HT14X – Combined Convection and Radiation

The HT14X is one of a range of small scale heat transfer laboratory teaching accessories which demonstrate the basic modes of heat transfer (conduction, convection and radiation).

Description

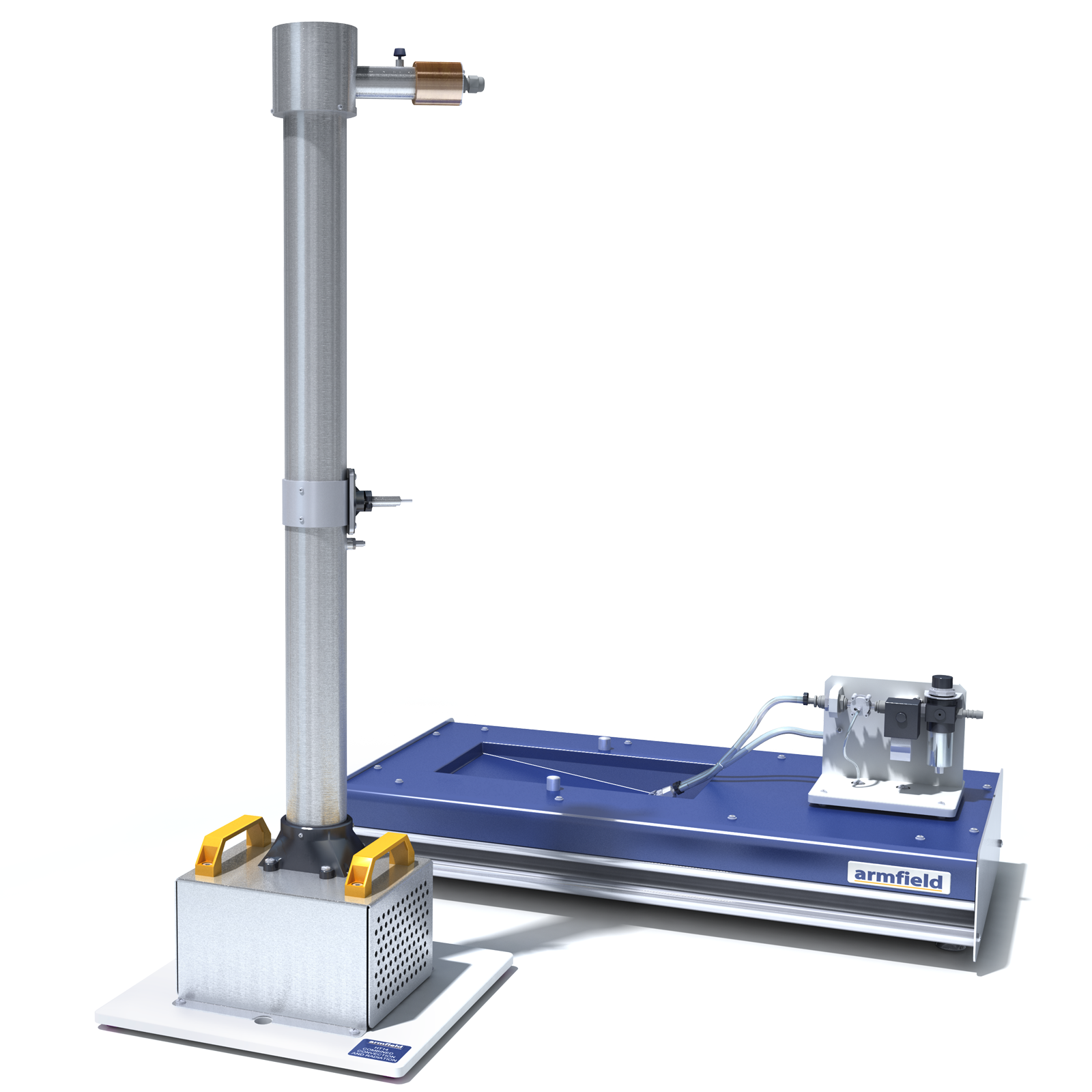

