W11 Aerobic Digester

The continuous activated sludge process has been successfully employed in public health engineering installations for nearly a century.

The Armfield Aerobic Digester is a benchtop unit designed as a comprehensive study facility of this process.

A synthetic waste water feed may be used to gain a working knowledge of the operational parameters and purification efficiencies.

Description

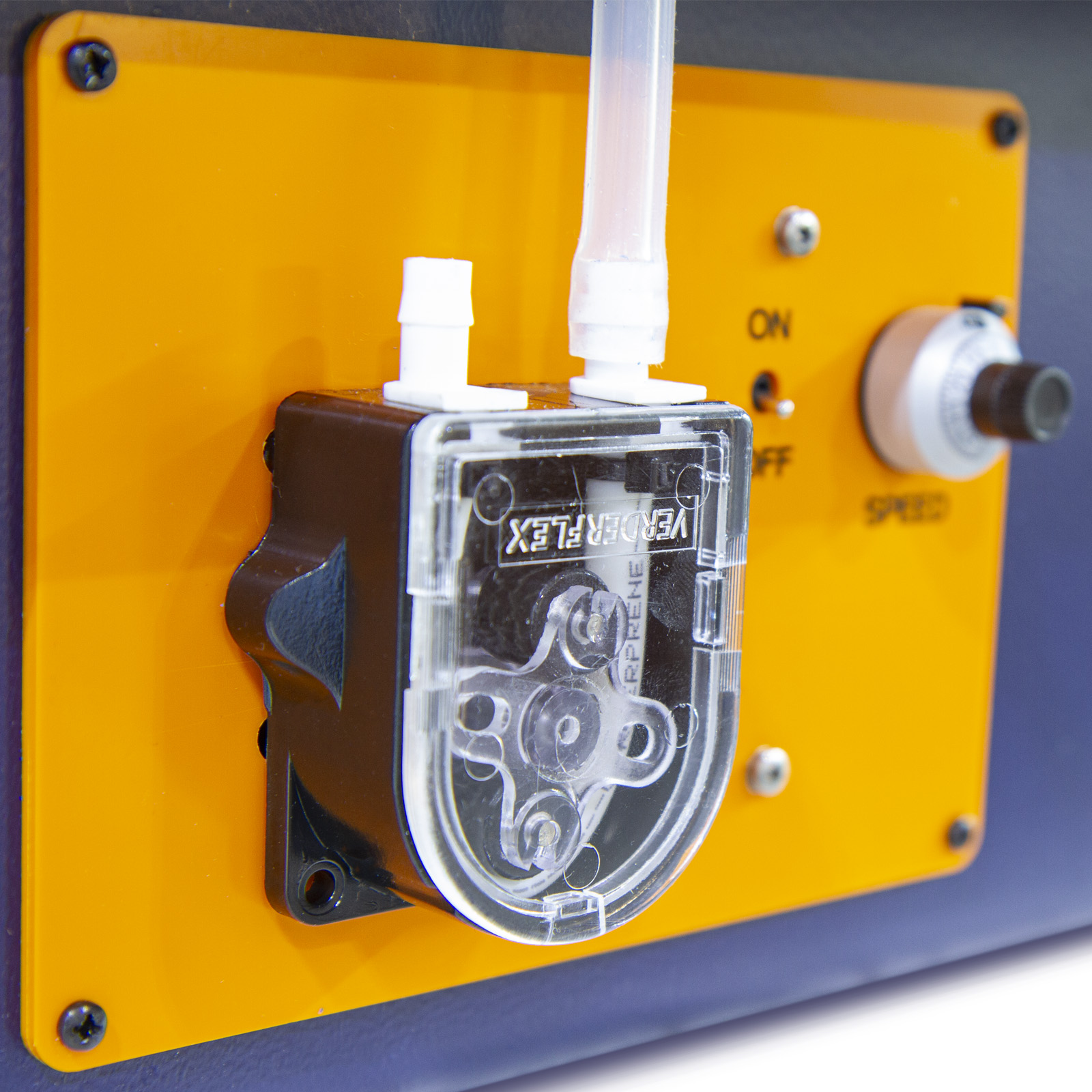

Waste water is drawn from a floor-standing feed tank (not supplied) by a DC motor-driven peristaltic pump. Rotational speed – and thus flow rate – is accurately set by a ten-turn potentiometer.

The pump delivers the feed to the reactor vessel through a transparent lid. Air is supplied at a measured rate by a small compressor, and discharges into the base of the reactor via a spider-arm dispenser. This design prevents blockages and produces sufficient bubbling for stirring and reaction. The liquid level in the reactor is maintained at a constant value of five to ten litres, by an adjustable overflow device connected to the outer annular chamber of the vessel. Discharge is by gravity to a floor-standing product tank (not supplied).

The reactor temperature is maintained by a three-term controller, which varies power to an immersion heater within the vessel. Any temperature between ambient and +35°C may be selected, the best conditions being a few degrees above the diurnal maximum in the user’s laboratory.

Dissolved oxygen and pH probes and meters are included.

The reactor lid contains a gas exit port, suitable for sampling the gases for subsequent analysis.

Technical Specifications

Feed pump: 24V DC, peristaltic, 0-30rpm corresponding to 0-40 L/day

Air compressor: 120V/240V, 0-3.0 L/min (STP)

Reactor vessel: 10L maximum capacity

pH meter range: 0.00 to 14.00

DO meter range: 0-100% saturation, resolution: 2%

Reactor heater: Toughened glass, electrical immersion 200W

Temperature controller: 3-term PID (temperature limit set at 35°C)

Features & Benefits

- Small Scales bench mounted design

- Provides demonstration of continuous activated sludge process

Downloads

- Acclimation of a completely mixed biological reactor

- Measurement of COD and MLSS changes as criteria of performance

- Establishing the stoichiometry and kinetics of aerobic processes

- Gas/liquid mass transfer

- Residence time distributions

- 100% scale-up to industrial requirements

- Studying the effect on effluent quality of:

Inflow substrate concentration (‘loading rate’)

Liquid flow rate and reactor volume (‘detention time’)

Air flow rate

Temperature

pH stability

Nutrient deficiency

- A 10L bench mounted aerobic digester, complete with peristaltic feed pump, air compressor and temperature control system

- Dissolved oxygen and pH probes and meters are included

- The reactor comprises a cylindrical porous liner held in position with sealing rings between the lid and the base to facilitate removal for cleaning and replacement

- Suspended solids are held within the reactor volume, while treated water permeates through the porous liner into an outer annular exit chamber

- The water level is maintained by an adjustable constant head overflow device

- This digester system is designed to operate safely and reproducibly for periods of several days

- The equipment is mounted on a moulded plastic base, equipped with an internally moulded drain channel, designed to cope with spillages and washdown water

- Operational manual with teaching exercises

CW-17 – Chilled Water Circulating Unit

Electrical supply:

W11-A: 220-240V/1ph/50Hz

W11-B: 120V/1ph/60Hz

W11-G: 220-240V/1ph/60Hz

Plastic feed and product tanks – capacity typically 30-50l, floor standing (not supplied)

Synthetic waste water (not supplied)

Packed and crated shipping specifications

Volume: 0.50m³

Gross weight: 40Kg

Length: 1.00m

Width: 0.50m

Height: 0.50m

- W11-A:

- W11-B:

- W11-G:

- CW-17-A (optional)