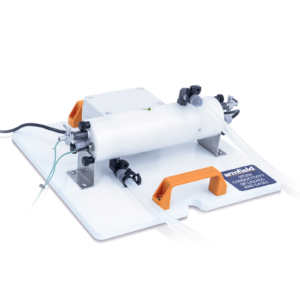

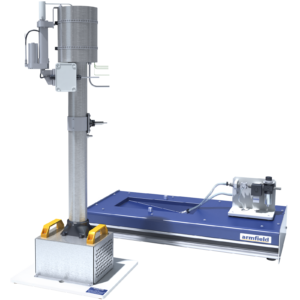

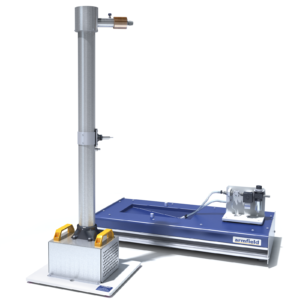

HT10X – Computer Controlled Heat Transfer Service Unit

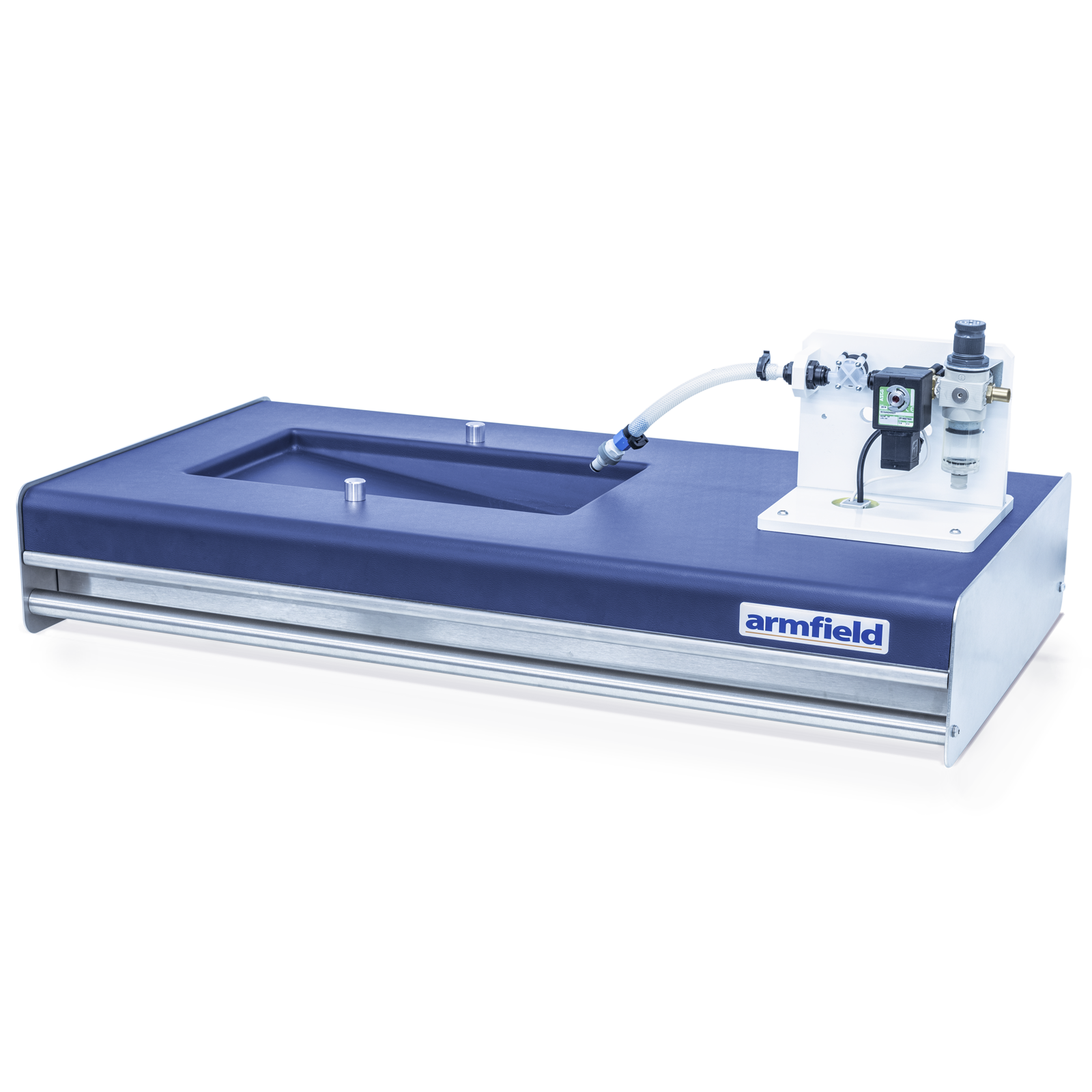

A bench top service unit, designed to accommodate a range of modular small scale experiment accessories, which demonstrate several modes of heat transfer phenomena.

Description

The Armfield HT10X is a service unit that can be used in conjunction with a range of small-scale accessories for a wide range of demonstrations into the modes of heat transfer.

The factors that affect heat transfer can be investigated and some of the practical problems associated with the transfer of heat can be visualised.

The heat transfer accessories may be individually connected to the HT10X service unit, which provides the necessary electrical supplies and measurement facilities for investigation and comparison of the different heat transfer characteristics.

Technical Specifications

Outputs:

- ABMC 24V port for linear actuator and Peltier plate

- DC1 24V port for DC blower fan (HT14X, HT16X, HT19X)

- DC2 24V port for the heater power (All accessories except HT17X)

- AUX 24V port for centrifugal pump (HT17X)

Inputs:

- Thermocouples: up to 10, dependent on accessory,

- 12 thermocouple ports available in total

- Heat radiation meter (HT13X)

- Light radiation meter (HT13X)

- Air velocity meter (HT14X HT16X, HT19X)

- Solenoid valve for water flow rate control (HT11X, HT12X, HT18X)

-

- The HT10X has some inbuilt potential for future expansion

of the armBUS systems and sensors. This includes:

– 2x 5-way M12 ports

– 2x K-type thermocouple ports