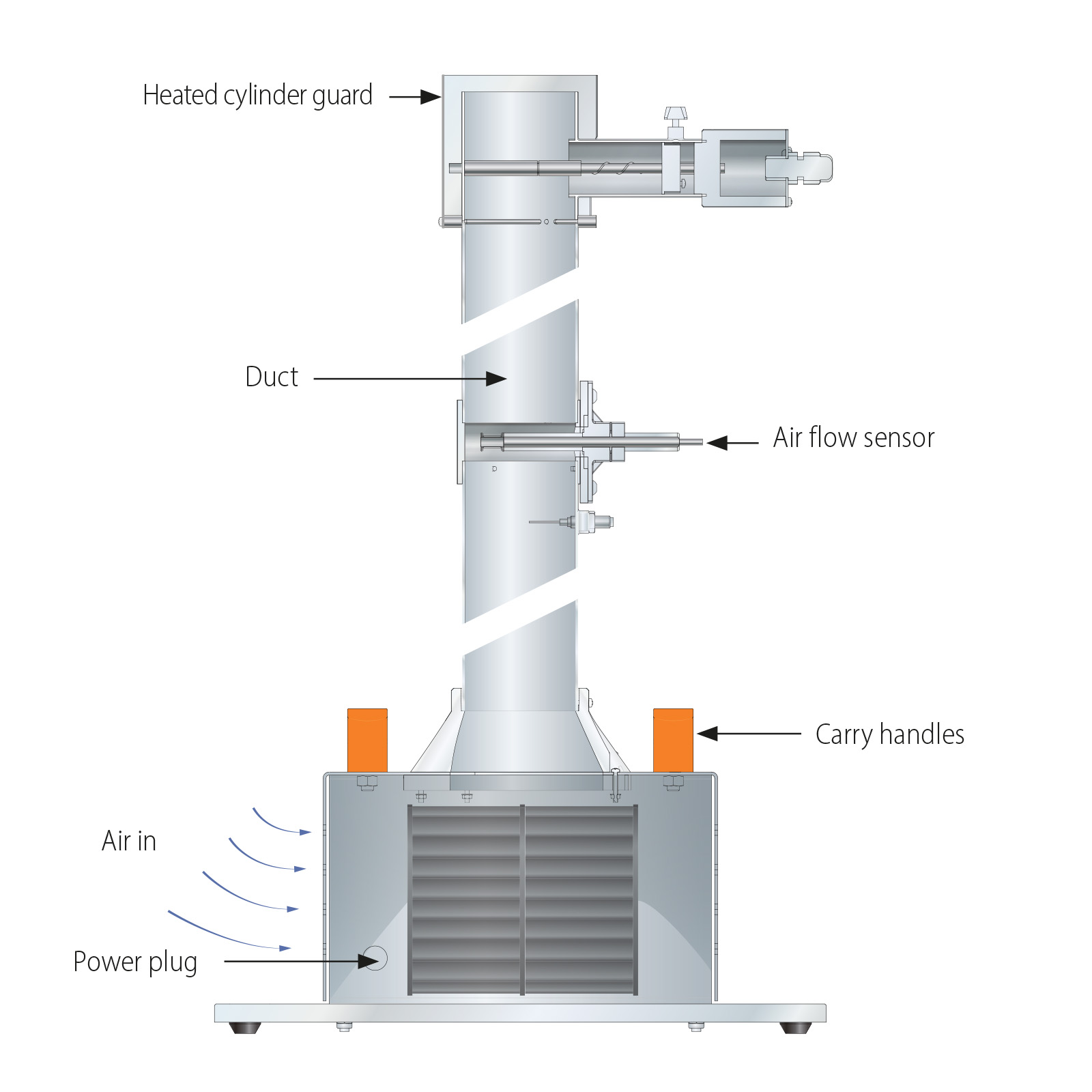

The equipment consists of a centrifugal fan with a vertical outlet duct. At the top of the duct there is a heated cylinder. The mounting arrangement for the cylinder in the duct is designed to minimise loss of heat by conduction to the wall of the duct.

