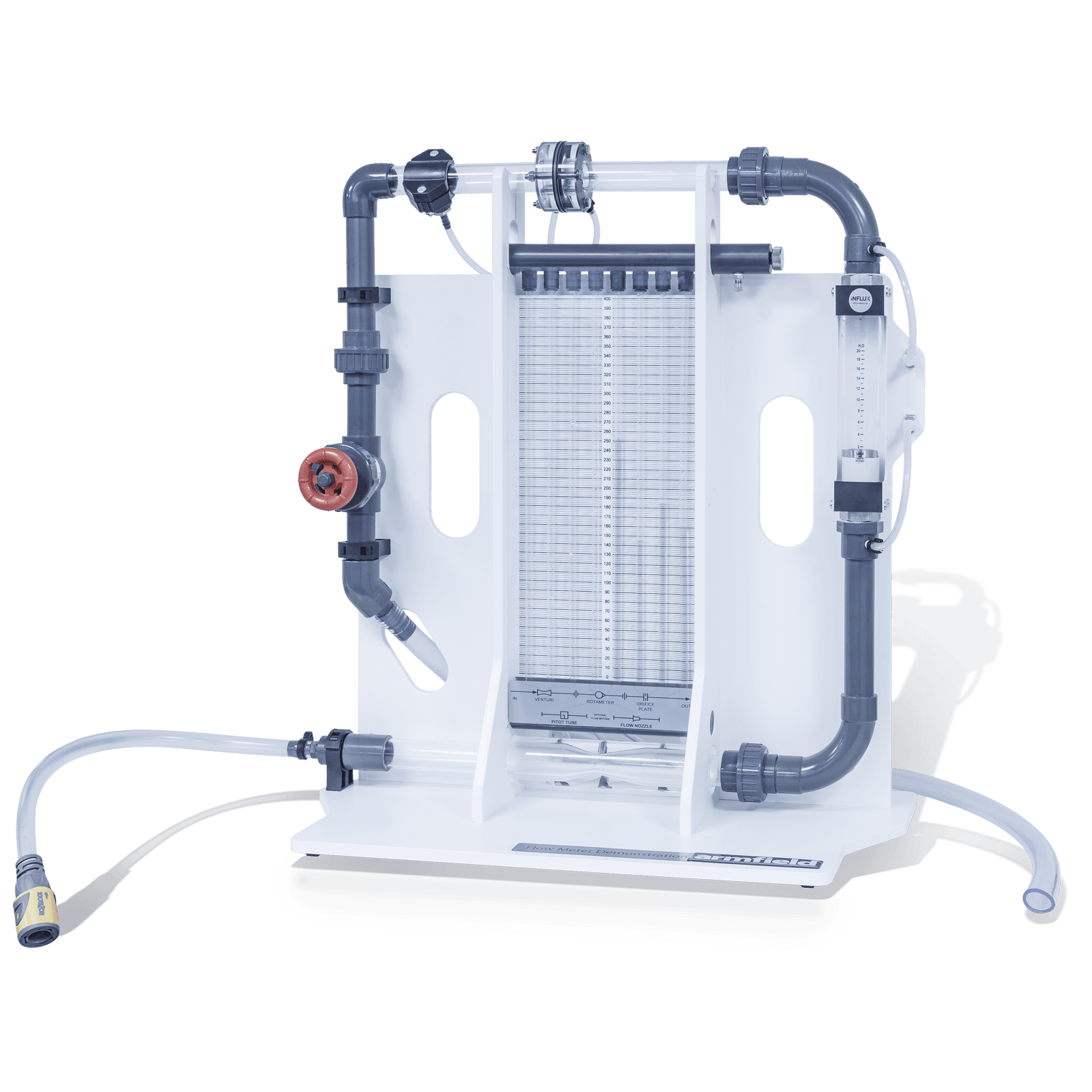

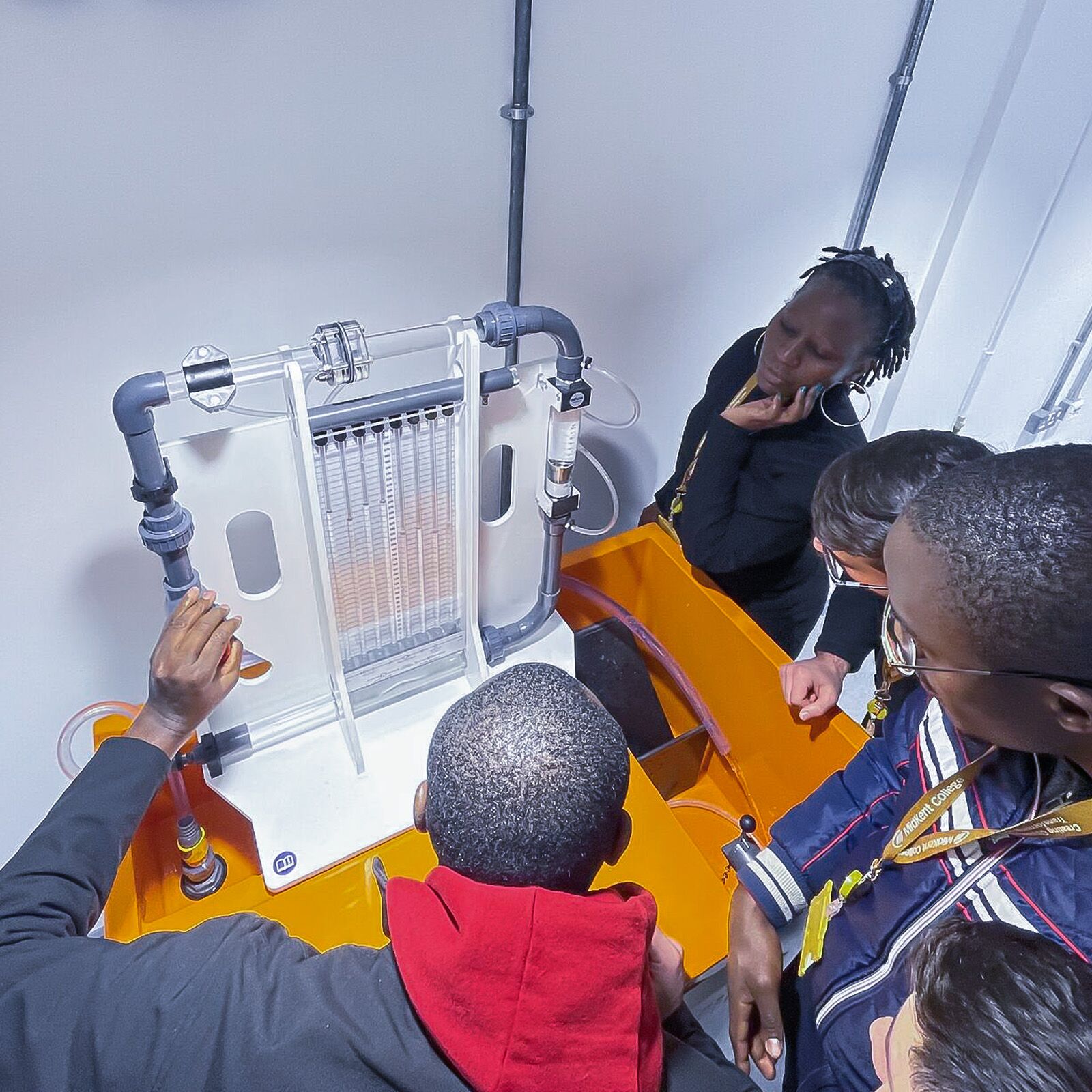

