Post Category: Industrial Food Technology

What is Direct Steam Injection?

Direct Steam Injection (DSI) is a highly efficient method of heating liquids and slurries by injecting steam directly into the product stream. Unlike indirect heating methods, which rely on heat exchangers or coils to transfer heat, DSI allows for the immediate transfer of the steam’s energy directly into the product. This ensures fast, consistent heating with minimal heat loss and enhanced energy efficiency.

In a direct steam injection system, steam is introduced into the product using a steam injector or sparger. The steam condenses instantly upon contact, transferring both sensible and latent heat. This leads to rapid temperature increases and precise temperature control — crucial for industries that require consistent product quality and efficient processing.

How Direct Steam Injection Works

The steam injector introduces high-velocity steam into the product stream. As the steam mixes with the product, it condenses and releases heat. This results in:

- Instantaneous heating – Quick heating minimises processing times.

- Uniform temperature control – Steam is evenly distributed for consistent heating.

- Energy efficiency – Direct contact reduces heat loss, making the process more energy efficient.

Benefits of Direct Steam Injection

- Faster Heating – The direct contact method allows for rapid heat transfer and reduced processing time.

- Precise Temperature Control – Immediate and uniform heat distribution ensures consistent product temperatures.

- Increased Energy Efficiency – Direct heating reduces energy loss, improving overall efficiency.

- Compact Design – DSI systems take up less space than indirect heating setups.

- Improved Product Quality – Rapid and even heating prevents burning, over-processing, or texture loss.

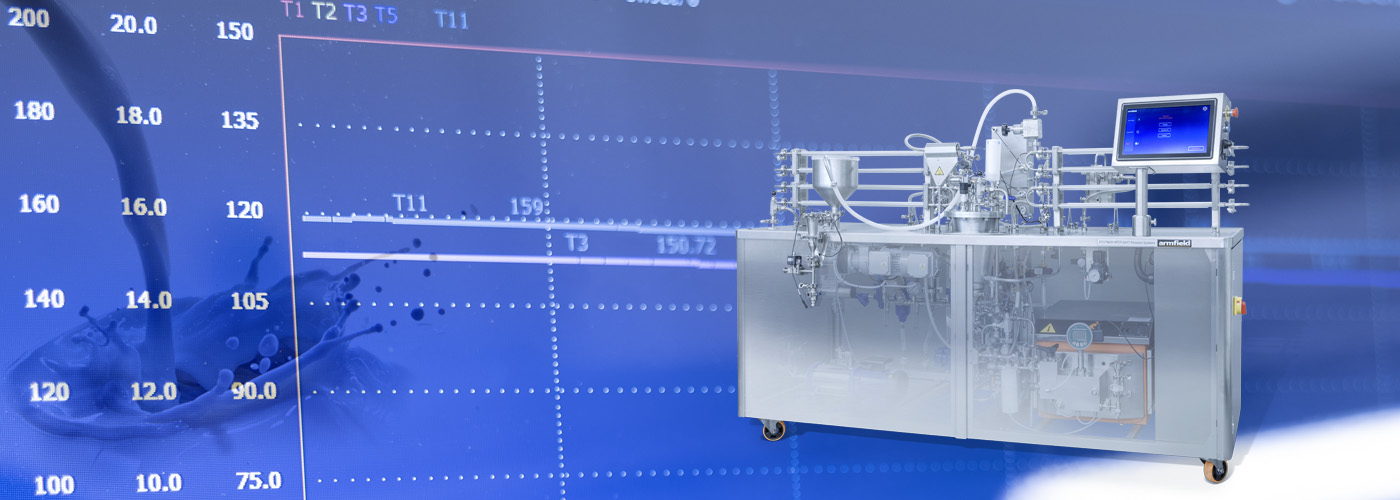

Armfield Equipment Featuring Direct Steam Injection: FT174

The FT174 Modular Miniature Scale HTST/UHT Process System from Armfield is a state-of-the-art solution that utilises direct steam injection to deliver high-performance heating and processing capabilities. Designed for precise high-temperature short-time (HTST) and ultra-high-temperature (UHT) processing, the FT174 is ideal for research and development in the food, beverage, and pharmaceutical industries.

