CEK MKII – Fluid Mixing Studies

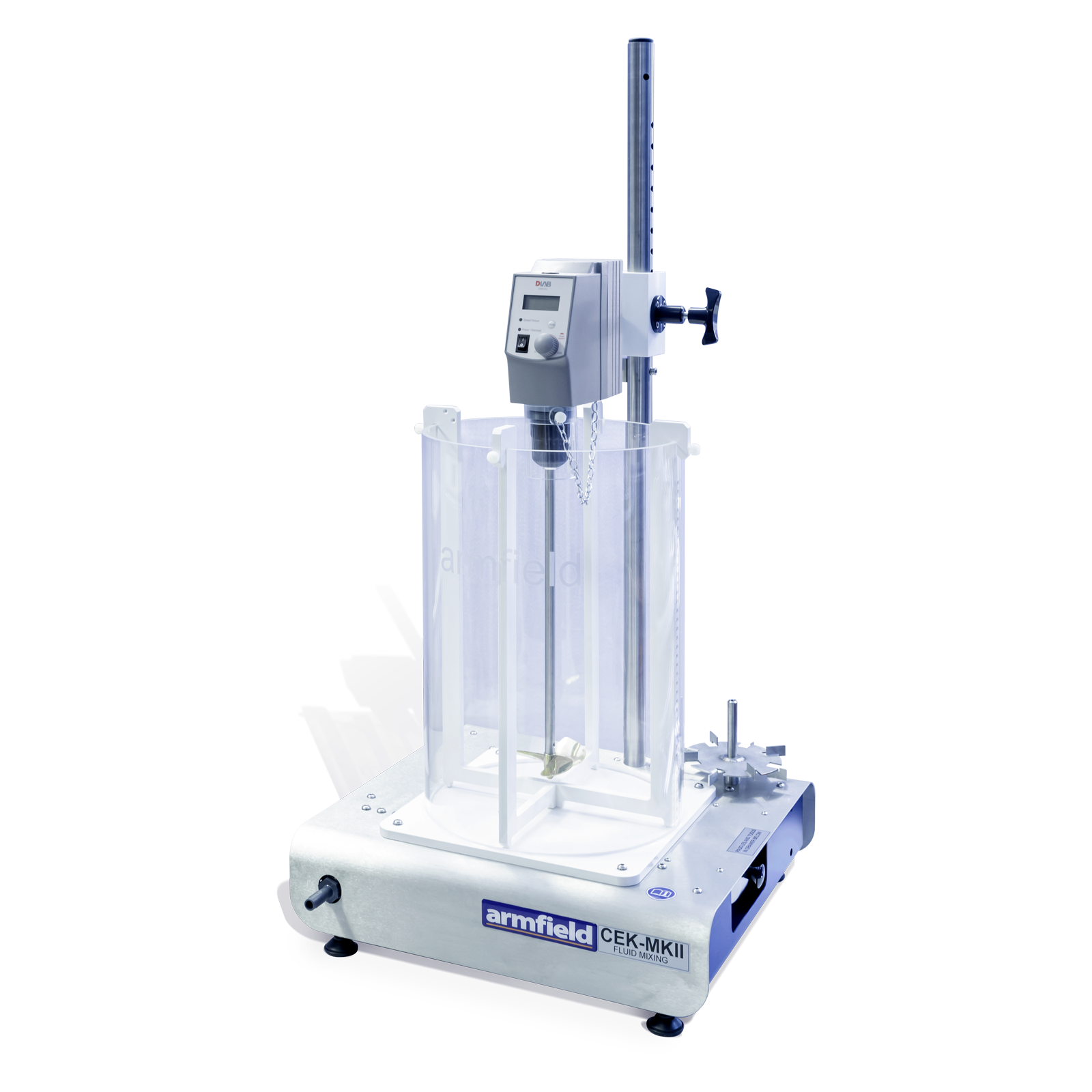

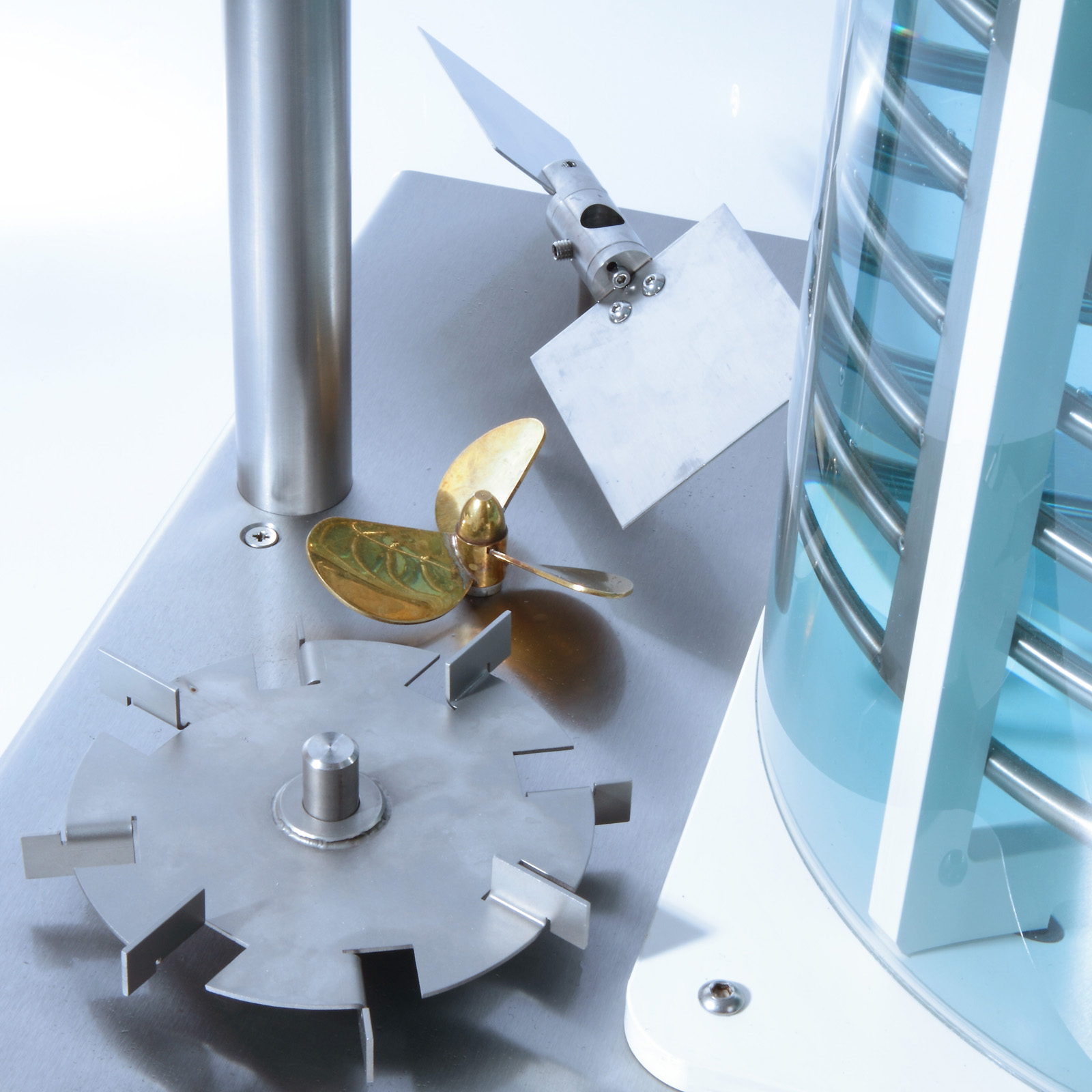

