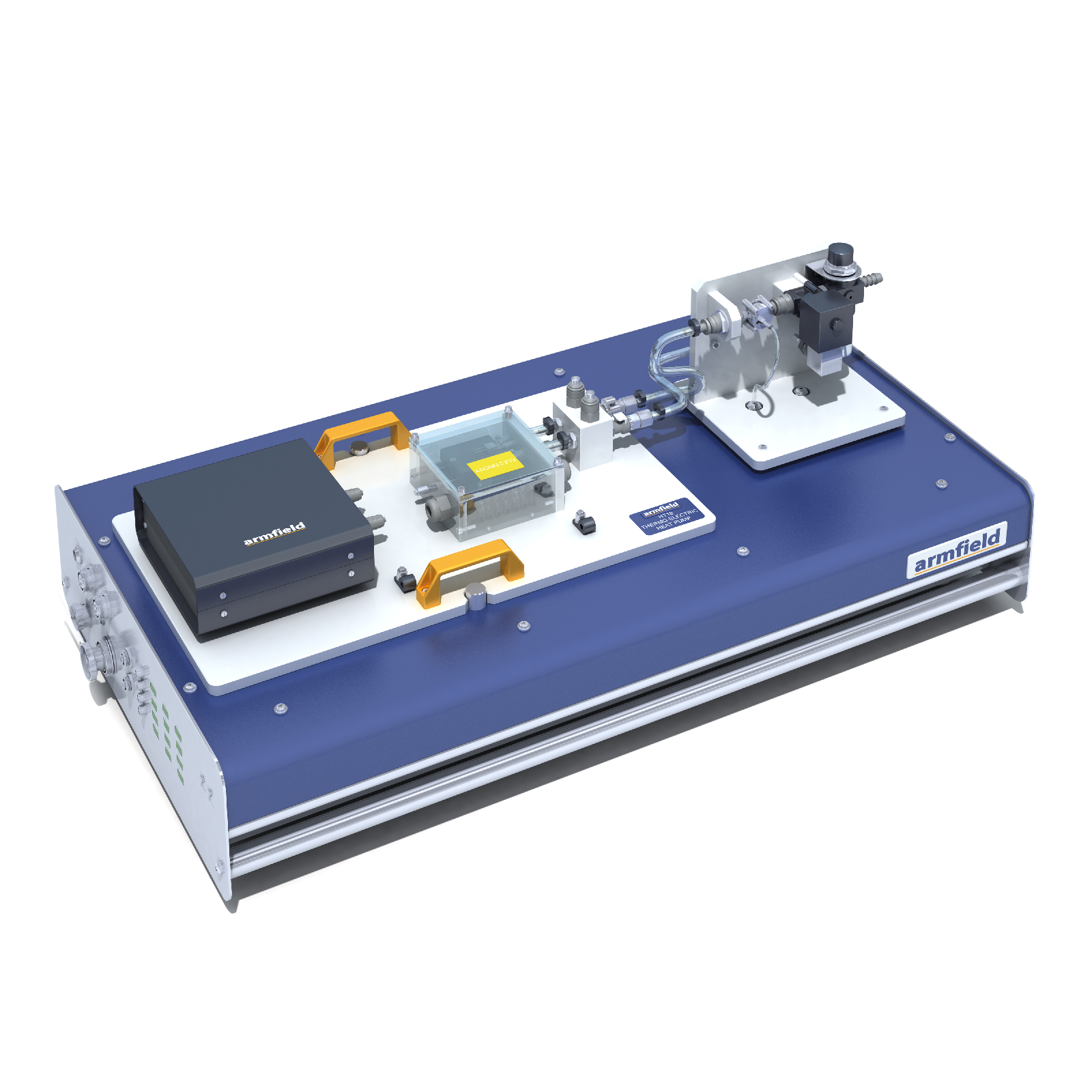

HT18X – Thermo-Electric Heat Pump

Based on a Peltier device, the Armfield HT18X Thermo-Electric Heat Pump demonstrates how electrical power can be used to extract heat from a cool surface and transfer it to a hot surface.

