CEL-MKII Fixed and Fluidised Bed Apparatus

The CEL-MKII is designed to facilitate the study of flow through fixed and fluidised beds of solid particles.

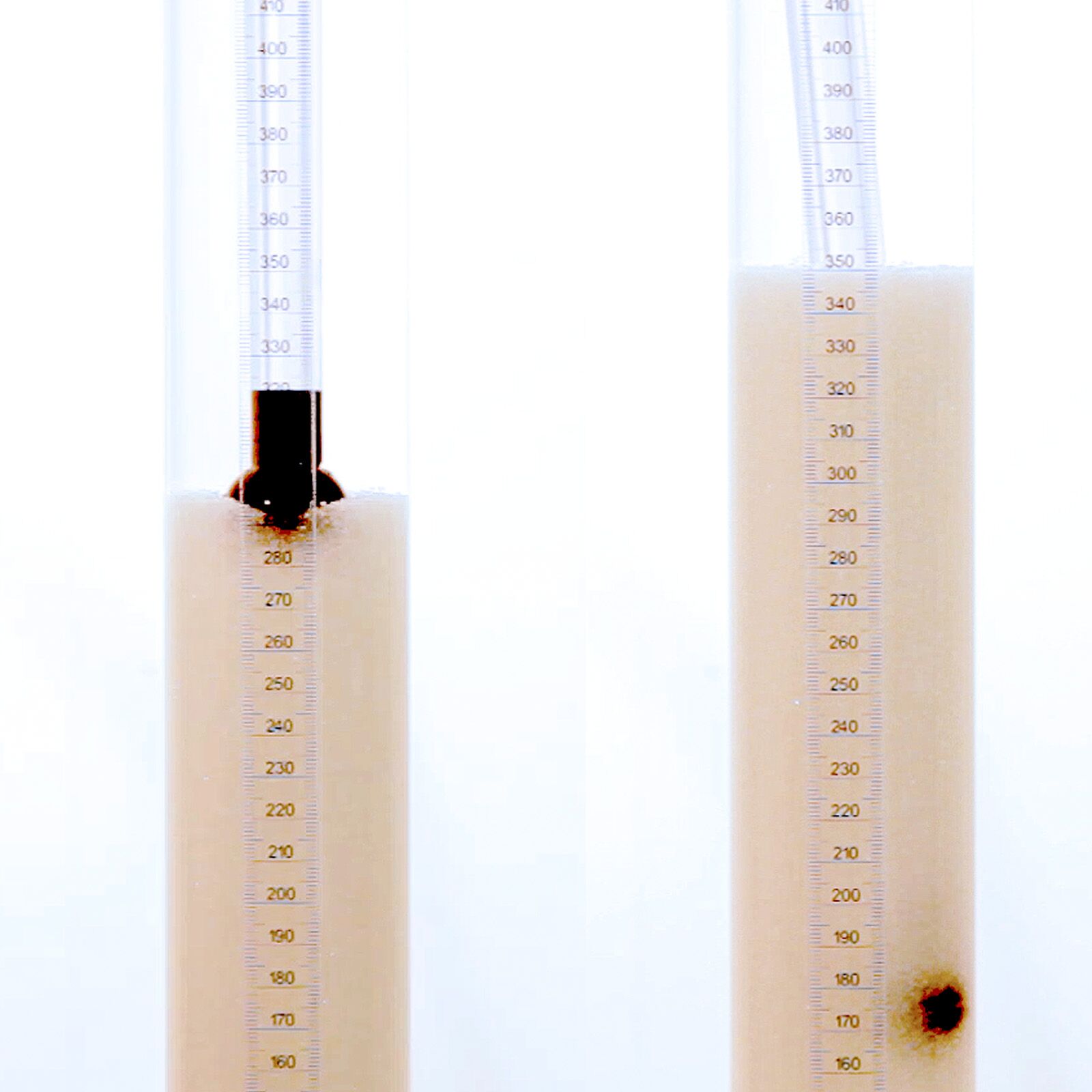

This new improved MKII version has three columns, one for use with water and two for use with air.

The separate air and water columns enable the difference between ‘aggregative’ and ‘particulate’ fluidised bed characteristics to be demonstrated.