Key Features of the FT174:

- Flexible Flow Rates – Operates at flow rates between 10–60 LPH for UHT and up to 100 LPH for HTST to suit a wide range of process requirements.

- Modular Design – The system allows for quick and easy configuration based on specific process needs

- Indirect Heating Capability – Tubular, plate and scraped surface heat exchangers can be specified

- Direct Steam Injection Capability – Enables rapid heating and precise temperature control.

- PLC-Controlled with Touchscreen Interface – Provides real-time monitoring and process adjustments.

- Aseptic Processing and Homogenisation – Ensures product integrity and consistency.

- Easy Maintenance – Designed for straightforward cleaning and maintenance to minimise downtime.

- Integrated Cooling and Chilling – After heating, the product can be cooled or chilled to specific temperatures using a chilled water supply.

The FT174 offers a comprehensive solution for high-performance processing, making it ideal for product development and small-scale production. Its ability to combine direct steam injection with HTST/UHT processing ensures high product quality and efficiency.

Learn more about the FT174 here

Historical Perspective: Evolution and Significance of Direct Steam Injection

The concept of steam injection dates back to the early 20th century when steam was first used for industrial heating. Early systems relied on heat exchangers and jacketed vessels, which often resulted in uneven heating and high energy costs.

The breakthrough came with the development of direct steam injection technology, which allowed manufacturers to bypass heat exchangers and introduce steam directly into the product. This created a more efficient and effective heating process. Over time, technological improvements, including the development of high-performance steam injectors and spargers, have enhanced the precision and scalability of DSI systems.

Notable Examples of Direct Steam Injection in Key Industries

Food and Beverage Industry

Direct steam injection is widely used for pasteurisation, sterilisation, and cooking. It ensures fast, consistent heating without compromising flavour, texture, or nutritional value. Products such as dairy, soups, and sauces benefit from the rapid heating and precise temperature control offered by DSI.

Pharmaceutical Industry

The pharmaceutical sector relies on DSI for sterilisation and precise temperature regulation during drug production and formulation. The FT174’s ability to handle aseptic processing makes it an ideal choice for pharmaceutical applications.

Chemical Industry

Direct steam injection is used in the chemical industry to heat process fluids, accelerate reaction times, and maintain consistent product quality. The ability to adjust steam pressure and flow rates allows for high levels of process control.

Factors to Consider When Choosing a Direct Steam Injection System

- Flow Rates – The system should handle both low and high flow rates without causing steam hammer.

- Temperature Control – High-performance control valves ensure consistent heating.

- Product Compatibility – The system must be suitable for different product viscosities and process requirements.

- Steam Pressure – The steam pressure should match the process requirements to avoid cavitation or incomplete condensation.

Why Choose Armfield?

At Armfield, we have over 50 years of experience in designing and manufacturing industry-leading direct steam injection systems. The FT174 stands out due to its high-performance capabilities, ease of use, and adaptability for research and production.

Discover the Power of Direct Steam Injection with Armfield

Interested in enhancing your production efficiency with the FT174 Modular Miniature Scale HTST/UHT Process System? Contact Armfield today to learn more about how direct steam injection can benefit your business.

Armfield at Fi Europe 2024

Armfield at Fi Europe 2024: Celebrating 30 Years of Innovation

Armfield, a global leader in food technology education equipment, is proud to announce its participation in the upcoming Food Ingredients (Fi) Europe show, held from 19th to 21st November 2024 at Messe Frankfurt, Germany. This milestone marks Armfield’s 30th year of attendance at this prestigious event, reinforcing its position as a trusted partner in the field of laboratory and pilot equipment for food processing.

