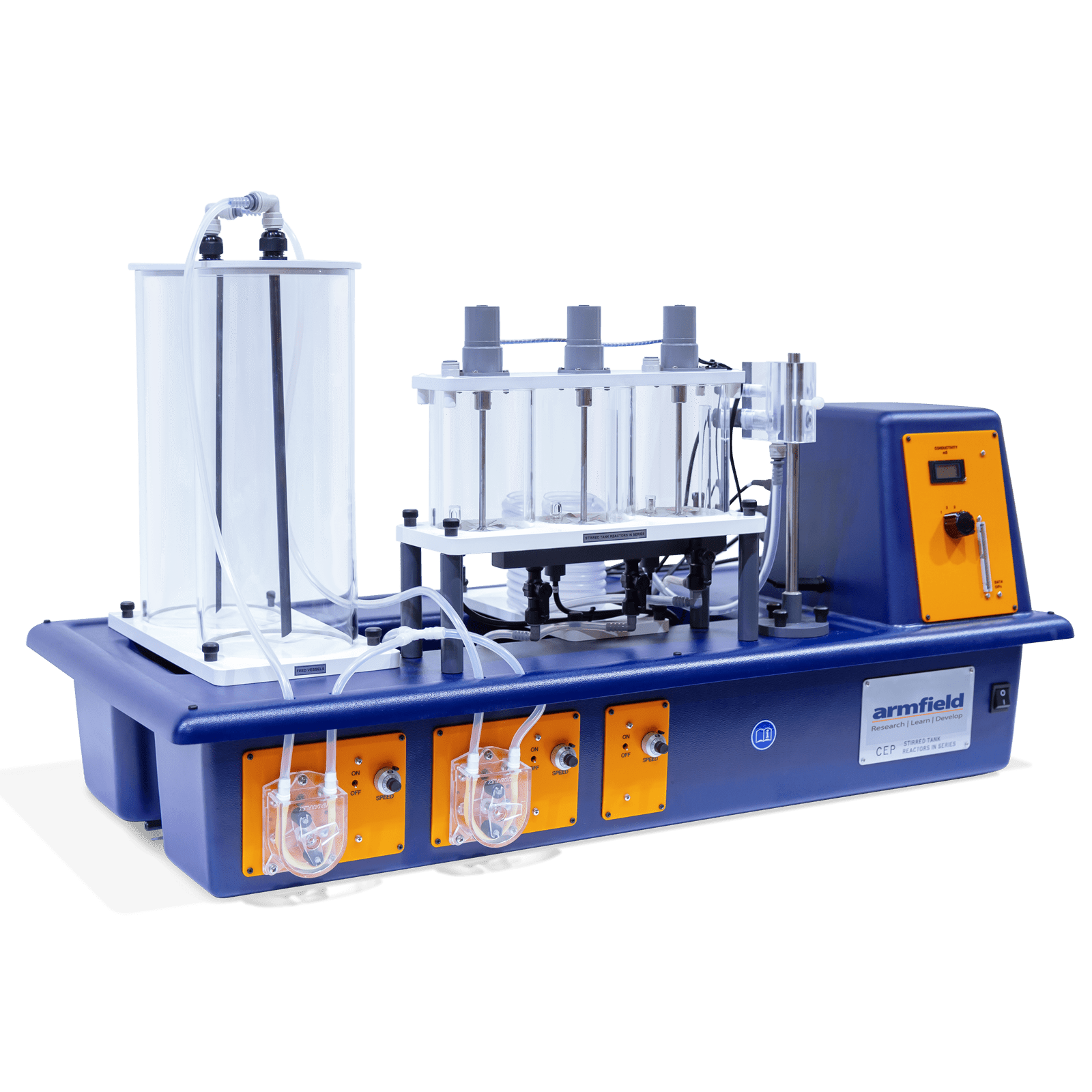

CEP-MKII – Stirred Tank Reactors in Series

The Armfield CEP-MKII Stirred Tank Reactors in Series Unit is designed to follow the dynamics of the perfectly mixed multistage process. Dynamic behaviour can be studied as can multistage chemical reaction.

Bench mounted and self-contained, the unit requires only to be connected to a single-phase electrical supply for operation.

Description

The Armfield CEP-MKII Stirred Tank Reactors in Series Unit is designed to follow the dynamics of the perfectly mixed multistage process. Dynamic behaviour can be studied as can multistage chemical reaction. Bench mounted and self-contained, the unit requires only to be connected to a single-phase electrical supply for operation.