Description

Based on a Peltier device, the Armfield HT18X Thermo-Electric Heat Pump demonstrates how electrical power can be used to extract heat from a cool surface and transfer it to a hot surface.

The HT18X is designed for use with the Armfield HT10X Heat Transfer Service Unit.

Based on a Peltier device, the Armfield HT18X Thermo-Electric Heat Pump demonstrates how electrical power can be used to extract heat from a cool surface and transfer it to a hot surface. This effect is becoming widely used for point cooling (e.g. of semiconductor devices) and small-scale volumetric cooling.

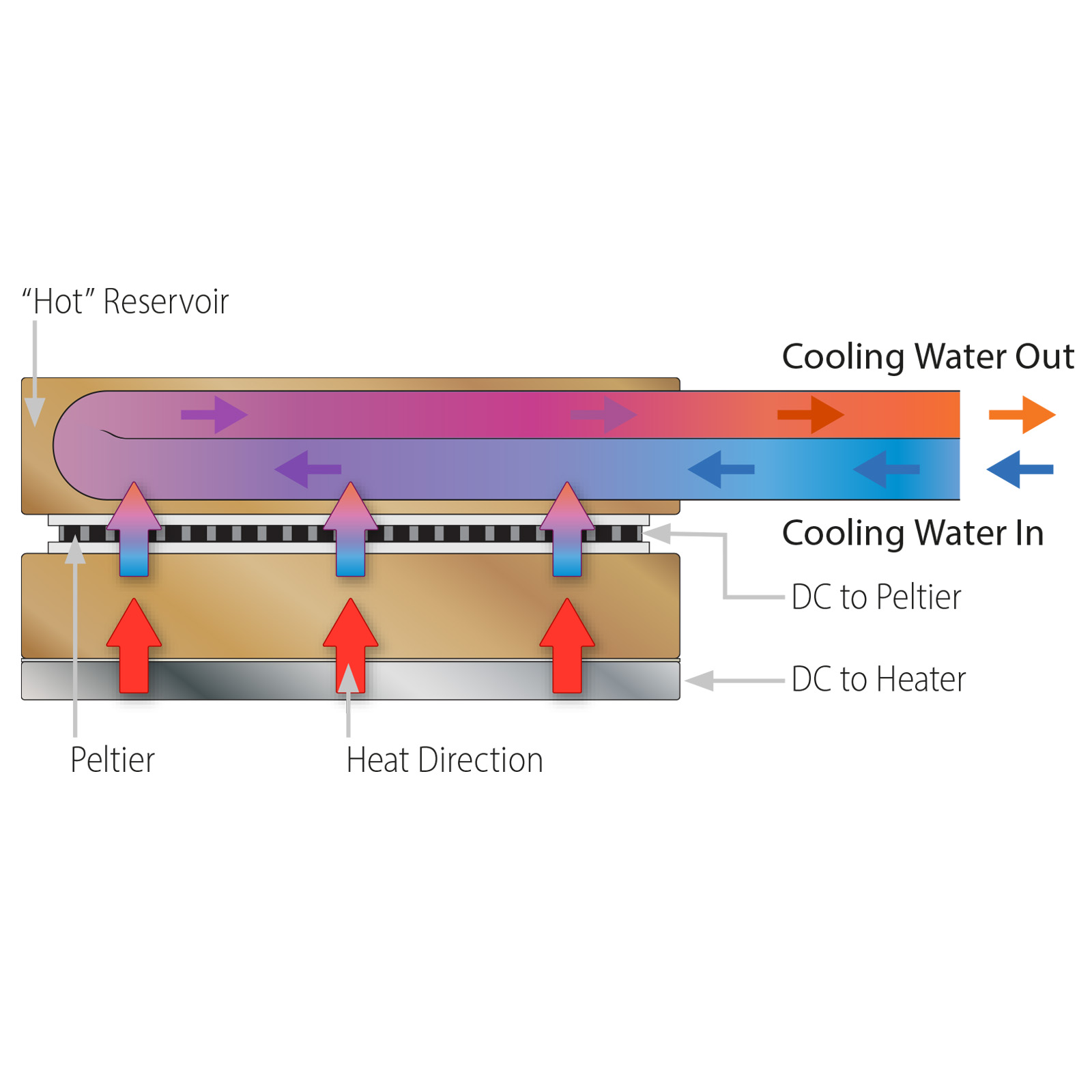

The thermoelectric Peltier device is positioned in a heat transfer path, between two copper blocks. It extracts heat from one block (cold reservoir) and transfers it to the other block (hot reservoir). In order to measure the heat transfer rate, the cold reservoir is fitted with an electric heater, powered by the HT10X service unit. By varying the electric power into the system, the behaviour of the system at different operating points and temperatures can be established.

The heat extracted is transferred to the hot reservoir, together with heat generated by the electrical supply to the Peltier device. This heat is removed by a water-cooled heat exchanger. The flow rates can be adjusted to provide a range of operating temperatures.

The Peltier device can also be used to generate a small quantity of electric power when a temperature difference is applied. This effect can also be demonstrated with this unit.