What to Expect at Fi Europe 2024

Fi Europe has established itself as the foremost event for the food and beverage industry, uniting top suppliers, buyers, R&D experts, and production specialists from across the globe. Since its inception in 1986, Fi Europe has facilitated billions of Euros worth of business, creating invaluable partnerships that have propelled the industry forward. Attendees will experience a showcase of cutting-edge ingredients, technologies, and solutions that drive innovation and sustainability.

Armfield will be located at Stand 3.1C20, where visitors will have the opportunity to explore its latest laboratory pilot plant equipment, including:

- FT174 Modular Miniature-scale HTST/UHT System: A highly versatile unit designed for advanced food processing experiments. Learn more.

- FT102XA Carbonator and Filler: Known for its reliability and robust design, perfect for small batches and pilot-scale processing. Find out more.

These demonstrations will highlight Armfield’s commitment to providing state-of-the-art equipment that supports both academic learning and practical industrial applications.

The Legacy of Fi Europe

Food Ingredients Europe began as a biennial event in 1986, hosted in major European cities. Today, it runs annually, often alongside Health Ingredients Europe, to deliver an unparalleled platform where the most innovative ideas meet real-world solutions. The event has welcomed over half a million attendees throughout its history and remains a cornerstone for those seeking to network, learn, and enhance their business capabilities.

Fi Europe 2024 is set to draw thousands of industry professionals and will showcase pioneering ingredients and services that are poised to shape the future of food technology.

Why Visit Armfield?

For three decades, Armfield has been at the forefront of food and beverage technology, providing comprehensive solutions that empower both universities and industry professionals alike. By visiting our stand, attendees will:

- Witness the capabilities of high-performance machinery tailored for product development and research purposes.

- Receive expert insights from our knowledgeable team, ready to answer questions and provide guidance.

- Explore potential partnerships and discover how Armfield’s solutions can be integrated into academic or research initiatives.

Our presence at Fi Europe embodies our dedication to continuous improvement and support for the educational sector. We believe in fostering strong industry relationships that pave the way for new innovations.

Join Us at Fi Europe 2024

We invite you to join Armfield at Stand 3.1C20 to discover how our solutions can elevate your food technology programs. Whether you’re an academic, a researcher, or a professional in the food processing industry, our team is excited to meet you and share our latest advancements.

For further details or to explore our product catalogue ahead of the event, please contact us or request a product brochure.

Visit us at Stand 3.1C20 from 19th to 21st November at Messe Frankfurt.

The Science of Carbonation and Armfield’s FT102XA

Fizzing with Flavour: The Science of Carbonation and Armfield’s FT102XA

Carbonation is a crucial process in creating the sparkling drinks we all love, from soft drinks to alcoholic beverages. At the forefront of carbonation technology is Armfield, a leader in the manufacture and distribution of innovative carbonation machines. Among their most advanced offerings is the FT102XA, a state-of-the-art machine designed to revolutionise the carbonation, filling, and capping process for beverages. With its cutting-edge technology and remarkable precision, the FT102XA ensures that beverage producers can create the perfect fizz every time.

What is Carbonation?

Carbonation involves the infusion of carbon dioxide (CO₂) gas into liquids, creating the bubbles that make drinks effervescent. This process not only enhances the texture but also alters the flavour by introducing a slight tang through the formation of carbonic acid. Carbonation has a rich history dating back to the 18th century and continues to be a key factor in modern beverage production.

The FT102XA: Revolutionising Carbonation Technology

Armfield’s FT102XA carbonation machine is at the cutting edge of beverage technology. With high-precision carbonation and filling capabilities, the FT102XA enables manufacturers to carbonate premixed products or water and syrup in a post-mix configuration. It’s a versatile machine, capable of handling a wide range of beverages, including soft drinks, alcoholic beverages, and even highly foaming products that would typically pose challenges in carbonation.

Here’s what makes the FT102XA stand out:

High Precision and Flexibility

The FT102XA is equipped with advanced features that ensure accurate carbonation levels, with the ability to reach over 12g/l of CO₂ with an impressive accuracy of ±0.1g/l. Whether you’re filling PET, glass bottles, or cans, the FT102XA can seamlessly switch between different packaging options, including screw capping, crown capping, and its newly integrated can seaming system.

