SV903 – Journal Friction Apparatus

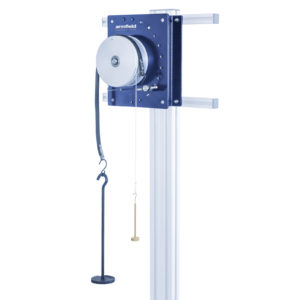

This apparatus is designed to determine the friction torque in a plain journal bearing under varying conditions of load, speed and lubrication.

Description

This apparatus is designed to determine the friction torque in a plain journal bearing under varying conditions of load, speed and lubrication.

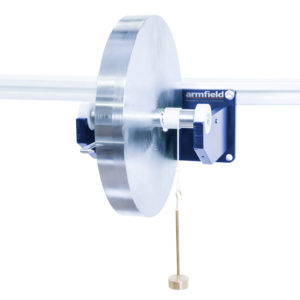

The ground steel shaft is driven by a variable speed electric motor. The journal housing has a thermometer pocket, a sight feed lubricator and a removable end cover. Oil cannot be thrown out. Friction due to end face contact is very much reduced by the use of a “floating” sleeve.

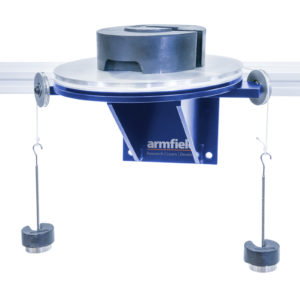

Friction torque is measured by adding weights to a load hanger suspended from the damped torque arm. Weights added to the lower hanger apply a steady load to the bearing of up to 650N. Phosphor bronze, sintered bronze and impregnated PTFE sleeves are supplied as standard journal housings.

An electronic tachometer is provided for measurement of the shaft speed, which can be controlled using the control potentiometer on the front control box.

An oil drip tray is provided to ensure all oil passing through the journal bearing is captured. A full set of weights, hangers and tools is provided along with a comprehensive instruction manual for student and lecturer.

Technical Specifications

- Shaft speed: 1500rpm

- Motor speed control potentiometer

- Drip feed lubricator for journal bearing lubrication

- Torque arm lever 4:1 ratio

- Journal shaft: Steel, Ø40mm nominal

- Journal bearings: Outside diameter = Ø50mm / Inside diameter = Ø40mm

Features & Benefits

- Wall mounted apparatus

- Can be mounted to the SV100 Bench Mounted Frame

- Pure torsion applied to the table

- Apparatus supplied with four sets of pivots

- The seating is in mild steel and the pivot is in brass

- Ball thrust bearing is included

- All load hangers and calibrated weights are supplied

Determination of coefficient of friction between two bearing surfaces under the following conditions:

- Dry, no lubrication

- Lightly lubricated

- Fully lubricated

To investigate the effect of lubrication on:

- Journal load

- Shaft speed

- Operating temperature

- Type of lubricant

To establish the relationship between the friction torque and:

- Journal load

- Operating temperature

- Type of lubricant

- Automotive

- Friction

- Machines

- Clutches

- Brakes

- Bearing

- Wear

- Torque

- Slip

- Lubrication

- SV903 Journal Friction Apparatus

- 3 x Journal bearing

- 2 x Load hanger

- 1 x Cleaning pad

- 1 x Power lead

- 1 x Thermometer

- 1 x Spirit level

- Hex wrench set

- 1 x Tin of light oil

- Weights: 10 x 0.1N; 10 x 0.2N; 1 x 1N; 2 x 2N; 1 x 5N; 1 x 10N; 2 x 20N; 2 x 50N

Friction

- SV900 Friction on an Inclined Plane

- SV901 Clutch Plate Friction Apparatus

- SV902 Pivot Friction Apparatus (including set of weights)

- SV903 Journal Friction Apparatus

- SV904 Bearing Friction Apparatus

- SV905 Rope Belt Friction Apparatus

- SV906 Friction of Belts Apparatus

- SV907 Brake Drum Friction Apparatus (including set of weights)

- 110/120V, 60Hz or 220/240V, 50Hz

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.27m³

Gross Weight: 42kg

Length: 0.560m

Width: 0.480m

Height: 1m

SV903 Journal Friction Apparatus