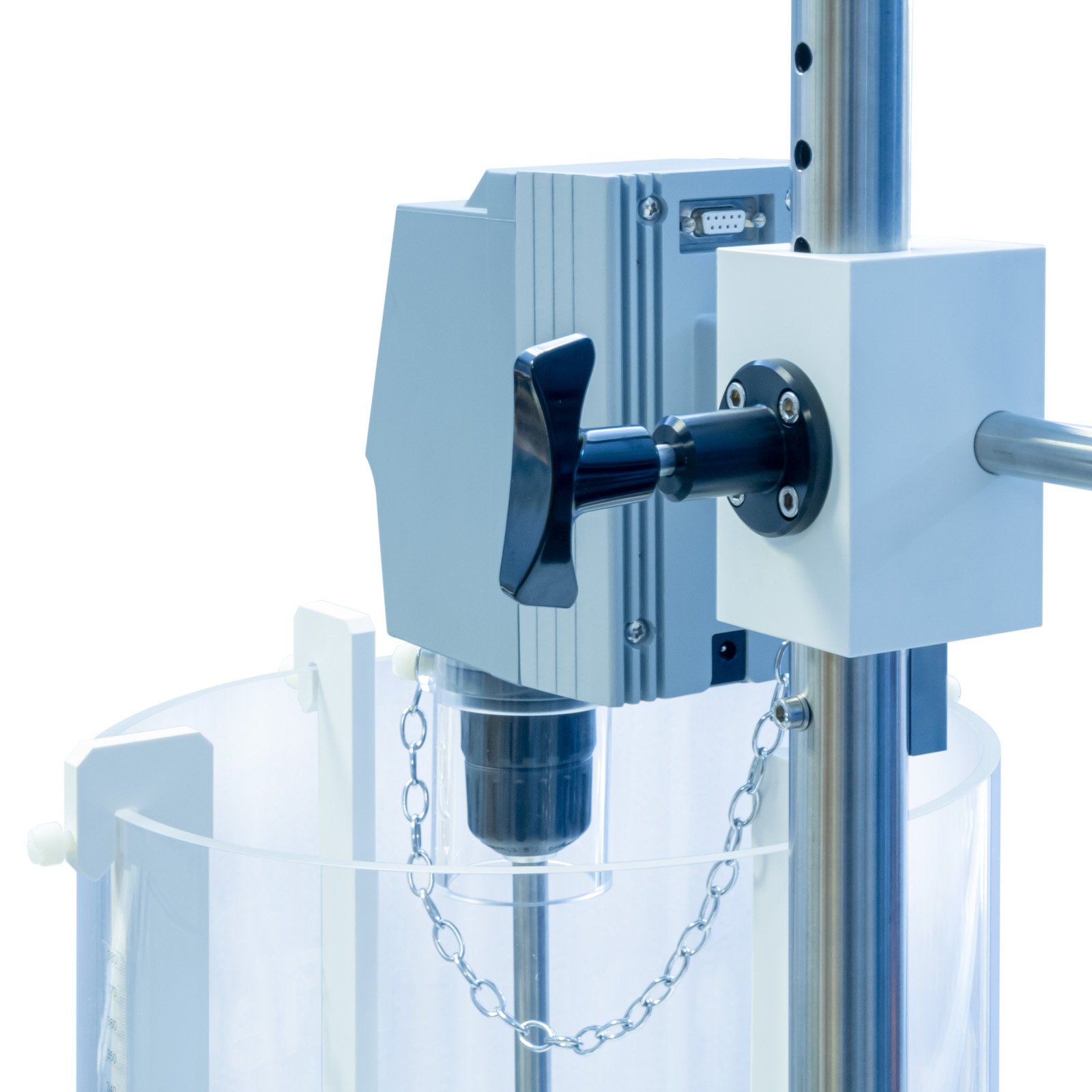

The apparatus comprises a clear acrylic mixing vessel mounted on a stainless steel base. Above this is mounted a variable-speed electronic mixer with electronic torque measurement incorporated.