The system’s flexibility is enhanced by its pre-mixing and post-mixing capabilities, allowing producers to choose the most efficient method based on the beverage type. Whether it’s sparkling water or a complex flavoured soda, the FT102XA handles it all with ease.

Built for Efficiency

Efficiency is key in any production environment, and the FT102XA is designed with that in mind. Its internally mounted high-efficiency chiller eliminates the need for an external cooling system, saving valuable space in laboratories or production facilities. Moreover, its minimum batch volume capability—ranging from 1 to 3 litres—means it can handle small batches efficiently, making it ideal for pilot-scale production or niche beverage lines.

The machine also offers the ability to measure dissolved oxygen and CO₂ directly, a feature that provides precise control over carbonation levels and ensures consistent product quality across batches.

Handling High-Foaming Products

One of the major challenges in carbonation is managing highly foaming beverages, such as certain beers or sparkling wines. The FT102XA includes a new vacuum system that makes it compatible with high-foaming products, ensuring that carbonation is achieved without compromising on quality or volume.

CO₂ Recycling for Sustainability

Environmental considerations are more important than ever in modern manufacturing. The FT102XA addresses this with its CO₂ recycling capability, which not only improves efficiency but also reduces the environmental impact of beverage production. By capturing and reusing CO₂, the machine cuts down on waste and lowers the carbon footprint of the carbonation process, making it a more sustainable choice for manufacturers.

Advanced Control Systems

The FT102XA is equipped with Armfield’s ArmBUS control system, offering users access to 32 pre-set process recipes. This high level of automation ensures that each batch is carbonated with precision and consistency. Additionally, the system allows for full data capture, which can be exported for analysis, making it easier for manufacturers to track and optimise their processes.

Technical Capabilities of the FT102XA

The FT102XA is not just about precision and efficiency—it’s also built to meet the technical demands of modern beverage production. Here are some of its standout technical specifications:

- Vessel capacity: 15 or 30 litres working capacity

- Gas content: 0-12 g/l, suitable for CO₂, N₂, or safe gas alternatives

- Capping methods: Screw capping, crown capping, can seaming, and Rip-cap

- Minimum batch volume: 1-3 litres, depending on the vessel used

- Maximum vessel pressure: 4 bar

- Contact surfaces: Made from food-safe materials such as 316L stainless steel, PTFE, and borosilicate glass

These features make the FT102XA an ideal choice for both small-scale and larger production environments, providing flexibility and precision in carbonation across a wide range of beverages.

The Environmental Impact of Carbonation

While carbonation is a vital part of modern beverage production, it does have environmental implications, particularly when it comes to single-use plastics. Armfield’s FT102XA offers a more sustainable approach by supporting CO₂ recycling and the use of eco-friendly packaging materials like bioplastics and glass. The machine’s ability to handle PET, bioplastic, glass, and cans means it caters to the increasing demand for environmentally responsible packaging solutions.

Popular Carbonated Beverages and How the FT102XA Enhances Production

From cola to sparkling water, carbonated beverages dominate the global drinks market. The FT102XA offers the technology to enhance the production of these drinks by ensuring consistent carbonation, precise filling, and reliable capping. The machine is also capable of handling syrup dosing into bottles, offering flexibility for manufacturers who produce a variety of beverages, including sodas and energy drinks.

With the FT102XA, Armfield ensures that each drink is carbonated to perfection, maintaining the balance between flavour and fizz that consumers love.

Frequently Asked Questions

What is the FT102XA capable of in terms of beverage production? The FT102XA is designed to carbonate, fill, and cap beverages in a range of packaging types, including PET, glass, and cans. It is capable of handling both soft drinks and alcoholic beverages, as well as highly foaming products like certain beers and sparkling wines.

