UOP5 MKII – Liquid / liquid Extraction Unit

Liquid / liquid extraction is important in chemical engineering where the separation of one or more of the components from a liquid mixture is required.

Description

Liquid / liquid extraction is an important operation in chemical engineering where the separation of one or more of the components from a liquid mixture is required. Traditionally this has been difficult to demonstrate in the laboratory, requiring the use of highly toxic, expensive and / or environmentally damaging solvents. The Armfield UOP5-MkII introduces a system using 1-Octanol or Canola oil which are safe, readily available and inexpensive.

The UOP5-MkII comprises a glass separation column, 1600mm long and 50mm diameter, packed with glass Raschig rings which provide a large surface area for the extraction process. Four process tanks are included, a feed tank and collection tank for the organic phase and a feed tank and collection tank for the aqueous phase.

The aqueous circuit includes a variable speed rotary diaphragm pump with built in rotation counter that allows the flow rate to be determined. Conductivity and temperature sensors in both the feed and return lines allow the amount of acid transferred to the aqueous phase to be determined.

The organic circuit uses a variable speed diaphragm pump that is air powered and contains no electrical components allowing safe operation using organic solvents in such as 1-Octanol.

The 1-Octanol containing up to 1.5% of Propionic acid is pumped from the organic feed tank to the base of the extraction column. Demineralised water is pumped from the aqueous feed tank to the top of the extraction column. The density difference between the phases causes counter-current flow in opposite directions through the packed column where the acid is removed from the organic component into the aqueous component. The two phases exiting the column are collected in the appropriate return tank. The phase boundary can be changed between the top of the column and the bottom of the column by operating a single valve. Fine adjustments can be made to the location of the lower boundary to compensate for variation in specific gravity of the organic phase.

Temperature and conductivity sensors be determined at the inlet and outlet of the column allow the concentration of Propionic acid in the aqueous phase to be determined. From this information the extraction efficiency of the process can be calculated. All the sensor readings and calculated values are available for data logging on a personal computer (not supplied).

To obtain accurate results it is important that deionised water is used for the aqueous phase.

After use, the organic phase will retain a small amount of acid. If required, the concentration of acid can be established using titration, and then topped up with more acid ready for the next run at the required concentration.

Using the recommended 1-Octanol or Canola oil system, this process can be repeated. Alternatively the used organic solvent can be disposed of periodically and replaced.

Note: The UOP5-MkII has been specifically designed for use with 1-Octanol. Although 1-Octanol is classed as flammable, it is difficult to ignite and is safe to use providing reasonable handling precautions are taken. A number of design features have been incorporated into the equipment to ensure safe operation. For safe operation, the UOP5-MkII can only be operated at an ambient temperature less than 35ºC. Hence the equipment should be installed in a temperature controlled laboratory if this temperature will be exceeded. This allows for the use of other organic solvents compatible with the materials of construction.

Technical Specifications

Solvent temperatures: Ambient to 50°C, individually controllable

Pump rate: 0-13.5 l/hr

Feed rate: 0-3 l/hr

Rotation speed: 1 rev/15min (4 revs/hr)

Cell compartment: 0.16 l capacity

Features & Benefits

- Touch panel for control / calibration of pumps and display of measurements

- Recommended system uses water to separate Propionic acid from 1-Octanol

- Operation with the organic or the aqueous phase as the continuous phase inside the column

- Location of the phase boundary is predetermined by the density difference between the phases with no sensors or controls involved

- A single valve sets the organic phase or the aqueous phase as the continuous phase as required for a particular exercise

- Simple adjustment of lower phase boundary to compensate for variation in specific gravity of the organic phase

- Sensors measure the temperature and conductivity of the aqueous phase before and after the extraction process allowing the