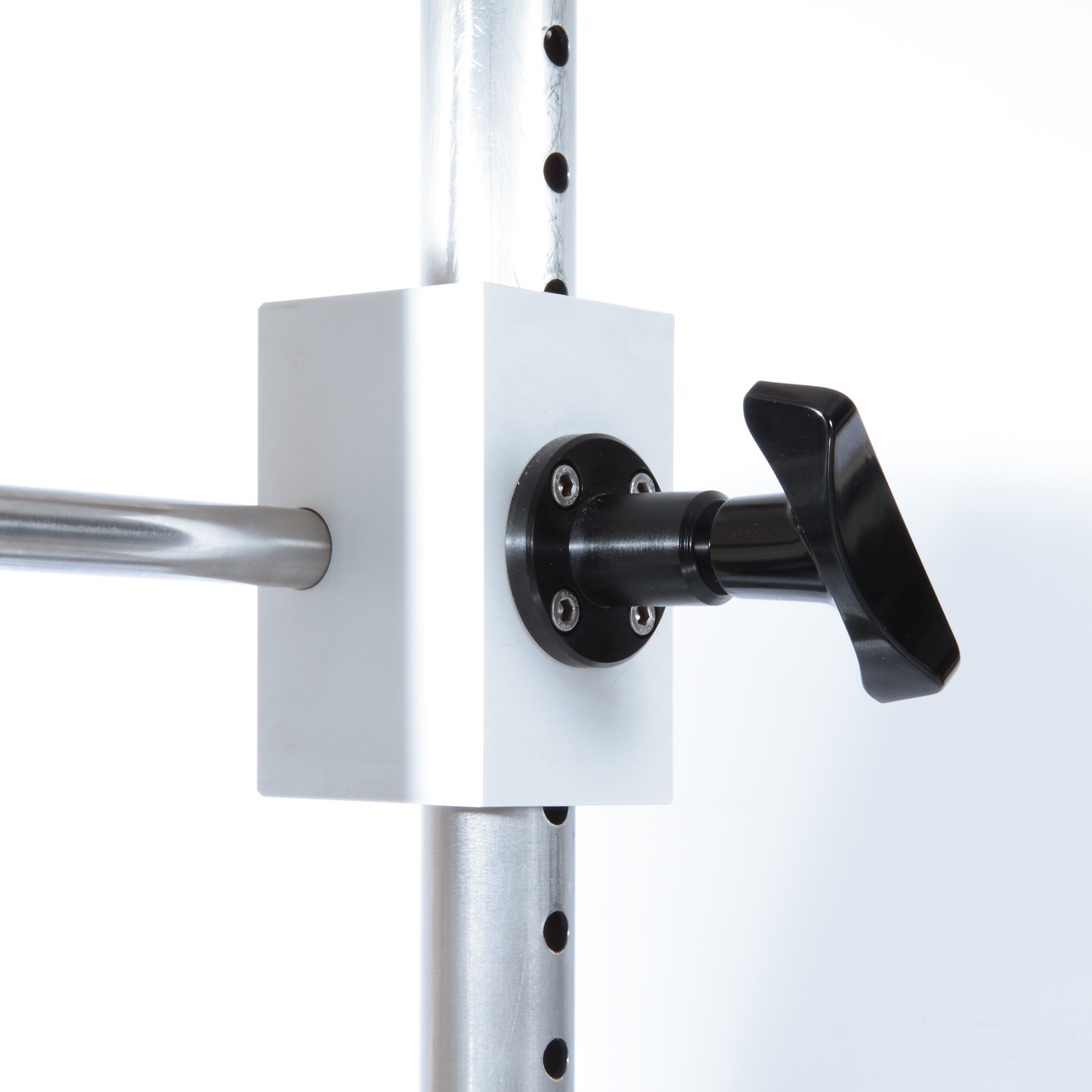

A set of PVC baffles can be fitted into the mixer with a simple screw mechanism to hold them in place. Under the stainless steel base is a storage compartment for the various small mixer components and the simple tools (hexagonal keys) required to change them. The larger mixer components are stored on pins behind the vessel.

Description

The apparatus comprises a clear acrylic mixing vessel mounted on a stainless steel base. Above this is mounted a variable-speed electronic mixer with electronic torque measurement incorporated.