How does the FT102XA handle different types of packaging? The machine is incredibly versatile, offering screw capping, crown capping, and an integral can seaming system. This flexibility ensures that beverage producers can package their products in a variety of formats without compromising on quality or efficiency.

What makes the FT102XA environmentally friendly? The FT102XA includes a CO₂ recycling feature that reduces waste and lowers the environmental impact of beverage production. It also supports the use of bioplastic and glass packaging, offering more sustainable alternatives to traditional plastic bottles.

How does the FT102XA manage high-foaming products? The FT102XA is equipped with a vacuum system specifically designed to handle highly foaming beverages. This ensures that carbonation is achieved smoothly, without the risk of excessive foaming or spillage.

Take Your Beverage Production to the Next Level with the FT102XA

If you’re looking to enhance the carbonation and filling processes in your beverage production, the FT102XA offers unparalleled accuracy, flexibility, and sustainability. Contact Armfield today to learn more about how the FT102XA can transform your production line. Contact us here.

You may also like

- Armfield announces the successful launch of our FT102XA Carbonator.

- Reducing Energy Consumption in Food Manufacturing

- Kombucha and Armfield

Reducing Energy Consumption in Food Manufacturing

Reducing energy consumption in food manufacturing is becoming an urgent priority for businesses across the globe. Not only does energy usage directly impact production costs, but it also contributes significantly to environmental concerns such as greenhouse gas emissions and climate change. For companies looking to balance operational efficiency with sustainability, addressing energy consumption is essential.

At Armfield, we provide advanced solutions tailored for food manufacturers, offering pilot plant equipment and other food technology equipment that can significantly reduce energy consumption while maintaining high production standards. Our equipment is designed to improve energy efficiency, reduce waste, and contribute to a more sustainable future.

Energy Consumption in the Food Manufacturing Industry

Food manufacturing is one of the most energy-intensive industries globally, with refrigeration, heating, and processing accounting for the majority of energy usage. Studies show that energy costs make up about 15% of total operational expenses for many food manufacturers. As energy prices continue to soar, the pressure is on for companies to adopt energy-saving practices to remain competitive and meet regulatory requirements.

Armfield understands these challenges and provides cutting-edge pilot plants that enable manufacturers to test processes on a smaller scale before beginning full production, significantly optimising energy usage. Our food technology equipment helps businesses achieve energy savings through innovative design, including advanced heat exchangers and energy-efficient motors that reduce energy wastage.

How Food Technology Equipment Can Reduce Energy Consumption

Food manufacturers can reduce energy consumption by integrating energy-efficient equipment into their production lines. Equipment optimisation plays a key role in reducing operational costs and improving energy performance. Armfield’s pilot plant technology allows companies to assess production processes in a controlled environment, identifying areas for improvement before scaling up to full production. This means manufacturers can refine their energy use, cutting down on waste and inefficiency.

Energy-efficient equipment from Armfield can also support businesses in achieving their sustainability goals. Our solutions include energy-efficient lighting, advanced refrigeration systems, and innovative heat exchangers that recover waste heat and reuse it in the production process. These technologies enable food manufacturers to reduce their carbon footprint and save significantly on energy costs.

Benefits of Implementing Energy-Saving Practices

The benefits of reducing energy consumption in food manufacturing go far beyond cost savings. By investing in energy-saving measures, companies can reduce their carbon emissions, lower operational costs, and improve overall energy performance. Furthermore, implementing such practices contributes to the industry’s broader sustainability goals, enhancing brand reputation and meeting consumer demand for environmentally friendly products.

At Armfield, we have seen firsthand the transformative impact of our pilot plants on energy efficiency in the food industry. For example, our Pasteurisation and UHT systems (FT74XA, FT174XA and FT94X) are able to collect the temperature data enabling the user to analyse the energy usage for processing with different parameters. By being able to run small batches, the user can refine the process parameters to create the same tastes by with lower energy consumption and apply these changes to production.

For example, one of our clients, a major dairy producer, implemented our energy-efficient processing technology and saw a 25% reduction in their overall energy consumption within the first year of use. This not only reduced their operational costs but also helped them meet their sustainability targets.

