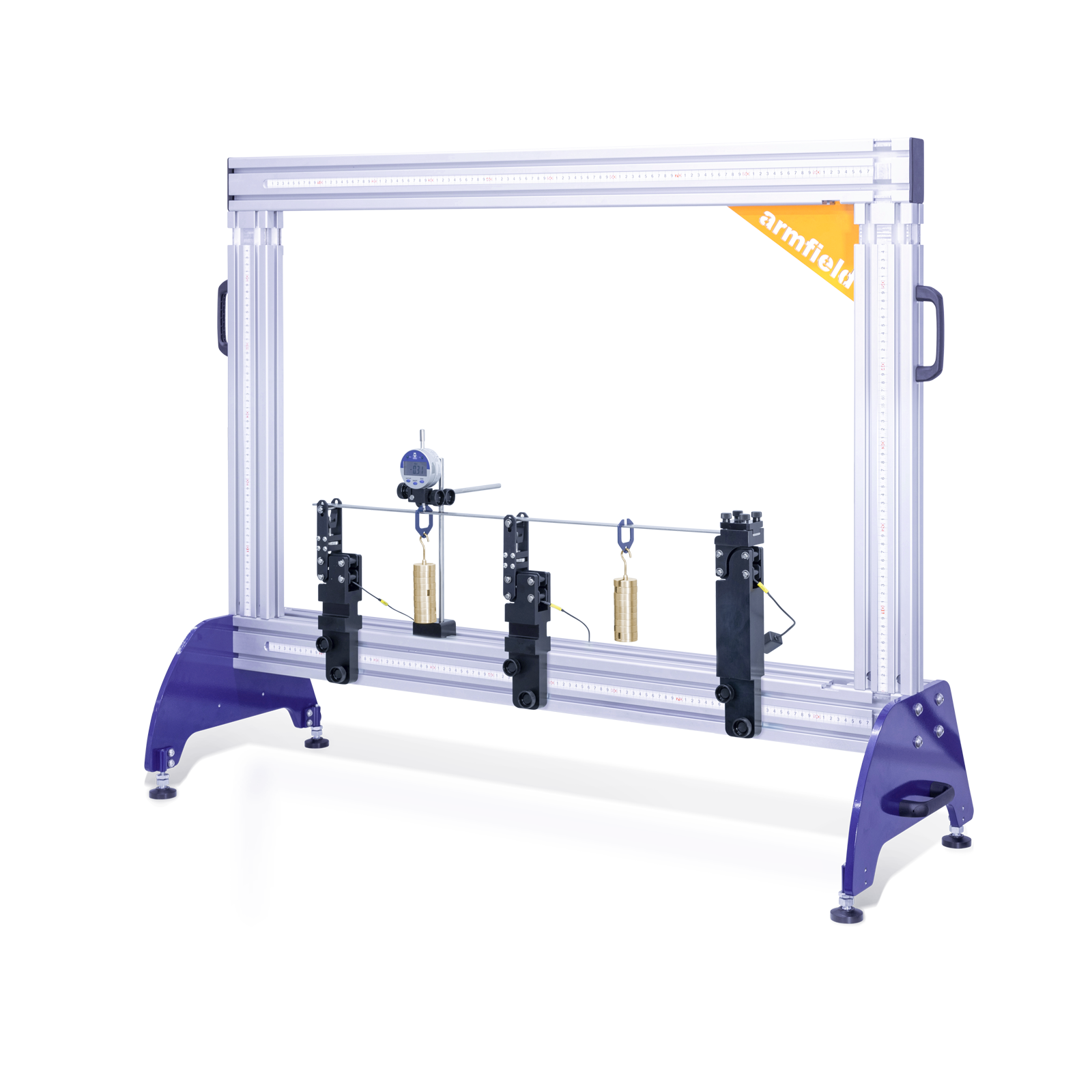

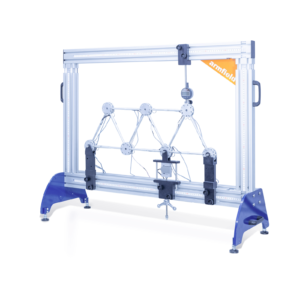

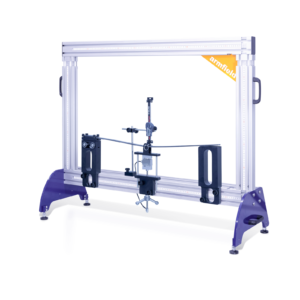

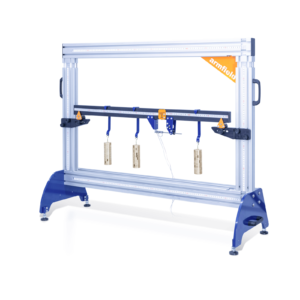

SV500 – Continuous and Indeterminate Beams

The experiment continuous and indeterminate beams allows the experimental investigation of the deflection of beams and the resulting reaction forces at the supports for multiple different continuous and indeterminate setups.

This experiment has the following properties:

- Assembly of multiple different beam experiments via two sinking and one fixed support capable of measuring reaction loads, a fixed support capable of measuring fixing moment, point load weight hangers and uniformly distributed loads (UDL) weight sleeves

