UOP14-MKII – Crystallisation unit

Crystallisation is a valuable process in chemical engineering where the precipitation of a dissolved salt in a liquid mixture is required. The Armfield UOP14-MKII demonstrates this process in the laboratory so that students may gain a thorough understanding of this industrial technique.

Description

Crystallisation is a valuable process in chemical engineering where the precipitation of dissolved salt in a liquid mixture is required. The Armfield UOP14-MKII demonstrates this process in the laboratory so that students may gain a thorough understanding of this industrial technique.

Meaningful experiments can be conducted within a typical laboratory period and students benefit from visual observation of the process.

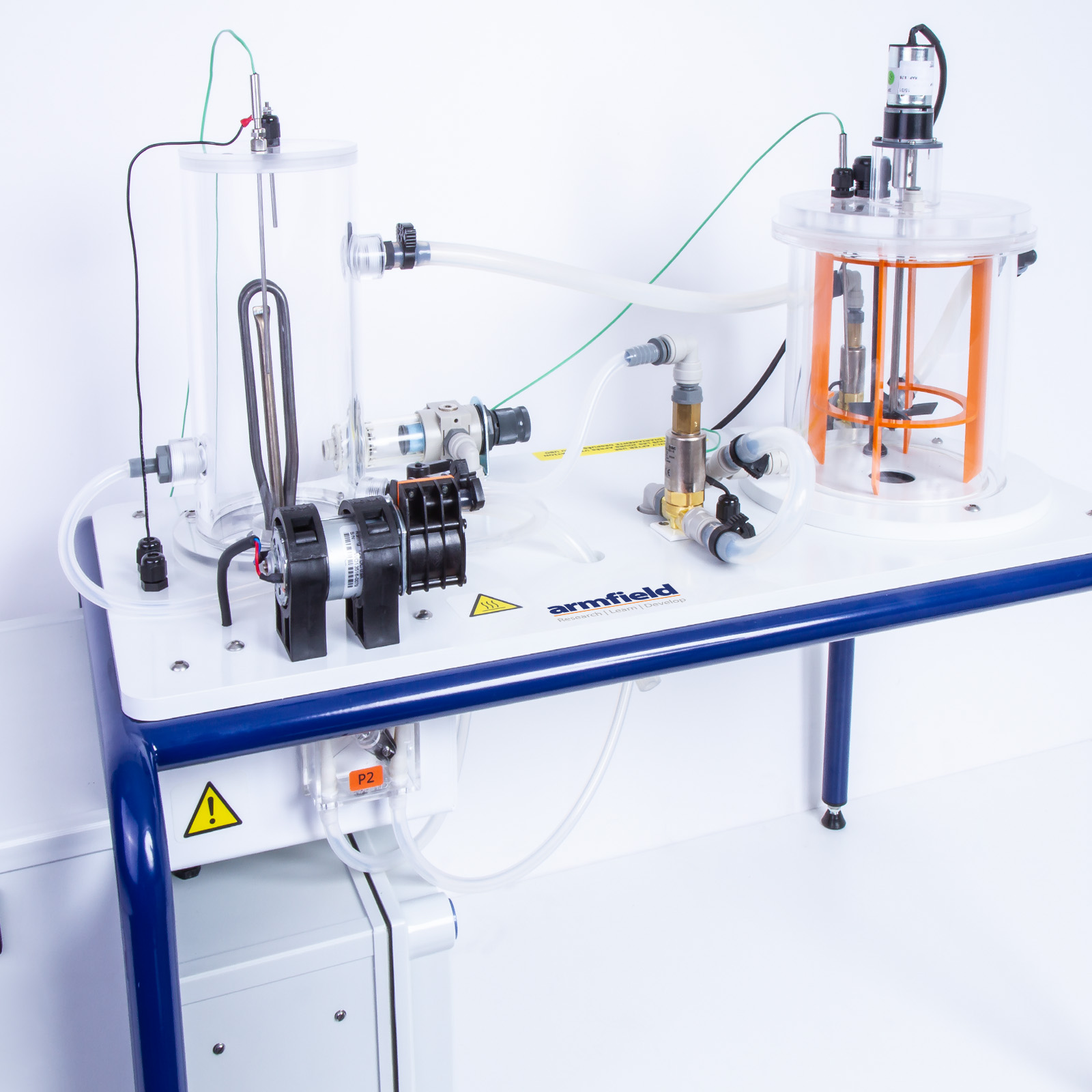

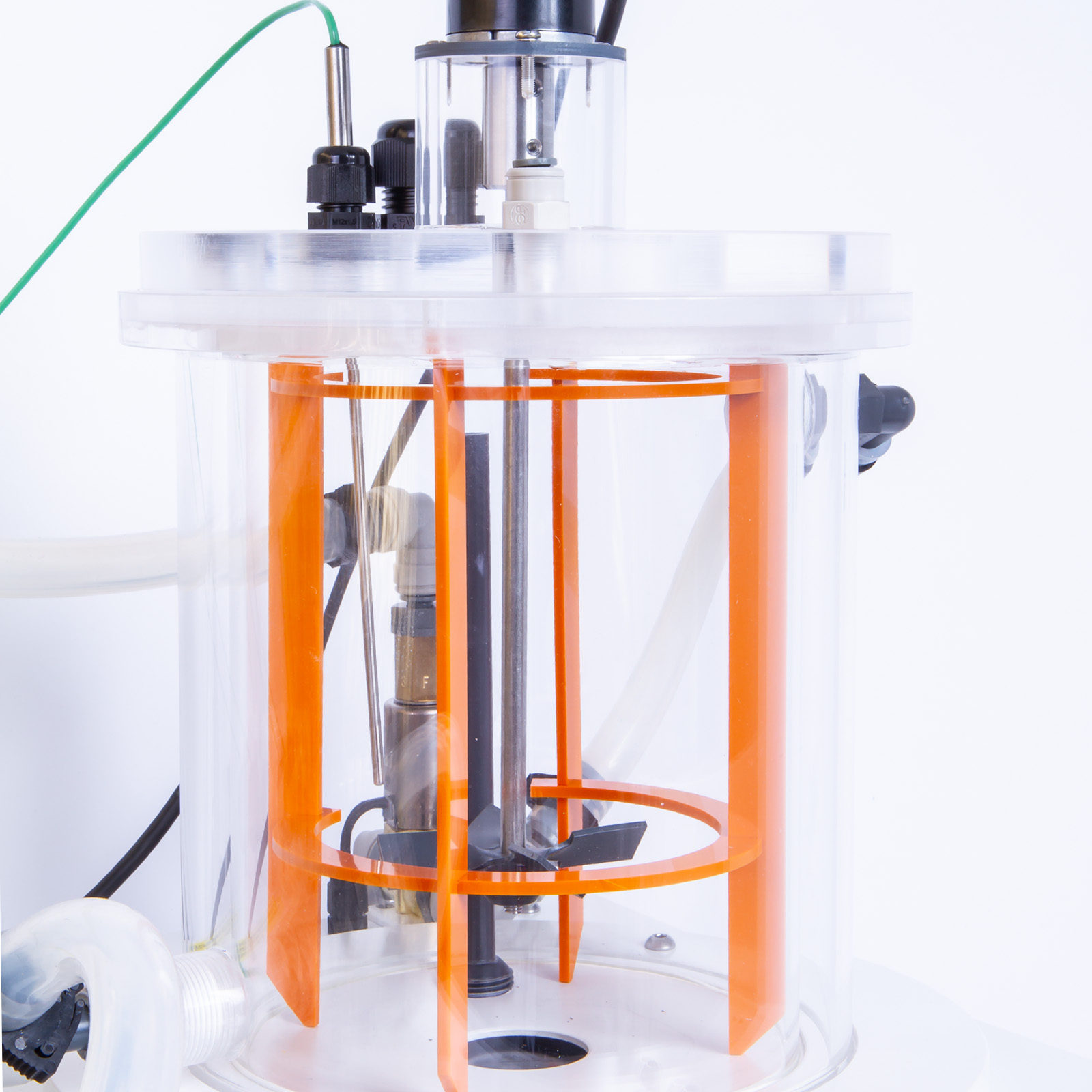

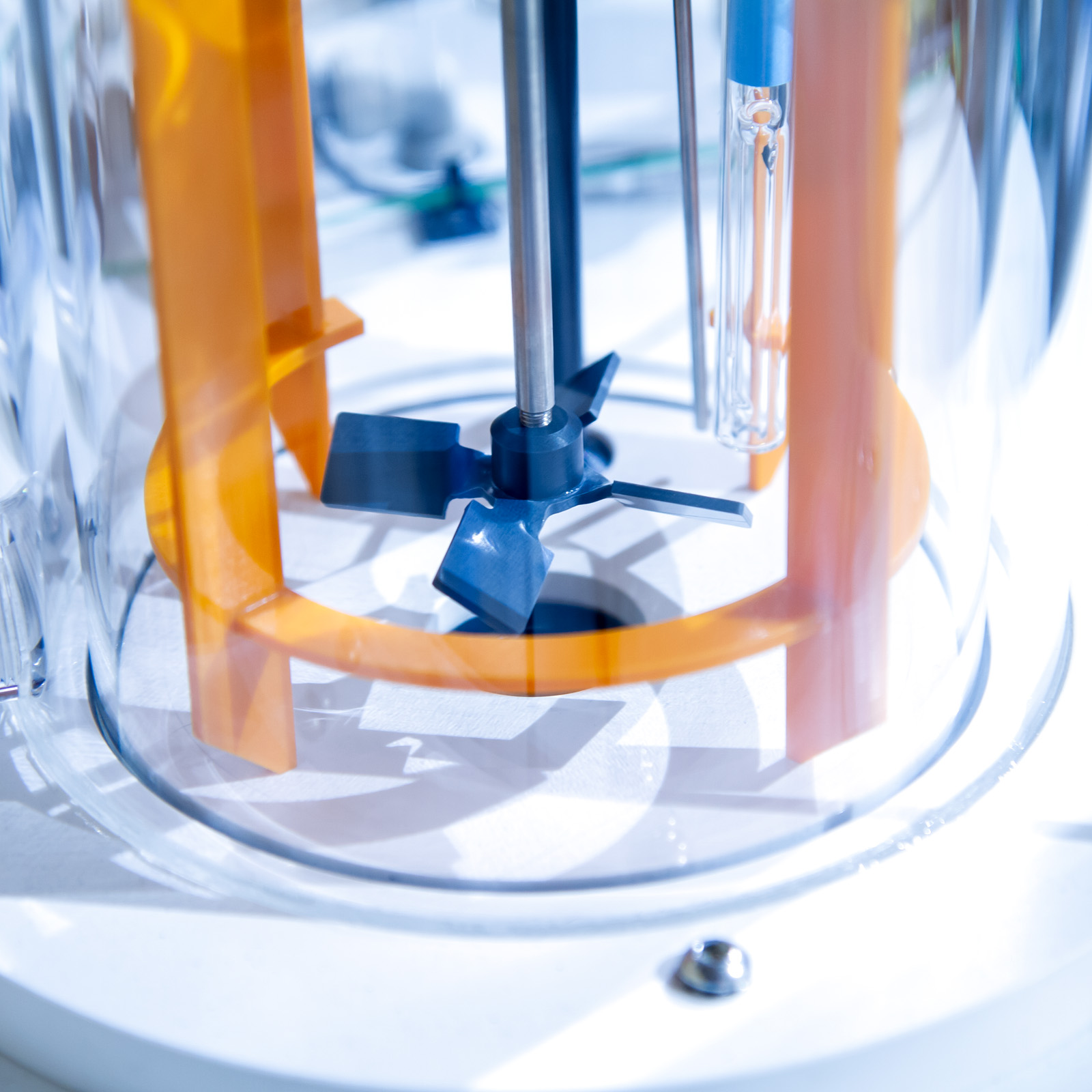

The UOP14-MKII introduces students to the fundamentals of crystallisation using a solution-cooling method. It is a benchtop unit with a clear crystallisation reactor, which enables visualisation of the crystallisation phenomena.