Overcoming Challenges to Energy Efficiency

Although the benefits of reducing energy consumption are clear, many food manufacturers face challenges when implementing energy-saving technologies. Initial investment costs, resistance to change, and the complexity of integrating new systems can deter companies from adopting these measures.

However, these challenges can be overcome with the right approach. For instance, manufacturers can start by conducting an energy audit to identify areas where improvements can be made. At Armfield, we offer comprehensive support to help food manufacturers implement our energy-efficient pilot plant and equipment solutions, ensuring a smooth transition and quick return on investment. The data collected from our systems can be analysed to find the optimum

Furthermore, involving employees in the energy-saving process is crucial. By educating staff on the importance of energy efficiency and encouraging their participation in energy-saving practices, companies can foster a culture of sustainability within their operations.

How Food Companies Can Support Energy Reduction Efforts

Businesses also play a vital role in promoting energy efficiency within the food manufacturing industry. By supporting brands that prioritise sustainability and reduce their environmental impact, consumers can drive demand for more responsible manufacturing practices. Many companies are now making public commitments to reducing their carbon footprint, and consumers can make informed purchasing decisions based on these sustainability efforts.

At Armfield, we believe that collaboration between manufacturers, consumers, and government bodies is essential to achieving significant reductions in energy consumption across the food industry. By working together, we can create a more sustainable future for food production.

FAQs on Reducing Energy Consumption in Food Manufacturing

1. How can equipment be optimised to reduce energy consumption in the food processing industry?

Equipment can be optimised by upgrading to energy-efficient technology, such as Armfield’s pilot plants. These allow for precise control and testing of processes to identify areas of energy waste and improve overall energy performance before scaling to full production.

2. What steps can energy-intensive businesses take to cut down on their carbon footprint?

Energy-intensive businesses can conduct an energy audit to identify inefficiencies, invest in renewable energy sources, and upgrade to energy-efficient equipment like the solutions provided by Armfield. Implementing these measures can reduce carbon emissions and improve operational efficiency.

3. Why is it important for companies in the food and beverage industry to prioritise reducing their energy usage?

Reducing energy usage lowers operational costs, improves profitability, and helps companies comply with environmental regulations. Additionally, consumers are increasingly favouring brands that adopt sustainable practices, making energy efficiency a key competitive advantage.

Takeaways

Reducing energy consumption in food manufacturing is crucial for both economic and environmental reasons. By adopting energy-efficient practices, food manufacturers can not only cut costs but also reduce their carbon footprint and contribute to a more sustainable future.

At Armfield, we are proud to offer solutions that support these goals. Our range of pilot plants and food technology equipment helps companies optimise their energy usage, streamline production processes, and meet the growing demand for sustainable practices. With our expertise and cutting-edge technology, we are committed to helping food manufacturers achieve significant energy savings.

Does your food production business need to reduce your energy consumption? Contact us to learn more about how Armfield’s food technology equipment can help your business achieve its energy-saving goals.

