C16 – Hydrogen Bubble Flow Visualisation System

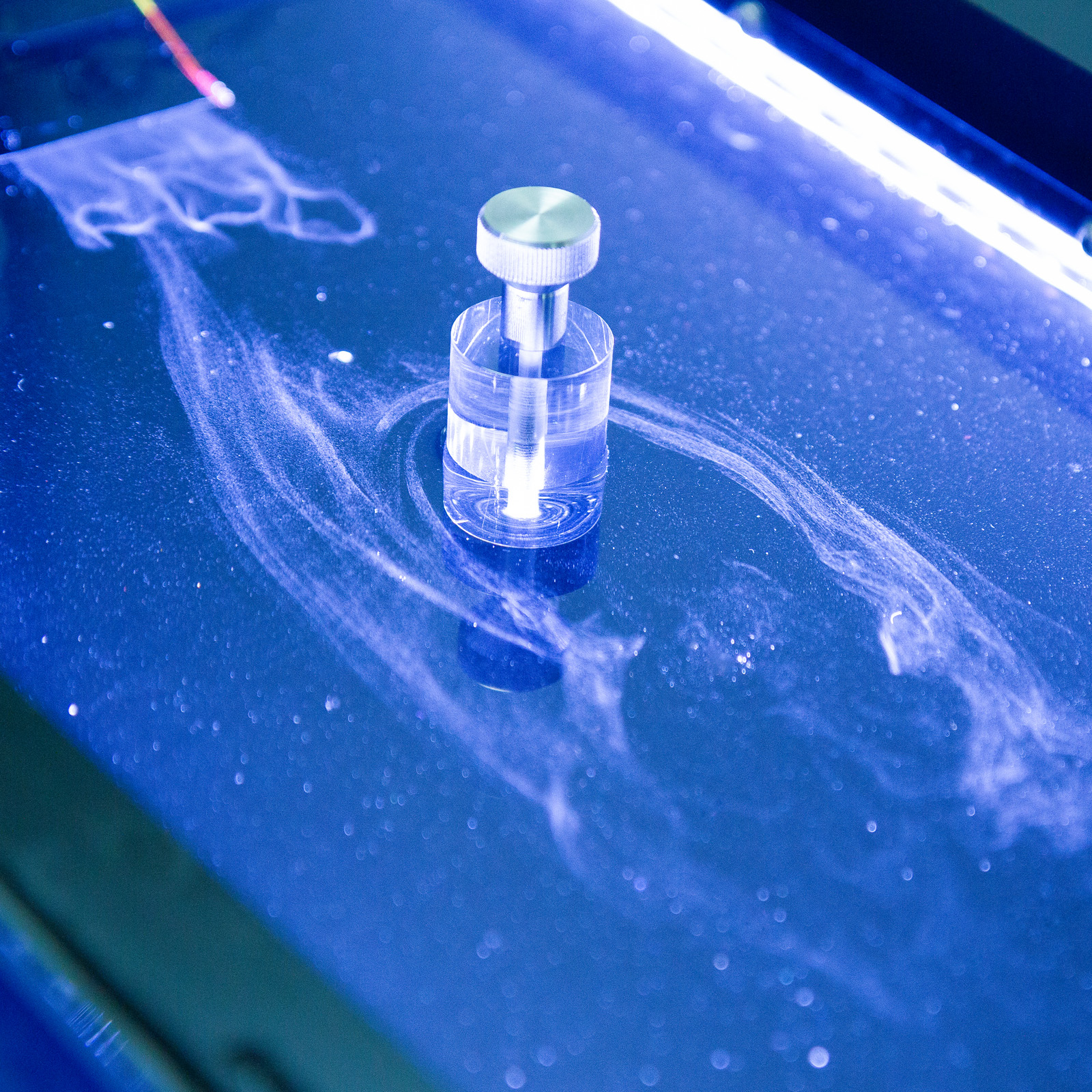

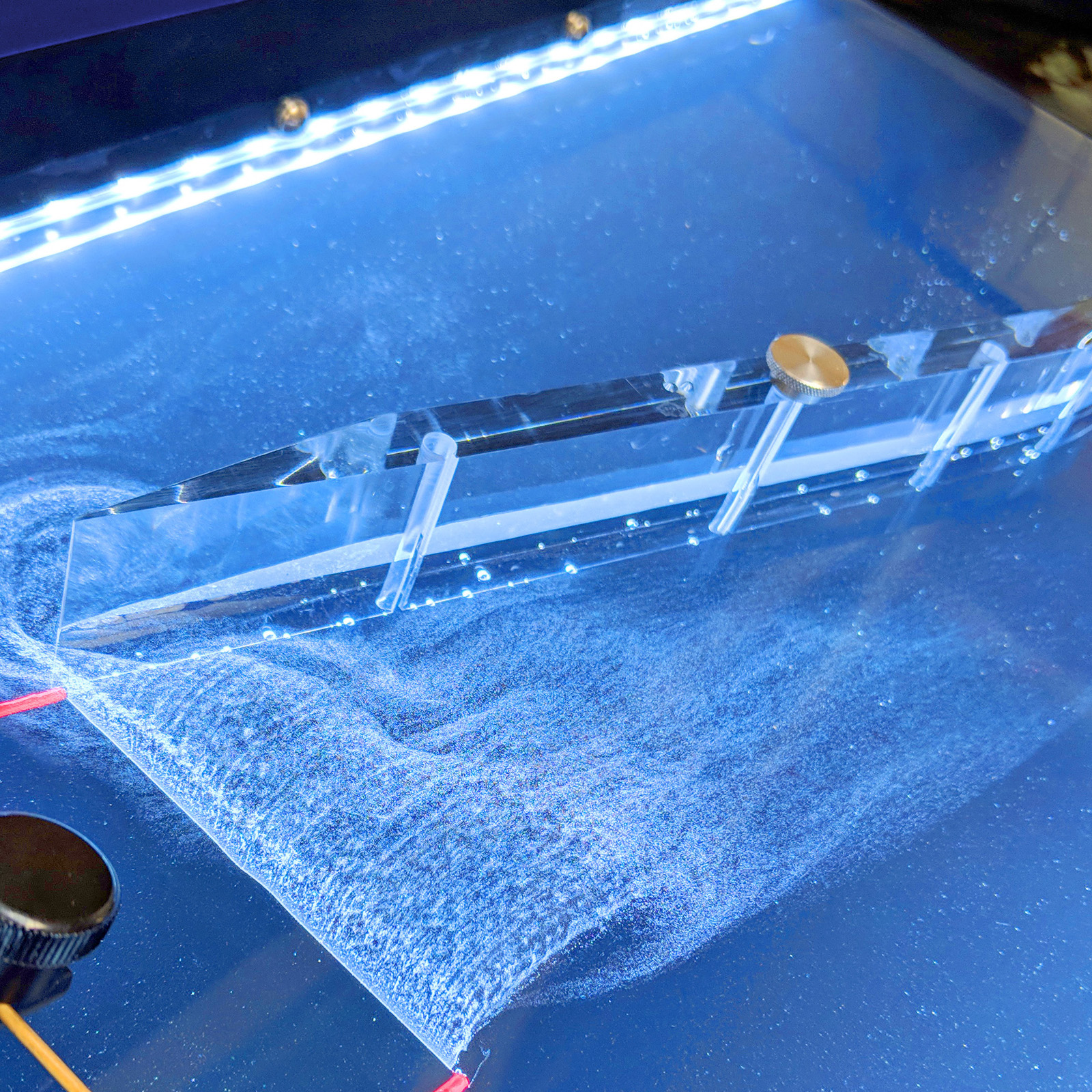

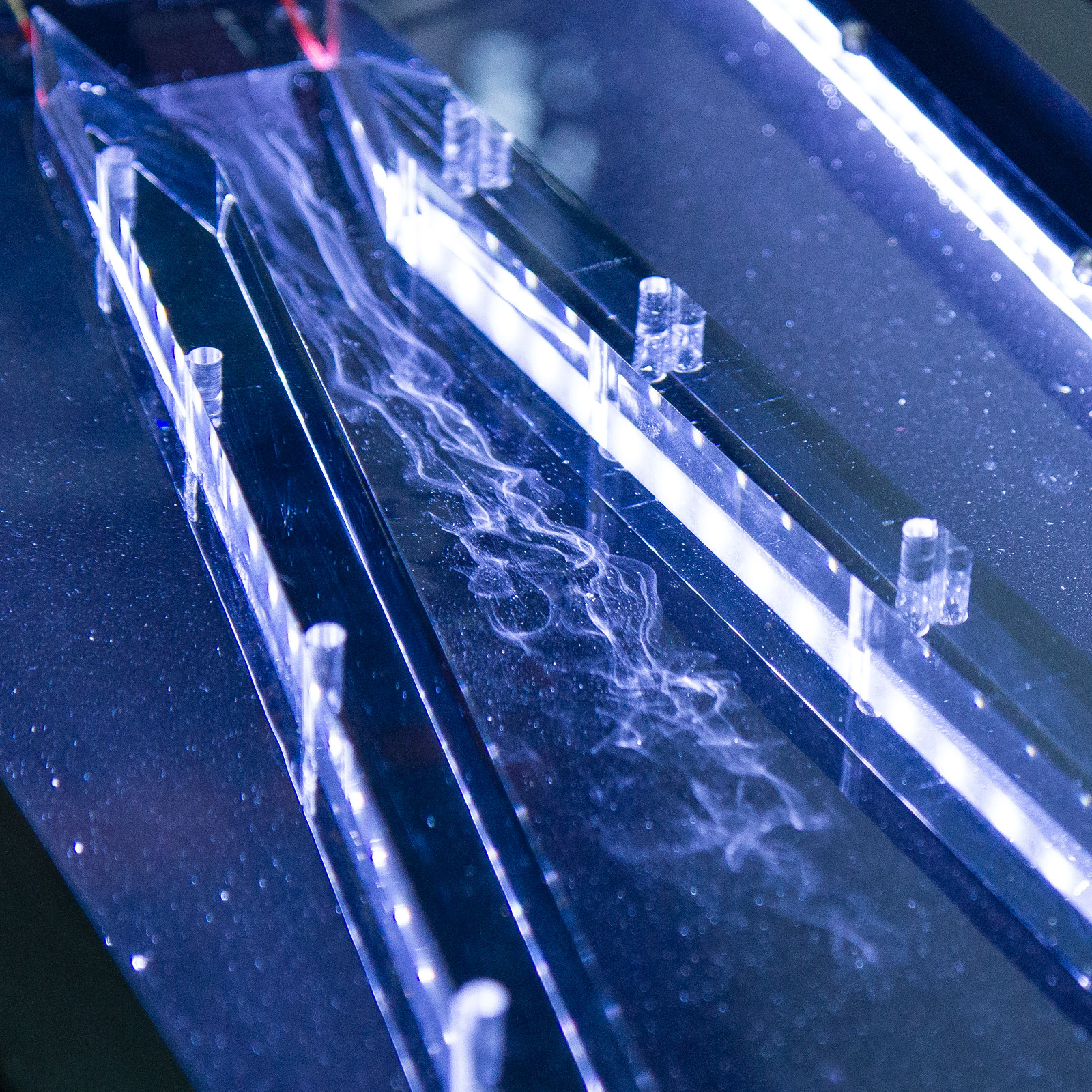

The Armfield Hydrogen Bubble Flow Visualisation System has been designed to enable viewing of the complex flow patterns associated with water flowing past solid objects or boundaries. The hydrogen bubble technique is highly visual and is particularly useful for laboratory and lecture theatre work.

A stream of small hydrogen bubbles accurately follows the water and clearly shows any changes in the direction of the water as it flows around objects in its path.

Description

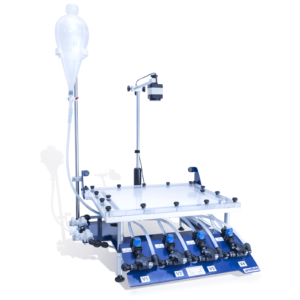

The armfield hydrogen bubble flow visualisation system is compact, bench mounted and self-contained requiring only filling with water and connecting to a mains electrical supply.

It comprises a flow tank, a separate electronic control console and a comprehensive set of clear acrylic flow visualisation models.