Description

Upward flow of fluid through a bed of particles is a naturally occurring phenomenon, for example in the movement of ground water. Industrial applications include ion exchange, extraction of soluble components from raw materials and other chemical processes.

The Armfield CEL-MKII apparatus facilitates the study of flow through fixed and fluidised particle beds. The simultaneous study of air and water systems and the phenomenon of ‘bubbling’ can be observed.

The apparatus comprises three clear acrylic columns mounted above a moulded ABS base. The base contains a water reservoir with a variable speed submersible pump that pumps water through an electronic flow meter into the base of the left-hand column. This column features an overflow pipe that returns the water back into the sump.

The two air columns are fed by variable pressure regulators, which can be used to adjust the air flow rate through the column. The air flow rate is measured using pressure sensors at discharge orifices at the top of the columns. The integral microcontroller calculates the flow rates from the pressure readings and displays these on the front panel.

Pressure drops on all three columns are measured by differential pressure sensors connected to tapping points at the top and bottom of the columns.

All process measurements are displayed simultaneously on the front panel display and are available on the USB output for data logging. The software also provides powerful graph-plotting facilities.

Technical Specifications

Features & Benefits

- Determining the voidage of granular material

- Flow through fixed and fluidised beds using water as the fluidising medium

- Flow through fixed and fluidised beds using air as the fluidising medium

- To determine the pressure drop (head loss) across the beds with different particle sizes

- Verification of Carman-Kozeny’s equation

- To compare the predicted onset of fluidisation with the measured pressure drop

- To compare the onset of fluidisation between two particle sizes

- To observe the onset of fluidisation and differentiate between the characteristics of a fixed bed and fluidised bed

- To observe the onset of fluidisation and differentiate between the characteristics of a fixed bed and a fluidised bed for different particle sizes.

- To investigate the difference between different sized granular material on fluidisation characteristics, using air as the fluidising medium.

- Demonstration of liquefaction and liquefied soil phenomena (e.g. quicksand)

- To investigate the characteristics associated with water flowing vertically upwards through beds of different granular material

- A benchtop apparatus for the study of fixed and fluidised beds of solid particles

- Three cylindrical columns, one for water and two for air, each column with a diameter of 50mm and height of 550mm

- Columns mounted above a blue ABS moulded base containing an 8l water reservoir

- Two sizes of bed material supplied, ranges: 0.5-0.75mm and 0.2- 0.3mm

- Complete with a demonstration of liquefaction and how the properties of liquefied particles change with agitation

- Variable speed submersible pump to recirculate water up to a rate of 2 l/min

- Each column has tapping points and differential pressure sensors

- Air flow rate measured by orifice pressure sensors with the flow rate being calculated by an integral microcontroller

- Electronic front panel display shows flow rates and pressure drops for all three columns simultaneously

- Powered by universal power adaptor with worldwide approvals

- Supplied with powerful data logging software (PC not supplied)

Air compressor – AC1

Max pressure: 8 bar

Max air flow: 100 l/min at 1 bar

Capacity: 6l

Motor power: 820W

Weight: 8.8kg

Noise: 80dB typical at 1m

Electricity Requirements:

Requires 24V DC at 5A – The equipment is supplied with a universal mains adaptor suitable for 100V to 240V AC, 50/60Hz

Compressed Air:

50 l/min at 2 bar minimum (8 bar max)

(Air inlet connection for 6mm rigid plastic pneumatic tube supplied)

Note:

Armfield can provide a suitable portable air compressor, see below

Computer:

Software requires the user to have a PC running Windows 7 or above with a USB port.

PACKED AND CRATED SHIPPING SPECIFICATIONS

CEL-MKII

Volume: 0.6m³

Gross Weight: 35kg

AC1

Volume: 0.3m³

Gross Weight: 20kg

CEL-MKII

Length: 1.00m

Width: 0.50m

Height: 0.83m

AC1

Length: 0.45m

Width: 0.29m

Height: 0.40m

CEL-MKII

CEL-MKII-EU with Schuko mains lead

CEL-MKII-UK with UK mains lead

CEL-MKII-B with USA 115V mains lead

AC1

AC1-A 220-240V / 1ph / 50Hz

AC1-B 120V / 1ph / 60Hz

AC1-G 220-240V / 1ph / 60Hz