UOP12 – Filtration Unit

Filtration is an extremely important unit operation used by industries such as chemical, food and water treatment.

Description

Filtration is an extremely important unit operation used by industries such as chemical, food and water treatment.

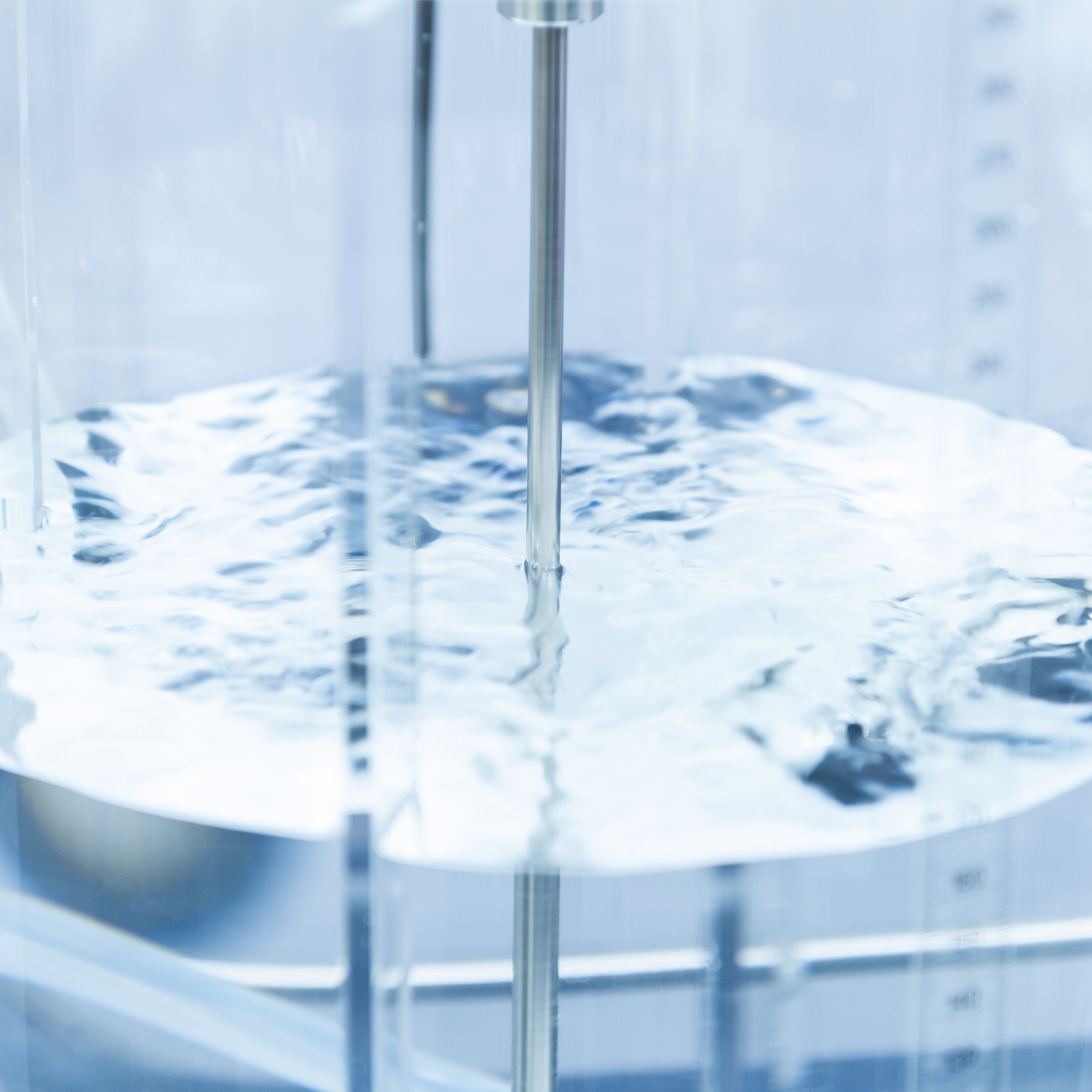

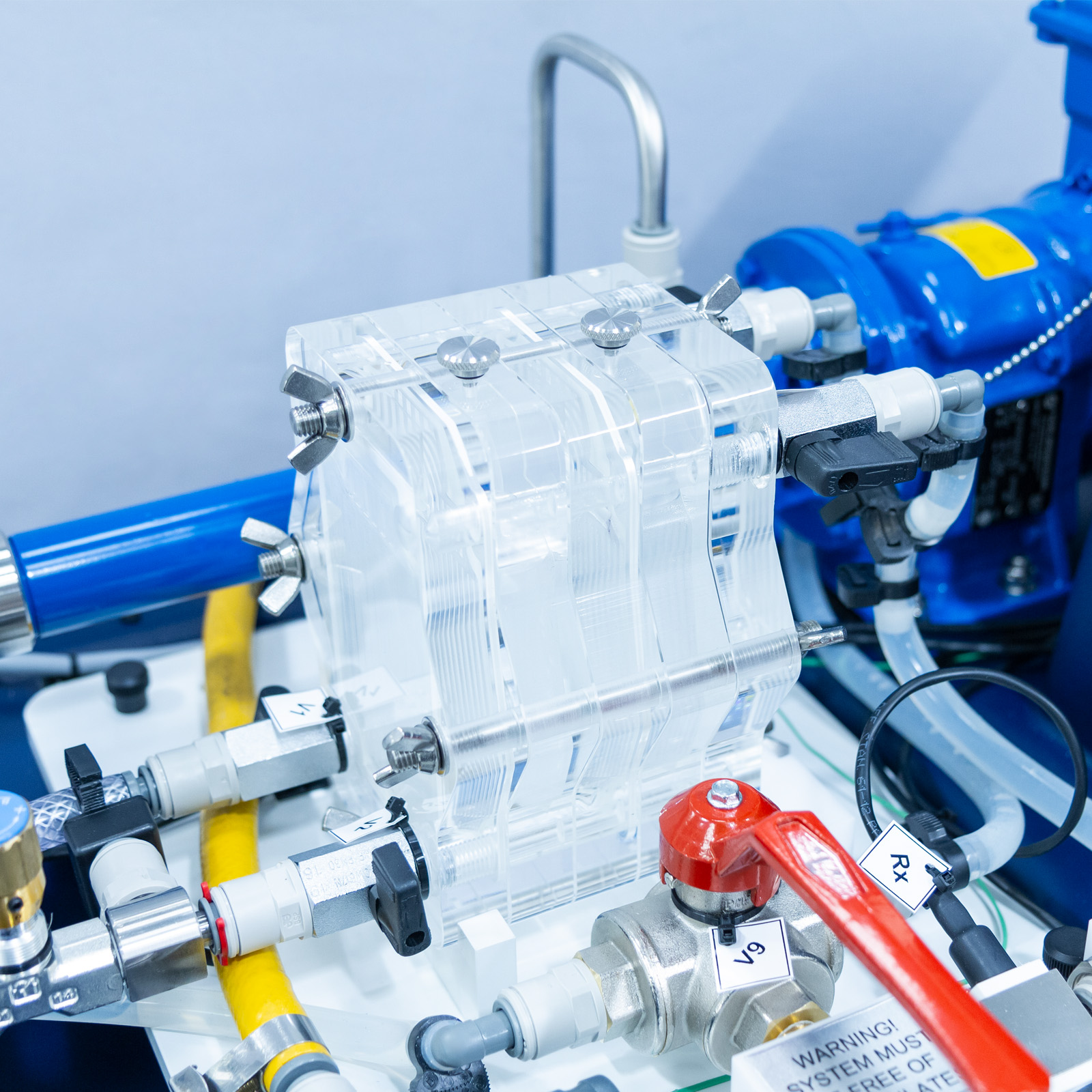

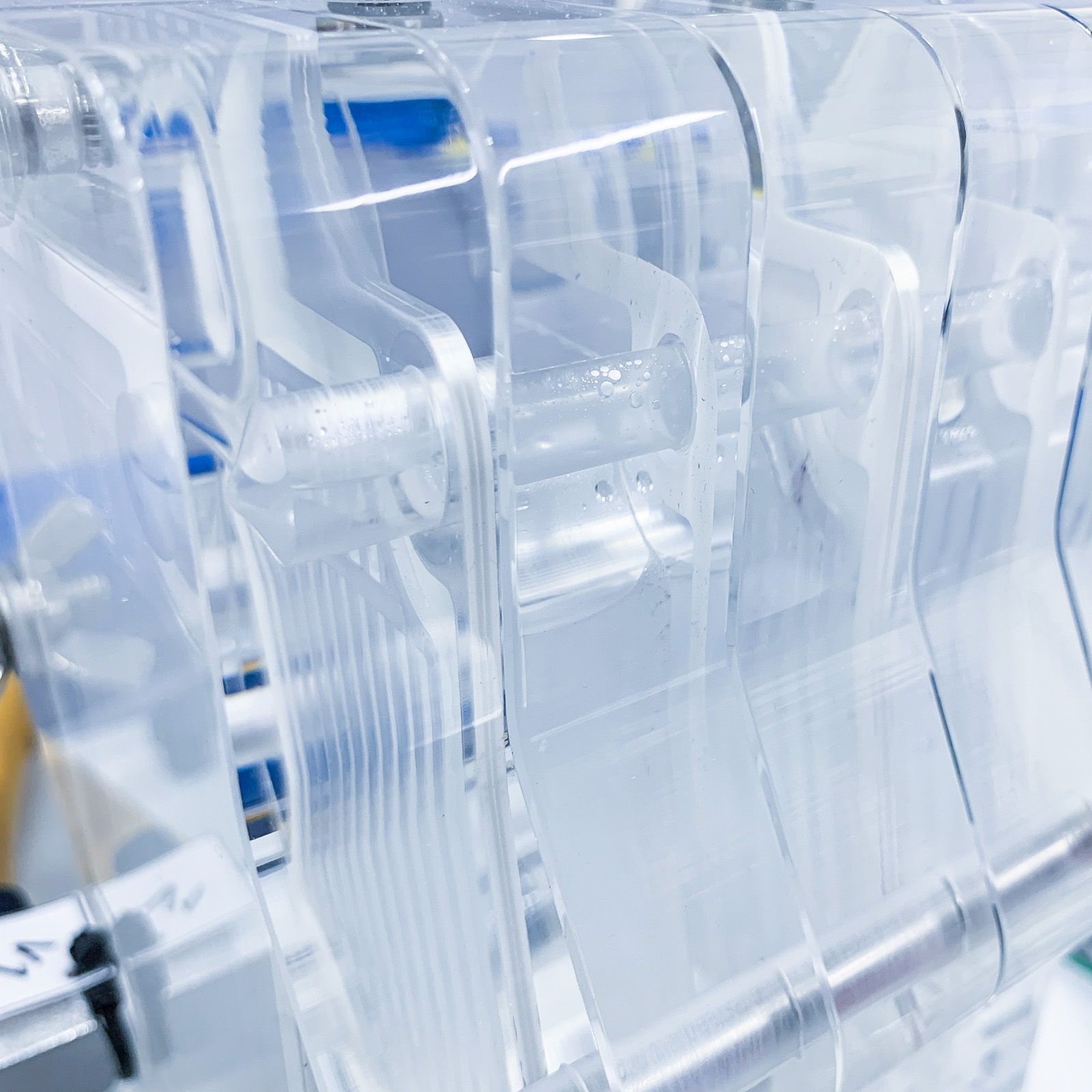

UOP12 is a benchtop unit designed to introduce students to the fundamentals of solid/liquid filtration. The apparatus consists of an acrylic feed tank connecting to a progressing cavity pump which feeds a slurry to the acrylic plate and frame filter press.