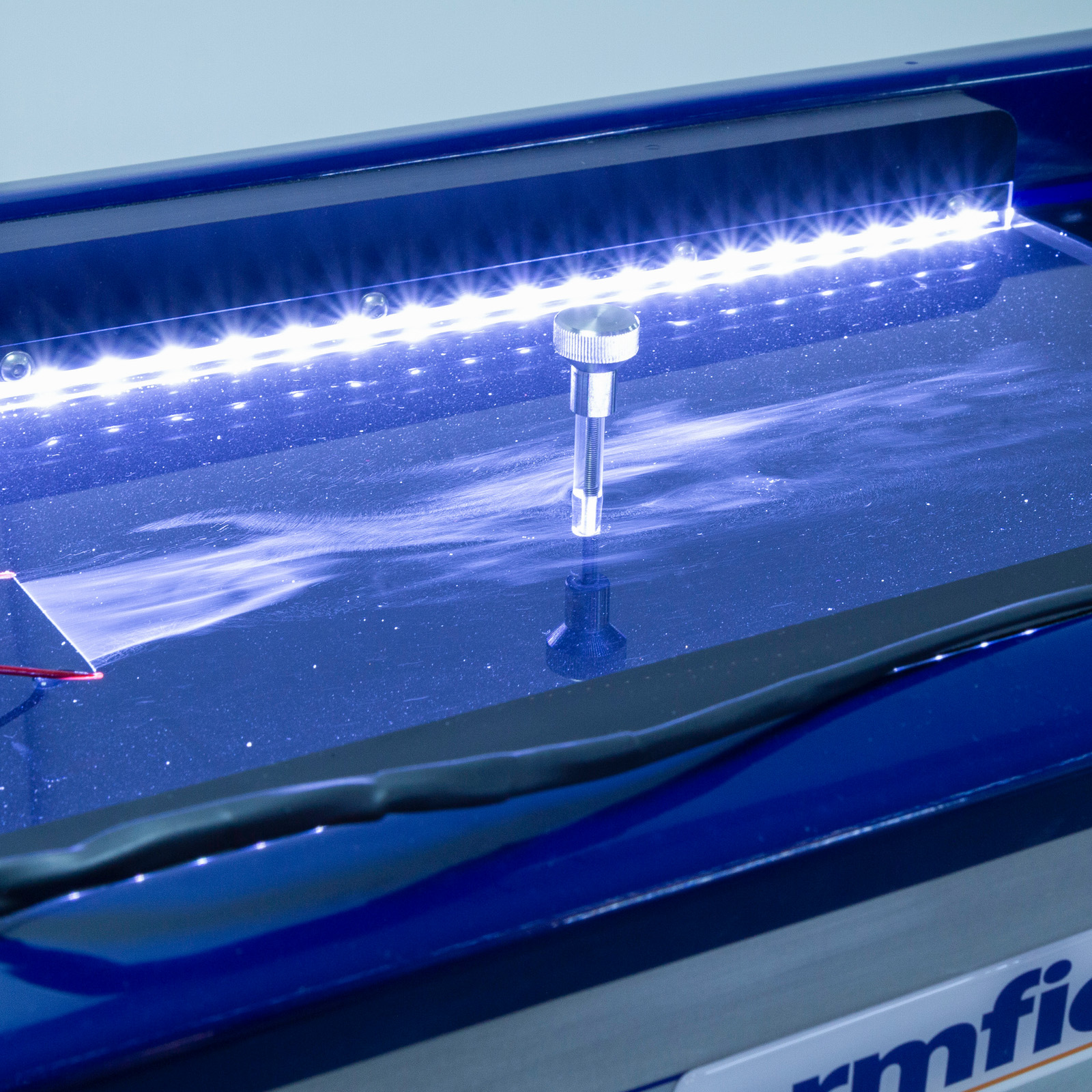

The top of the flow tank is manufactured from glass-reinforced plastic (GRP) for durability and incorporates a wide, shallow working section with a flat black acrylic bed for flow visualisation studies. A smooth flow of water at variable velocity is passed through the working section. This is achieved by using a unique fluid drive unit, in combination with flow straighteners. The depth in the working section can be changed by a set of weir strips at the discharge end.