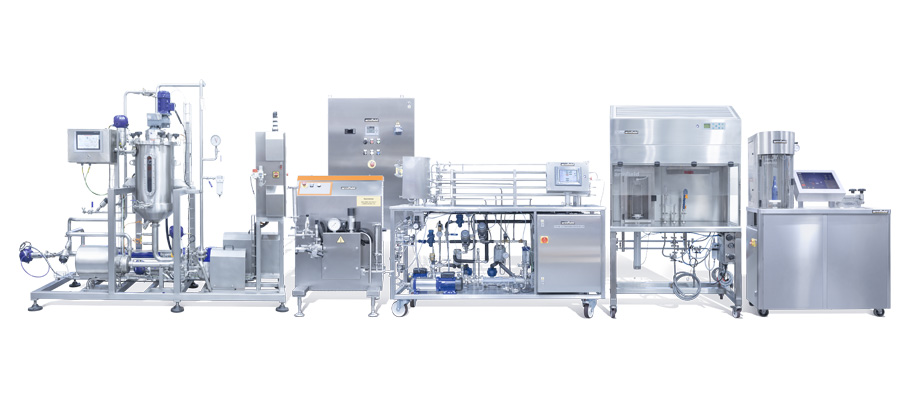

Pilot Plant Equipment: An Overview Guide – Armfield

Pilot plant equipment plays a crucial role in the food industry, acting as a bridge between small-scale lab experiments and full-scale production. At Armfield, we provide top-tier solutions for industrial food technology, emphasising the importance of both high quality materials, process control and repeatability. This guide explores the significance, types, and considerations of this kind of equipment, particularly focusing on its application in the liquid food sector.

What is a Pilot Plant?

A pilot plant is a small-scale version of a production plant used to test and optimise new processes and products. Unlike lab experiments, which often involve very small quantities, this type of equipment simulates industrial conditions to provide realistic data on how a process will perform on a larger scale. They are crucial for refining recipes, improving efficiency, and ensuring the feasibility of scaling up from prototype to full production.

The Importance of Such Equipment

Our plant equipment is integral to the development of new food products and processes. It allows for experimentation and validation in conditions that closely mirror those of a full-scale production environment. This step is essential for identifying potential issues, testing variations, and ensuring that new processes are both effective and economically viable before committing to large-scale production.

Types of Pilot Plant Equipment

Armfield offers a comprehensive range of equipment specifically designed for research, development, and small-scale production in the food and beverage industries. These systems cater to processes such as pasteurisation, sterilisation, mixing, drying and more. Here’s an overview of the key equipment offered in this range:

Heat Treatment Systems (HTST, UHT and Pasteurisation)

- Carbonators (including filling and capping)

- Spray Dryers

- Homogenisers

- Mixing and Blending Equipment

- Continuous SSHE crystallisers

- Filtration Systems

- Oils refining

Desolventising – Bleaching – Neutralising – washing – Hydrogenation – Deodorising

Distillation Columns

For processes requiring separation or purification, distillation columns are indispensable. In the food industry, they can be used to concentrate flavours, remove impurities, or separate components of a mixture. These columns must be designed to handle varying flow rates and temperatures, reflecting the complexities of large-scale operations.

Key Features and Capabilities

Pilot plant equipment must be designed with features that support scalability and efficiency. Key considerations include:

- Size and Capacity: Equipment must be appropriately sized to handle the quantities required for testing without compromising the quality of the results.

- Materials: The choice of materials for construction affects durability, safety, and compatibility with various food products. Stainless steel 316 is commonly used due to its resistance to corrosion and ease of cleaning.

- Control Systems: Advanced control systems allow for precise monitoring and adjustment of process parameters, ensuring accurate replication of industrial conditions.

Selecting and Designing Pilot Plant Equipment

Choosing the right pilot plant equipment involves several factors:

- Scalability: Equipment should be designed to facilitate easy scaling up from small batches to full-scale production. This involves considering how process parameters and equipment performance will change as scale increases.

- Cost-Effectiveness: While high-quality equipment is essential, it should also be cost-effective. Balancing initial investment with long-term benefits and operational costs is crucial.

- Customisation: Depending on the specific needs of the food product or process, some degree of customisation may be required to optimise performance.

Industries Utilising Pilot Plant Equipment

This equipment finds applications across various industries, including:

- Food and Beverage: Essential for developing new recipes, improving processing techniques, and ensuring quality control.

- Pharmaceuticals: Used for testing drug formulations and production processes.

- Chemical Manufacturing: Facilitates the development and optimisation of chemical processes.

Benefits of Using Pilot Plant Equipment

Utilising pilot plant equipment offers numerous advantages:

- Risk Reduction: By testing processes on a smaller scale, potential issues can be identified and addressed before committing to full-scale production.

- Cost Savings: Early detection of problems can prevent costly production errors and ensure more efficient use of resources.