A set of PVC baffles can be fitted into the mixer with a simple screw mechanism to hold them in place. Under the stainless steel base is a storage compartment for the various small mixer components and the simple tools (hexagonal keys) required to change them. The larger mixer components are stored on pins behind the vessel.

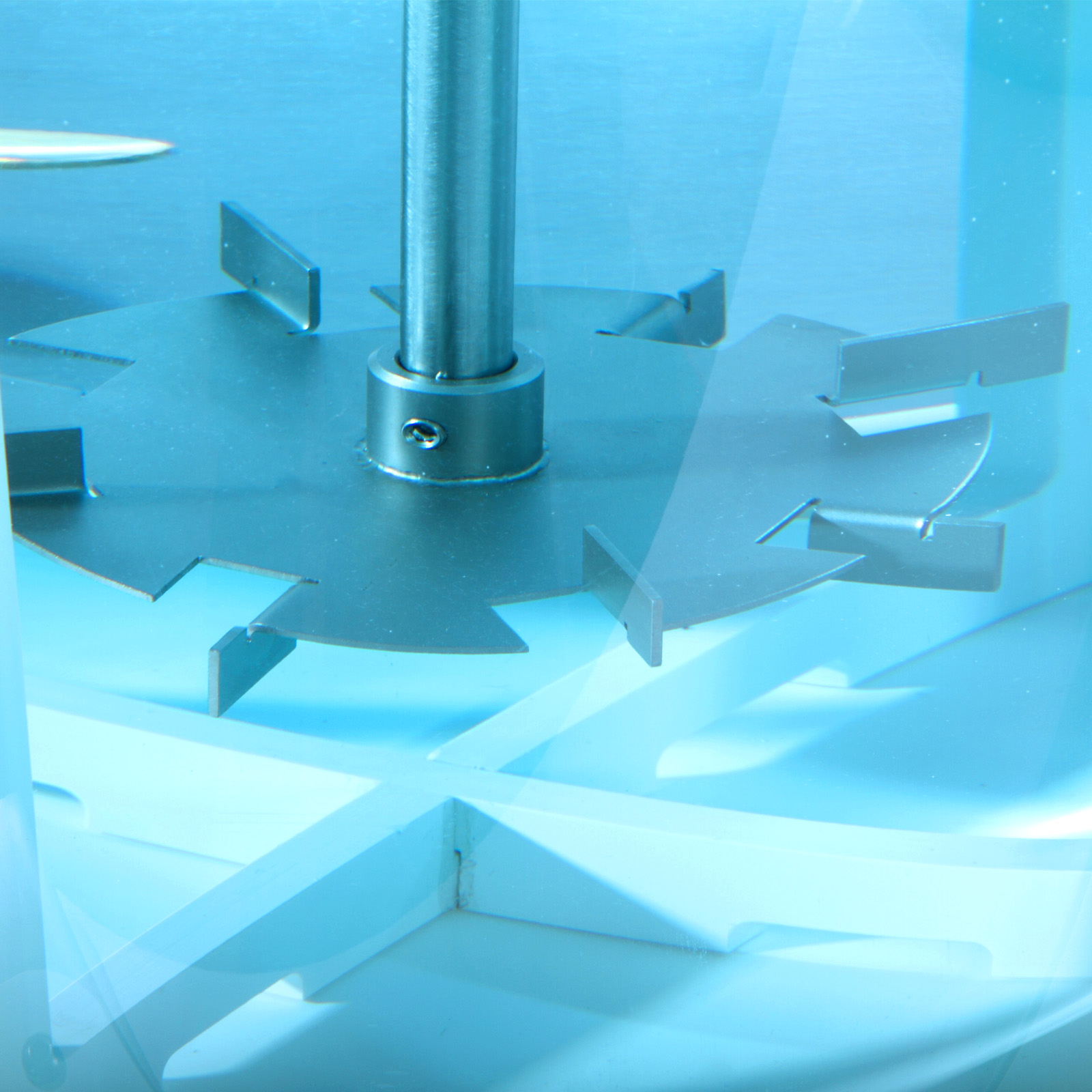

The Rushton turbine impeller is a one-piece stainless steel fabrication with eight alternate upward and downward-pointing blades.