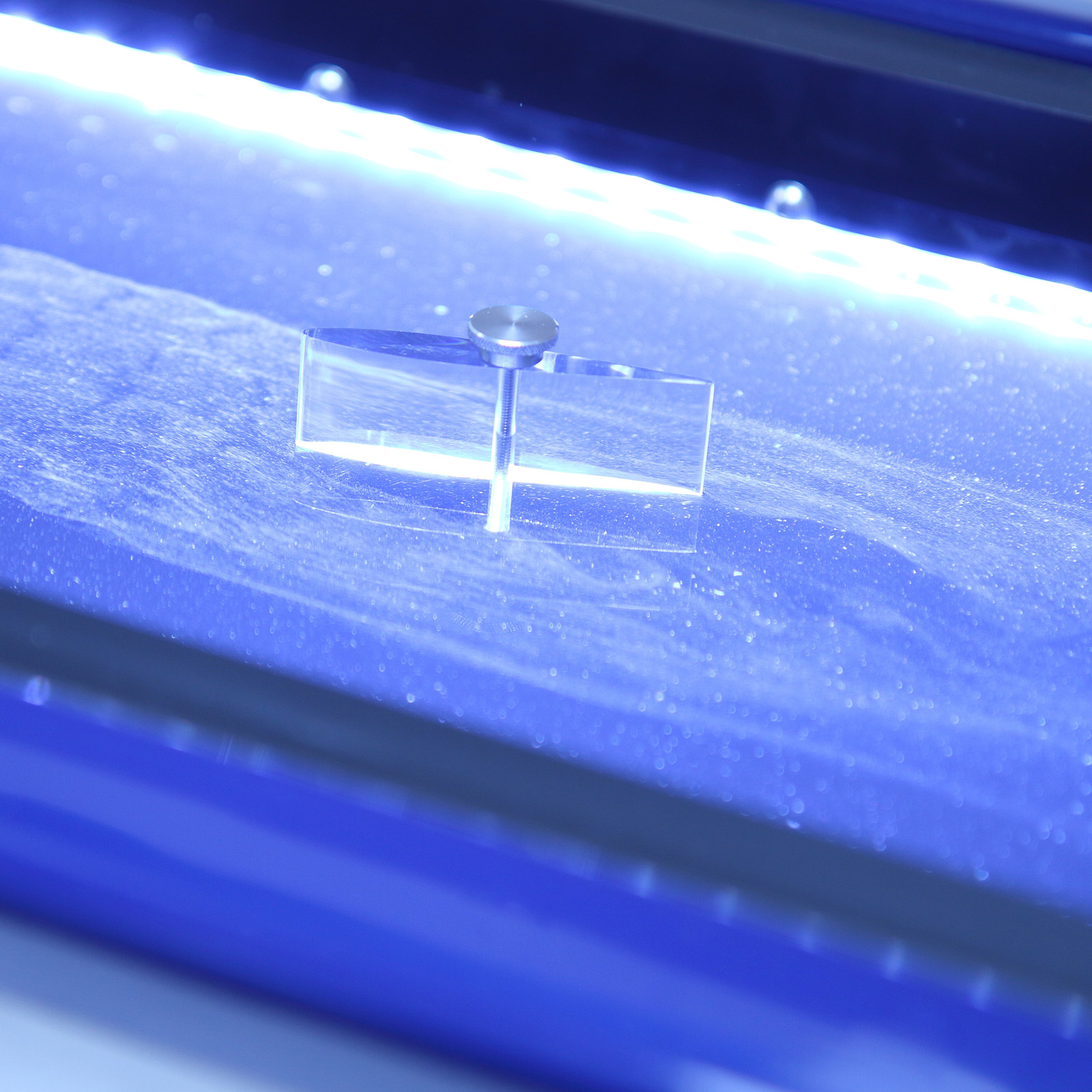

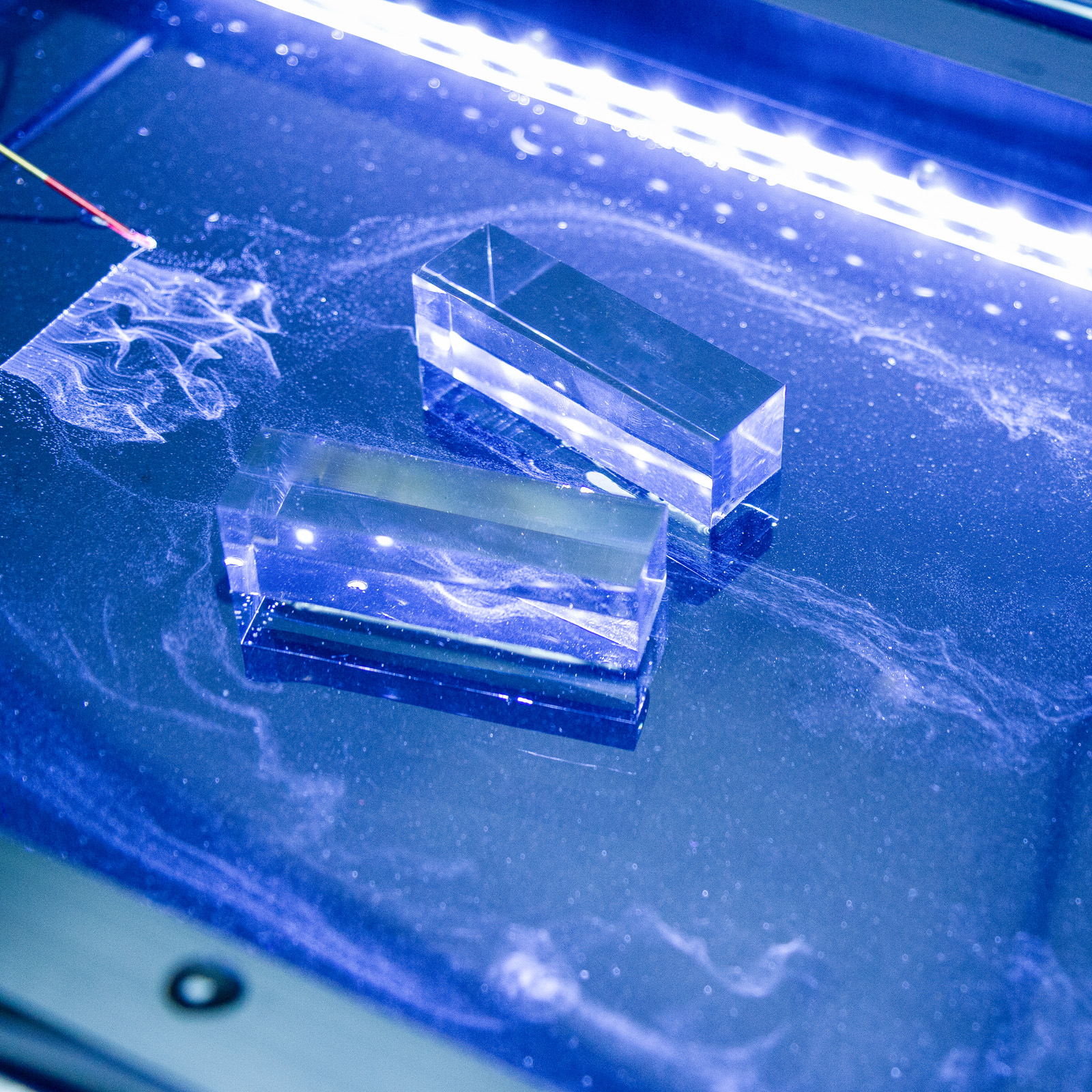

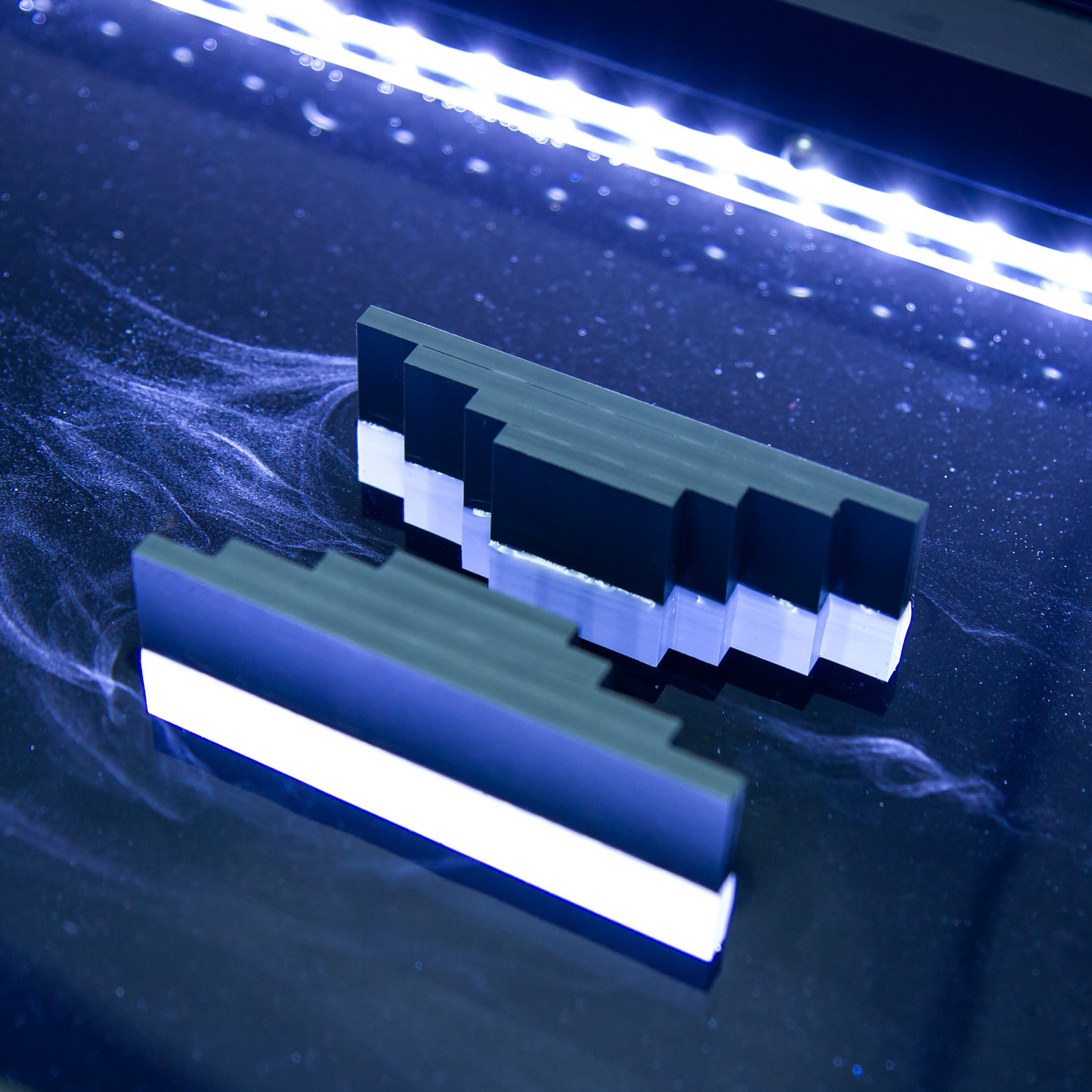

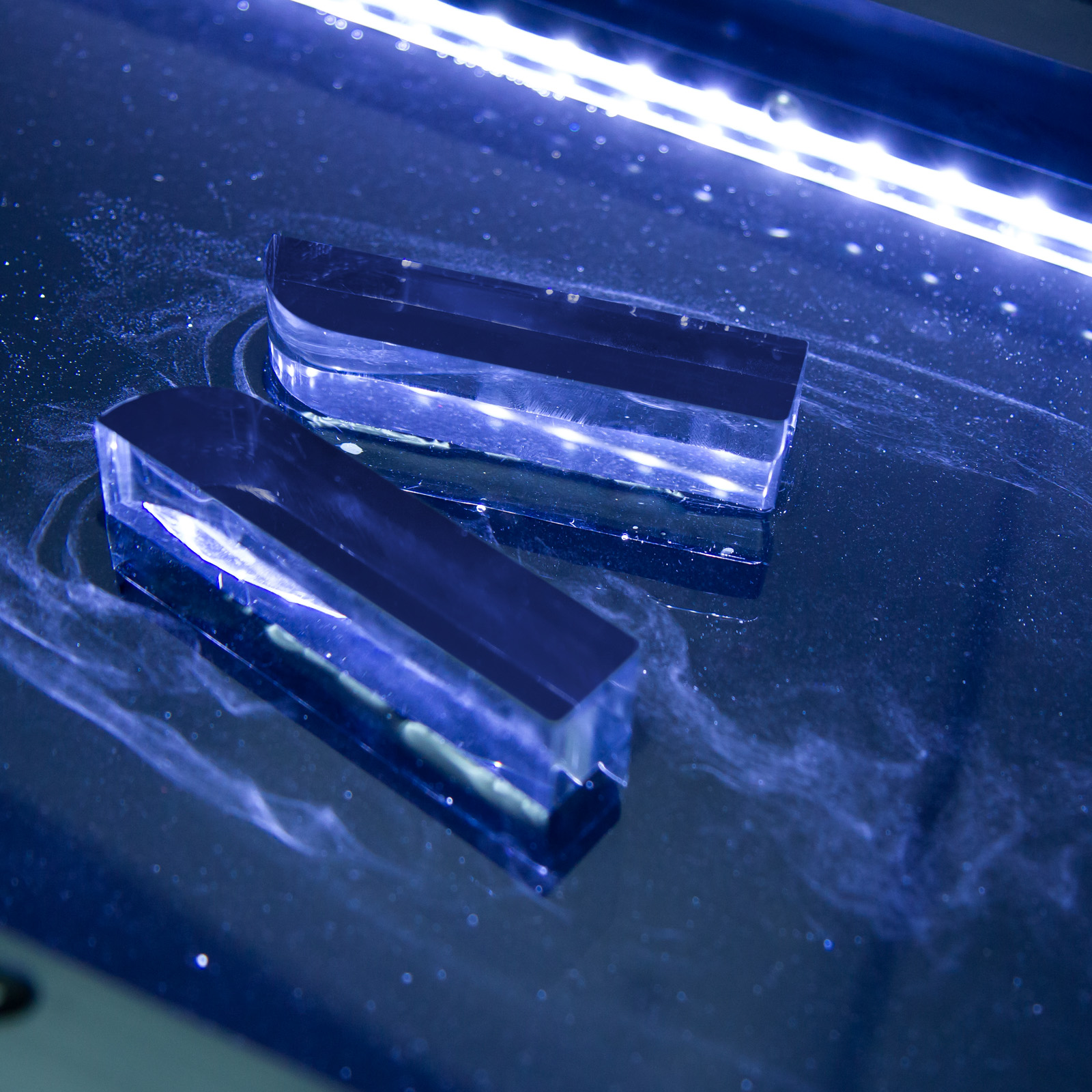

A number of acrylic models are provided with the equipment, such as an aerofoil section and cylinders of different diameter. These can be positioned in the working section to show the flow effects around these shapes. User-defined models can also be used.

A lighting module, placed in the water at the side of the working section, produces a wide beam of light below the surface of the water and illuminates the hydrogen bubbles to aid visualisation of the flow patterns.