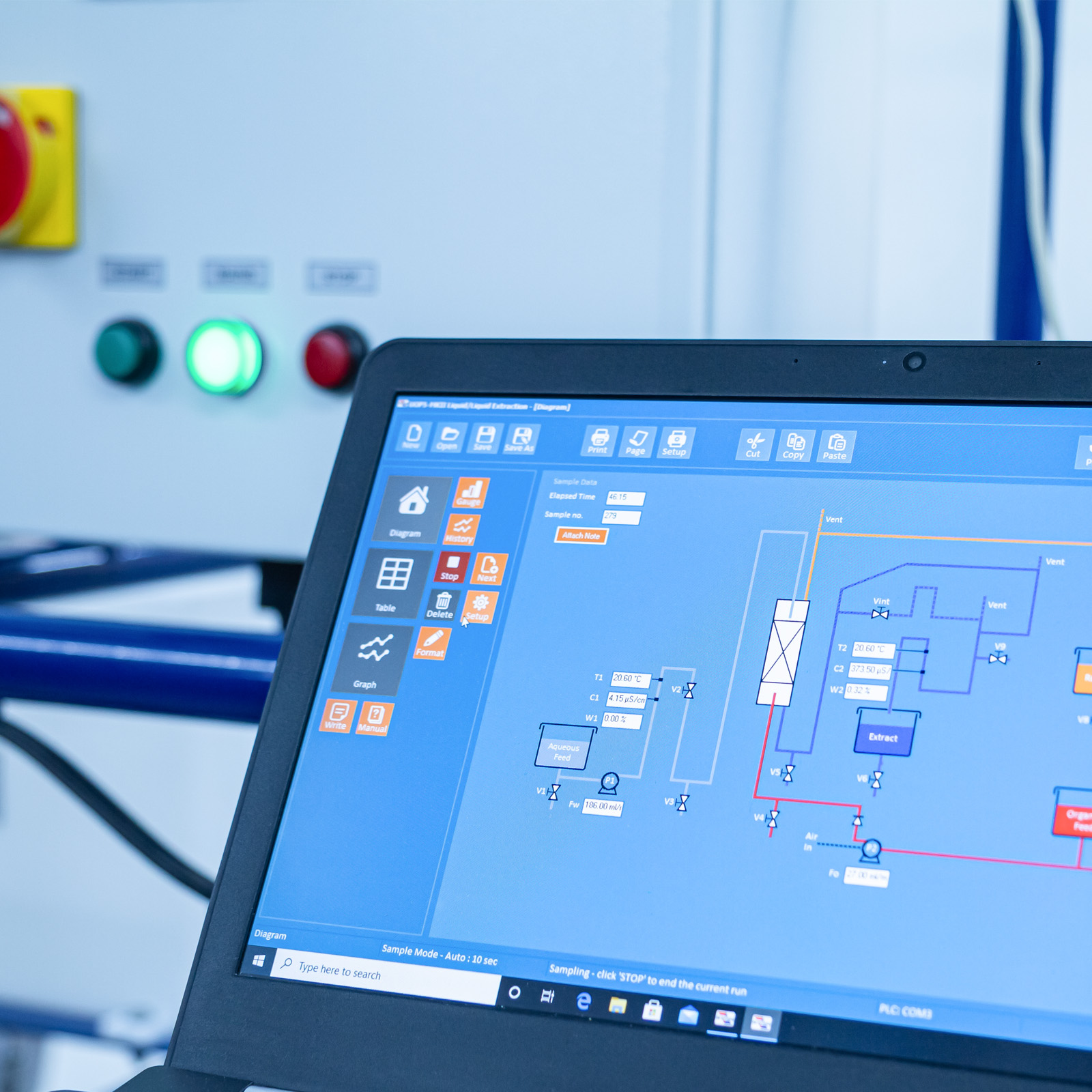

concentration of acid to be determined and the extraction efficiency to be calculated - Includes PC software allowing data logging of measurements and calculation of acid concentration in the aqueous phase

- No solvent recovery system is necessary using the recommended organic solvent system

- Designed to handle 1-Octanol or Canola oil with a thermostat to limit maximum operating temperature for safe operation

- Pneumatic diaphragm pump used to minimise risk of ignition of the organic phase

- Hydrodynamics of a packed liquid / liquid extraction column

- Differences in extraction performance using the organic phase or the aqueous phase as the continuous phase

- Investigation into the effect of changes in aqueous and organic flow rate

- Mass balances and the calculation of mass transfer coefficient

- Air compressor AC1 (If no compressed air supply is available)

- Maximum Pressure: 6 Bar

- Maximum Airflow: 100 l/min at 1 Bar

- Capacity: 6l

- Motor power: 820W

- Noise: 80 dBA typical at 1m

- A laboratory liquid / liquid extraction column designed for use with 1-Octanol and Propionic acid

- Column length 1.6m (1.2m working length), 50mm diameter, made from glass

- Column packed with 15mm glass Rashig rings

- Aqueous phase circulation system with a 25l feed tank, 25l return tank and variable speed pump. Pump is calibrated and gives flows of 50-250ml/min

- Organic phase circulation system with an 18l feed tank, 18l return tank and variable speed air operated pump. Pump is calibrated and gives flows of 50-250ml/min

- Includes valves for taking samples of both phases for analysis

- Touch panel for control / calibration of pumps and display of measurements

- A single valve sets either the organic phase or the aqueous phase as the continuous phase

- Fine adjustment of the lower phase interface to compensate for variation in specific gravity of the 1-Octanol

- Instrumentation measures the inlet and outlet concentrations in the aqueous phase when using the recommended acid

- Data logging as standard, software calculates acid concentration in the aqueous phase from which extraction efficiency can be determined (requires PC, not supplied)

Electrical supply:

UOP5-MkII-A: 220-240V/1ph/50Hz, 1A

UOP5-MkII-B: 120V/1ph/60Hz, 2A

UOP5-MkII-G: 220-240V/1ph/60Hz, 1A

Water supply:

Initial fill with 20l of demineralised water

(No permanent connection required)

Compressed air:

Clean, dry compressed air 40 l/min at 3–10 bar

(Air inlet connection for 6mm rigid plastic pneumatic tubing supplied)

Note: Armfield can provide a suitable portable air compressor, see below

Computer: A Windows PC (not supplied) running Windows 98 or later, with USB port is required if running the data logging software

PACKED AND CRATED SHIPPING SPECIFICATIONS

UOP5-MKII

Volume: 3.0m³

Gross Weight: 230Kg

AC1

Volume: 0.3m³

Gross Weight: 8.2Kg

UOP5-MKII

Length: 1.220m

Width: 0.760m

Height: 2.045m

AC1

Length: 0.452m

Width: 0.405m

Height: 0.293m

UOP5-MkII:

UOP5-MkII-A Supplied with European and UK mains leads

UOP5-MkII-B Supplied with USA 115V mains lead

UOP5-MKII-G Supplied with USA 230V mains lead

AC1:

AC1-A 220-240V/1ph/50Hz

AC1-B 120V/1ph/60Hz