- The HT10X has some inbuilt potential for future expansion

-

Features & Benefits

- Small-scale, computer control bench top equipment

- Common service unit avoids unnecessary cost duplication for control and instrumentation

- Multiple accessories available covering a wide range of heat transfer investigations

- Fail-safe hardware facilities for remote operation, e.g. over the internet, when used with the customers software via NetCan

- Connects armBUS via USB

- 20 users can connect to view the live readings within the local network. (Requires ArmBus-NetCan)

- Full control or read only access available at the time of setup when multiple users operating the machine

- Educational software, including mimic diagrams, real-time control, data logging and graph plotting

- PID control of heater and water flow control enabling steady state to be achieved in less than two minutes

- Small-scale, computer control bench top equipment

- Common service unit avoids unnecessary cost duplication for control and instrumentation

- Multiple accessories available covering a wide range of heat transfer investigations

- Fail-safe hardware facilities for remote operation, e.g. over the internet, when used with the customers software via NetCan

- Connects armBUS via USB

- 20 users can connect to view the live readings within the local network. (Requires ArmBus-NetCan)

- Full control or read only access available at the time of setup when multiple users operating the machine

- Educational software, including mimic diagrams, real-time control, data logging and graph plotting

- PID control of heater and water flow control enabling steady state to be achieved in less than two minutes