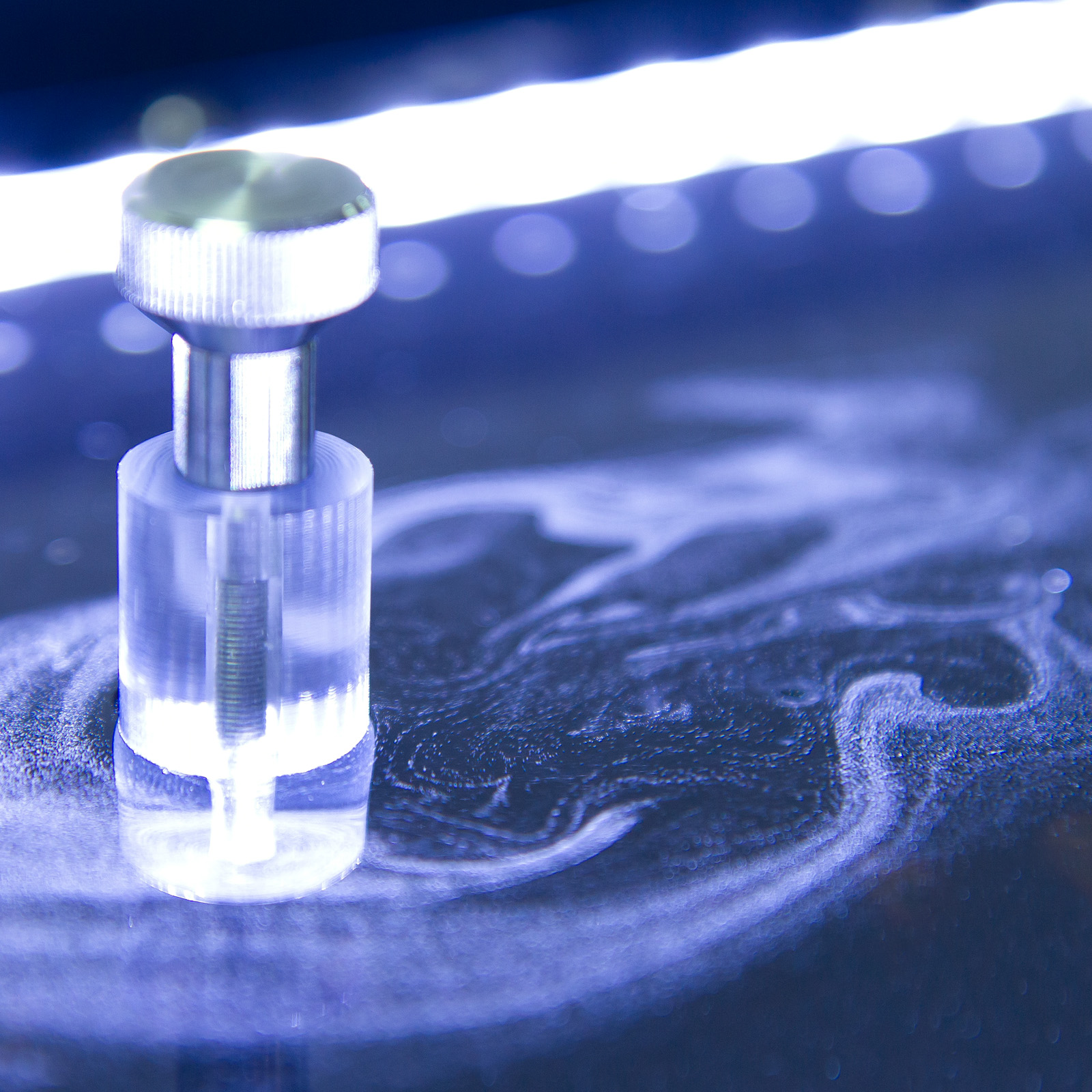

The hydrogen bubbles are produced by a fine platinum/iridium cathode wire located under the surface of the water and normal to the direction of flow. The wire is kept taut by a forked holder (supplied in three widths) and is held in the required position by tripod with adjustable support. Hydrogen bubbles can be produced using plain tap water, however Glauber’s salt (sodium sulphate) is also supplied with the unit for research purposes.

The electronic control console provides all of the necessary electrical services for the flow tank and incorporates the hydrogen bubble generator. All operating parameters are displayed on a liquid crystal display. Controls are included for the water pump, light source and hydrogen bubble generator.

The size of the hydrogen bubbles can be varied by adjusting the current to the cathode wire. The generator automatically maintains the current at the required value by varying the supply voltage to compensate for changes in the loop resistance.

The generator can produce a continuous stream of bubbles if required. However, to aid visualisation and enable quantitative measurements to be made, the bubbles can be turned ‘on’ and ‘off’ in a series of pulses, the pulses and spaces being independently and continuously variable with both times indicated on the display.

Technical Specifications

- Pulse generator: 3 to 2500ms on and off period

- Light Source: 48 High Intensity Light Emitting Diodes

- 3 x Electrodes: 35mm, 50mm and 75mm Wide

- Cathode type: Platinum/Iridium

- 3 x Stop Logs

- 1 x Set of Clear Acrylic Flow Visualisation Models in Protective Container Comprising:

– 2 x Straight Guide (330mm Long)

– 2 x Spacer Block for Straight Guides

– 2 x Blocks with Radiused Ends

– 4 x Cylinders (6mm, 12mm, 18mm and 25mm diameter)

– 1 x Aerofoil Section

– 1 x Flat Plate with Radiused End

– 2 x Rectangular Block (70mm x 40mm x 20mm)

– 1 x Curved Plate

– 2 x Stepped Block

Features & Benefits

- Low-voltage operation via universal power supply for improved safety

- LED illumination

- Supplied with:

– Set of Three Weirs

– Set of Three Electrodes

– Set of Clear Acrylic Flow Visualisation Models

- Visualisation of two-dimensional flow using hydrogen bubbles