- 3 different beam specimens of different section sizes and material

- Measurement of beam deflection using a digital indicator

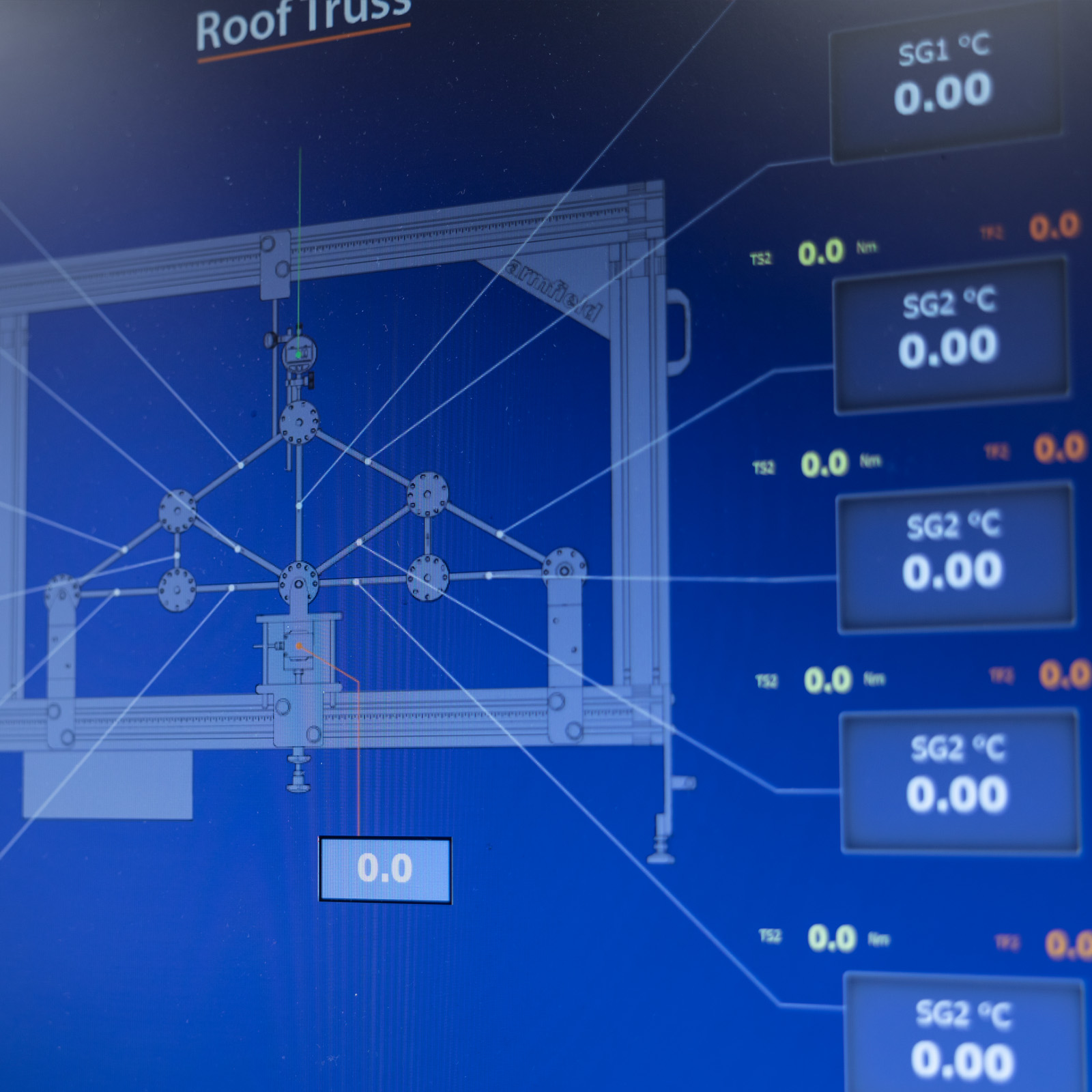

Supplied with Armfield structures software as standard

Description

The beam specimens are made from either aluminium or stainless steel and are 20mm wide with either a thickness of 3 or 5mm.