When used in conjunction with HT10X, the instrumentation is provided to measure the temperatures of the blocks, the electric power supplied to the Peltier device, the cooling water flow rate and the cooling water temperature rise. Heater power measurement allows you to establish a complete energy balance for the system.

The cooling water flow rate is measured by a turbine type flow sensor.

A control valve on the HT10X service unit allows the flow of cooling water to be varied, if required, over the operating range of 0-1.5 l/min. The control valve can be PID controlled for improved supply pressure disturbance reduction.

All facilities are controlled directly from the PC (not supplied), including heater power, Peltier power and water flow rate. All measured information is available on the PC. The HT18X includes its own integral USB interface, connecting to the same PC as the HT10X. The software supplied integrates the data to and from both these interfaces into a simple, user-friendly software control environment.

Technical Specifications

- Small-scale accessory designed to demonstrate the use of a Peltier device to transfer heat across surfaces

- Comprises a Peltier device, a heater, and a water-cooled heat exchanger

- Heat transfer rates up to 68W

- Heater power, Peltier drive and cooling flow rate all fully electronically adjustable under computer control

- Service unit allows for measurement of cooling water temperatures and flow to allow an overall energy balance

- The accessory is mounted on a PVC baseplate, which is designed to sit on the heat transfer service unit without the need for tools