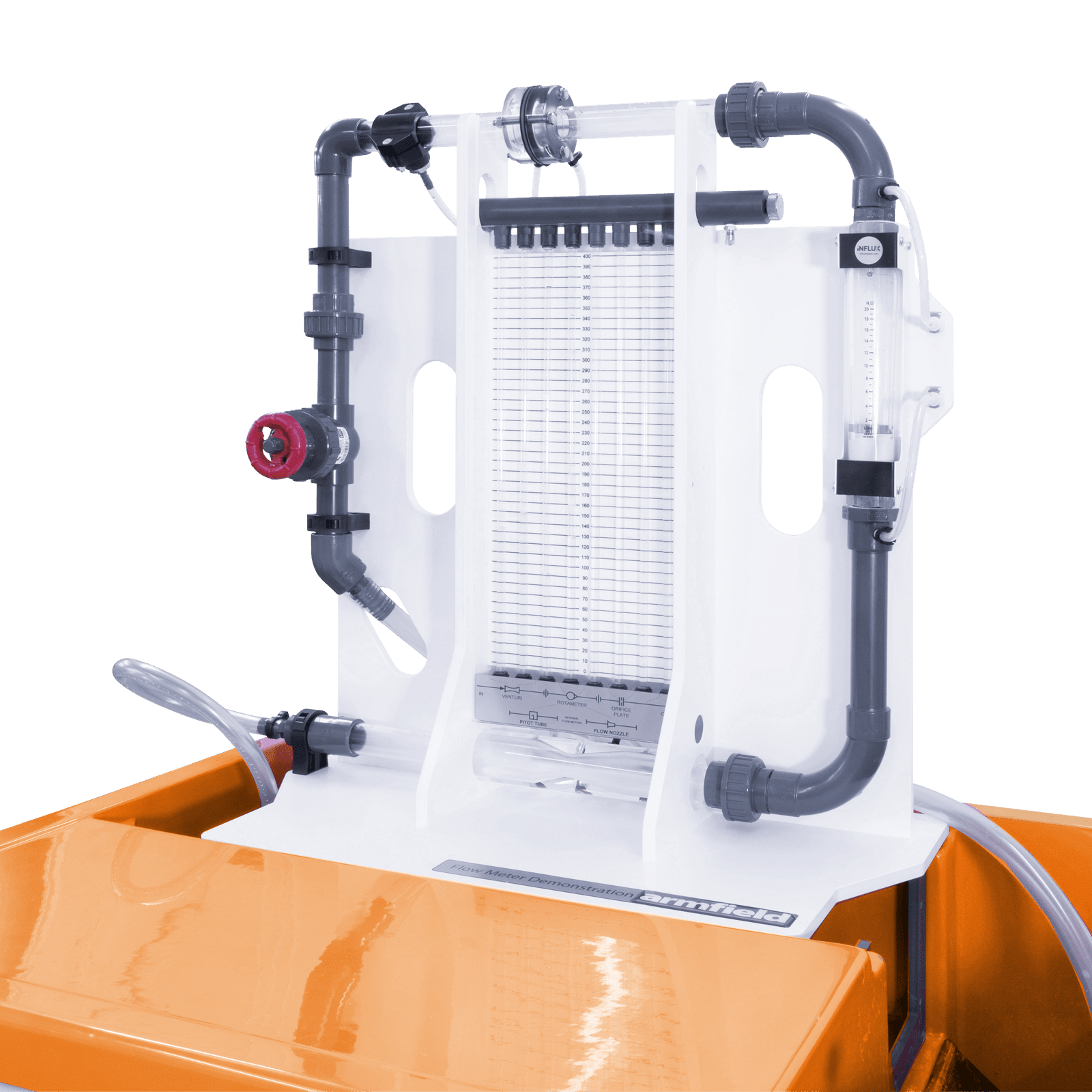

F1-21-MKII Flow Meter Demonstration

This accessory is designed to introduce students to three basic types of flow meter:

-

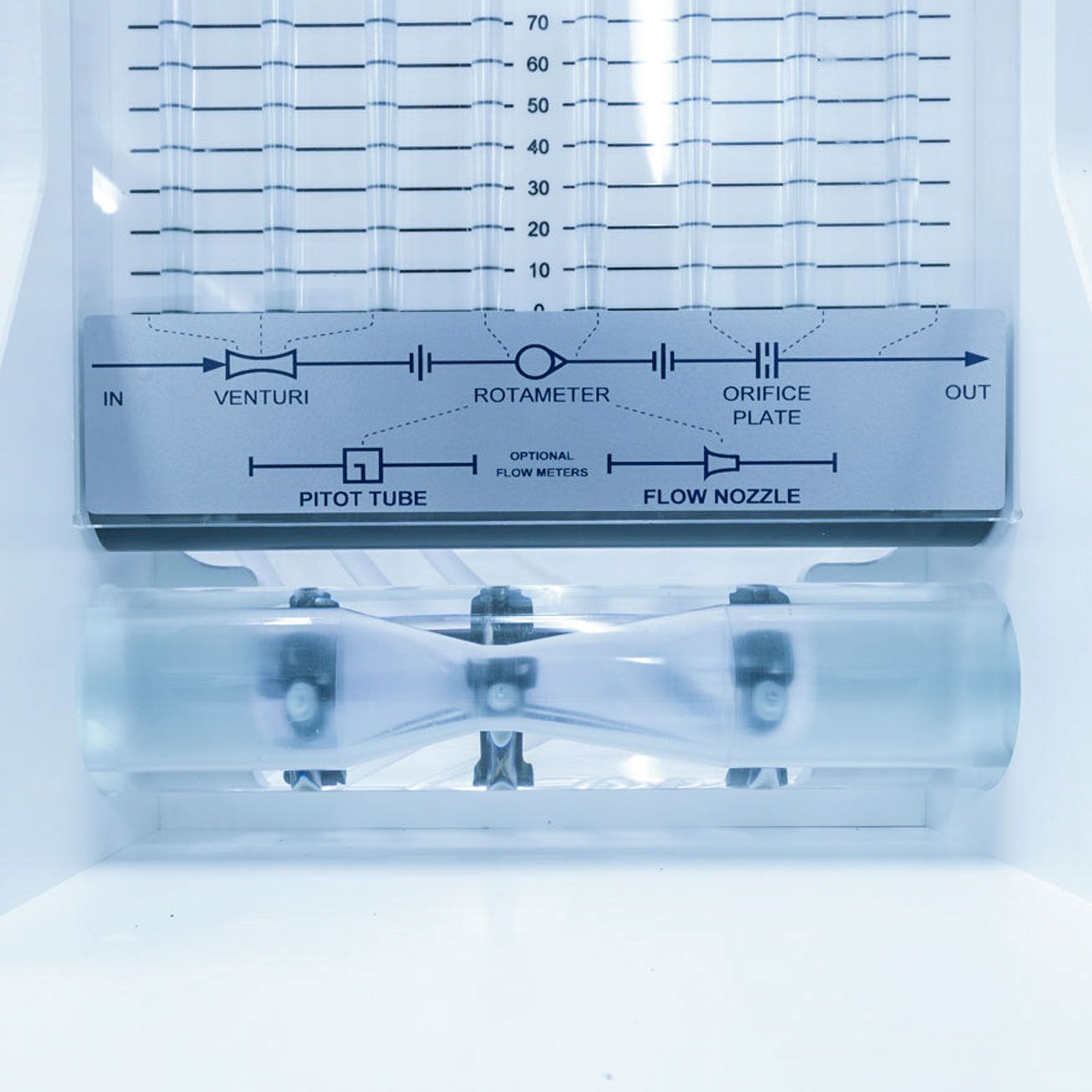

- Venturi meter

- Variable area flowmeter (Rotameter)

- Orifice plate

- 8 pressure tappings are connected and displayed on the manometer bank to visualise pressure profiles