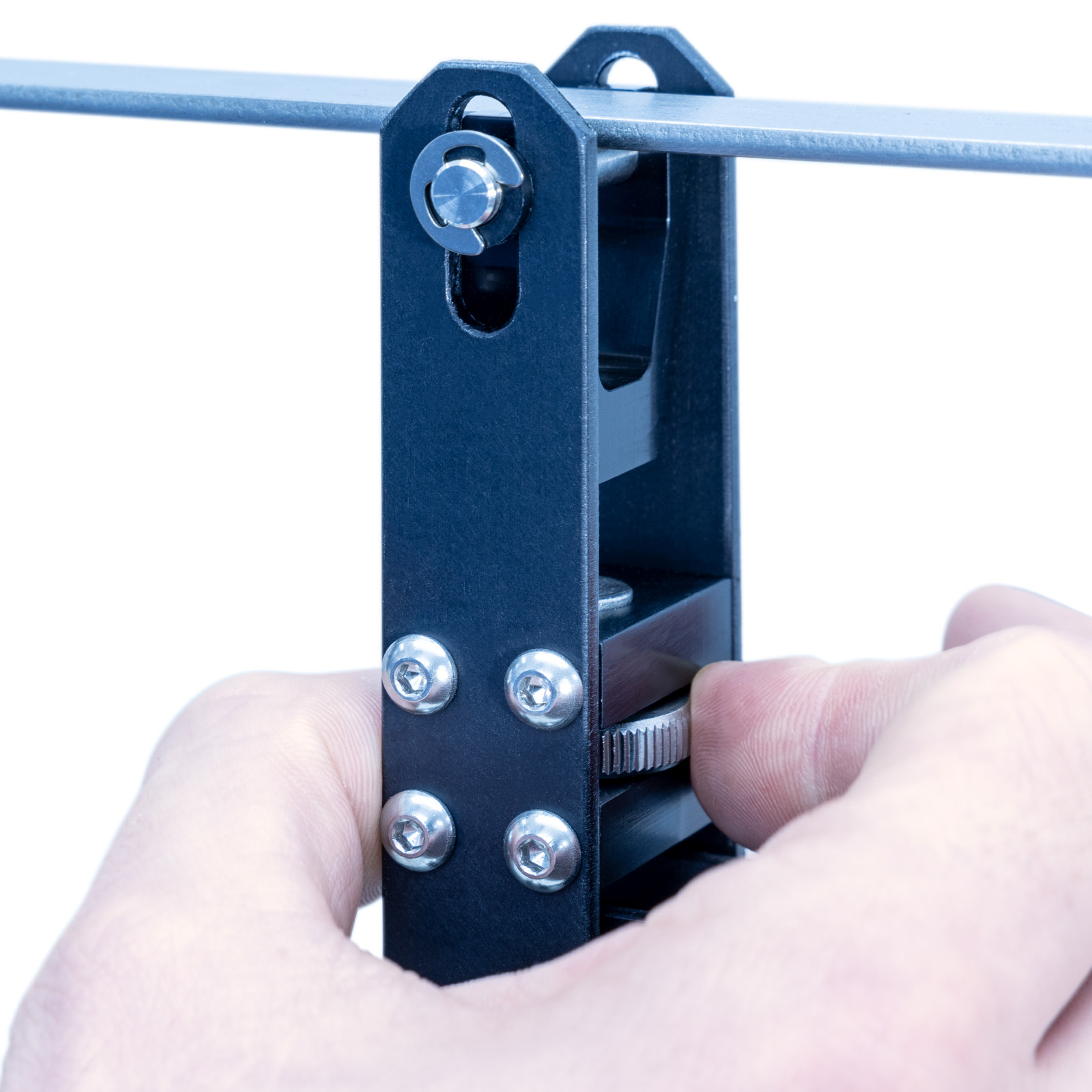

Three different types of support are supplied with the experiment. The first of which is a simple support that is capable of measuring the reaction force at the support as well as being able to act as a sinking support. The second support can be used in either a fixed configuration where a clamping plate holds the beam in place, simulating a fixed support or by removing the clamping plate, the support can be used to simulate a simple support. This support also has the capability to measure the reaction force acting at the support.

The final support is a support that is able to measure the fixing moment due to the fixed support.

Point loads are applied to the beam through either two point load hangers or a UDL sleeve in combination with the two 500g slotted weight hangers. The point load hangers can be moved along the length of the beam allowing many different loading conditions to be explored.

The slotted weights supplied and the weight hangers can be used inside the UDL sleeve to simulate a UDL load applied to the beam. The UDL sleeve has a central access point allowing the beam deflection to be accurately measured.

Technical Specifications

Beam Specimens

- 3 x Beam Specimen length: 720mm

- Beam sizes and material: 20 x 3mm (Stainless Steel & Aluminium), 20 x 5 mm (Aluminium)

- Young’s Modulus of Aluminium Beam: 70 Gpa

- Young’s Modulus of Stainless-Steel Beam: 193 Gpa

Appliable loads

- 2 x Slotted weight hanger total mass: 500g (1% tolerance)

- 2 x UDL Sleeve quantity

- Load Cell

- Force Range: 0 – 17.6N

