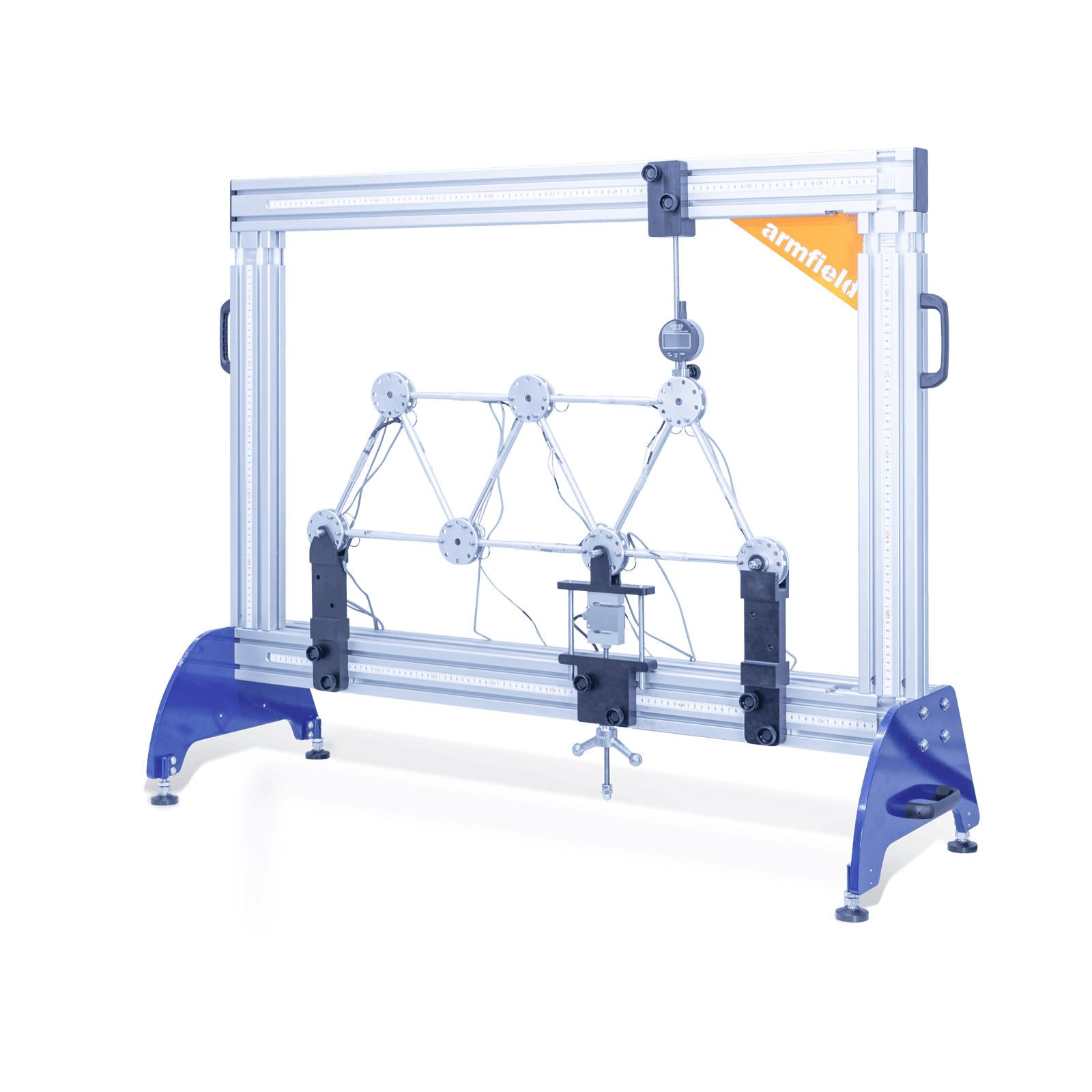

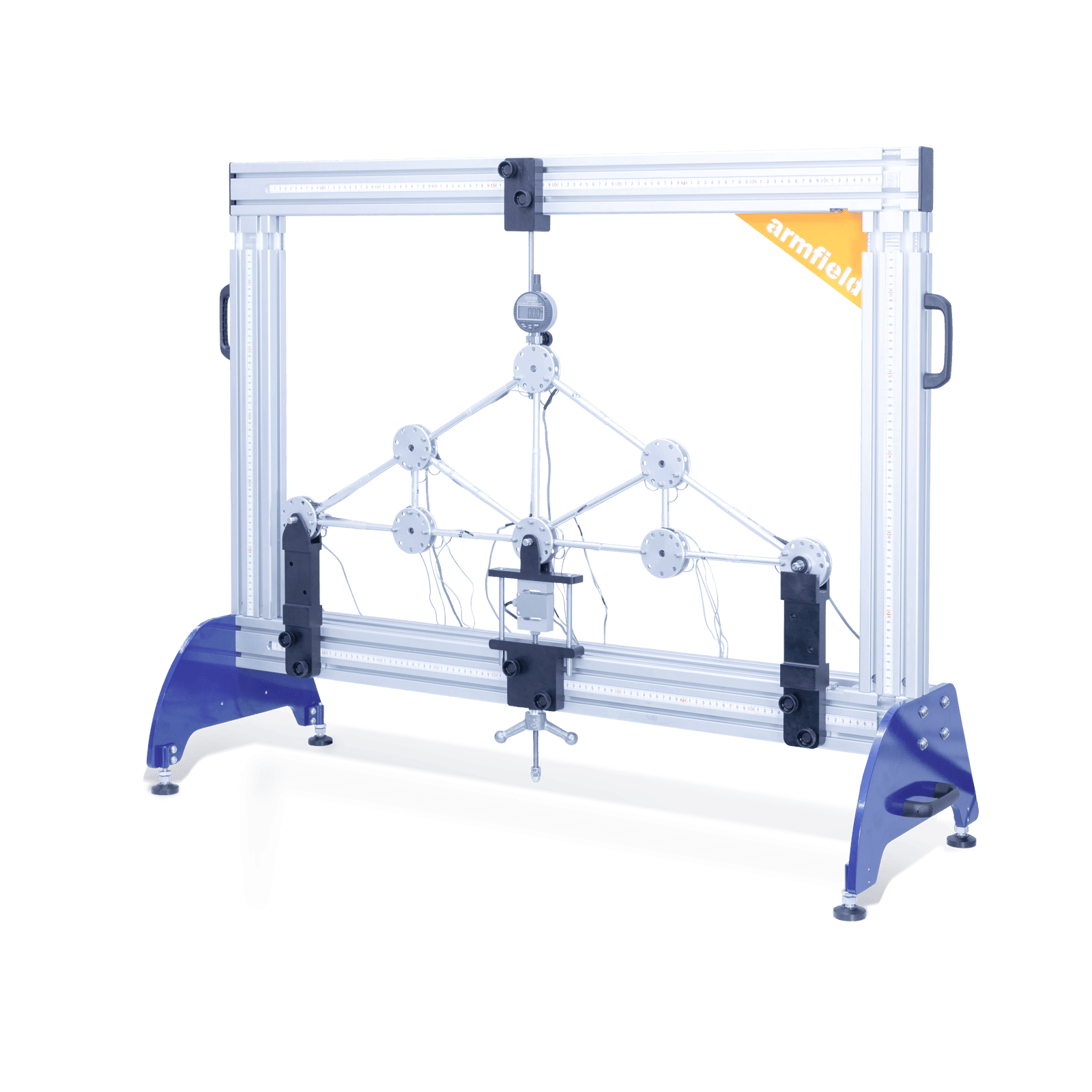

SV200 – Pin-Jointed Frameworks (Roof and Warren Truss)

The experiment Deflection of Trusses allows the experimental investigation of deformation in trusses under load.

This then allows Castigliano theorems to be proven.