- Improved Quality: Pilot plants enable fine-tuning of processes to enhance product quality and consistency.

Operating and Maintaining Pilot Plant Equipment

Proper operation and maintenance of pilot plant equipment are crucial for reliable performance. Key practices include:

- Regular Maintenance: Routine checks and maintenance help prevent breakdowns and extend the lifespan of the equipment.

- Safety Precautions: Adhering to safety guidelines ensures the well-being of operators and the integrity of the equipment.

- Troubleshooting: Common issues such as leaks or malfunctions should be addressed promptly to avoid disruptions in testing.

Troubleshooting Common Issues

When problems arise with pilot plant equipment, common issues include:

- Leaks: Often caused by worn seals or faulty connections. Regular inspections and timely repairs can prevent leaks.

- Malfunctions: Equipment may fail to operate correctly due to electrical or mechanical issues. Diagnostic tools and professional support are essential for effective troubleshooting.

Summary

Pilot plant, equipment is a cornerstone of innovation in the food industry, facilitating the development and refinement of new products and processes. At Armfield, we offer comprehensive solutions designed to meet the evolving needs of industrial food technology. Our focus on training and teaching ensures that users are equipped with the knowledge to maximise the benefits of pilot plant equipment.

For more information on how our pilot plant equipment can support your food industry projects, contact us today.

Trial Laboratory is fully operational

Armfield’s Trial Laboratory is fully operational, using video calling for remote sessions and in-person trials now available. With recent technology upgrades, we have been able to run very successful trials on a wide variety of equipment and products.

Food Ingredients Exhibition in Frankfurt

Join Armfield at the Food Ingredients Exhibition in Frankfurt 30th November – 2nd December! The team will be there to welcome you and talk about your research and development needs. We can provide expert knowledge in small scale processing systems such as:

– carbonators

– pasteurisers

– mixing and separation

– solvent extractors

– spray drying

– oils refining systems

– and much more!

We are happy to help with any questions you might have, no matter how small!

Our booth is 31J82 so please drop by or book an appointment through the app to see a specific member of our team.

Armfield Inc Industrial Food Department Out and About

Armfield’s American office had their Industrial Food Department out showing at the South-eastern IFT Hybrid Food Expo and Orlando at the IFT Local Suppliers Shows.

Titus Porter was on hand to explain the vast range of products available from Armfield related to Food Technology. As usual, the shows were very successful even during these difficult times.

See more at www.armfield.com

Armfield launches its new laboratory

A new laboratory is launched at Armfield! Available with a large range of equipment to process varying applications related dairy, beverage, pharmaceutical, food, oils ingredients and other liquid processes. These units can be utilised to confirm your need and give you confidence to purchase the Armfield equipment.

Also available is a full trials facility for business to business trials requirements. With trained personnel available at all times you are guaranteed useable results in real time, on hand support and a full data acquisition file included with a written report.Now with social distancing rules in place, trained and experienced staff can test products on your behalf and send you the data to prove our concepts and results, or provide virtual trials.

Speak to our sales team to find out more:

Kombucha and Armfield

The ancient recipe for Kombucha involves only tea leaves, sugar, water and the mother culture of bacteria and yeast. Adjusting the quantities of the ingredients will change the flavour of the final beverage so no two drinks from different brewers will taste the same.

The process must be monitored and refined to maintain your unique flavour and keep consistency between batches. This is where Armfield can help with the FT140X.

The temperature of the drink can be monitored and controlled throughout the process meaning it is kept consistent between consecutive batches. With built in low-speed agitators you can periodically mix the batch to improve the contact of the yeast and bacteria to the sugars, lowering the time needed to ferment and increasing your final yield. The double jacket gives close temperature control throughout the fermentation process giving you repeatable and unbeatable results.

For bottling your winning products, the Armfield FT102X gives consistent filling and carbonation (if required) capabilities for reproducible results every batch.

Contact us – www.armfield.co.uk

Armfield Updates

Subscribe to our occasional newsletter for the latest product updates from Armfield Engineering.