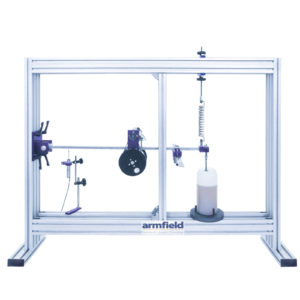

SD3 – Torsional Vibration Apparatus

This benchtop mounted unit is used to study torsion and torsional vibration.

Also supplied with the apparatus is a manual torsion arrangement, which allows a known angular twist to be applied to the specimen. A cord is wrapped around one of the large discs and a load is applied via a hanger and weights set. The angle of twist for incremental loading is recorded and the modulus of rigidity can be calculated.

Oscillations sensors are mounted integrally with each mass.

Description

This benchtop mounted unit is used to study torsion and torsional vibration. The apparatus is constructed around a profiled aluminium base with levelling feet, onto which is mounted 4 vertical chuck pillars.

Each pillar contains a central shaft running in precision bearings with a chuck at one end which grips a torsion specimen. Each chuck also contains a large disc of varying mass and inertia. With these chucks it is possible to assemble a torsion specimen with up to 3 masses. Vibrations are transmitted into the torsion specimen by means of an exciter, which is electronically speed controlled from the main control unit.

To change the end conditions of the apparatus a fifth chuck houses a chuck which rigidly clamps the end of the torsion specimen to achieve a fixed end.

Also supplied with the apparatus is a manual torsion arrangement, which allows a known angular twist to be applied to the specimen. A cord is wrapped around one of the large discs and a load is applied via a hanger and weights set. The angle of twist for incremental loading is recorded and the modulus of rigidity can be calculated. Oscillations sensors are mounted integrally with each mass pillar and provide signals of the amplitude of vibration.

The control unit conditions these signals and makes them available to an oscilloscope (not supplied) for vibration analysis.

Technical Specifications

- Stainless steel torsion specimen: 1300mm long x Ø6mm

- Crank offset: 0.15mm

- Up to 20Hz excitation frequency

- 20mm thick x Ø150mm inertia disc (2 off) – Steel

- 15mm thick x Ø228mm inertia disc (1 off) – Plastic

- 6 x 5N Weights

Operational conditions:

Storage temperature: -10°C to +70°C

Operating temperature range: +10°C to +50°C

Operating relative humidity range: 0 to 95%, non-condensing

Features & Benefits

- Very visual demonstration of torsional vibration

- Fully guarded motor

- Free and fixed end conditions

- Oscillation speed digitally controlled and displayed

- Manual twist of specimen using set of weights and hanger

- Mechanical damping supplied

- Optional digital oscilloscope (INST063)

- Supplied with software

- Determination of the torsional stiffness of a torsion bar

- Determination of the mass moment of inertia

- Decay behaviour of torsional vibration

- Forced torsional vibration and resonance

- Torsional vibration system with three weights allowing single, two and three mass torsional vibration to be investigated

- Demonstration of the effect of frictional damping

- 1 x SD3 Torsional Vibration Apparatus

- 1 x Control console

- 1 x Power lead

- 5 x Spare fuse

- 4 x BNC cable

- 1 x Spare timing belt

- 1 x Tape measure

- 1 x Stop watch

- 1 x Load hanger

- 1 x Hex wrench set

- Instruction manual

- Packing list

- Test sheet

- Torsion

- Torsional stiffness

- Resonance

- Multi-mass torsional systems

Essential:

AIU: Armfield Interface Unit (Sold separately)

Recommended:

INST063: PC USB Oscilloscope

Electrical supply: 110/120V, 60Hz or 220/240V, 50Hz

PC with a USB port, running Windows 7 or above

Packed and crated shipping specifications

Volume: 0.52m3

Gross: weight 70kg

Length: 1.400m

Width: 0.410m

Height: 0.400m

SD3: Torsional Vibration Apparatus

AIU: Armfield Interface Unit (Sold separately)

INST063: PC USB Oscilloscope