The experiment Forces in a Truss/Redundant Truss is intended for use with the Armfield Universal Frame and enables the experimental investigation of deflection of trusses under load.

This then allows Castigliano theorems to be proven.

This exercise module has the following properties:

- Assembly of both a basic roof and Warren truss via various length members, detent pins and joint hubs

- Quick and easy assembly of members via special detent pins and joint hubs

- Up to 10 members possible in one joint hub

- Loading unit with spindle drive and universal load cell for force measurement

- Members suitable for use with both trusses

Software Included as standard

Description

The truss hub members are made of tubular aluminium with an outside diameter of 10.0mm and a wall thickness of 1.0mm.

The truss members are pre-cut to the following lengths:

- 80.5mm

- 176.5mm

- 198mm

- 207.5mm

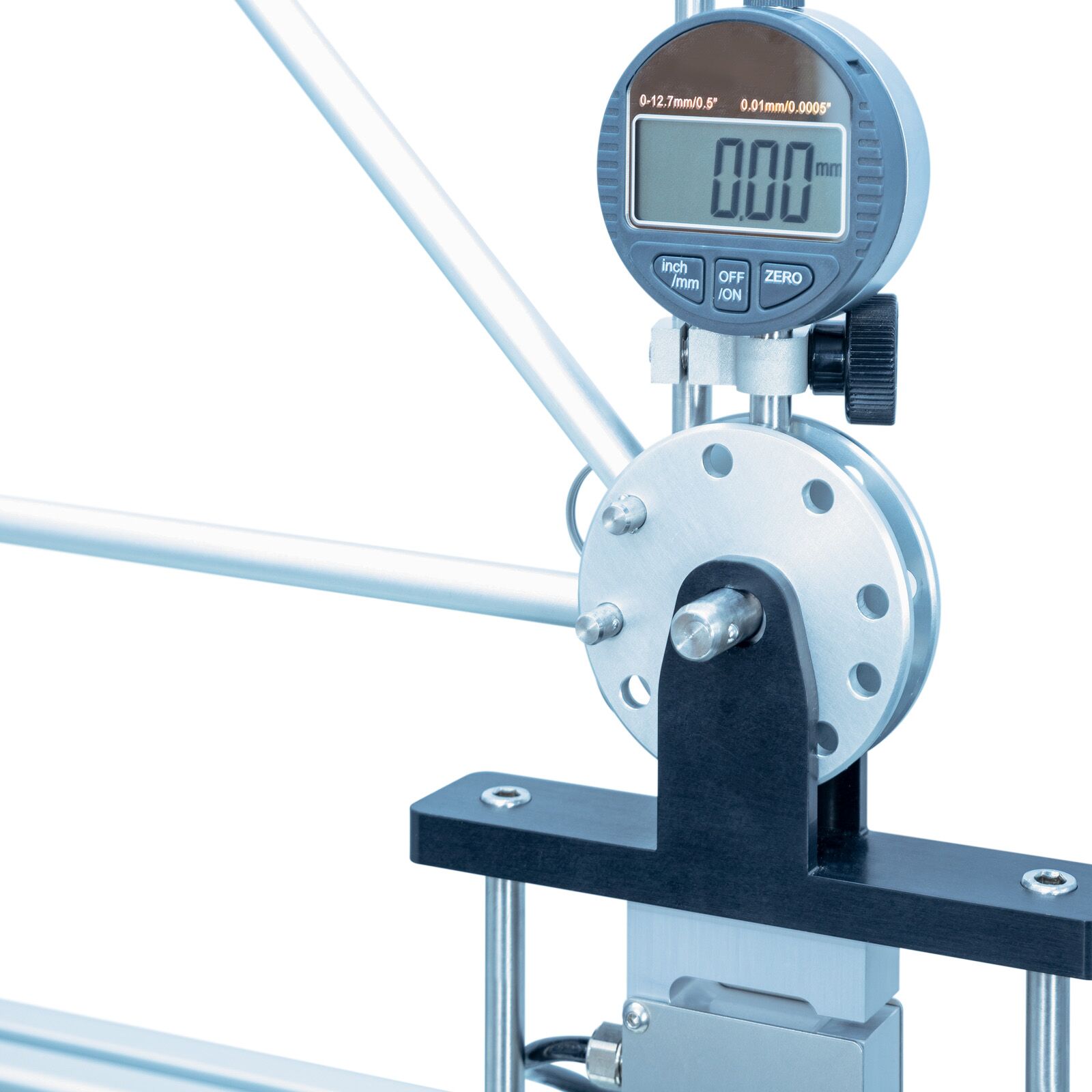

All members are clearance-drilled at each end to allow the detent pins to engage freely in the joint hub. The machined joint hubs are drilled with a circular pattern of holes for the detent pin connections. In each joint hub there are 10 holes so that scale divisions of 30° and 45° are possible.

The smallest angle spacing between two members is 30°, this enables up to 10 members to engage on one truss hub. One member on each truss hub must be rigidly located in the joint hub via a drilled location hole. This is necessary in order to obtain a rigid, statically certain truss, without this, the joint hub would itself become an additional member of the truss.

Place the two sealed bearings, one either side of the free joint hub, connecting them using one Ø10 x 40mm long detent pin. This allows the joint hub to move along the bearing side mounting block.

The external stresses are applied to the truss via the load cell assembly. The experiment frame deforms under the force and the deflection of the frame can be measured. In order to be able to generate a force the respective test truss must first be pre-stressed. Play in the truss hubs is eliminated in order to achieve this. Pre-stressing is completed by applying a small force via the load cell assembly to remove any slack in the experiment frame.

