Post Category: FT25X Agents

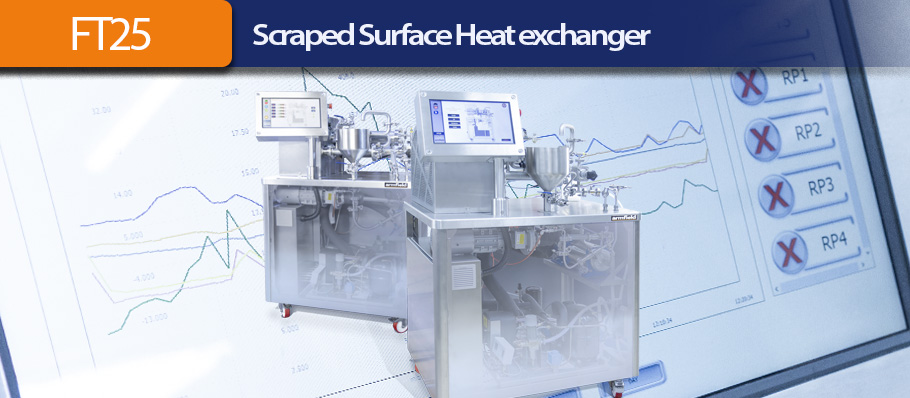

Armfield FT25 Scraped Surface Heat exchanger

New Generation Crystallisers

Armfield have released the new generation of R&D Scraped Surface Heat exchanger crystallisers for fats, oils and ice cream. Mounted on a very small footprint frame, our systems allow you to process up to pressures of 40 bar, option dependent.

Based on collaboration with industry an enhanced scaled down version of a production plant has been created allowing for rapid testing of new and existing formulations in the laboratory. Parameters can be altered quickly allowing for optimisation of the process, with the data being logged for QA/QC purposes.

Contact Industrial Food Technology sales at www.armfield.co.uk