SV306 – Bending Stress in a Beam

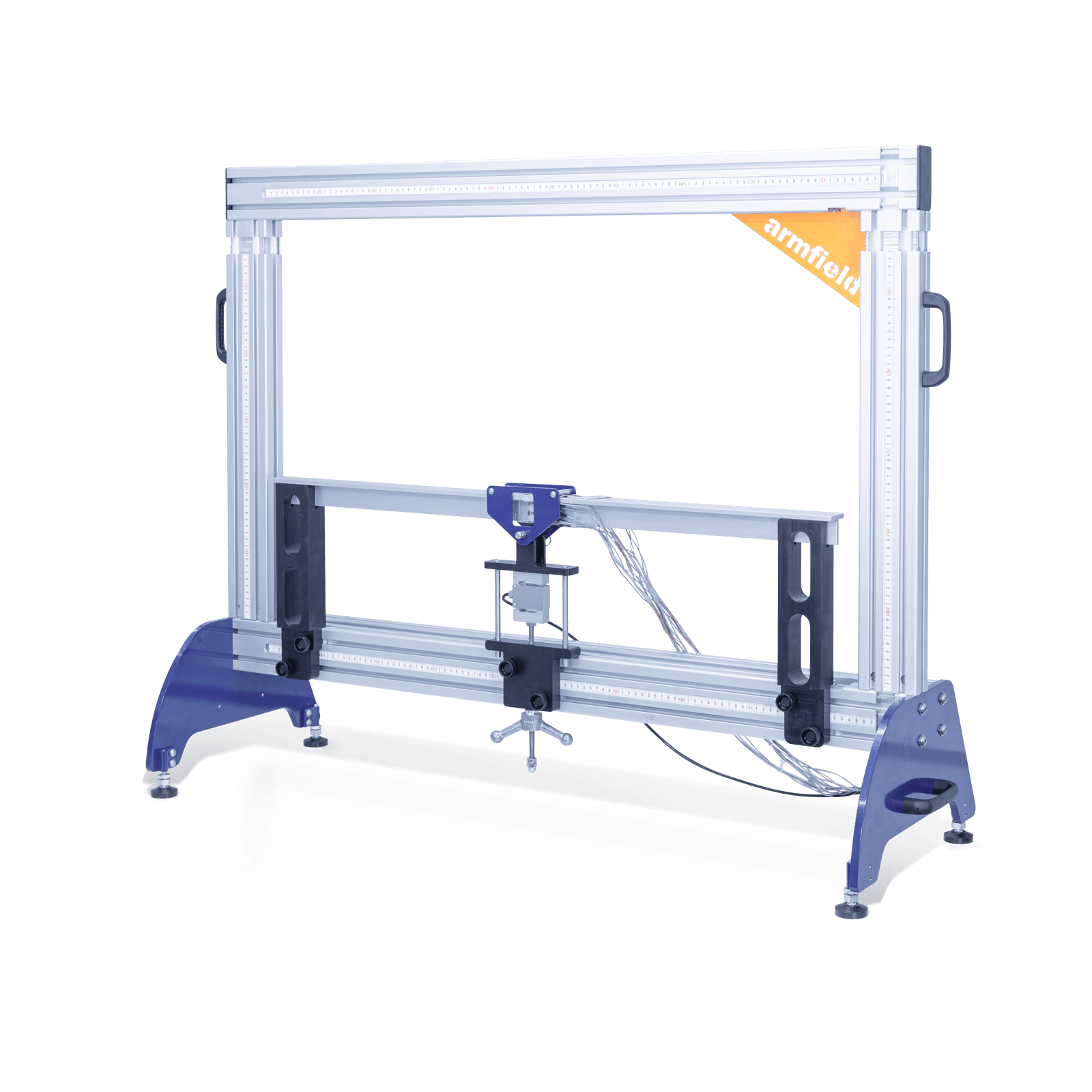

The experiment bending stress in a beam allows the experimental investigation of the internal stresses of a simply supported beam placed into four-point bending.

This experiment has the following properties:

- T section beam fitted with nine strain gauges to measure the strain at various points on the section

- Load cell assembly to apply any load up to 500 N via a load application bracket, evenly distributing the load over two points

- Adjustable simple supports

Description

The beam used in this experiment has nine strain gauges fitted at the mid span location at various points on its section. Each strain gauge has a mated strain gauge on the other side of the beam which is used to eliminate the effect of thermal expansion from the strain measurement.

The T beam rests on two simple supports with a central slot to accommodate the web of the T beam. The simple supports are fixed to the Universal Frame bottom beam using thumb screws which allow the user to adjust the position of the supports and change the working length of the beam.

