FT30-MKIII Spray Dryer

This bench mounted unit is designed for the rapid assessment of processes involving aqueous emulsions, solutions, suspensions and colloids.

The spray dryer can be used for the following applications in the food industry:

- Beverages

- Fish extracts

- Heat sensitive materials

- Milk and egg products

- Cereals

- Plant and vegetable extracts

Description

The all-glass construction and design of the spray assembly minimises any possible contamination and will produce a free-flowing, near-spherical powder. In the spray-drying process the product is introduced in liquid form and emerges as a dry, fine powder. Thermal shock is minimal.

The process may be used for powder coating (agglomeration) where the fine product is adhered together into small balls with the aid of filmogen.

Other processes where spray drying is found to be successful are micro-encapsulation and englobulation.

A fine jet of the liquid to be dried is brought into contact with a hot air stream. This evaporates the spray moisture and carries the solid particles into the cyclone separator. The solids are collected in a sample jar at the base of the cyclone and the exhaust vapour is directed to the outside atmosphere, or fume/dust extractor.

Technical Specifications

- Drying capacity: Maximum approximately 1000ml/h

- Product flow rate range: 60 – 2000 ml/h

- Spray air pressure range: 0.2 -2 Bar

- Jet size: 0.5mm

- Mass balance range: 0-6kg

- Heater: 3kW

- Blower: Fixed @ 70m³/hr

- Maximum air pressure: 70mbar

- Feed pump volume range: 60 ~ 2000ml/h

- Minimum test volume without FT18-20: 15L

Features & Benefits

The spray dryer can be used for the following applications in the food industry:

- Beverages

- Flavours & Colourings

- Milk & Egg Products

- Plant & Vegetable Extracts

- Pharmaceuticals

- Heat Sensitive Materials

- Plastics

- Polymers and Resins

- Perfumes

- Ceramics & Advanced Materials

- Soaps & Detergents

- Dyestuffs

- Foodstuffs

- Adhesives

- Oxides

- Textiles

- Heat sensitive materials

- Fish extracts

The unit is supplied complete; ready for operation.

Materials of construction:

Cabinet: All steel, coated with hard chemical-resistant finish

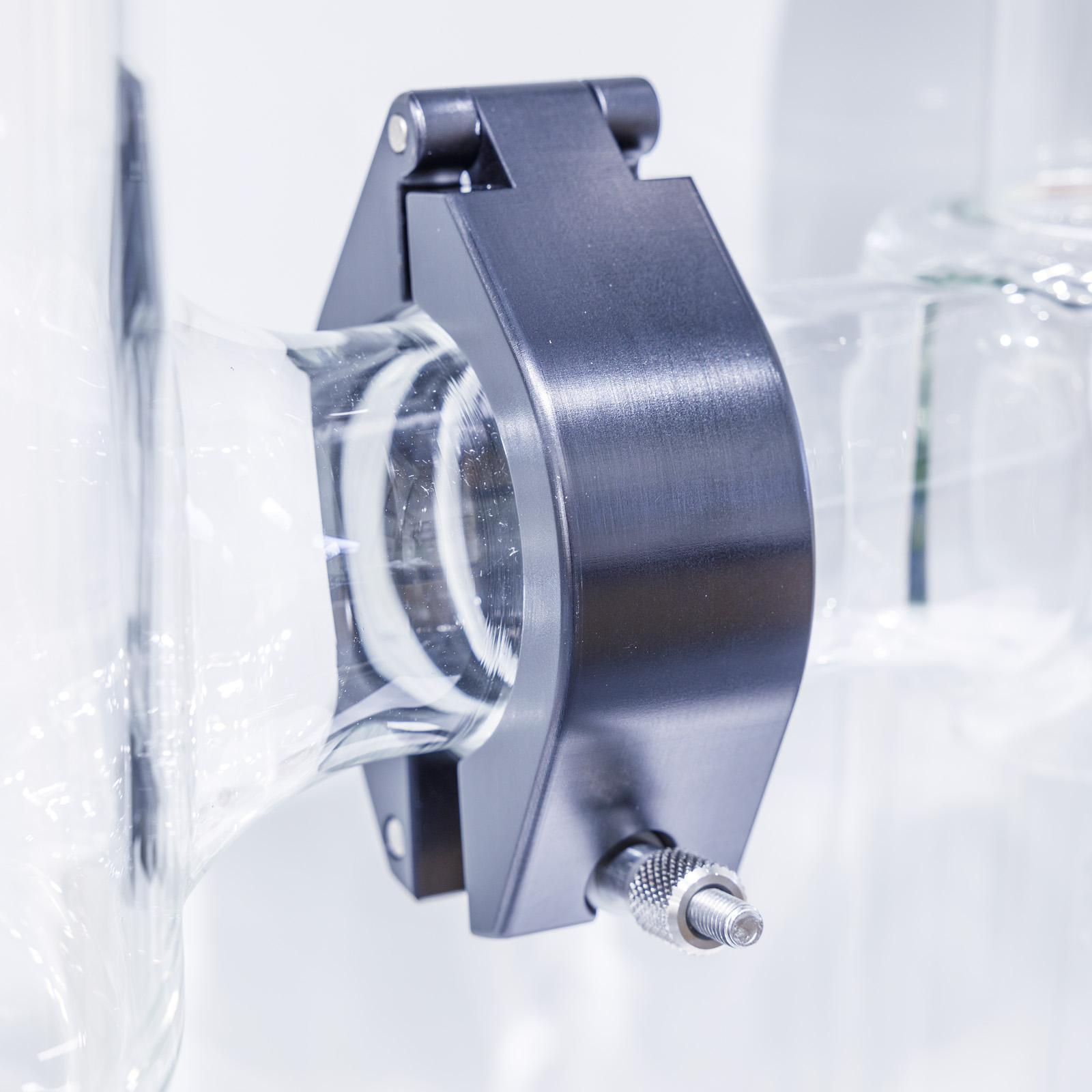

Dryer components: Glass with gasket-free ground glass flanges

Control panel includes:

- Digital controller and display of inlet temperature

- Digital display of outlet temperature

- Rotary knob to control pump speed

- On/off switches for the blower, heater, and mains supply

- Pilot lights positioned in the panel indicate specific operations to be illustrated

- Bench mounted spray dryer for processing aqueous emulsions, solutions, suspensions and colloids

- Downward co-current operation (a fine jet of the liquid is brought into contact with a hot air stream)

- Incorporates manual jet de-blocking device

Electrical supply:

FT30-MkIII-A: 220-240V / 1ph / 50Hz

FT30-MkIII-B: 120V / 1ph / 60Hz

FT30-MkIII-G: 220-240V / 1ph / 60Hz

Compressed air: 27 l/min @ 3 bar

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 1.20m³

Gross weight: 190kg

OVERALL DIMENSIONS

Height: 1.10m

Width: 0.50m

Depth: 0.50m

Weight: 60kg

- FT30-MkIII-A 220-240V / 1ph / 50Hz

- FT30-MkIII-B 120V / 1ph / 60Hz

- FT30-MkIII-G 220-240V / 1ph / 60Hz