- Fixing moment lever arm: 97mm

- Fixing moment range: 0 – 1.7Nm

Digital indicator

- Measurable range of the digital indicator: 12.7mm

- 2 x Resolution: 0.01mm

Features & Benefits

- Assembly of multiple different beam experiments via two sinking and one fixed support

- 3 different beam specimens of different section sizes and material

- Flexible setup arrangements including 2 supports allowing variety of test arrangement and structural theories to be demonstrated

- Supplied with Armfield structures software as standard

- Reactions of a continuous beam

- Reactions of a indeterminate beam

- Deflection of a continuous beam

- Deflection of a indeterminate beam

- Reactions and fixing moments of a continuous and indeterminate beam

- The principle of superposition

- Sinking supports

- Cantilevers and propped cantilever

- Principle of moments

- Reactions

- Deflection

- Theory of Bending

- Cantilevers

- Continuous Beams

- Indeterminate Beams

- Storage temperature: -10°C to +70°C

- Operating temperature range: +10°C to +50°C

- Operating relative humidity range: 0 to 95%, non-condensing

SV100: Bench Mounted Frame

SV101: Structures Interface Unit

Electrical supply:

110/120V, 60Hz

220/240V, 50Hz

- SV100: Bench Mounted Frame

- SV101: Structures Interface Unit

- PC with a USB port, running Windows 7 or above

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.1m³

Gross Weight: 25kg

Length: 1.176m

Width: 0.392m

Height: 0.922m

- SV500: Continuous and Indeterminate Beams

- SV100: Bench Mounted Frame (Sold separately)

- SV101: Structures Interface Unit (Sold separately)