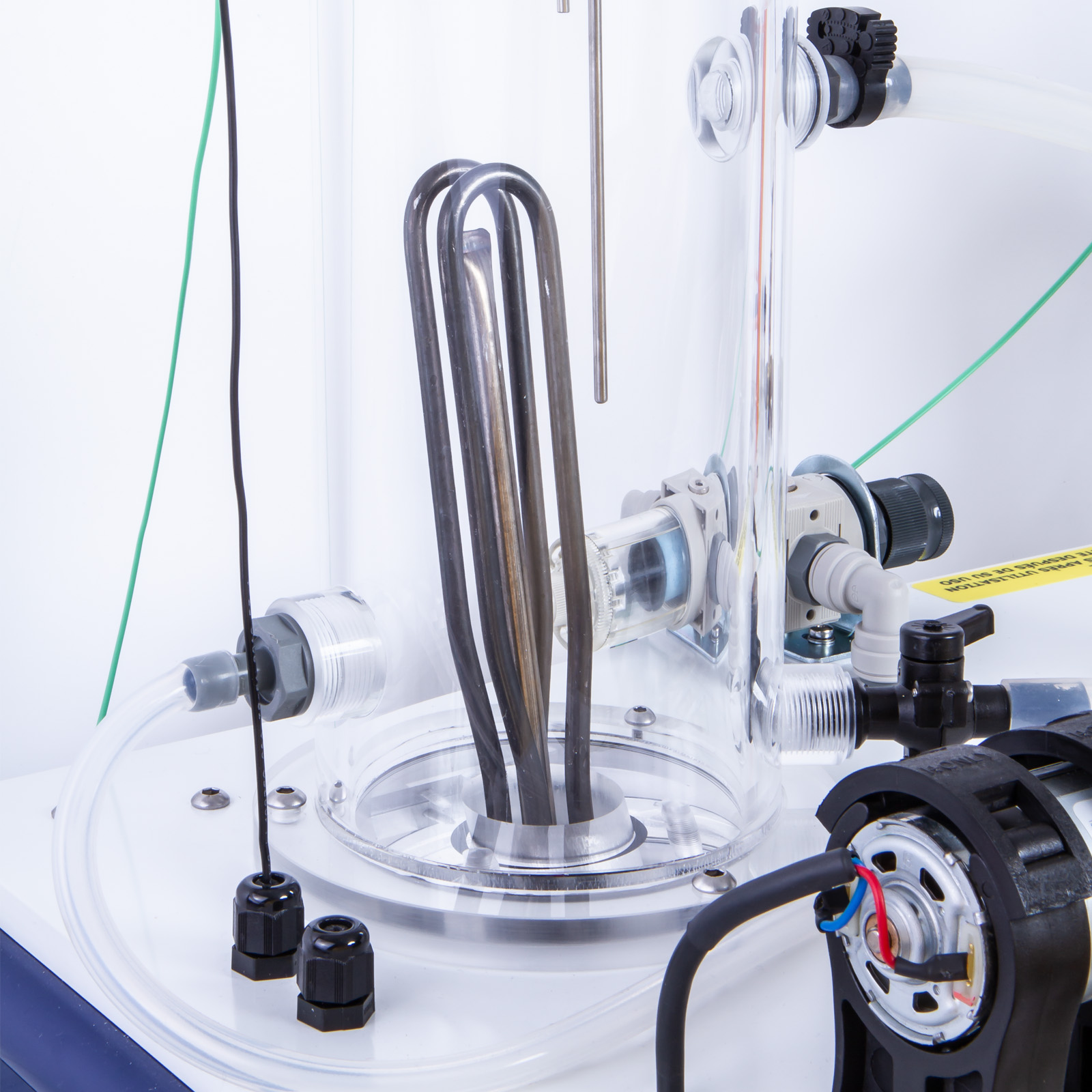

The equipment consists of a jacketed crystallisation vessel provided with temperature control and agitation.

The solution is heated by circulating hot water through the jacket from the hot water vessel in a closed-loop system and the solution is cooled by circulating cold water from mains water supply or a chiller.

At the end of the batch operation, the crystals and mother liquor are collected using the beaker supplied, filtered, washed and then dried in the oven. The dried crystals are then sieved using the set of sieves supplied to analyse the crystal size distribution.