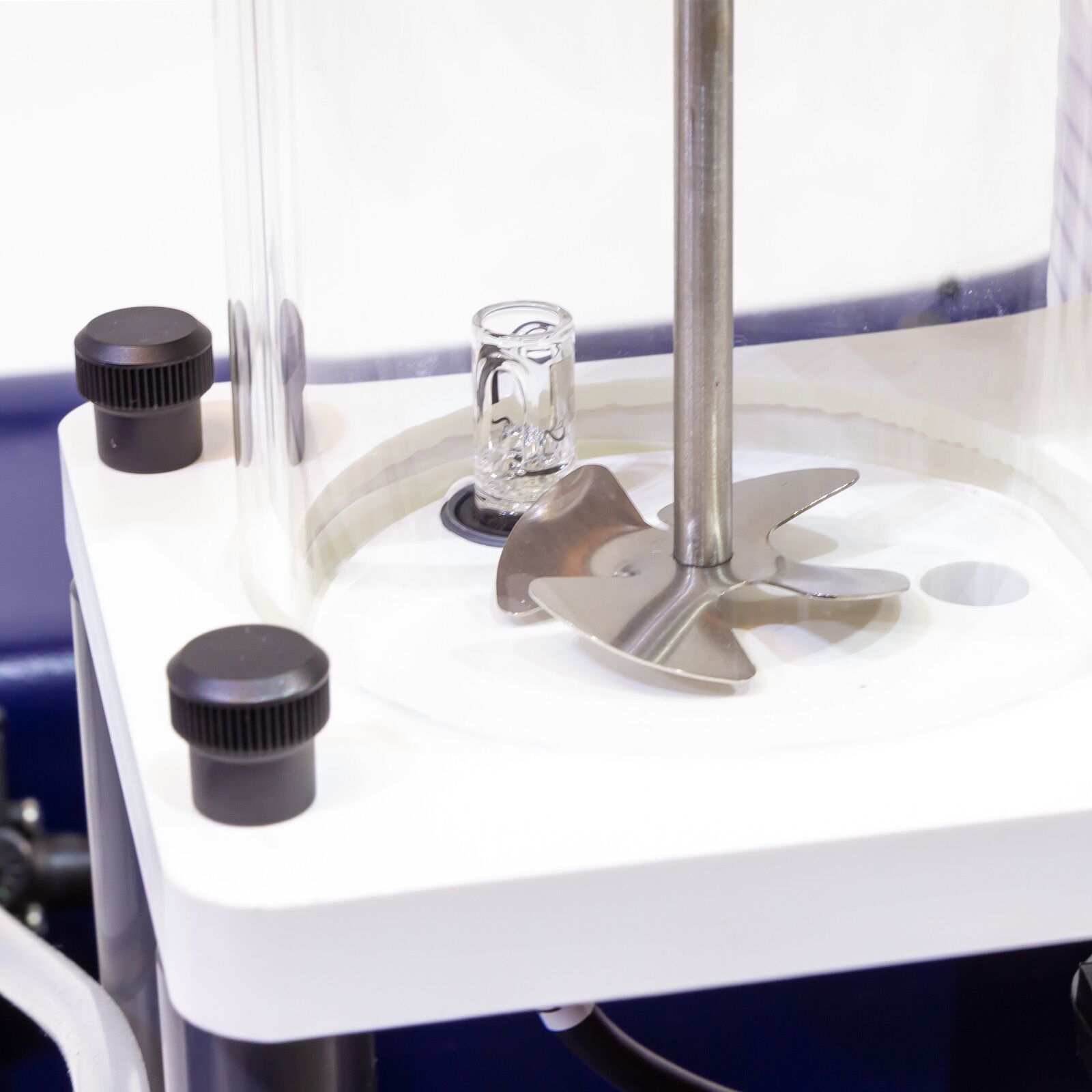

There are three reactor vessels connected in series, each containing a propellor agitator driven by a variable speed electric motor.