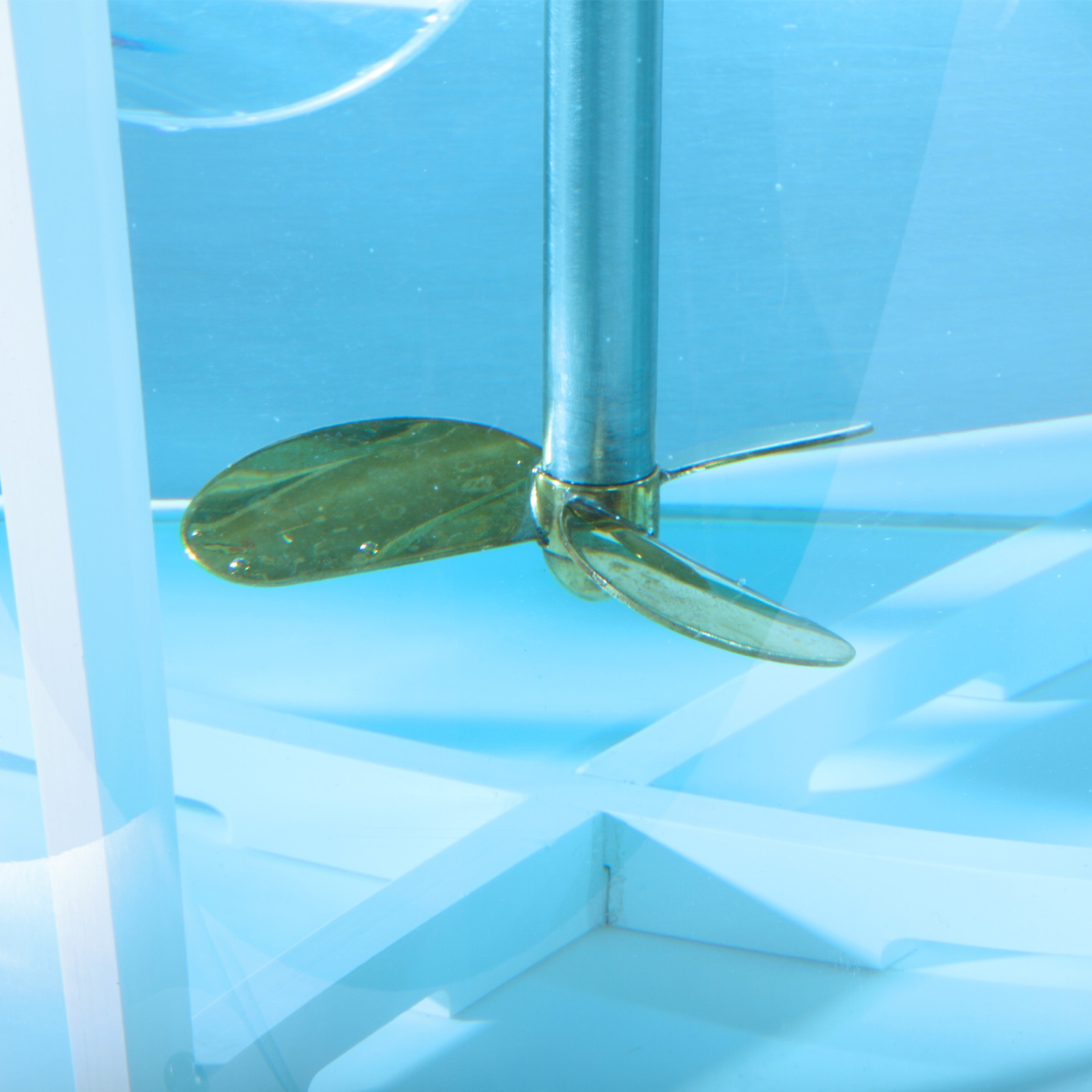

The flat blade impeller comes with six sizes of blade, each of which can be fitted in seven positions (vertical, plus 30/45/60 degrees leading and trailing edge). The blades are simple to configure and position accurately in place using a single screw. A propeller type stirrer is also included for comparison.