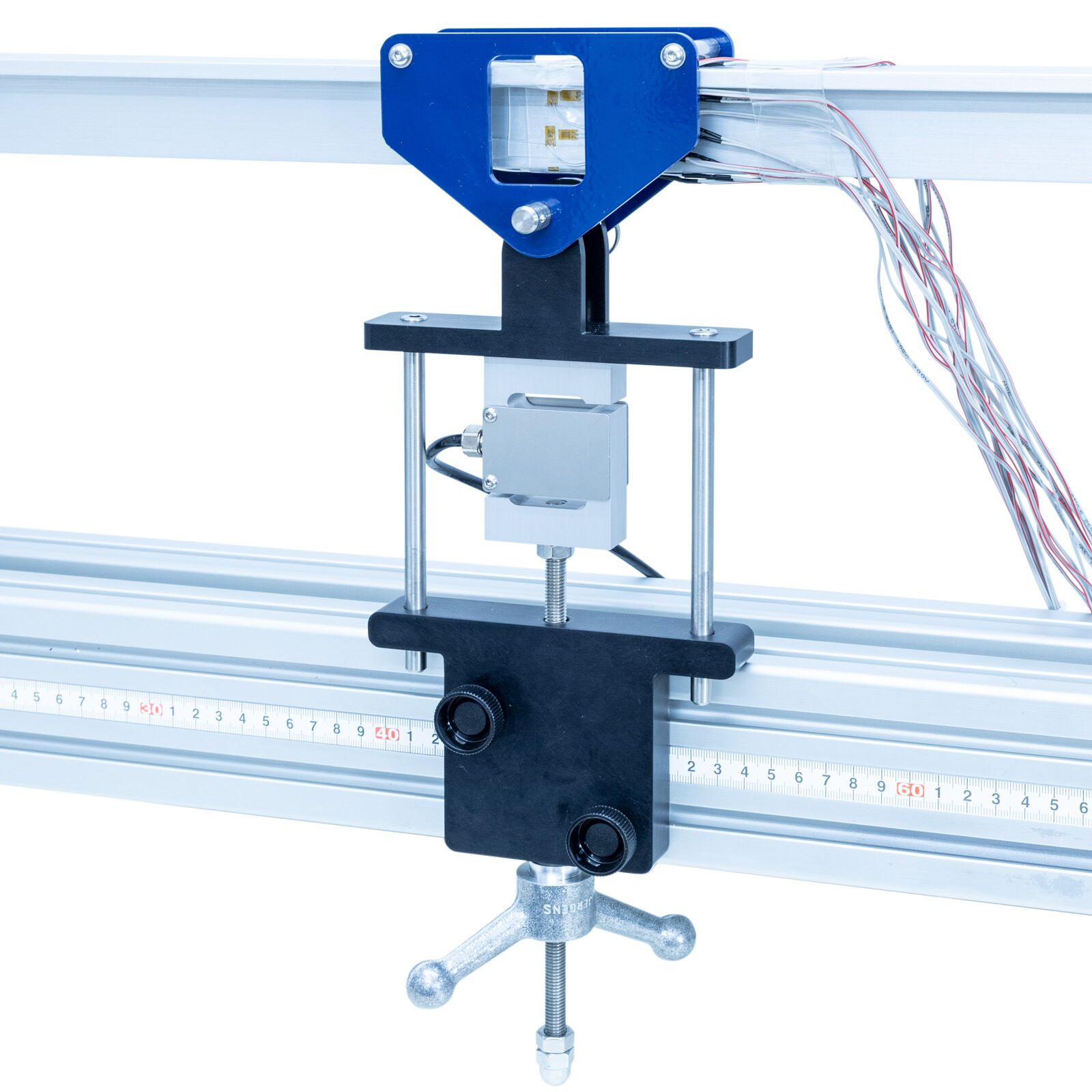

Point loads are applied to the beam through a load application bracket. The load application bracket takes the applied load from the load cell assembly and equally divides it between two point loads equi-distant from the load cell, placing the beam into four-point bending.

The load cell is operated by applying a deflection to the beam using the thumb nut at the base of the load cell. The load cell then measures the load invoked by the applied deflection.

Technical Specifications

- 1 x T Beam fitted with Strain Gauges

- Material: BS EN 755-2, EN AW-6082 T6

- Yield Stress = 260 Mpa

- Young’s Modulus = 70 Gpa

- Beam Length = 900 mm

- Flange depth (d1) = 6.35 mm

- Beam width / breadth (b1) = 38.1mm

- Web depth (d2) = 38.1 mm – 6.35 mm = 31.75mm

- Web width / breadth (b2) = 6.35mm

- Distance between point loads =100mm

- 2 x Simple Supports

- 1 x Load Cell Assembly

- Force range: 0 – 500 N

- 1 x Load Application Bracket

- 1 x Detent Pin

- Universal Frame Mounting Hardware

Features & Benefits

- Allows custom specimen usage

- Span can be adjusted

- Supplied with Armfield structures software as standard

- Bending Equation

- Neutral Axis

- Working with Stress and Strains and their conversion

- Second Moment of Area

- Bending Stress

- Strain

- Strain Gauges

- Bending Equation

- Neutral Axis

- Second Moment of Area

- Storage temperature: -10°C to +70°C

- Operating temperature range: +10°C to +50°C

- Operating relative humidity range: 0 to 95%, non condensing

- SV100: Bench Mounted Frame

- SV101: Structures Interface Unit

Electrical supply:

110/120V, 60Hz

220/240V, 50Hz

- SV100: Bench Mounted Frame

- SV101: Structures Interface Unit

PC with a USB port, running Windows 7 or above

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.1m³

Gross Weight: 25kg

Length: 1.176m

Width: 0.392m

Height: 0.922m

- SV306: Bending Stress in a Beam

- SV100: Bench Mounted Frame (Sold separately)

- SV101: Structures Interface Unit (Sold separately)