W3-MKII Permeability – Fluidisation Studies Apparatus

The W3MKII Permeability/Fluidisation Apparatus enables permeability, fluidisation and attrition testing to be demonstrated using tap water, and suitable porous granular media.

Students can measure and understand the characteristics of flow through a bed of particles and test various media that may be contemplated for use in deep bed filters.

Description

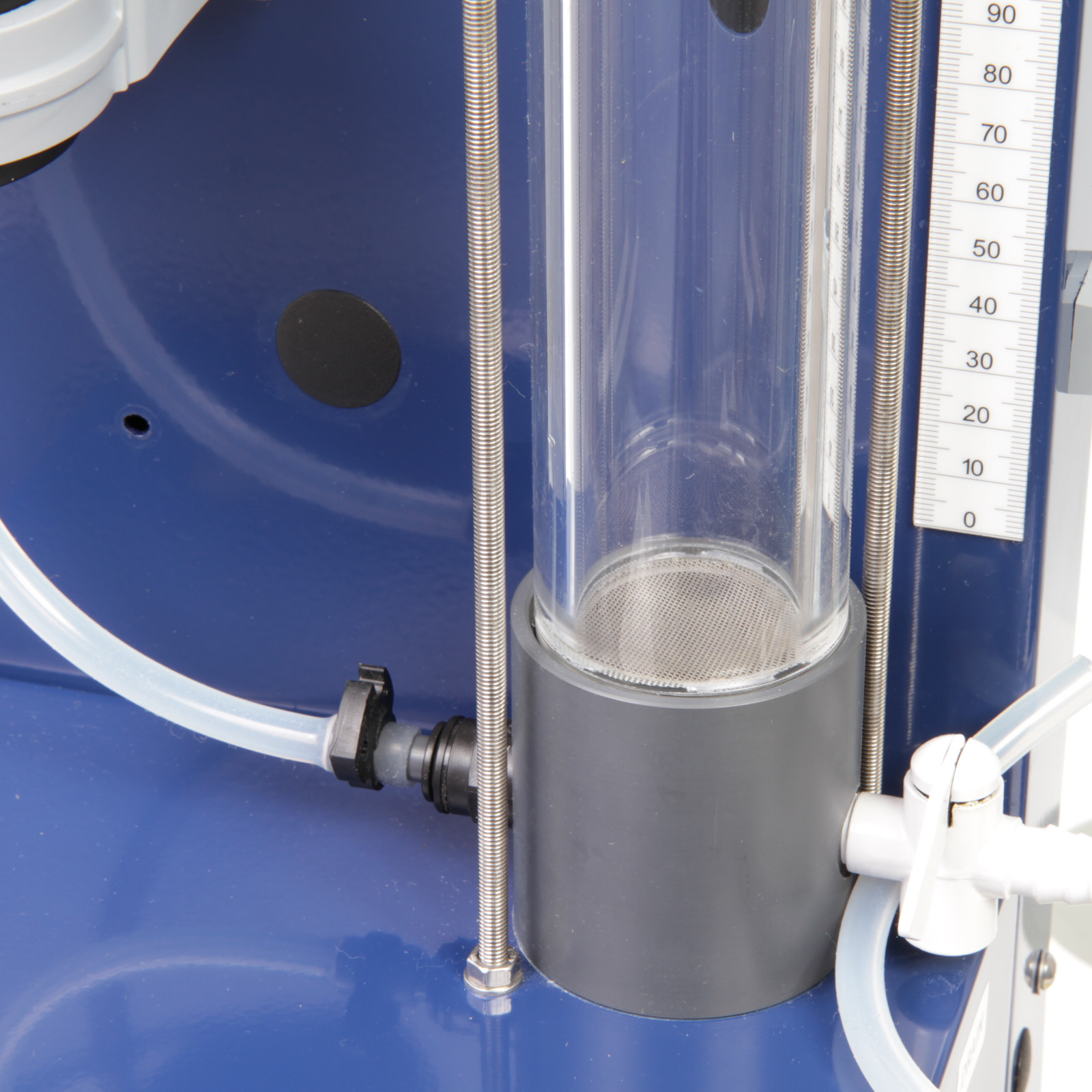

A bed of granular medium (usually Ballotini, but other materials can be used, such as sand or anthracite) is placed in a readily demountable tube through which water can be made to flow in either downward through the column to demonstrate permeability or upwards to demonstrate attrition and fluidisation.

At the base of the column is a sieve mesh to retain granular material. Differential pressure sensor enables measurement of pressure drop across the bed. The test section tube and all tubing connections are transparent to allow entire process to be observed and the presence of air bubbles easily detected.

Technical Specifications

Sample tube: I/D 0.038m

Sample tube length: 0.507m

Pump: 24 L/hr

Flow meter range: 0-3 L/min

Glass funnel: 1.5L

Solenoid valves: 2

Pressure range: 0-5 psi

Features & Benefits

- Metal framework with transparent test section for observation

- Control and data logging via PC

- Flowmeter to measure the flowrate

- Solenoid valves for automatic selection of process

- Operational manual with teaching exercises

- Universal single-wire interface

- Electronic pressure sensor

- Pressure-drop measurements and correlations for flow through packed beds

- Verification of Kozeny’s equation

- Characteristics of a liquid fluidised bed

- Measurement of permeability of selected solids

- Attrition tests

- Apparatus to verify Darcy’s law, to examine Kozeny’s equation and to observe liquid fluidisation behaviour of a granular bed

- Equipment consists of a metal framework, transparent test section for observation

- Pump 24 L/hr

- 2 x Solenoid Valves

- Differential Pressure Sensor 0-5psi

- 1.5L glass funnel

- Test material (Ballotini) for the packed bed is supplied with the unit

- Software for control and data logging

- Operational manual with teaching exercises

- Sieve shaker (CEN MKII-13)

The ArmBUS software enables the operator to select the appropriate stage of the process and a mimic diagram with measured variables is displayed. The speed of the pump can be varied to meet the required flow rate.

Results are saved in a log, which can be viewed and manipulated with the ArmBUS results viewer. Results can be printed or exported in a spreadsheet format, which can be opened in a wide range of packages for further analysis.

Electrical supply: supplied with a universal mains adaptor suitable for 100-240V / 1ph / 50-60Hz

Software requires a computer running Windows XP or above with a USB port (computer not supplied by Armfield)

Alternative bed materials such as sand, anthracite (not supplied)

Packed and crated shipping specifications

Volume: 1.5m³

Gross weight: 15Kg

Length: 0.43m

Width: 0.38m

Height: 0.97m

- W3-MkII

- CEN MKII-13 (optional)