The CEK MkII is supplied with armSOFT aLITE software, which logs the speed and torque of the mixer. From these values it calculates the mixer power and can display the data in real-time using its powerful graph-plotting facilities. To use this facility a standard Windows PC with serial interface (or a USB serial adaptor) is required. These are not supplied by Armfield.

- Highly visual, with variable-speed mixer with a range of interchangeable impellers

- High-speed mixing available, 50 to 2,200rpm

- Precise electronic RPM setting

- Electronic measurement of torque

- Removable baffles (zero, two or four-baffle configuration)

- Data logging software

- True Rushton turbine impeller

- Precise angle setting for the adjustable flat blade impellers

- Optional removable heating/cooling coil with temperature sensor and meter

Technical Specifications

Features & Benefits

- A benchtop laboratory mixing system for demonstrating and teaching fundamental principles of mixing

- Electronically controlled variable-speed drive system with accurate RPM measurement display

- Electronic measurement and display of torque on the drive head

- The drive can be varied from 50-2,200rpm (note, not all the impellers are suitable for use at high speed)

- Impellers include a true Rushton turbine with eight alternate upward and downward-pointing vertical blades, a propeller and six different sizes of flat blades

- The flat blades are attached to a common mounting hub with a simple mechanism providing a precise blade angle. Seven different blade angles can be set for each blade size

- The Rushton turbine and flat-bladed impellers are manufactured from stainless steel

- Supplied with software to log the speed (RPM) and drive torque, calculate the power and display the data in graphs and tables