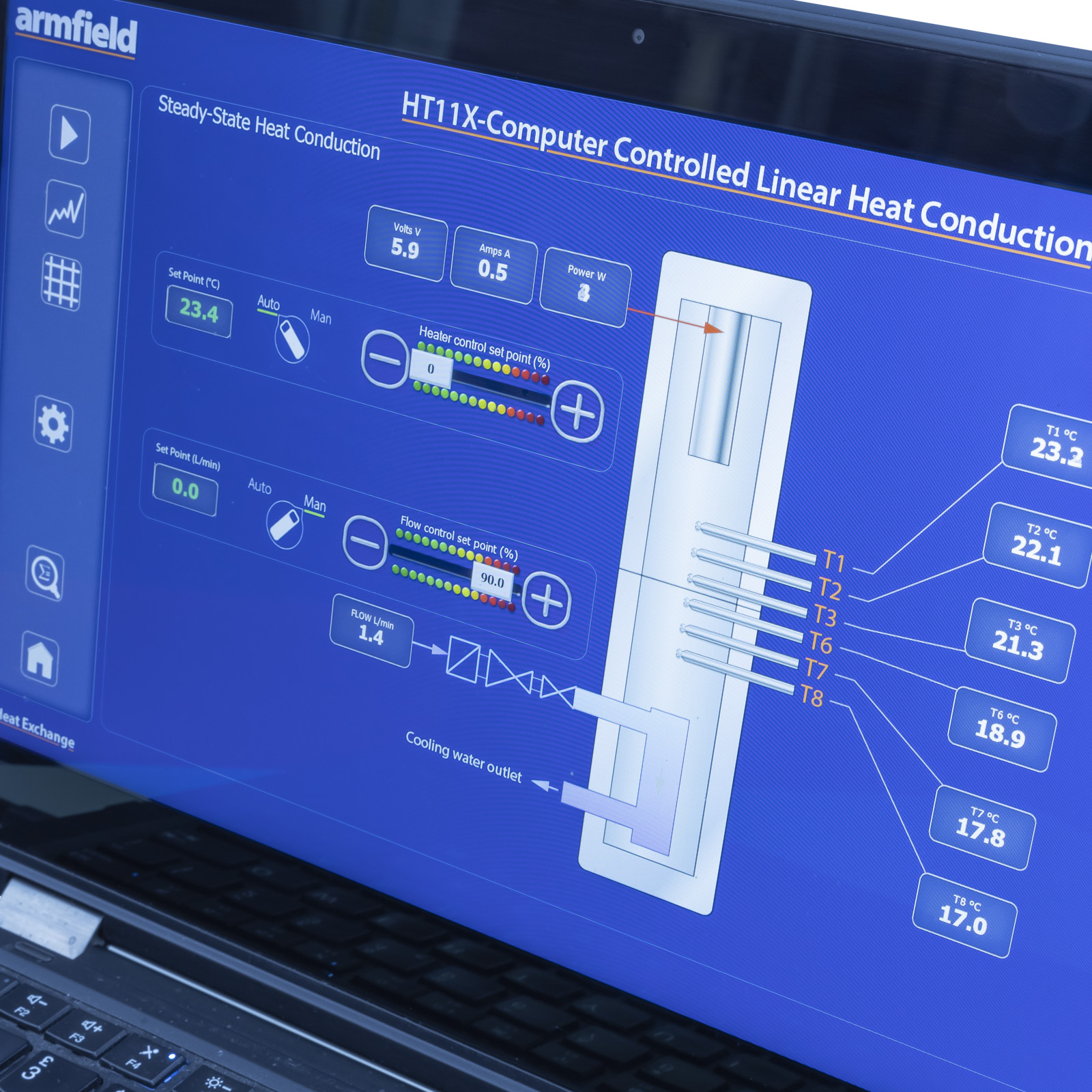

A full ArmBus educational software suite is provided with the HT10X for all the Armfield heat transfer accessories.

Individual experiment interfaces and displayed data types vary to match selected experiment accessories, common examples are listed below:

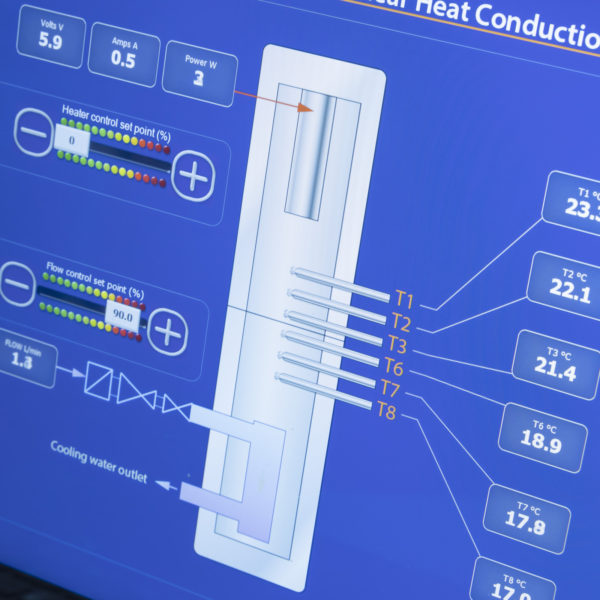

- Temperatures and other signals such as flow rates, heater voltage and current are displayed on a diagrammatic representation of the equipment

