FT18-MKII Modular Cross Flow Filtration

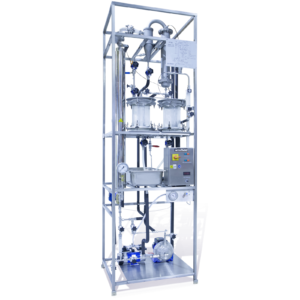

The Armfield FT18-MkII is a pilot-scale cross-flow filtration system designed to operate with a range of membrane module configurations. It can operate with minimal material but still give data that is useful for process scale-up.

Use the full range of cross-flow filtration applications from microfiltration through to reverse osmosis. The perfect tool to use, following on from flat sheet membrane trials with the FT17, for further process development and scale-up.

Description

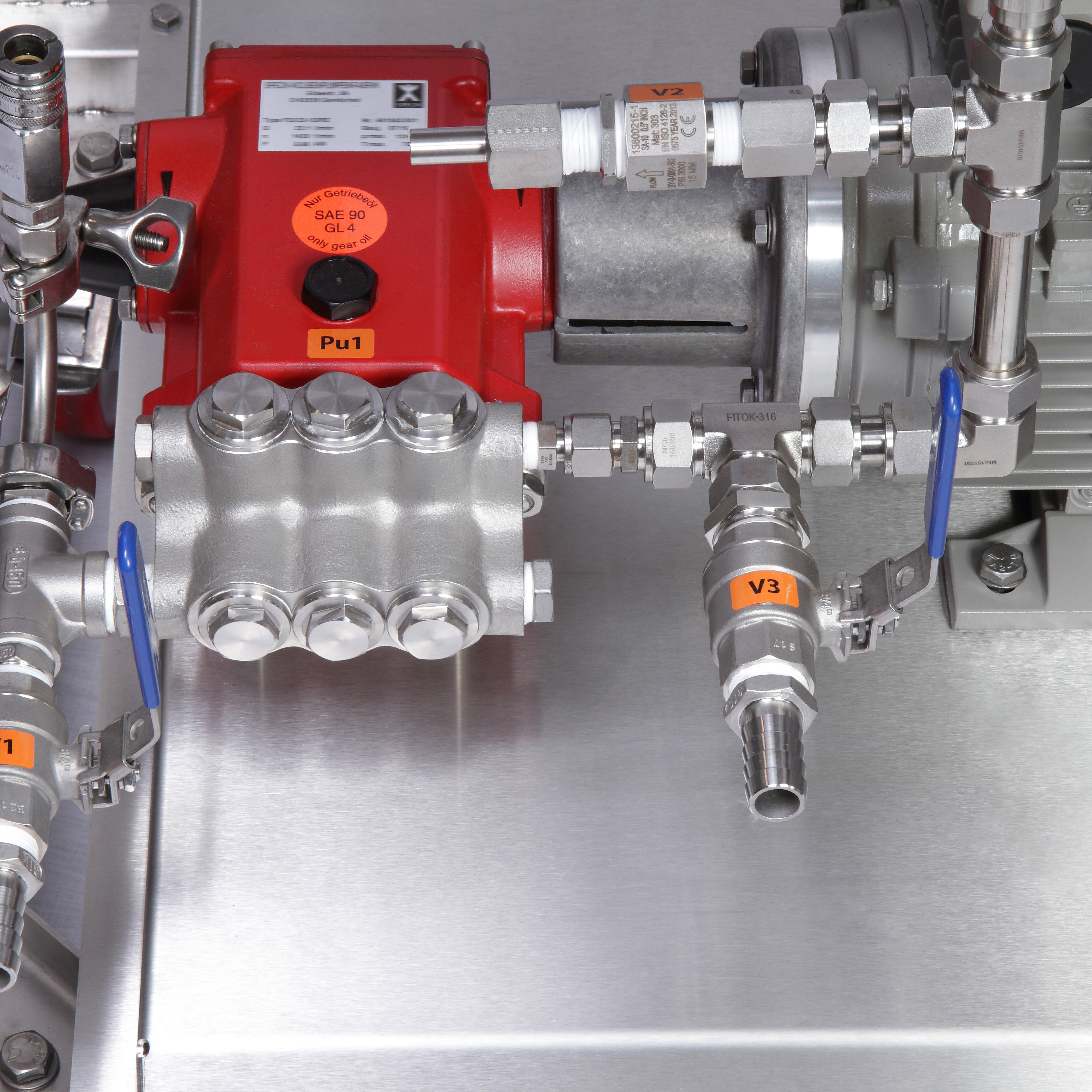

The system uses a high-pressure piston-recirculation pump to circulate product through the filter module of choice. The variable speed triple-piston design combined with high-pressure flexibles minimises pressure pulsation. The operator can use their own feed vessel or this can be specified (FT18-20 option). The speed of the recirculation pump can be adjusted to suit the particular filtration module and the product.

A level sensor mounted on the pump inlet protects the pump from running dry.

The retentate back-pressure valve enables pressures up to 50 bar to be achieved. A relief valve protects against overpressure.

There is a permeate back-pressure valve so that accurate transmembrane pressures (TMP) can be set. Pressure sensors are sited on the retentate side on the inlet and outlet of the filter module, as well as on the permeate side. Any temperature gain in the retentate through recirculation at high pressure is removed using a 316 stainless steel shell and tube heat exchanger, which has corrugated tubes for improved heat transfer.

The transmembrane pressure can be finely controlled with independent back pressure valves. This reduces the fouling on the membrane when operating at higher pressures, extending the lifetime of the membrane.

Technical Specifications

Maximum flow rate: 1400 l/hr