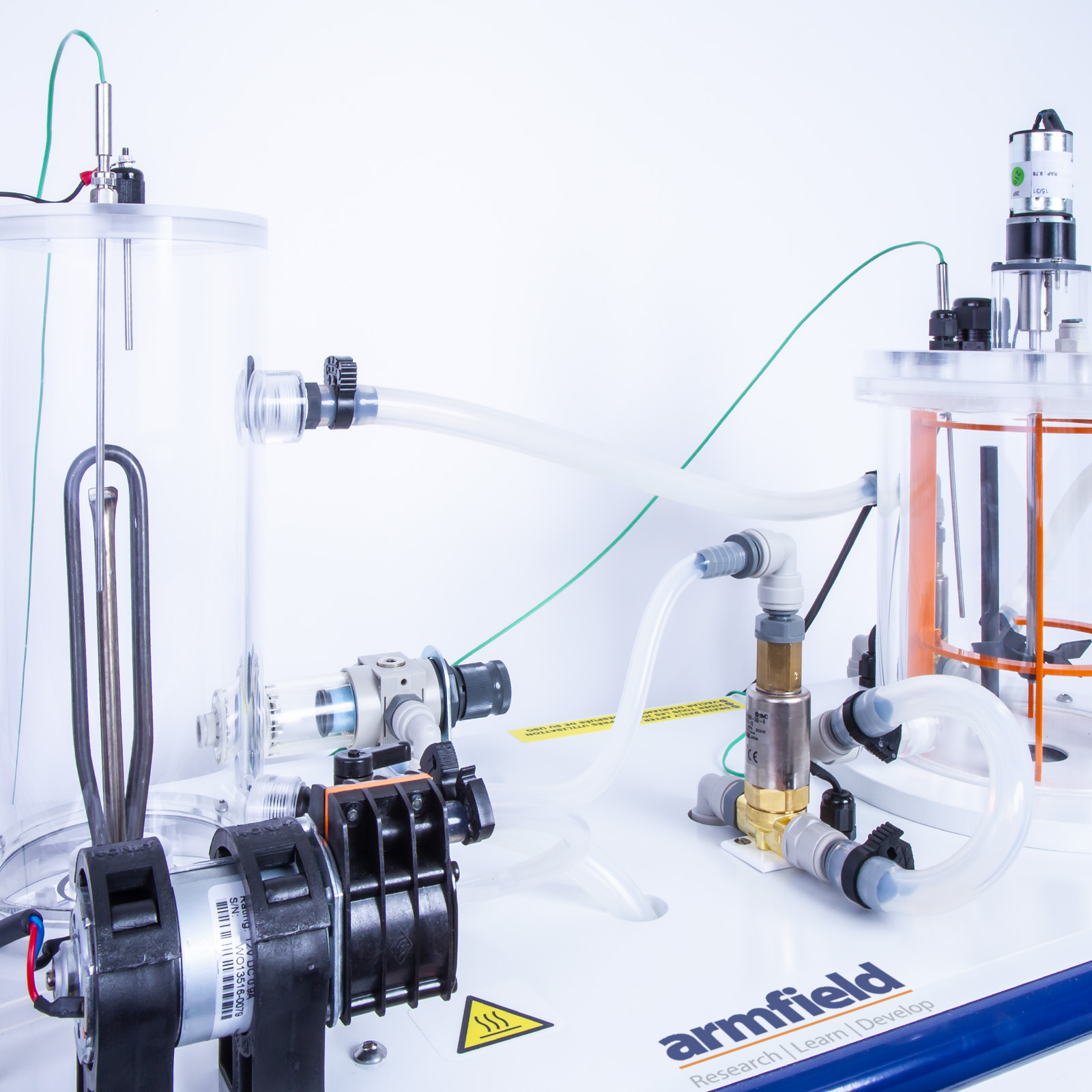

A conductivity sensor is included, which enables crystallisation to be monitored.

Different cooling rates can be investigated by the application of different water flow rates. A needle valve and flow meter are provided to vary the water flow rate quickly and easily to enable investigation of different crystallisation conditions, such as fast and slow cooling rates.

The instruction manual included contains experiments, providing a thorough grounding in the operation of crystallisation systems in the context of unit operations for chemical engineering students.

The equipment is supplied complete with a USB computer interface and data logging software.

The system may also be used in a continuous mode when used with the Armfield Crystallisation Unit UOP14-11 Continuous Feed Accessory.