Description

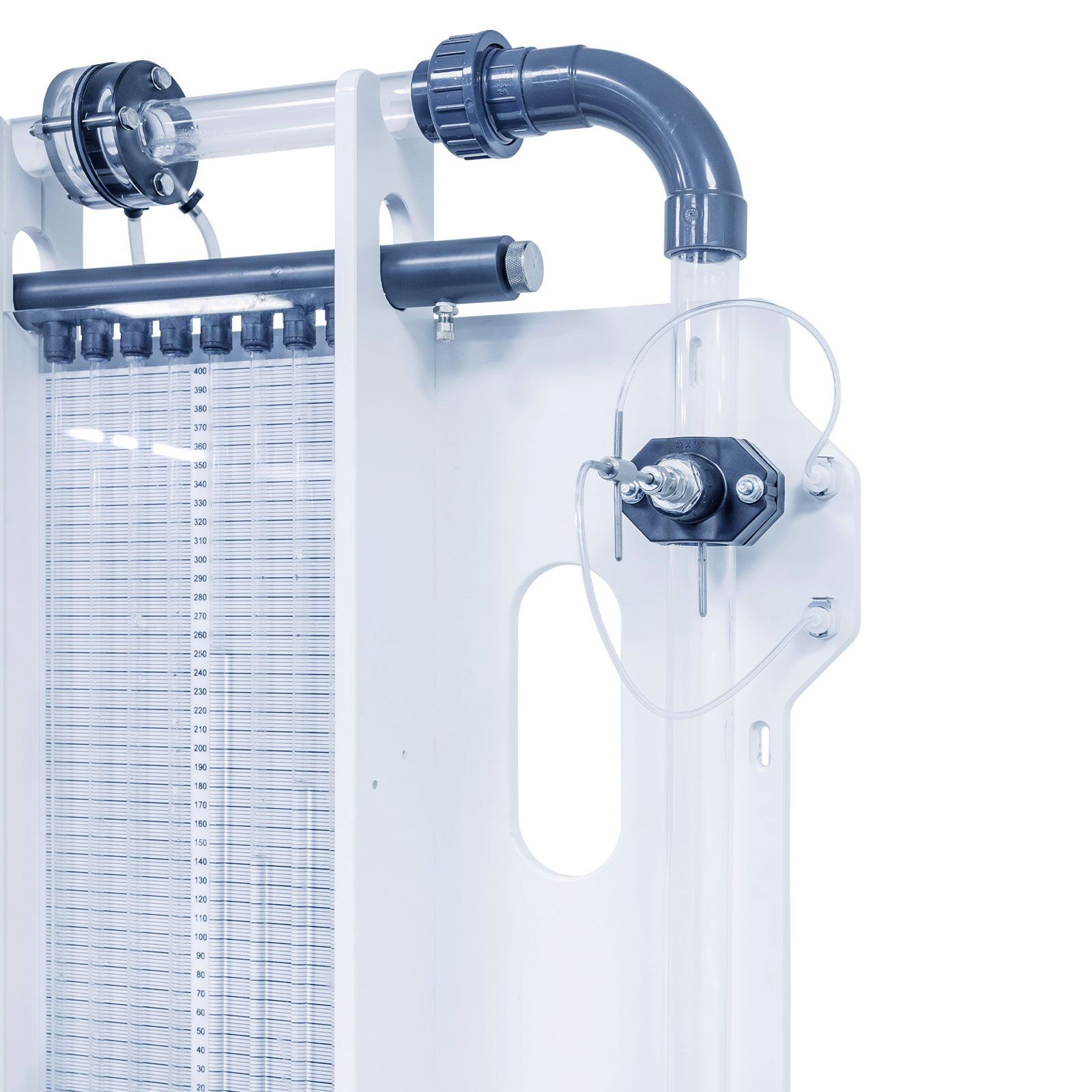

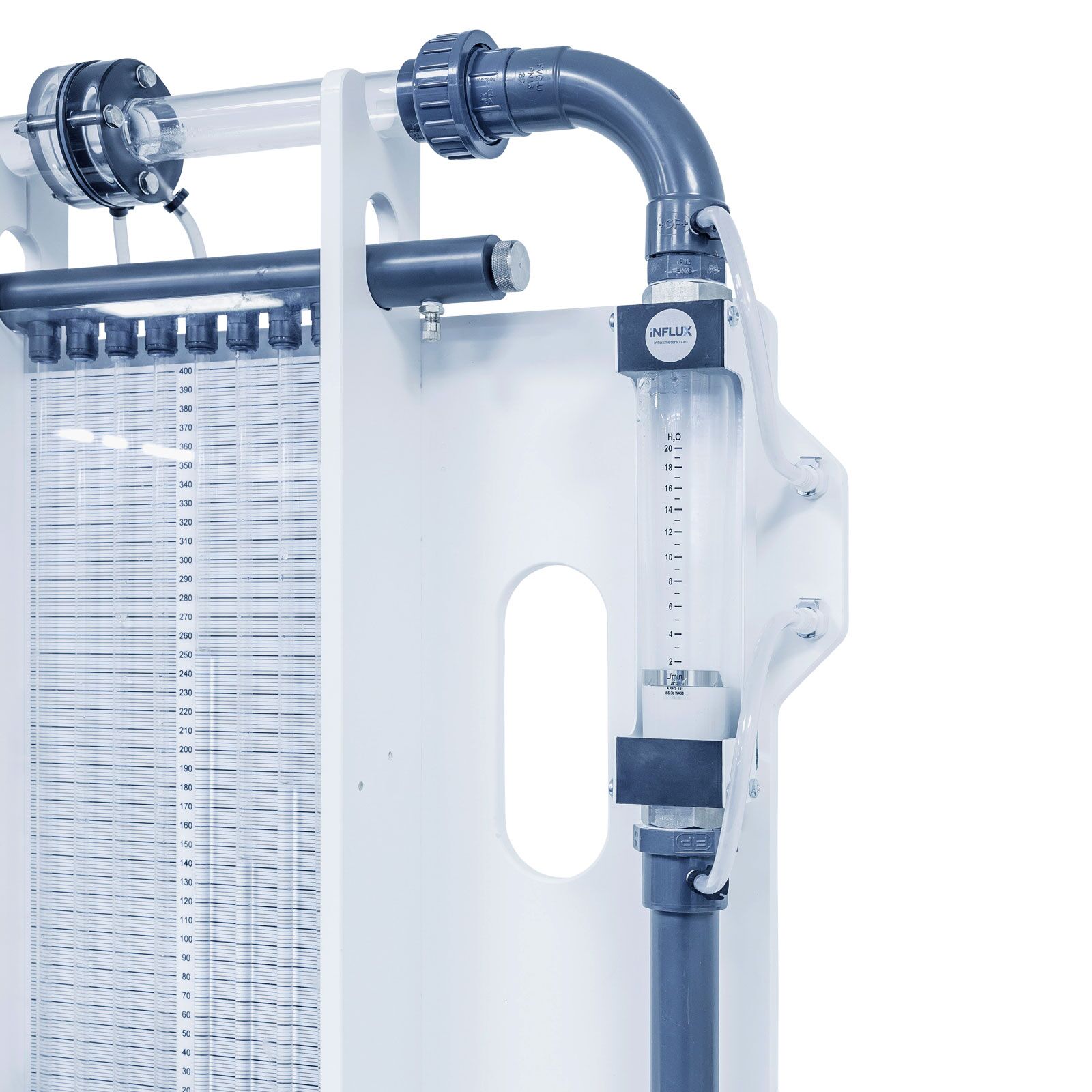

The equipment consists of a Venturi meter, variable area meter and orifice plate, installed in a series configuration to permit direct comparison. A flow control valve permits variation of the flow rate through the circuit. Pressure tappings are incorporated so that the head loss characteristics of each flow meter may be measured. These tappings are connected to an eight-tube manometer bank incorporating a manifold with an air bleed valve.

Pressurisation of the manometers is facilitated by a hand pump. The circuit and manometer are attached to a support framework, which stands on the working top of the Hydraulics Bench. The bench is used as the source of water supply and for volumetrically calibrating each flow meter.

- Optional Pitot Static Tube

- Optional Flow Nozzle

Technical Specifications

Manometer range: 0-400mm

Number of manometer: tubes 8

Orifice plate diameter: 17mm

Variable area meter: 2-20 l/min

Venturi dimensions

Throat diameter: 14mm

Upstream pipe diameter: 26mm

Upstream taper: 21° inclusive

Downstream taper: 9° inclusive

Requires Hydraulics Bench Service unit F1-10/F1-10-2

Features & Benefits

This accessory is designed to introduce students to three basic types of flow meter:

-

-

- Venturi meter

- Variable area flowmeter (Rotameter)

- Orifice plate

- 8 pressure tappings are connected and displayed on the manometer bank to visualise pressure profiles

-

-

- Optional Pitot Static Tube

- Optional Flow Nozzle

- To investigate the operation and characteristics of a Venturi meter, variable area flowmeter and orifice plate including accuracy and energy losses

- Comparison of pressure drops across each flow measurement device

- Calibrating each flow meter using the volumetric measuring tank of the hydraulics bench

- Application of the Bernoulli equation for incompressible fluids

- Optionally available Pitot Static tube and Flow Nozzle

Watch a short video about the F1-21-MKII in English:

Mira un breve video sobre el F1-21-MKII en español:

F1-10 Hydraulics Bench to provide water flow.

Length: 0.68m

Width: 0.33m

Height: 0.83m

F1-21-MKII