Maximum operating pressure: 50 bar (See filter module options)

Pressure sensors: 0-60 bar

Mass balance range: 0-6kg

Minimum test volume without FT18-20: 15L

Features & Benefits

- Ability to assess the important cross-flow filtration module types on a single system

- Electronic instrumented option (-50) to allow the effect of process variables on filtration performance to be measured and logged

- Assessment of the effect of backpulsing on extending the time between CIP steps

- Reduced processing volume enables development with minimal product

- Simple cleaning and maintenance protocols

- Four membrane module options:

– Ceramic (FT18-5)

– Spiral wound (FT18-6)

– Hollow fibre (FT18-7)

– Tubular (FT18-8)

- Capable of microfiltration, ultrafiltration, nanofiltration and reverse osmosis operations

- Maximum filtration pressure of 50 bar (module dependant)

- Clean-in-place capability (CIP)

- Backpulsing option (suitable for FT18-5 and FT18-7)

- Variable retentate flow rate in order to change filtration cross-flow velocity

- Retentate and permeate back pressure valves

- Pressure sensors on the retentate inlet and outlet of the filtration module and on the permeate line

- Mass balance option for permeate flow rate measurement

- All parameters can be data logged

Food:

Dairy: Removal of micro-organisms from milk and cheese brines, milk protein standardisation and concentration, whey demineralisation, whey protein fractionation, defatting of whey proteins, and filtration

Fermented foods: Clarification of wine, beer and vinegar, removal of alcohol from wine and beer, post-fermentation yeast recovery, wine lifting

Fruit juices: Clarification and concentration

Water:

Water and waste water purification, desalination, water softening

Pharma:

Concentration and purification of macromolecules, sterile filtration, viral clearance, cell separation, water purification

Edible oils:

Degumming of vegetable oils

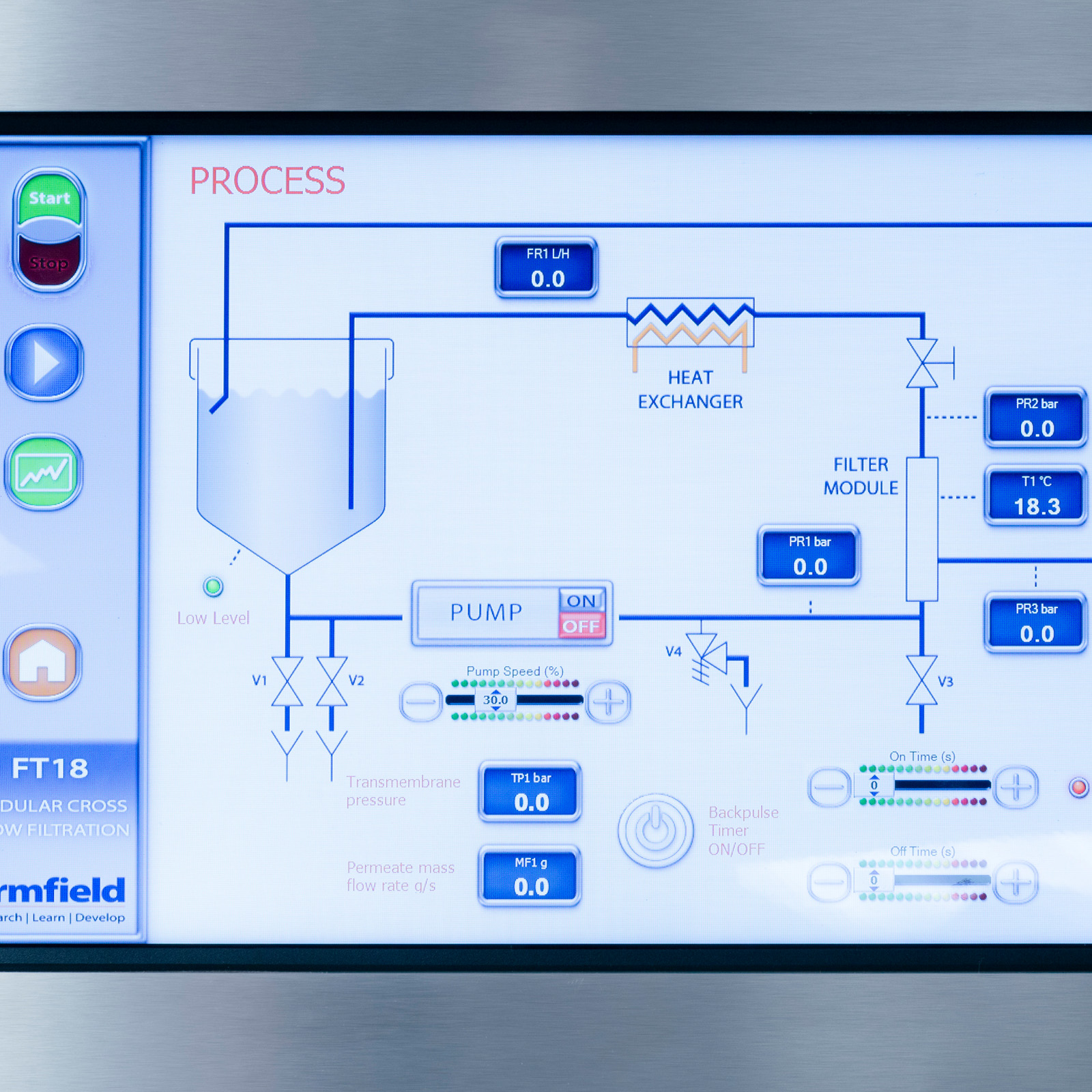

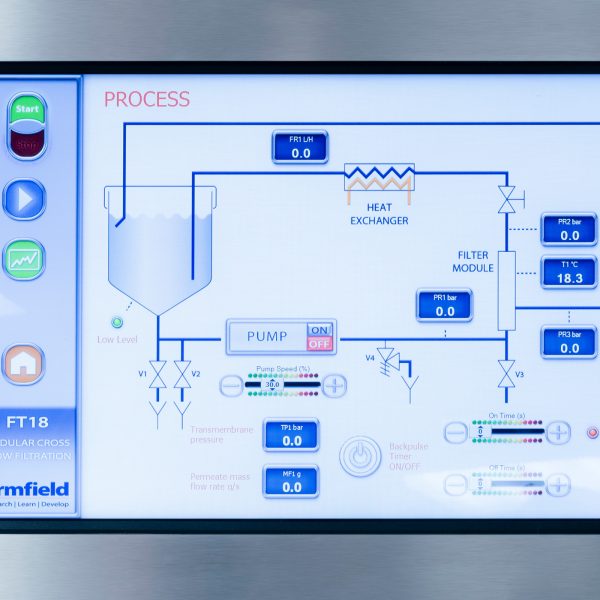

The armSOFT software displays the equipment flow diagram with readings displayed for all sensors.