A pressure sensor on the output of the pump measures the filtration pressure. The filter press consists of two end plates, two frame plates and a wash plate. The filtrate passes through an optical sensor which determines the efficiency of the filtration process.

Filtrate temperature is also measured. The second inlet to the filter is for mains water for filter cake washing. A second pressure sensor and a needle valve control the water pressure during the washing cycle. A three-way valve allows filtrate to be returned to the feed tank or to a filtrate vessel/drain.

The Armfield Filtration Unit demonstrates the principles of batch filtration using a fully functional plate and frame filter system. A continuous, tangential flow microfiltration unit using a hollow fibre filtration cartridge (a membrane technology application) is available as an option. Both types of filter are widely used in the commercial world.

The practical training exercises are appropriate to chemical and all other process related engineering courses, including technician training. An economic investigation allows the student to take experimental data and use it to help make decisions on the size and the operation of a filtration plant in order to meet economic and output targets.

BATCH FILTRATION WITH THE PLATE AND FRAME FILTER

UOP12 is a benchtop unit designed to introduce students to the fundamentals of solid/liquid filtration. The apparatus consists of an acrylic feed tank connecting to a progressing cavity pump which feeds a slurry to the acrylic plate and frame filter press.

A pressure sensor on the output of the pump measures the feed pressure. The filter press consists of two end plates, two frame plates and a wash plate. The filtrate passes through an optical sensor which determines the efficiency of the filtration process.

Filtrate temperature is also measured. The second inlet to the filter is for mains water for filter cake washing. A second pressure sensor and a needle valve control the water pressure during the washing cycle. A three-way valve allows filtrate to be returned to the feed tank or to a filtrate vessel/drain.

CONTINUOUS FILTRATION WITH THE TANGENTIAL FLOW HOLLOW FIBRE FILTER CARTRIDGE – UOP12-10

The tangential flow filter is available as an option. It is fitted in minutes simply by removing the plate and frame filter and fitting the hollow fibre cartridge and tubular heat exchanger.

The feed suspension is pumped from the feed tank through the tubular heat exchanger and then through a prefilter before passing into the hollow fibre filter cartridge. The heat exchanger uses mains water to remove heat originating from the feed pump.

Material which does not filter through the membranes of the hollow fibres, called the retentate, remains in the lumen and then exits the filter and is returned to the feed tank. Material that does pass through the membranes, the permeate, is collected in the permeate vessel.

Pressure is measured by sensors at the entrance and exit of the hollow fibre filter cartridge on the retentate side and also at the permeate exit from the cartridge. Temperature is measured on the retentate side of the filter cartridge. The optical sensor is used to measure protein concentration of the permeate stream.

Technical Specifications

Features & Benefits

BATCH FILTRATION WITH THE PLATE AND FRAME FILTER

- The plate and frame filter unit uses nylon as the filter medium. The unit is constructed in clear acrylic which enables the entire

filtration process to be observed: the feed slurry in the feed channels, the build up of filtered solids in the frame plates and the

clarified filtrate in the filtrate channels. The filter unit uses gaskets to prevent leakage and enable operation up to 2 bar. Bleed valves in the top of the frame plates enable trapped air to be removed for efficient filtration - An optical absorbance sensor is provided for on-line and off-line monitoring of the filtration process. It is also used to monitor the

efficiency of filter cake washing operations - A controller enables constant pressure operation by controlling the speed of the feed pump