The surface of the cylinder is coated with heat-resistant paint which provides a consistent emissivity close to unity. A K-type thermocouple (T10) attached to the wall of the cylinder, at mid position, enables the surface temperature to be measured under the varying operating conditions.

ArmBUS controlled variable-speed fan blows air through the outlet duct. A vane-type anemometer within the fan outlet duct enables the air velocity in the duct to be measured. Air velocity can be set within the accuracy of ±0.05m/s.

A K-type thermocouple (T9) in the outlet duct allows the ambient air temperature to be measured upstream of the heated cylinder.

PID controller allows rapid heater’s temperature set-point achievement and control to ±0.1°C.

Technical Specifications

- A small-scale accessory to introduce students to the principles of combined convection (free and forced) with radiation from horizontal heated cylinder

- Comprises a heated cylinder mounted in a vertical air duct, with a fan at the base of the duct, which can be used to provide a variable air flow over the cylinder

- Heater rating 100W at 24V DC

- K-type thermocouples measure the air temperature upstream and the surface temperature of the cylinder

- Air flow velocity through the duct, under computer control

- A comprehensive instruction manual is included

Features & Benefits

- Determining the combined heat transfer (Q radiation + Q convection) from a horizontal cylinder in natural convection over a wide range of power inputs and corresponding surface temperatures

- Measuring the domination of the convective heat transfer coefficient Hc at low surface temperatures and the domination of the radiation heat transfer coefficient Hr at high surface temperatures