- A comprehensive instruction manual is provided

Features & Benefits

- Performance of a Peltier device as a cooler

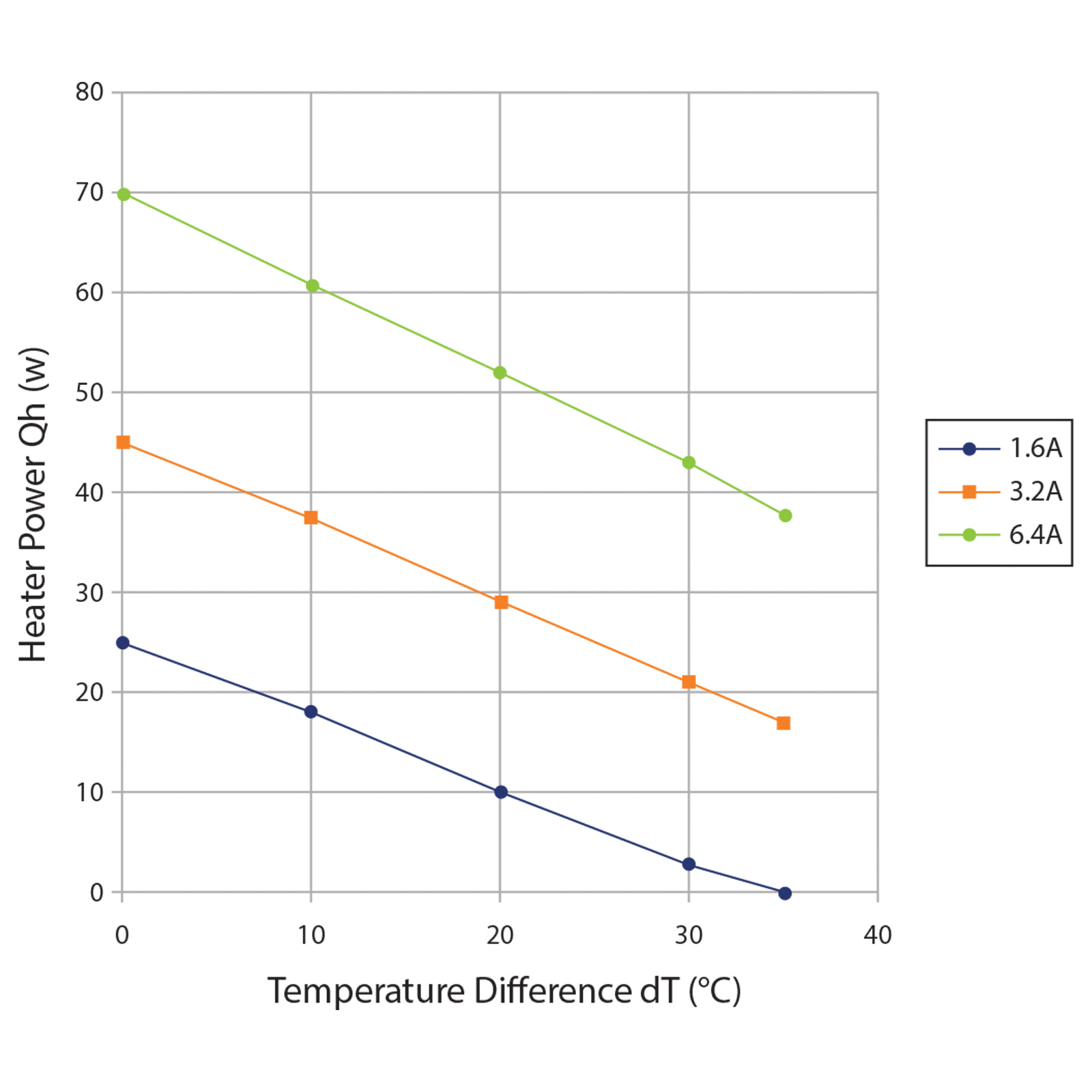

- Heat transfer characteristics as a function of temperature and drive current

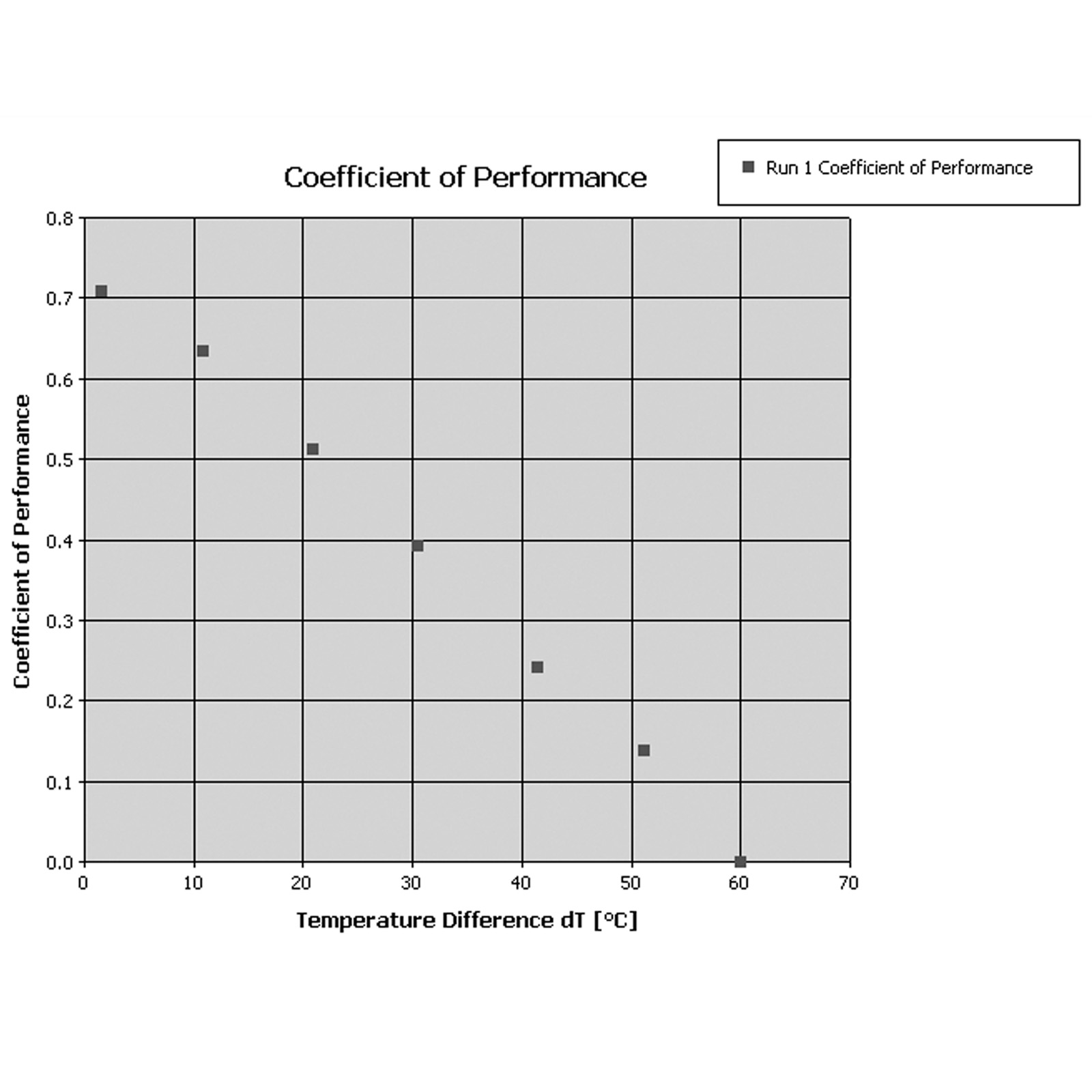

- Measurement of the coefficient of performance

- Energy balance

- Demonstration of a Peltier device as an electrical generator

- Small-scale accessory designed to demonstrate the use of a Peltier device to transfer heat across surfaces

- Comprises a Peltier device, a heater, and a water-cooled heat exchanger

- Heat transfer rates up to 68W

- Heater power, Peltier drive and cooling flow rate all fully electronically adjustable under computer control

- Service unit allows for measurement of cooling water temperatures and flow to allow an overall energy balance

- The accessory is mounted on a PVC baseplate, which is designed to sit on the heat transfer service unit without the need for tools

- A comprehensive instruction manual is provided

A full armBus educational software suite is provided with the HT10X for all the Armfield heat transfer accessories.

Individual experiment interfaces and displayed data types vary to match selected experiment accessories, common examples are listed below:

- Temperatures and other signals such as flow rates, heater voltage and current are displayed on a diagrammatic representation of the equipment

- Control outputs are operated by a control slider or typing in a value between 0 and 100%. Sensor values are read directly in engineering units

- PID automatic control option is available, permitting the temperature set-point to be achieved quickly and precisely, coping with disturbance rejection

- A maintenance screen allows for PID parameter adjustment and thermocouple calibration

- Data from the sensors are logged into a spreadsheet format, with operator control over the sampling intervals (or ‘single-shot’)

- Sophisticated graph-plotting facilities are provided, including plotting of both measured and calculated values

- Graphs update in real-time as the samples are being taken

- Processing of measured values to obtain calculated values is linked to the questions and answers to ensure student understanding

- Experiment data samples are saved, or exported in Microsoft Excel format

- Real-time sensor data is displayed independently from the data logging. It is possible to check the recent history graphical display to inspect the temperature stability prior to taking a sample

HT10X Computer-Controlled Heat Transfer Service Unit

All electrical requirements are obtained from the service unit

Volume: 0.09m³

Gross Weight: 15kg

Length: 0.53m

Width: 0.43m

Height: 0.13m

HT18X