- Observation of flow around standard shapes (cylinder, aerofoil etc)

- Analogy to aerodynamic flow

- Flow Separation

- Vortex formation, demonstration of Karman Vortices

- Understanding laminar and turbulent flow

- Demonstration of boundary layer growth

- Demonstration of boundary layer separation and eddy formation

- Quantitative analysis of flow patterns using pulsed bubbles

- Observation of flow around user created models (project work)

- Large-scale presentations/recording of patterns using a video camera or webcam (not supplied)

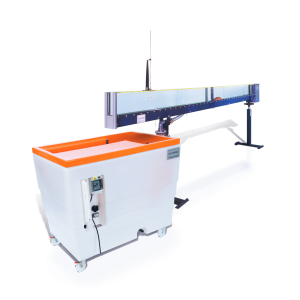

C16-11: Camera Bracket

This accessory enhances the C16’s use, by providing a mounting frame for a camera. This enables a still camera, video camera or webcam to record the flow patterns.

- A compact, bench-mounted, self-contained unit used for flow visualisation studies using water as the working fluid

- The unit comprises a flow tank incorporating the working section and pumped recirculation system, plus a separate electronic control console

- A low-voltage variable-speed pump with a unique fluid drive unit is located under the working section

- The electronic control console incorporates manual controls and a four-line, 20-digit LCD that displays the relevant operating parameters

- Flow patterns in the water are indicated by small hydrogen bubbles that are generated by an interchangeable fine platinum/iridium wire cathode

- A low-voltage light source illuminates the hydrogen bubbles in the working section

- Flow visualisation studies can be carried out using plain tap water without the need for additives

- Optional camera mount enables still camera, video camera or webcam (not supplied by Armfield) to record the flow patterns

- A tool kit is supplied

- A user instruction manual provides installation, commissioning, maintenance data, experimental information and suggested flow visualisation demonstrations

Electrical supply:

- supplied with a universal mains adaptor suitable for 110-240V / 1ph / 50-60Hz

Water: Initial fill of water

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 1.2m³

Gross Weight: 150Kg

Electronic control console

Length: 0.31m

Width: 0.26m

Height: 0.10m

Flow tank

Length: 0.845m

Width: 0.40m

Height: 0.225m (tank only)

- C16