SD-1.52 – Efficiency of Screw Threads

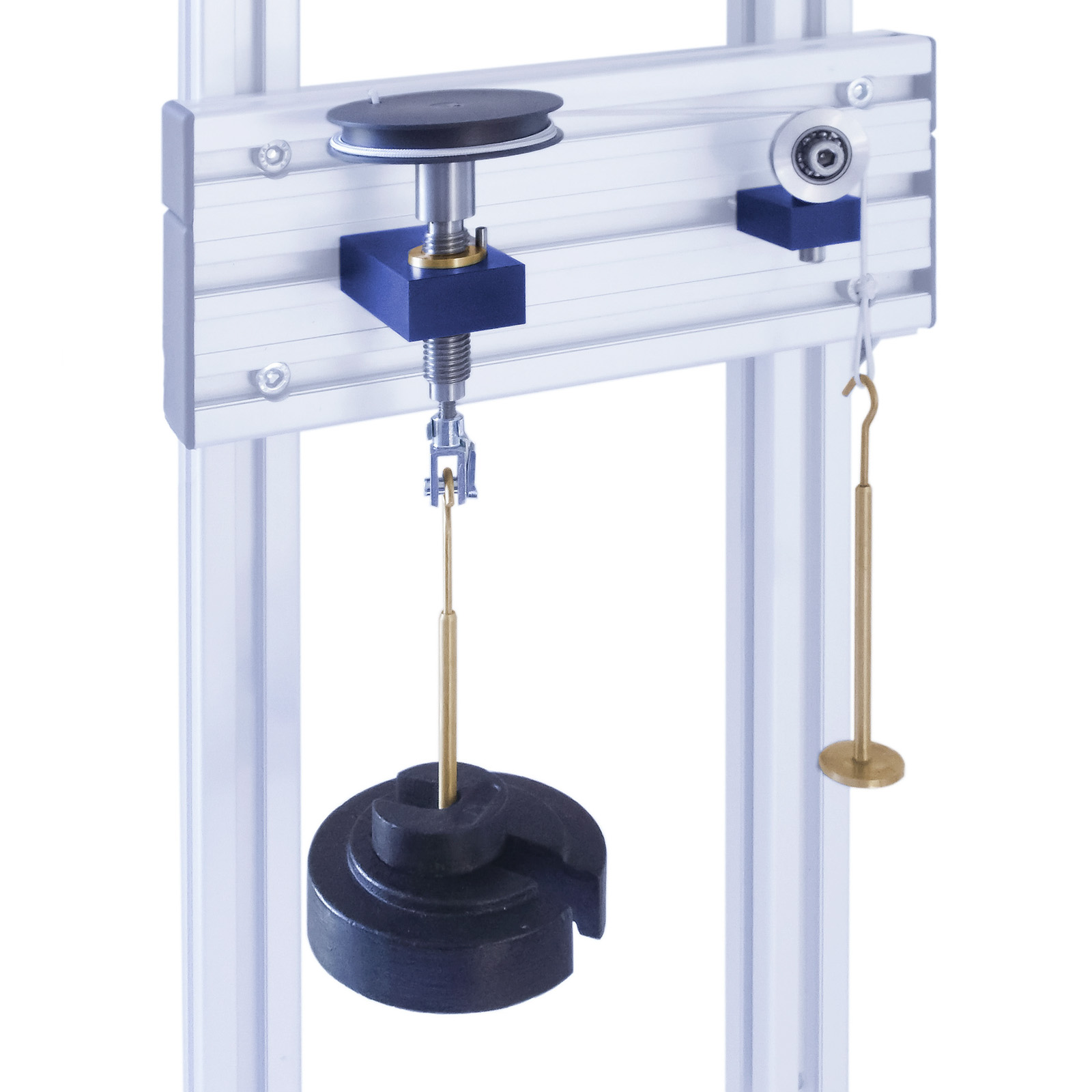

Compact wall mounted apparatus to conduct experiments on the efficiencies of carrying screw thread forms

Description

Three screw thread forms are supplied (‘Vee’ x 2 and square) each with an integral turntable mounted on the top side. Wrapped around the periphery of the turntable is a cord which allows the turntable to be rotated when loaded. Each thread has a mating nut with a profiled groove in its side. This groove locates onto a pin within the wall bracket assembly and stops the nut from rotating when the turntable and screw thread are rotated.

Each nut and thread pairing are quickly and easily interchanged.

The cord is run over the pulley and terminates to a load hanger. This hanger is described as the ‘EFFORT’ hanger. Another hanger is attached to the underside of the shaft of the screw thread and is described as the ‘LOAD’ hanger.

Students vary the LOAD using the calibrated weights and obtain the respective EFFORT required to raise or lower the screw thread. From this the efficiencies can be obtained.

Technical Specifications

- 1 x SD-1.52 main assembly

- 1 x M16 x 3mm Pitch thread with brass nut and cord

- 1 x M16 x 3mm Pitch, vee thread with brass nut and cord

- M16 x 2mm, Vee thread with brass nut

- 1 x 100g Hanger

- 1 x 10g Hanger

- 1 x 5N Hanger

- 1 x Primary weight set: 8 x 0.1N, 2 x 0.2N, 1 x 1N, 2 x 2N, 2 x 5N, 1 x 10N

- 1 x Secondary weight set: 1 x 20N, 4 x 50N

- 1 x Hanger link

- 1 x 5m Cord

Features & Benefits

- Wall mounted apparatus

- Introduction to simple machines

- Determination of velocity ratio mechanical advantage and efficiency

- Comparative efficiency of square and Vee form threads

- Three thread forms provided with integral turntables and cords

- Calibrated weights set and hangers supplied

- Experimental determination of velocity ratio and comparison with calculated value

- Comparison of relative efficiency of Vee and Square thread forms

- Determination of variation with load of effort, friction and efficiency

- Limiting efficiency of the machine

- Wall mounted apparatus to compare the efficiencies of square and `Vee` form screw threads

- Torque applied to threads using turntable and cord

- The effort can be applied to raise or lower the load

- Load applied to screw thread and effort hanger can be changed

Theory of Machines

- SD-1.50 Wheel and Axle

- SD-1.51 Wheel and Differential Axle Apparatus

- SD-1.52 Efficiency of Screw Threads

- SD-1.53 Gear Tooth Form Apparatus

- SD-1.54 Cam and Follower Apparatus

- SD-1.55 Simple Flywheel

- SD-1.56 Epicyclic Gear Train

- SD-1.57 Castor, Camber, and King Pin Inclination

- SD-1.58 Relation Between Angular and Linear Speeds

- SD-1.59 Disc Brake Apparatus

- SD-1.60 Static & Dynamic Balancing Apparatus

- SD-1.61 Governor Apparatus

- SD-1.62 Gear Assembly Unit Combined Drives

- SD-1.63 Single Epicyclic Gear Train

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.02m³

Gross Weight: 12kg

Length: 0.32m

Width: 0.23m

Height: 0.24m

SD-1.52 Efficiency of Screw Threads