- A set of baffles is included

- The equipment can be operated in zero, two or four-baffle configurations

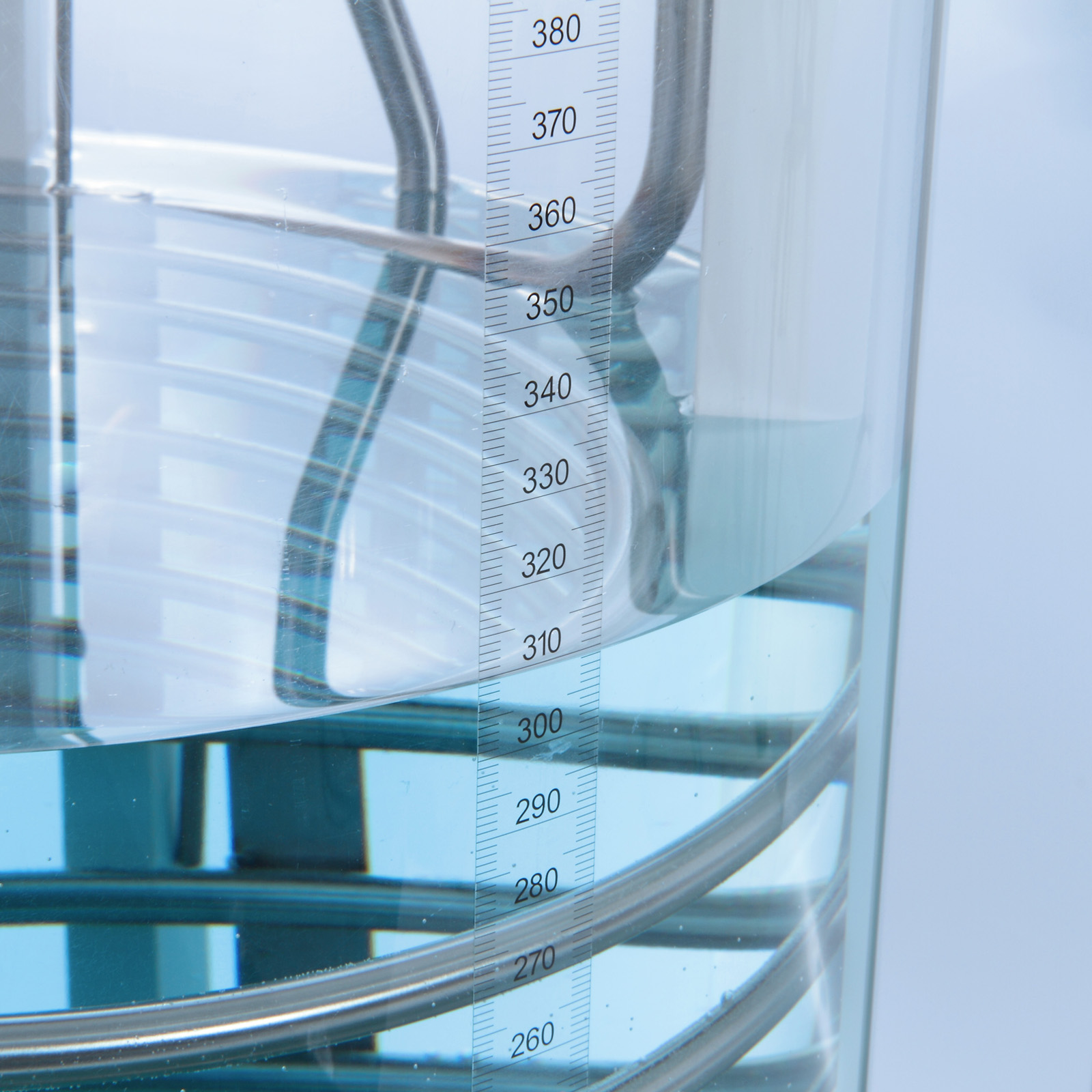

- An optional heat transfer coil is available complete with temperature sensor and display

- Powered by a universal power adaptor with worldwide approval

- To observe the various flow patterns that can be achieved by the use of different impellers with and without the use of baffles

- To show how the power consumed by a mixer varies with speed, type of impeller, and with the inclusion of baffles

- Torque/power/speed characteristics of different impellors

- To observe how different types of impeller turning at different speeds influence the rate of dispersion of solids throughout the liquid

- To observe the effectiveness of different impeller configurations running at different speeds, with and without baffles, on the mixing of immiscible liquids

- To study the effectiveness of different impeller configurations running at different speeds, with and without baffles, on the rate of mixing an electrolyte in water

- Investigation of how mixing time affects the quality of mixing

- Effect of flat blade paddles, propellers and agitators on mixing

- To predict the power absorbed by a large mixer using the Fluid Mixing Apparatus provided as a model and to draw a characteristic mixing curve

- To observe the effect of temperature on the viscosity of fluids and the corresponding changes in stirring characteristics

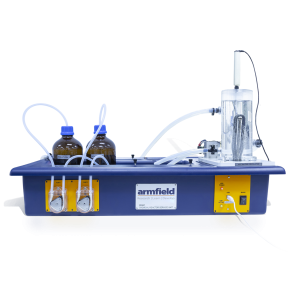

Heat Transfer Coil Option – CEK-MkII-3

This comprises a removable stainless steel coil that fits inside the mixing vessel, a temperature probe (thermocouple) to measure the temperature of the vessel contents and a hand-held temperature display. Hot or cold water from the laboratory supply can be passed through the coil to change the temperature of the vessel contents. This enables temperature and viscosity investigations to be undertaken.

Electricity Requirements:

Requires 24V DC at 5A – The equipment is supplied with a universal mains adaptor suitable for 100V to 240V AC, 50/60Hz

Computer:

Software requires the user to have a PC running Windows 7 or above with a USB port.

Water supply:

CEK-MkII-3: Requires a flow of hot or chilled water, typically 3 l/min, from a tap or circulation system.

Consumables:

20lt vegetable oil

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.3m³

Gross Weight: 40Kg

Length: 0.50m

Width: 0.40m

Height: 1.00m

CEK-MkII–EU with Shuko-style mains lead

CEK-MkII–UK with UK-style mains lead

CEK-MkII-B with 115V US NEMA 5-15 style mains lead