Cross-flow velocity, transmembrane pressure and flux are also displayed. There are also controls for feed pump stop/start and speed.

A data tab offers several options for processing and displaying the data from the equipment in the form of graphs and results tables.

Results are saved in a log that can be viewed and manipulated with the armSOFT Results Viewer or they can be exported in a generic spreadsheet format for further analysis.

Ceramic Filter Module (FT18-5)

Filter housing: 316 stainless steel

Filter length: 0.5m

N° of channels: 1

Channel internal diameter: 7mm

Membrane area: 0.022m2

Available membranes:

- MF: 110-800nm

- UF: 3-10nm (2-20 kDa)

- NF: 200-600 Da

Max operating pressure: 10 bar

Spiral wound filter module (FT18-6)

Filter housing: 1812 (1.8” x 12”) 316 stainless steel sanitary housing

Generic module for use with female elements from different membrane manufacturers

Membrane area depends on element (max: 0.45m2)

The module can be used for MF, UF, NF and RO operations

Max operating pressure: 40 bar

Hollow fibre filter module (FT18-7)

Membrane housing: Polysulfone

Filter length: 0.46m

Fibre internal diameter: 1.1mm

Max operating pressure: 2.1-2.8 bar

Membrane area: 0.09m2

Available membranes:

- 5-500 kDa

Tubular Filter Module (FT18-8)

Filter housing: 316 stainless steel

Filter length: 2 x 0.3m

Membrane area: 0.024m2

Max operating pressure: 50 bar (recommended)

Available membranes:

- UF: 2-200 kDa

- NF: 60-75% CaCl2 rejection

- RO: 80-99% NaCl rejection

Vessel (FT18-20)

30-litre 316 stainless steel retentate vessel for recirculated product, complete with sensor to protect against dry running. Mass balance option for permeate flow rate measurement.

Backpulsing/Backflushing (FT18-50-1)

This module enables filtration pressure to be reversed for a period of time during processing in order to reduce fouling and thus enable extended operation between cleaning cycles

This module is compatible with the Ceramic (FT18-5) and Hollow Fibre (FT18-7) filter modules only

Must be ordered with FT18-MkII base unit

- Electronic Instrumentation FT18-MKII-50

- The basic system has analogue pressure sensors and variable pump speed operation. It is operated via the unit itself

- The FT18-50 option enables the system to be controlled by Armbus software on a PC. Pressure sensors are electronic and all sensor values are displayed and logged through the software. This option also includes a retentate flow-meter and an electronic mass balance so that filtration performance can be monitored and logged in real time

- The FT18-60 option includes a touchscreen so that the unit can be operated without a PC

Electrical supply:

FT18-MkII-C: 380-415V/3ph/50Hz/10A

FT18-MkII-D: 208-220V/3ph/60Hz/20A

Water supply:

Towns water 10 l/min at 2 bar or equivalent flow recirculation chiller for lower temperatures

Air supply:

6 bar with minimal air consumption (required for FT18-50 option only)

Packed and created shipping specifications

Volume: 1.9m3

Gross weight: 300kg

Length: 0.72m

Width: 1.00m

Height: 1.50m

FT18-MkII-C: 380-415V/3ph/50Hz/10A

FT18-MkII-D: 208-220V/3ph/60Hz/20A

FT18-MkII-50-C: 380-415V/3ph/50Hz/10A (Includes digital instrumentation upgrade)

FT18-MkII-50-D: 208-220V/3ph/60Hz/20A (Includes digital instrumentation upgrade)

Note: These systems are supplied without modules or options. Please select one or more modules at time of placing your order.

Option ordering codes

FT18-5: Ceramic Filter Module (option)

FT18-6: Spiral Wound Filter Module (option)

FT18-7: Hollow Fibre Filter Module (option)

FT18-8: Tubular Filter Module (option)

FT18-20: Vessel (option)

FT18-50-1: Backpulsing/Backflushing (option)

ARMBUS-LCD-15.6-SS: Touchscreen system (option)

Please note: *FT18MKII-50-1 compatible with FT18-5 and FT18-7 filter modules only.

The FT18-50 options must be defined at time of order as these cannot be retro-fitted by the end user.