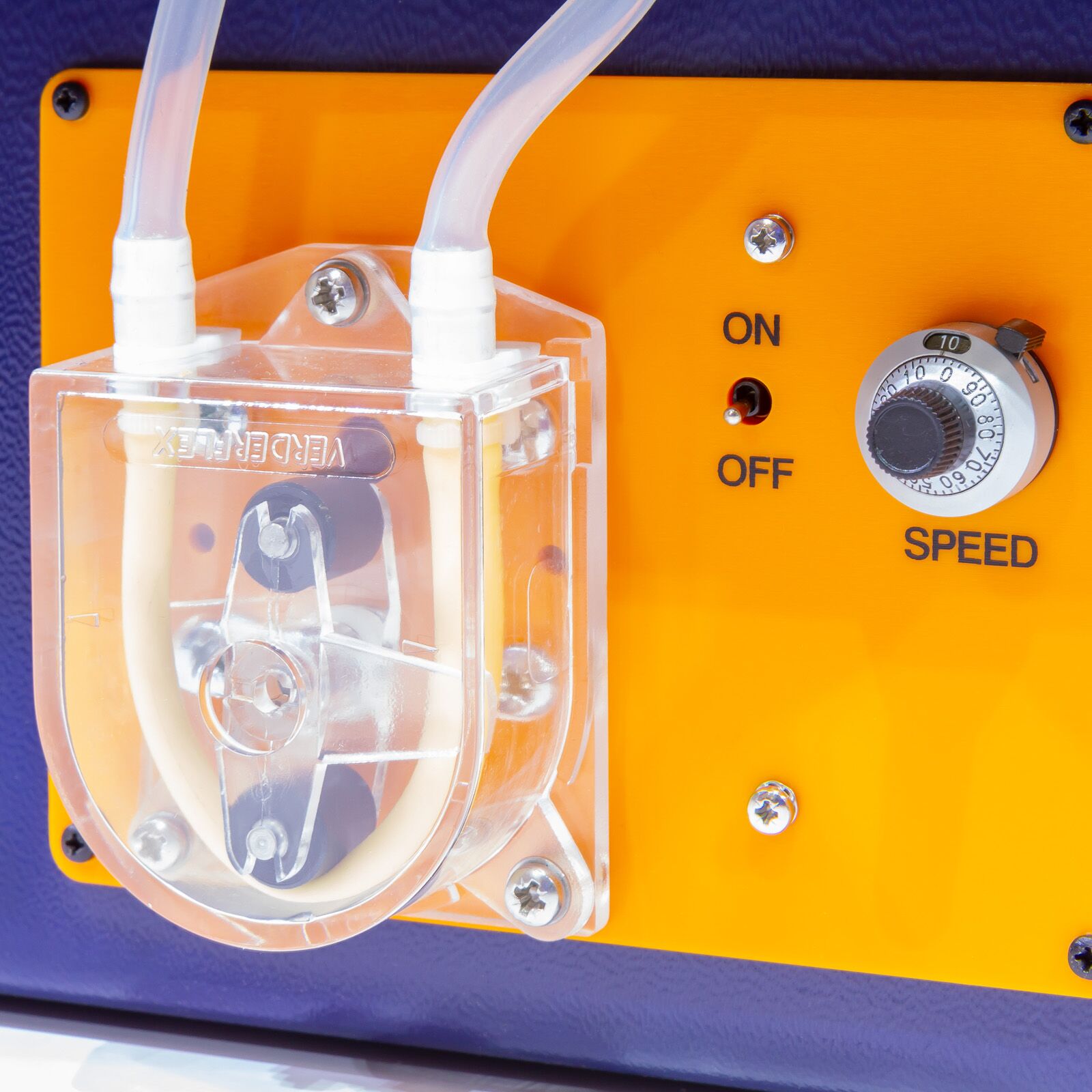

Two reagent vessels and two variable speed feed pumps feed reagents into the first reactor in line.

For certain experiments the feed can be connected to the third reactor and a dead time coil, also positioned on the vacuum formed plinth.

Each reactor and the exit port of the dead time coil are fitted with conductivity probes for monitoring the process.

Conductivity is displayed on a digital meter on the console through a selector switch and all four probes are connected to the supplied Armfield data logging accessory.

Technical Specifications

- A self-contained bench mounted small scale unit fitted with three continuous stirred reactors in series which are fed from two 5l tanks. Each reactor is fitted with a conductivity probe

- There are two independent, variable speed feed pumps

- A dead time residence coil can also be attached to the exit of the last reactor in the series

- Demonstration capabilities:

– Investigation of dynamic behaviour of stirred tank reactors in series

– Influence of flow rate and step input change

– Investigation of chemical reaction in a three-tank system

– Investigation of time constant using a dead time coil

Features & Benefits

- Investigation of dynamic behaviour of stirred tank reactors in series

- Effect of step input change

- Response to an impulse change

- Influence of flow rate

- Investigation of time constant using a dead time coil

- Investigation of chemical reaction in a three-tank system

Supplied as standard

CEP-MKII-DTA-ALITE data logging accessory

Software capabilities

The software is designed to simplify the tasks of both the students and faculty, by eliminating repetitive tasks, providing instruction on the investigation and the theory, and providing a record of the results. It enables the student to complete the investigation and process the results in a standard laboratory session, giving the time to repeat any necessary measurements and analysis.

Software features include:

- Presentation screens outlining the investigations, the theory and the equipment

- Detailed help texts describing how to use the software, set up the equipment, perform the investigation and the associated theory

- Real-time schematic representations of the equipment and sensor measurements

- Data logging, with full control over sample rates

- Fully flexible graph plotting

- Student questions

Software technical description

The system uses the Armfield data logging software package which digitises the analogue inputs and transfers the data to the computer. This enables the temperature or conductivity measurements, together with an indication of the pump rates set on the chemical reactors service units to be logged on a PC. The package comprises the hardware and appropriate software for the reactors.

The interface to the PC is via USB, requiring no additional hardware in the PC. Therefore any PC including laptop and notebook versions may be used.

The software is supplied on an USB key.

Software ordering specification

- Data logging accessory and educational software for Stirred Tank Reactors in Series

- Interface device, software and leads

Electricity Requirements:

CEP-MKII-A: 220-240V / 1ph / 50Hz / 5A

CEP-MKII-B: 120V / 1ph / 60Hz / 10A

CEP-MKII-G: 220-240V / 1ph / 60Hz / 5A

Consumables

- 100g Potassium chloride

- 20g NaOH Sodium hydroxide

- 50ml Ethyl acetate

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.8m³

Gross Weight: 50kg

Length: 1.00m

Width: 0.50m

Height: 0.55m

- CEP-MKII-A: 220-240V / 1ph / 50Hz / 5A

- CEP-MKII-B: 120V / 1ph / 60Hz / 10A

- CEP-MKII-G: 220-240V / 1ph / 60Hz / 5A