CM20 – Single-Cylinder Combustion Engine

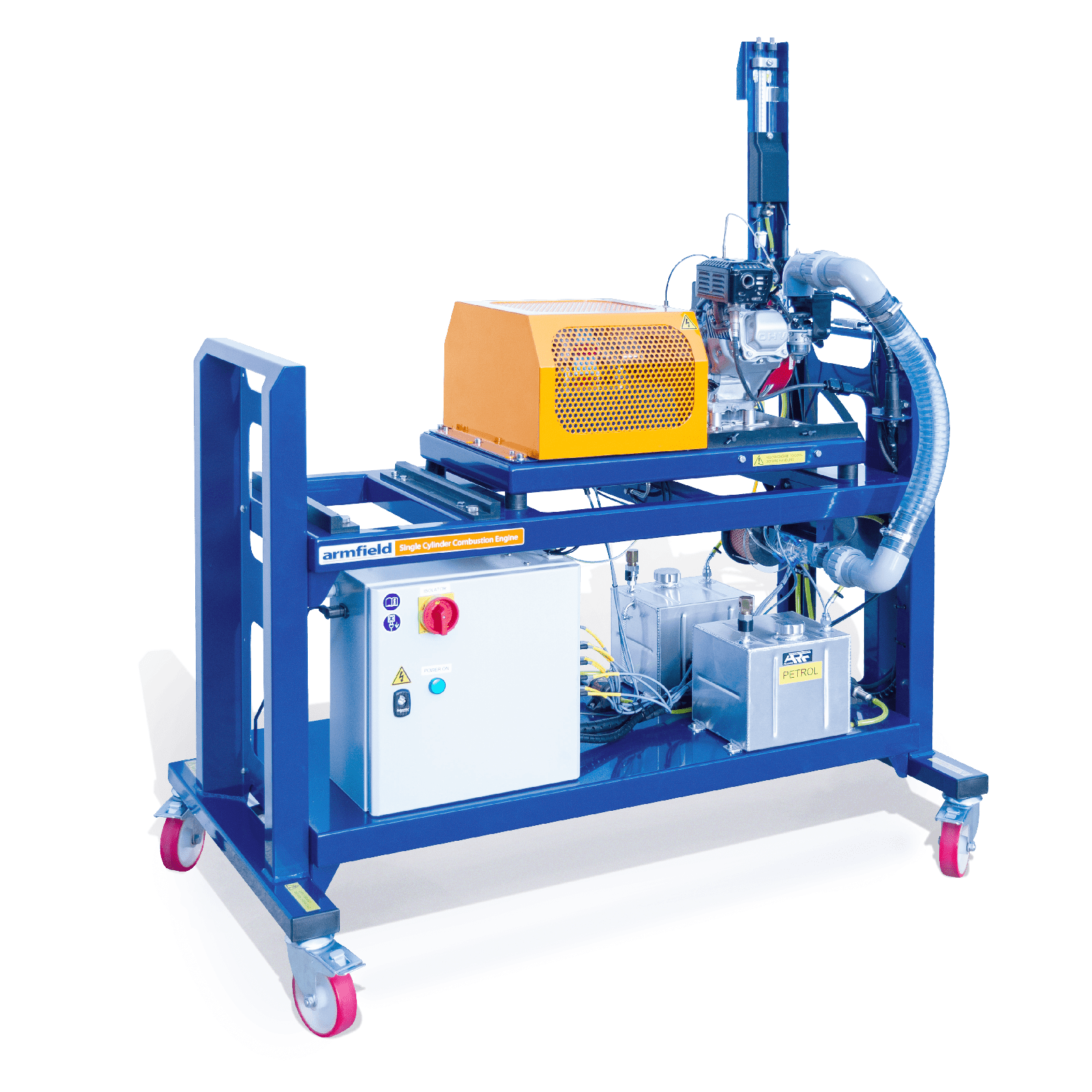

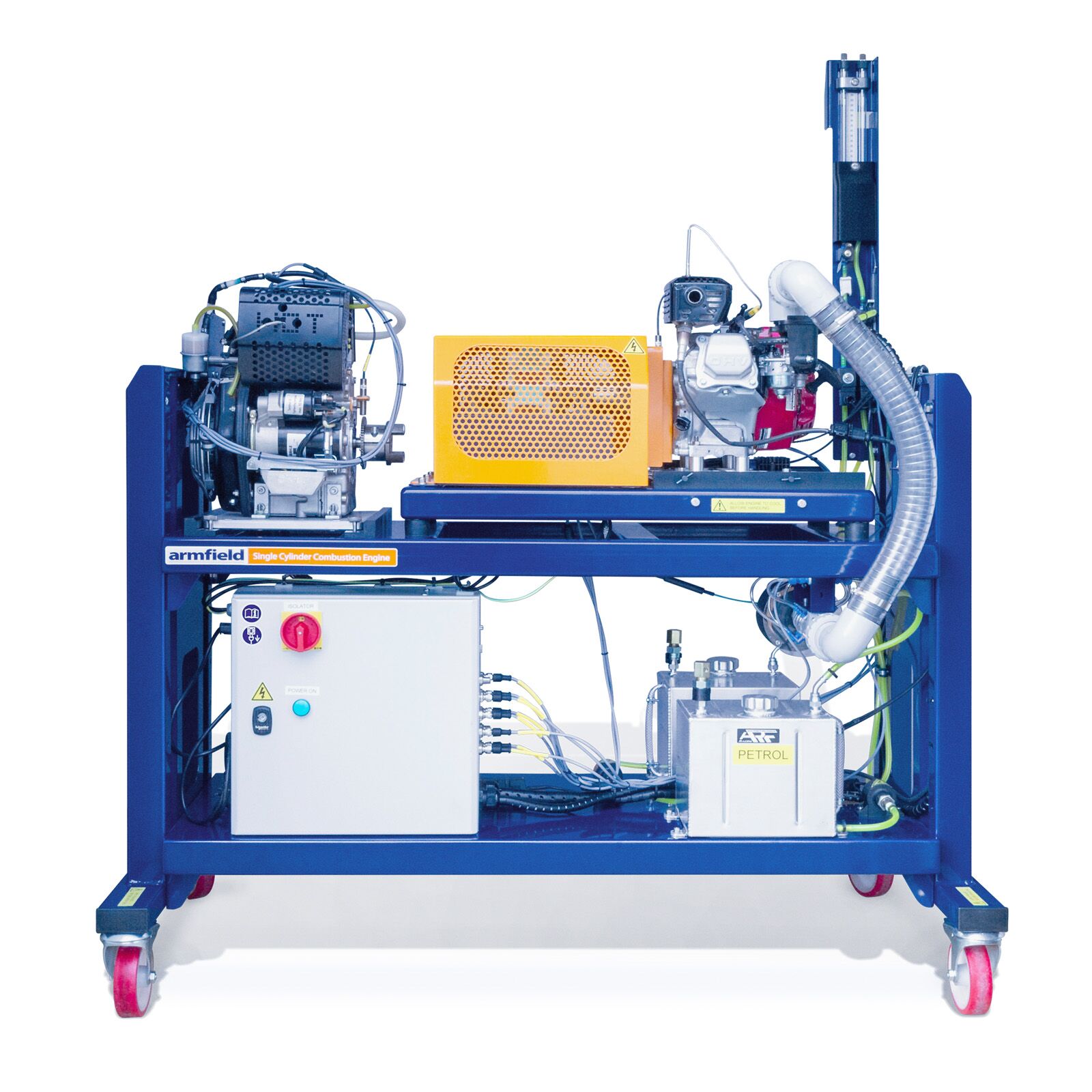

The Armfield CM20 Single Cylinder Engine Range provides a self-contained engine test rig that enables students to investigate a range of engine performance characteristics.

The unit is designed to be linked to the user’s computer or touch screen, linked to Armfield’s supplied software with sophisticated control and data acquisition.

Description

The Armfield CM20 Single Cylinder Engine Range provides a self-contained engine test rig that enables students to investigate a range of engine performance characteristics.

The unit is designed to be linked to the user’s computer or touch screen, linked to Armfield’s supplied software with sophisticated control and data acquisition.

The Armfield CM20 is a self-contained integrated, single-cylinder engine, dynamometer and instrumentation system, based on a range of gasoline and diesel industrial engines.