- The progressing cavity feed pump enables constant feed rate operation

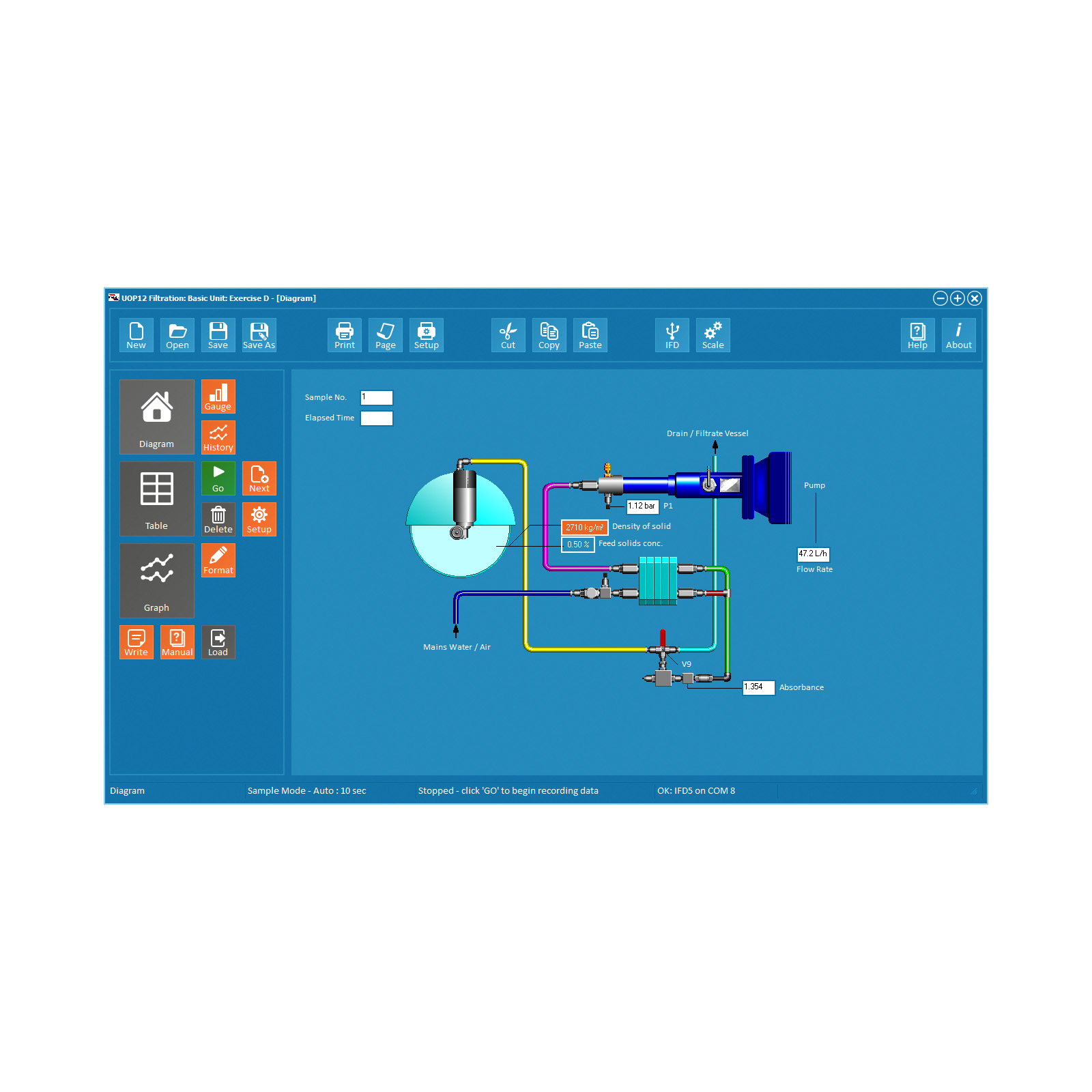

- All electrical sensors: pressure, optical absorbance, temperature and the feed pump flow rate can be logged using a PC (optional

teaching software available) - Water and calcium carbonate are the recommended working materials for reasons of safety and ease of use

CONTINUOUS FILTRATION WITH THE TANGENTIAL FLOW HOLLOW FIBRE FILTER CARTRIDGE – UOP12-10

- The tangential flow filtration system uses a hollow fibre filter cartridge. This consists of a cartridge containing a number of polysulfone hollow fibres. These fibres have a pore size of 0.2μm through which the protein marker can pass. The fibres are retained within a transparent plastic shell through which they and the permeate may be observed