The load cell assembly can be attached to the frame at any truss hub. It enables tensile and pressure forces of up to 400N to be applied and measured.

Technical Specifications

- 8 x Truss Joint Hub

- Truss Hub Angle graduations 30°, 45°, 60°, 90°

- 2 x 80.5mm Member

- 4 x 176.5mm Member

- 4 x 198mm Member

- 7 x 207.5mm Member

- Aluminium tube: Ø 10 x 1.0mm

- Material: 6060 T6 – BS EN 755-2:2016

- Cross-sectional area: 28.274 x 10-6m2

- 2 x Sealed Bearing 10mm x 26mm x 8mm

- 22 x 6mm Detent Pin

- Load Cell Assembly Force range: 0–400N

- Measurable range of the digital indicator: 12.7mm (DTI)

- Resolution: 0.01mm

Features & Benefits

- Allows construction of both a basic Roof Truss and Warren Truss

- Simplified versions of realistic structures

- Load can be applied at different joints

- Software included as standard

- Study of strains in a pinned Roof Truss

- Study of strains in a pinned Warren Truss

- Study of stresses in a pinned Roof Truss

- Study of stresses in a pinned Warren Truss

- Introduction to Bow’s Notation

- Comparison of different frameworks

- Castiglianos’ Theorem

- Statically Determinate

- Bow’s notation

- Stress

- Strain

- Reactions

- Storage temperature: -10°C to +70°C

- Operating temperature range: +10°C to +50°C

- Operating relative humidity range: 0 to 95%, non-condensing

SV100: Bench Mounted Frame

SV101: Structures Interface Unit

SV103: Frame Mounting Kit

Electrical supply:

110/120V, 60Hz

220/240V, 50Hz

- SV100: Bench Mounted Frame

- SV101: Structures Interface Unit

- SV103: Frame Mounting Kit

- PC with a USB port, running Windows 7 or above

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.1m³

Gross Weight: 25kg

Length: 1.176m

Width: 0.392m

Height: 0.922m

- SV200: Pin-Jointed Frameworks (Roof and Warren Truss)

- SV100: Bench Mounted Frame (Sold separately)

- SV101: Structures Interface Unit (Sold separately)

- SV103: Frame Mounting Kit (Sold separately)