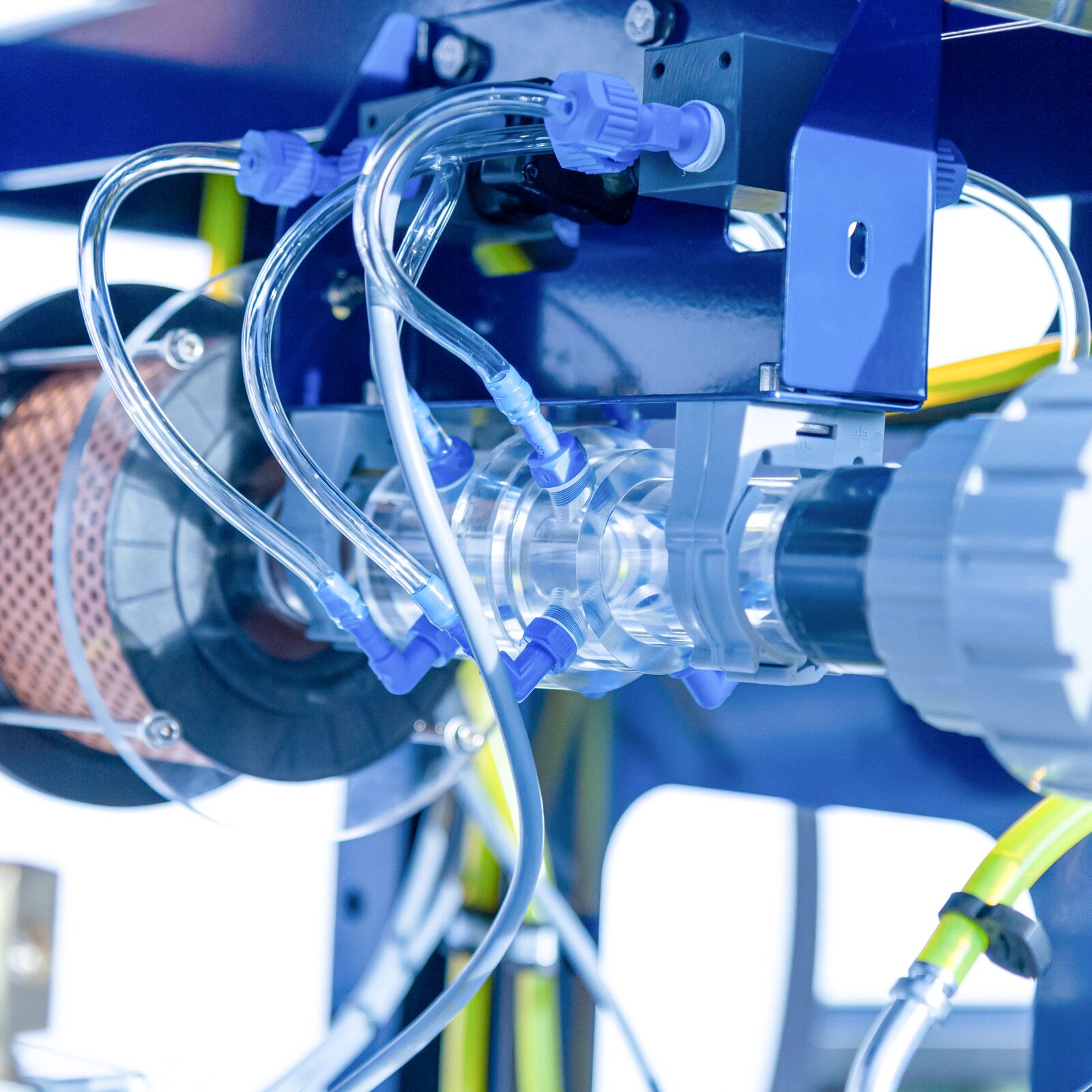

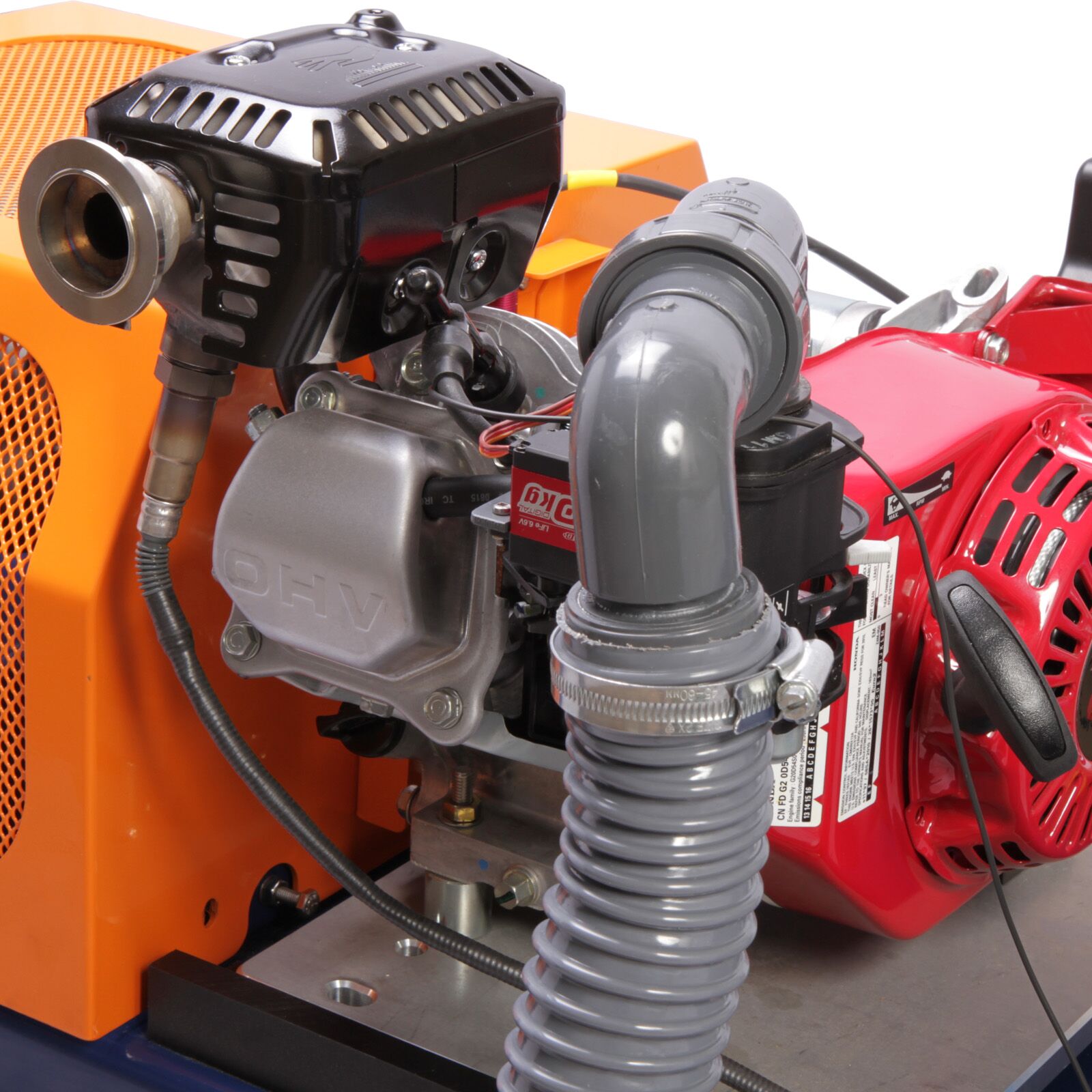

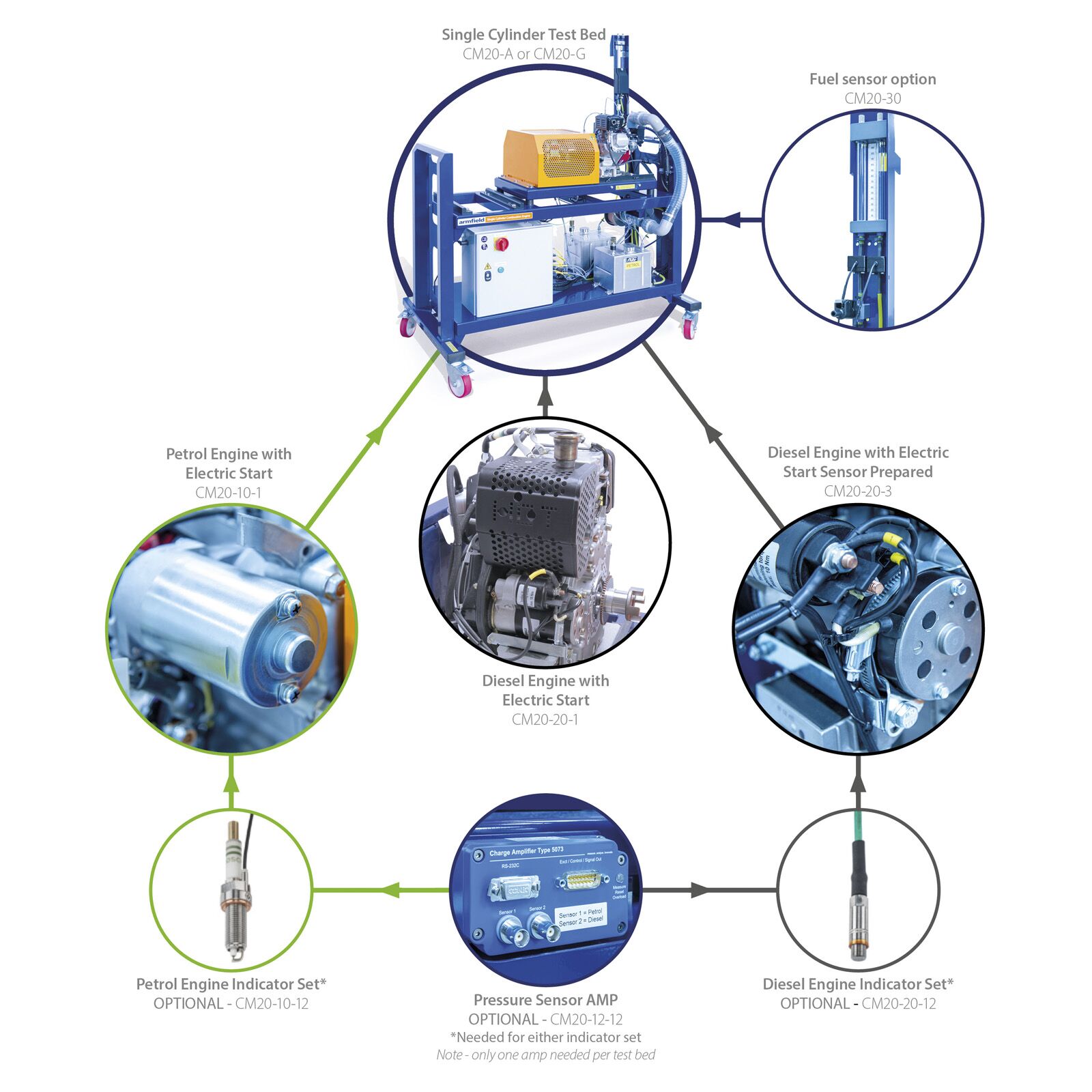

The CM20 utilises an eddy-current dynamometer to provide a variable load on the engine, enabling the characteristic power and torque curves to be reproduced in the laboratory dependent upon which sensor options are ordered. This multi-purpose test rig is designed to accept a series of Armfield gasoline and diesel engines available separately. The system comes complete with instrumentation, including rpm measurement, torque (from which power can be calculated), airflow and exhaust temperature. Other optional sensors can be purchased to further enhance the teaching capabilities of the CM20 including cylinder pressure sensors and fuel consumption.

The whole system is designed to be linked to a computer using the software provided. This provides real-time monitoring of the various sensors, with a wide range of data logging and graphical display options. Both the dynamometer and throttle can be controlled electronically, which makes installation into a closed test cell straightforward, and enables remote operation.

The CM20 should be installed in a well ventilated area with exhaust gas extraction facilities. The unit is supplied on wheels for ease of movement; these can be removed and the unit bolted to the floor for permanent installation.

Apart from the master on/off switch, everything can be controlled remotely, enabling the engine to be installed in a dedicated test cell and operated from outside the cell.

