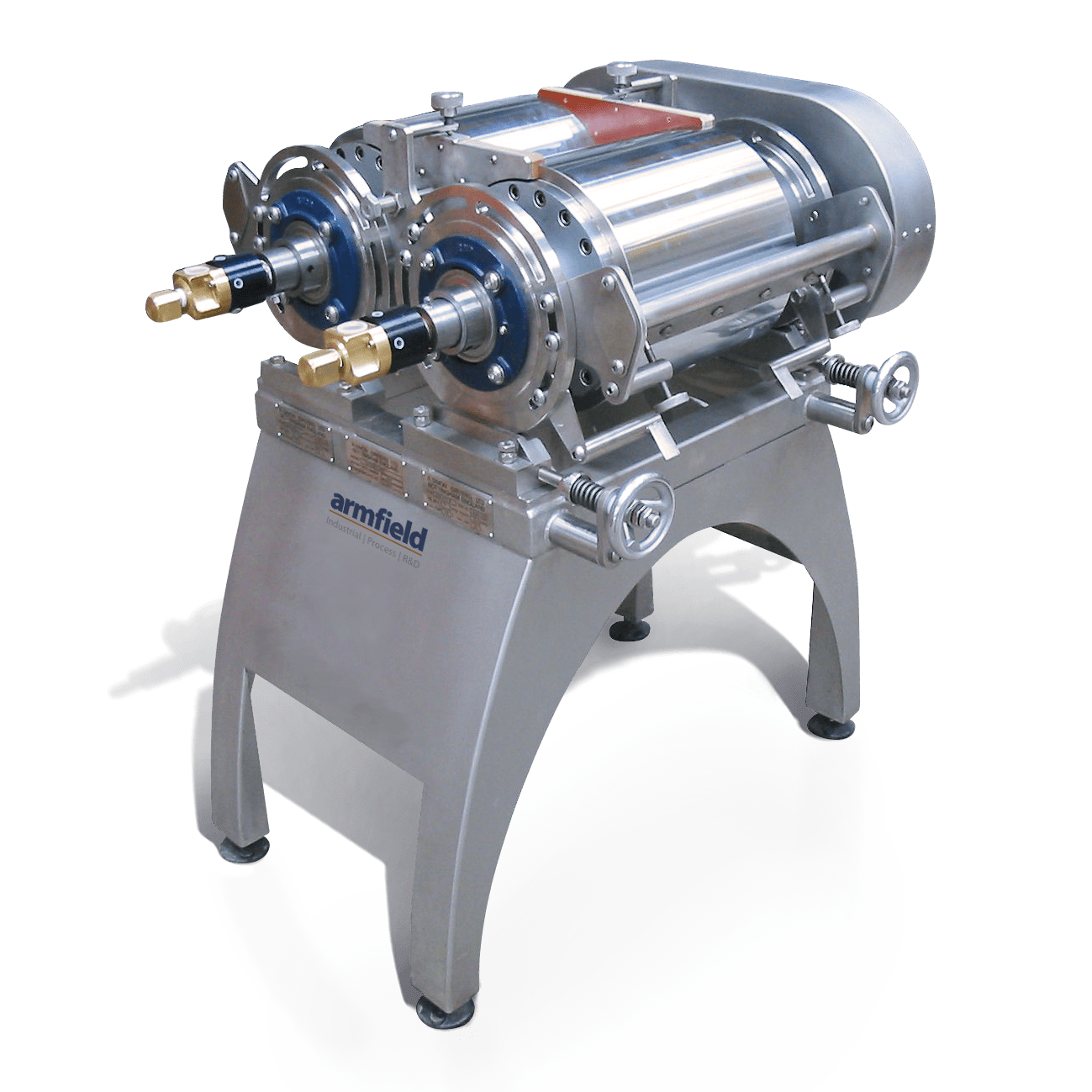

FT32 Laboratory Drum Dryer

A laboratory-scale drum dryer, designed for food, chemical and pharmaceutical research. The FT32 can be used for both process development and new product research demonstrating various applications of a drum dryer

Description

The Armfield Laboratory Drum Dryer is designed for food, chemical and pharmaceutical research.

The equipment is supplied fully assembled and ready for connection to site services. The liquid to be dried is fed into the valley created by the two drums, where it is applied to the drums as they rotate together, the dry product is removed by a knife on each drum.

The unit is constructed from stainless steel, providing hygienic surfaces that are resistant to chemical attack. The drums are hard chrome plated to ensure maximum heat transfer and the ability to scale up results to production-sized equipment.

The main drive is shaft mounted and its speed is adjusted by an electronic inverter in the control panel.