- Control outputs are operated by a control slider or typing in a value between 0 and 100%. Sensor values are read directly in engineering units

- PID automatic control option is available, permitting the temperature set-point to be achieved quickly and precisely, coping with disturbance rejection

- A maintenance screen allows for PID parameter adjustment and thermocouple calibration

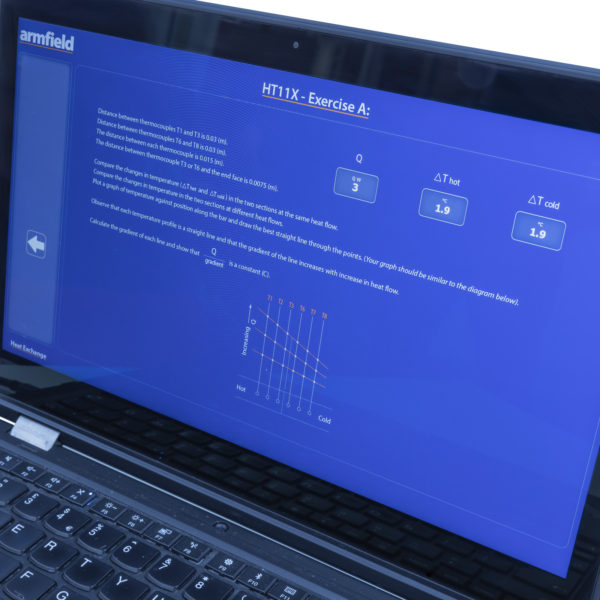

- Data from the sensors are logged into a spreadsheet format, with operator control over the sampling intervals (or ‘single-shot’)

- Sophisticated graph-plotting facilities are provided, including plotting of both measured and calculated values

- Graphs update in real-time as the samples are being taken

- Processing of measured values to obtain calculated values is linked to the questions and answers to ensure student understanding

- Experiment data samples are saved, or exported in Microsoft Excel format

- Real-time sensor data is displayed independently from the data logging. It is possible to check the recent history graphical display to inspect the temperature stability prior to taking a sample

A compact PC-Controlled bench top service unit, designed to accommodate a range of modular small scale experiment accessories, which demonstrate several modes of heat transfer phenomena.

- Comprises of controlled cold water control system (pressure regulator and water control valve), flowmeter, computer interface and all necessary instrumentation

- Through USB connection the same PC or multiple PC’s utilise the Armsoft GUI to control the cold-water flow rate, temperature of the heater and air velocity induced by the centrifugal blower

- Adjustable parameters can be controlled using PID set-point tracking control, therefore achieving the steady-state faster and rejecting disturbances better than conventional control

- Flowmeter operating range 0.6 to 10 L/min, resolution 0.1 L/min, operating temperature 0-125°C

- Up to twelve temperatures (K-type thermocouples) can be monitored using the service unit. Operating range, 0-133°C, resolution <0.1°C

- Low control voltage (~27V) protects against short circuiting and eliminates electrical hazards

- A full educational software and data logging suite is included, covering all modular heat transfer accessory modules

- A comprehensive instructional manual describing how to carry out practical teaching exercises in heat transfer is supplied. Assembly, installation and commissioning is detailed in the manual and within the ArmBus software help menu

armBUS NetCan, connects up-to 20 users to one piece of equipment.

- Single Phase Electrical supply: 90-240V 5.5A 50/60Hz or 277V 5.5A 50/60Hz

- Software requires a computer running Windows 7 or above with a USB port (computer not supplied by Armfield)

- At least one heat transfer module is required

- Cold water supply and drain: 1.5 Litres/minute at 1bar gauge (min)

Packed and crated shipping specifications

Volume: 0.33m³

Gross weight: 33kg

Length: 0.51m

Width: 0.95m

Height: 0.33m

HT10X

ArmBUS NetCan: Network Interface

You may also like…

-

HT20X – Conductivity of Liquids and Gases

Read more -

HT16X – Radiation Errors in Temperature Measurement

Read more -

HT11X – Linear Heat Conduction

Read more -

HT14X – Combined Convection and Radiation

Read more -

HT17X – Unsteady-State Heat Transfer

Read more -

HT15X – Extended Surface Heat Exchanger

Read more