- Yeast and a marker protein are used to simulate a biotechnology recovery process

- The optical absorbance sensor is used off-line in order to determine the degree of protein transmission across the membrane

- All electrical sensors: pressure, optical absorbance, temperature and the feed pump flow rate can be logged using a PC (optional teaching software available)

BATCH FILTRATION WITH THE PLATE AND FRAME FILTER

- Filter Assembly and Valve Sequencing

- Demonstrating Filtration through Plate and Frame filter Technology

- Understanding the principles of batch filtration using both constant pressure and constant flow operating modes

- Precoat Filtration

- Optimisation of Filtration Performance using Body Aid

- Darcy’s Law

- Determination of Medium and Cake Resistances

- Effect of Body Aid on Medium and Cake Resistances

- Filter Cake Washing and Dewatering

- Economic Optimisation of Filtration Operations (Scale up)

- Mash Balancing

CONTINUOUS FILTRATION WITH THE TANGENTIAL FLOW HOLLOW FIBRE FILTER CARTRIDGE – UOP12-10

- Demonstrating filtration through a hollow fibre cartridge system

- Understanding the principles of continuous microfiltration

- Examination of flux and transmission of a protein marker

- Measurement of fouling and the effect on filtration performance

BATCH FILTRATION WITH THE PLATE AND FRAME FILTER

Teaching exercises are included to familiarise students with the following topics:

- Demonstration of precoat filtration

- Optimization of filtration performance using body aid

- Demonstration of Darcy’s Law

- Determination of medium and cake resistances

- Effect of body aid on medium and cake resistances

- Filter cake washing and dewatering

- Economic optimization of filtration operations

CONTINUOUS FILTRATION WITH THE TANGENTIAL FLOW HOLLOW FIBRE FILTER CARTRIDGE – UOP12-10

Teaching exercises are included to enable the students to become familiar with the following topics:

- Determination of clean and dirty membrane resistances

- Determination of the transcartridge pressure drop

- Mass balancing of protein filtration

- Effect of transmembrane pressure on membrane flux and protein transmission

- Effect of tangential flow velocity on membrane flux and protein transmission

- A benchtop unit comprising a vacuum formed ABS plastic plinth, integral electrical console on which is mounted the filtration system

- A plate and frame batch filter (separation area 230cm2) is supplied as standard. Both constant flow rate and constant pressure operation are possible

- An optional tangential flow hollow fibre microfiltration cartridge (plus prefilter and shell and tube heat exchanger) can be fitted.

- The hollow fibre cartridge has a separation area of 110cm2 and a cut-off of 0.2μm

- Feed flow rate can be varied between 0-130 l/hr

- All electrical circuits are protected by appropriate protection devices

- The console contains a pump motor control and display panel

- A separate controller displays the filter inlet pressure and is used to control the pump speed. Another digital meter displays, via a selector switch, either outlet pressure, permeate pressure, temperature or optical absorbance. Sensor signals are also routed to an I/O port for connection to a PC

- Interface device and educational software package included

- A comprehensive instruction manual is included with a range of fully detailed laboratory teaching exercises

- UOP12-10 – Tangential flow filter accessory

Single phase mains electrical supply:

UOP12-A: 220-240V/1ph/50Hz, 10A

UOP12-B: 120V/1ph/60Hz, 15A

UOP12v -G: 220-240V/1ph/60Hz, 10A

Plate and frame filter:

- Optional mains water supply 3 l/min at 2 bar, optional pressurised air supply at 2 bar

Tangential flow filter option:

- Mains water supply 3 l/min at 2 bar

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 0.50m³

Gross Weight: 50Kg

Plate and frame filter

Length: 1.10m

Width: 0.50m

Height: 0.60m

Tangential flow filter

Length: 1.10m

Width: 0.50m

Height: 0.75m

UOP12-A: 220-240V / 1ph / 50Hz, 10 amp

UOP12-B: 120V / 1ph / 60Hz, 15 amp

UOP12-G: 220-240V / 1ph / 60Hz, 10 amp