Technical Specifications

- Drum size: 300mm diameter x 300mm long

- Drying duty Max material feed rate: 45 kg/hr

- Max water evaporated: 30 kg/hr

- Steam consumption: 40 kg/hr @ 6 barg

- Max Operating temperature: 162°C max

- Pressure: 7 bar max

Features & Benefits

- Max material feed rate 10 kg/hr

- The drums are hard chrome plated to ensure maximum heat transfer

- The equipment is supplied fully assembled

- Designed for food, chemical and pharmaceutical research

- Adjustable film thickness and drying rate

- Food stuffs

- Fruit & vegetables

- Yeast u Brewing

- Baby food

- Instant cereals

- Starches & flours

- Pet foods

- Chemicals

- Detergents

- Dye stuffs

- Ceramic slips

- Pharmaceutical research

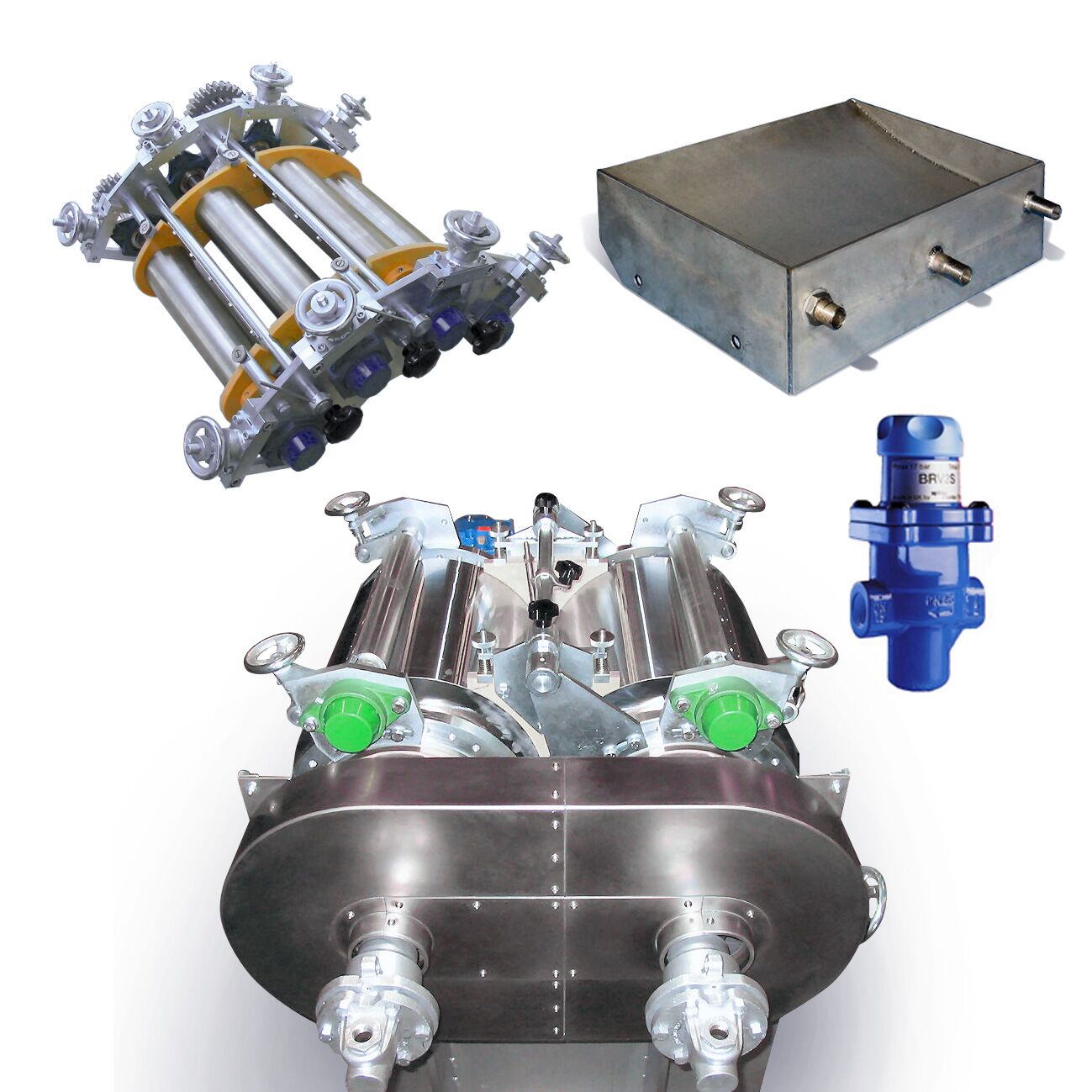

FT32-20: Vapour extraction system

- This is fitted above the dryer and draws the vapours produced when drying away through the fan and duct assembly

FT32-21: Feed system

- The stainless steel feed tank and variable-speed pump deliver the material to be dried through a solid pipeline to the dryer feed

FT32-24: Feed Roll Assembly

- The double drum dryer can be easily converted to operate as a single cylinder feed roll drum dryer, with this accessory.

FT32-25: Feed System Mixer

- A stainless steel, paddle-type mixer mounted on the feed tank on a hinged lid. This enables any particles in the feed to remain in suspension and reduces settling within the feed tank

Packed and created shipping specifications

Volume: 2.91m3

Weight: 850Kg

Length: 1.20m

Width: 0.97m

Height: 1.50m

FT32-C: 415V / 3ph / 50Hz

FT32-D: 208V / 3ph / 60Hz

FT32-E: 380V / 3ph / 50Hz

FT32-F: 220V / 3ph / 60Hz