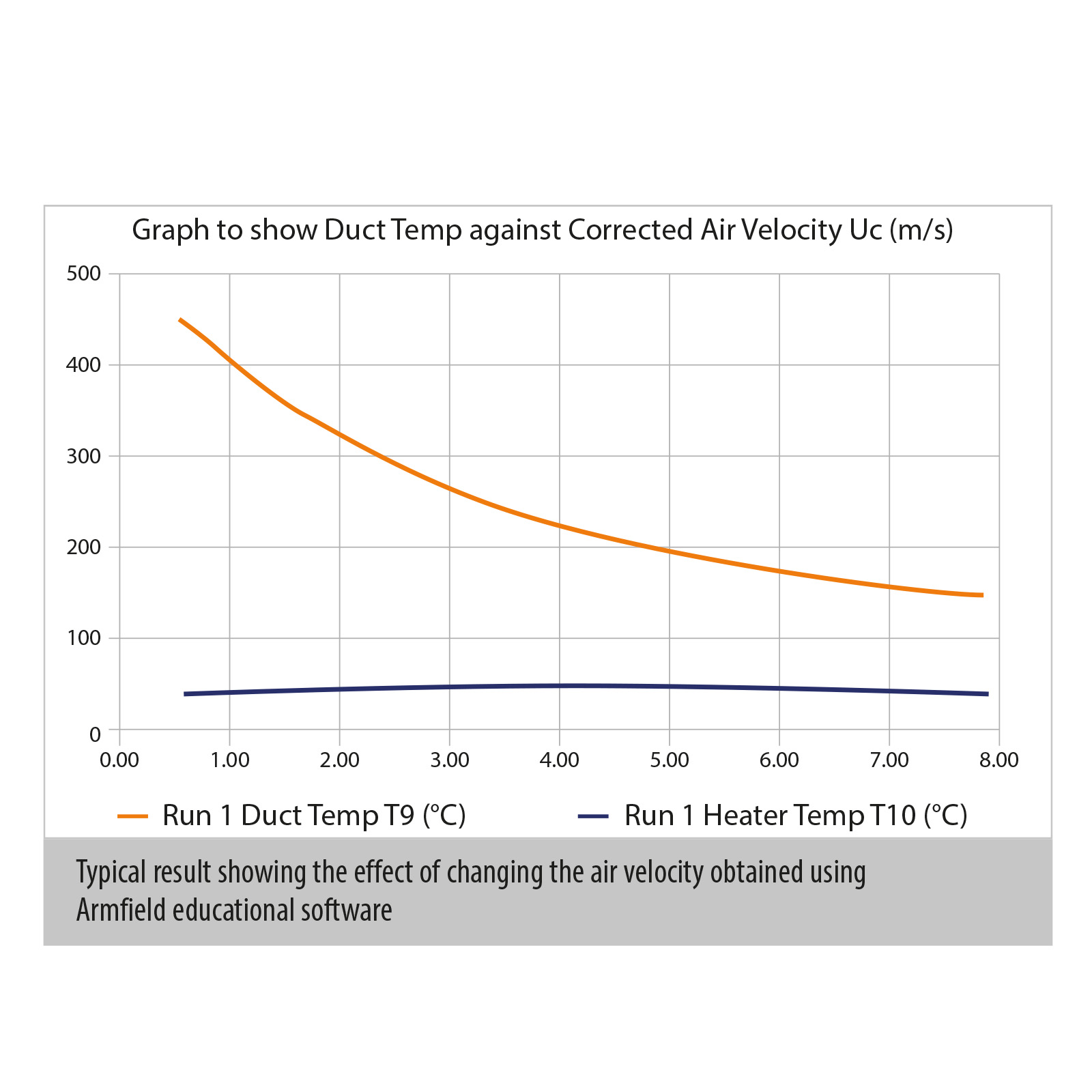

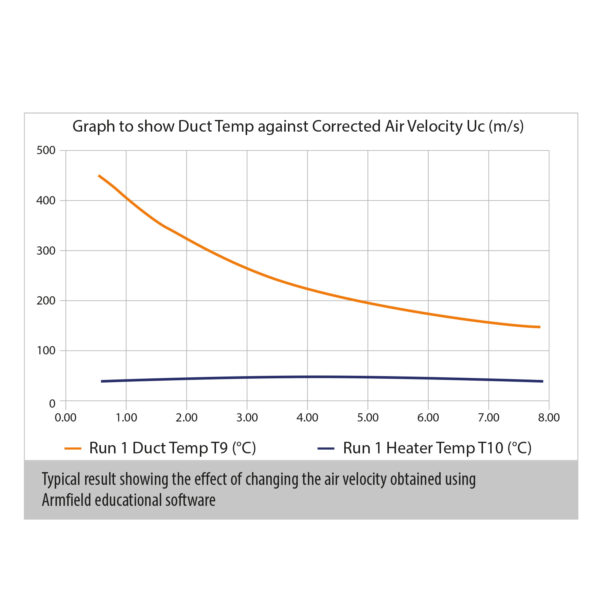

- Determining the effect of forced convection on the heat transfer from the cylinder at varying air velocities

A full armBus educational software suite is provided with the HT10X for all the Armfield heat transfer accessories.

Individual experiment interfaces and displayed data types vary to match selected experiment accessories, common examples are listed below:

- Temperatures and other signals such as flow rates, heater voltage and current are displayed on a diagrammatic representation of the equipment

- Control outputs are operated by a control slider or typing in a value between 0 and 100%. Sensor values are read directly in engineering units

- PID automatic control option is available, permitting the temperature set-point to be achieved quickly and precisely, coping with disturbance rejection

- A maintenance screen allows for PID parameter adjustment and thermocouple calibration

- Data from the sensors are logged into a spreadsheet format, with operator control over the sampling intervals (or ‘single-shot’)

- Sophisticated graph-plotting facilities are provided, including plotting of both measured and calculated values

- Graphs update in real-time as the samples are being taken

- Processing of measured values to obtain calculated values is linked to the questions and answers to ensure student understanding

- Experiment data samples are saved, or exported in Microsoft Excel format

- Real-time sensor data is displayed independently from the data logging. It is possible to check the recent history graphical display to inspect the temperature stability prior to taking a sample

HT10X Computer Controlled Heat Transfer Service Unit

- HT10X Computer Controlled Heat Transfer Service Unit

- All electrical requirements are obtained from the service unit

Packed and crated shipping specifications

Volume: 0.2m³

Gross weight: 29kg

Length: 0.35m

Width: 0.30m

Height: 1.20m

HT14X