Technical Specifications

UOP14-MKII

- 2-litre jacketed crystallisation vessel

- Hot water pump

- Flow meter 0.05-3 l/min

- 3 temperature sensors

- Conductivity probe 0-600mS

- Low-level liquid sensor

- Cold water supply pressure regulator

- Heater capacity 2kW

- Pressure regulator 0-2 bar

UOP14-11 (optional)

- Feed pump 0.5-10 l/hr

- 20-litre feed tank vessel

- Temperature controller

- Temperature sensor

Features & Benefits

Features

- Clear glass crystallisation vessel with acrylic jacket

- Control and data logging via PC

- Modulated control system for improved heating and cooling cycles

- Simplified connection of cold water supply to utilise either mains or chilled water where applicable

- Corrosion-resistant vessel internals

- Raised support frame which enables ease of crystal collection and cleaning

Benefits

- Enables study and investigation of the crystallisation process

- Clear acrylic vessel and pipework for visual demonstration of entire process

- User-friendly control of flow rates and levels within the vessel

- Corrosion-resistant baffle and impeller blade

- Convenient cold water supply connection for use with mains supply or chilled water supply via a chiller

- Raised frame which enables easy cleaning and crystal collection

- New hot water vessel for improved energy efficiency and improved heating cycle

- Understanding the principles of crystallisation

- Understanding crystallisation driving force

- Mass and energy balance

- Batch operation

- Continuous operation (option: requires UOP14-11)

(Study of continuous crystallisation kinetics UOP14-11) - Evaluation of crystallisation efficiency and crystallisation kinetics

- Study of the effect of different parameters such as agitation rate and cooling rate

- Crystal size distribution

UOP14-MkII Crystallisation Unit

- Benchtop metal frame unit

- Clear crystalliser vessel

- Hot water vessel with PID control loop

- 3 temperature sensors

- Conductivity probe

- Non-corrosive baffle and impeller blades

- USB port for data logging using the Armfield software

- Set of sieves for determining crystal size distribution

- Comprehensive instruction manual with detailed laboratory teaching exercises

- Isolating switch on the console

- Plastic bung with silicone sleeve

- Low liquid level sensor on the hot water vessel

- Hot and cold water pumps

- 3-litre beaker for collecting crystals and mother liquor

UOP14-11 Continuous Feed Accessory

- A benchtop unit comprising an ABS plastic plinth with integral electrical console onto which is mounted the stirred acrylic feed tank, with the heater and peristaltic pump

- A temperature sensor and 2.5kW heater mounted in the feed tank and linked to a PID controller for accurate solution temperature control

- A peristaltic pump, used to feed solution from the 20-litre feed tank to the reactor

UOP14-12 Buchner Filtration Kit

- An ejector / vacuum system

- Filter paper

- Funnel

- Rubber tubing

- Rubber bung

- Buchner flask

- Software requires a computer running Windows 7 or above with a USB port (Computer not supplied by Armfield).

- Laboratory oven to dry the crystals sample

- Potassium chloride

- Laboratory balance

- Deionised Water

Optional accessories

- UOP14-11 Continuous Feed Accessory

- UOP14-12 Buchner Filtration Kit

Related Products

UOP8 Tray Dryer

Single phase mains electrical supply:

UOP14MkII-A: 220-240V / 1ph / 50Hz, 13A

UOP14MkII-B: 120V / 1ph / 60Hz, 20A

UOP14MkII-G: 220V / 1ph / 60Hz, 13A

Cold water: 1 l/min @ 1 bar

PACKED AND CRATED SHIPPING SPECIFICATIONS

UOP14-MKII

Volume: 0.35m³

Gross Weight: 35Kg Max

UOP14-11

Volume: 0.35m³

Gross Weight: 35Kg Max

UOP14-12

Volume: 0.125m³

Gross Weight: 3Kg

UOP14-MKII

Length: 0.8m

Width: 0.9m

Height: 0.5m

UOP14-11

Length: 0.69m

Width: 1.00m

Height: 0.5m

UOP14-12

Length: 0.5m

Width: 0.5m

Height: 0.5m

- UOP14-MkII Crystallisation Unit

- UOP14-11 Continuous Feed Accessory

- UOP14-12 Buchner Filtration Accessory