Technical Specifications

Engine Specification

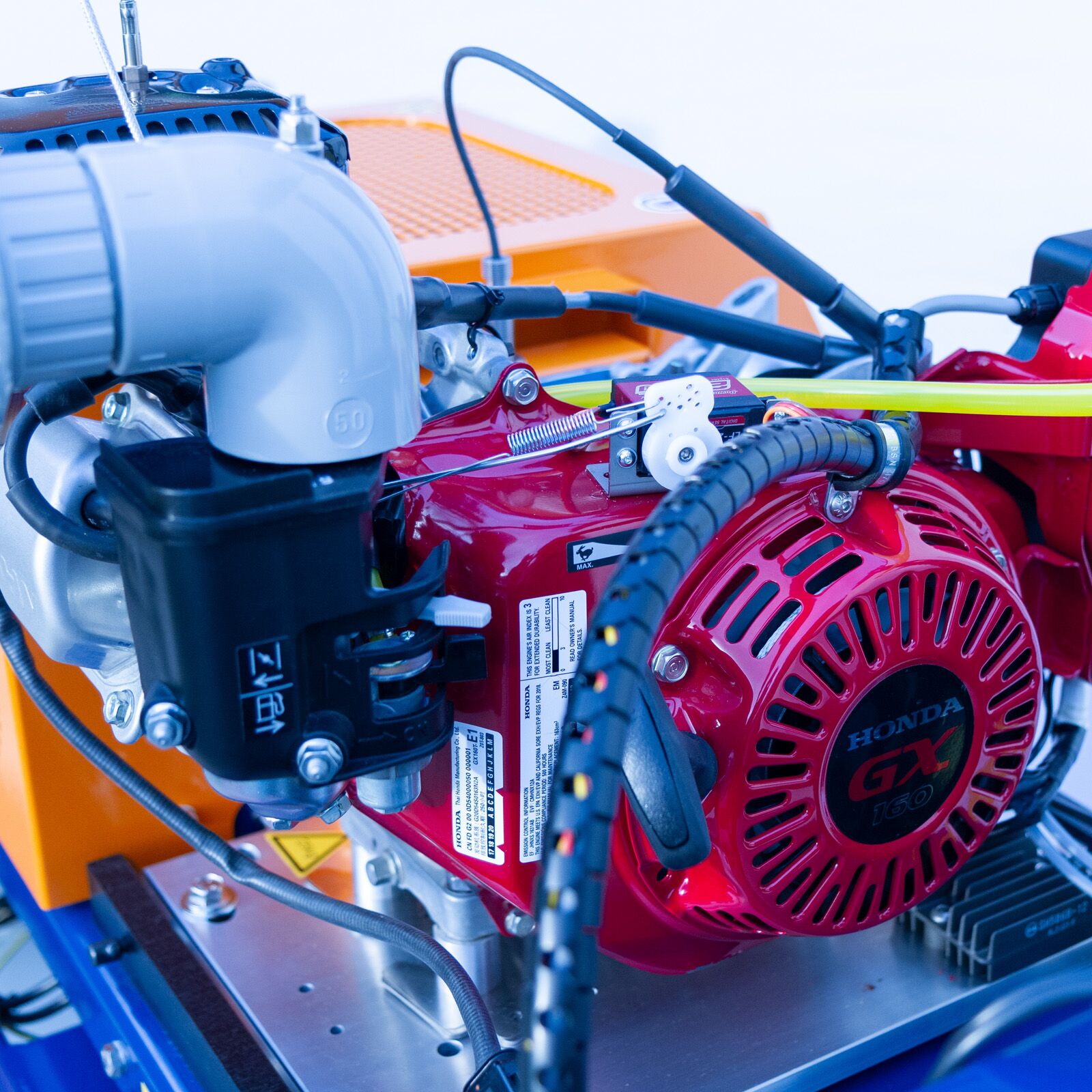

Petrol engine – CM20-10

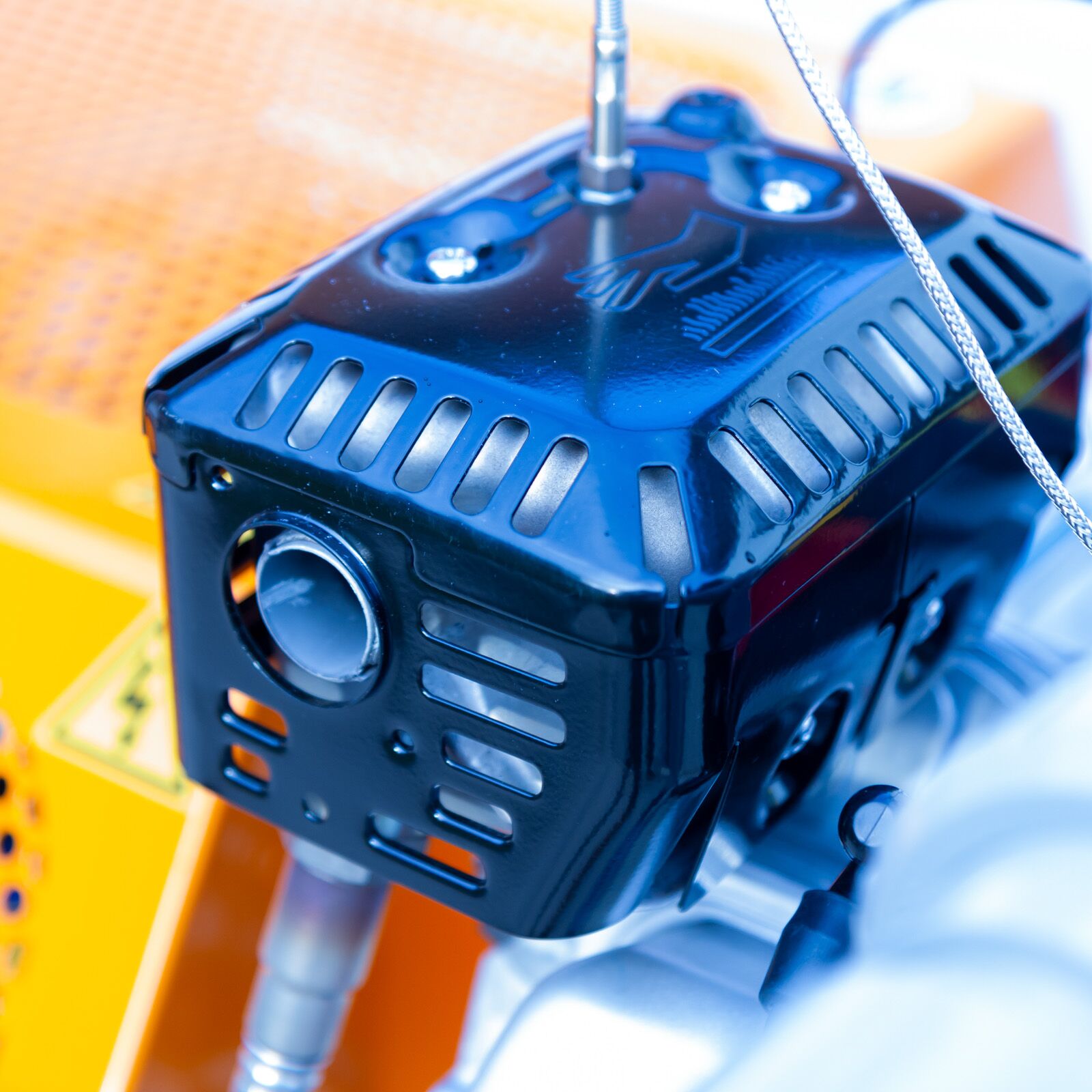

- Single-cylinder air-cooled four-stroke OHV

- Power output: 4.8HP (3.5kW)

- Displacement: 163cm³

Diesel engine – CM20-20

- Single-cylinder, direct-injection air-cooled diesel engine

- Power output: 4.8HP (3.5kW)

- Displacement: 243cm³

Dynamometer data – CM20

- Dynamometer type: Eddy current

- Cooling: Air-cooled

Features & Benefits

- Plotting of torque and power curves

- Determination of specific fuel consumption (option)

- Determination of volumetric efficiency and lambda (fuel-air ratio)

- Determination of the frictional power of the engine

- Cylinder pressure measurements

- Definition and use of an electronic cylinder pressure indication system (option)

- P-V diagram (optional sensor required)

- Exhaust calorimetry

The Armfield CM20 is armBUS integrated. For more information on the armBUS system, visit www.armfield.co.uk/armbus

- Test stand to measure the output of petrol (spark ignition) or diesel (compression ignition) engines up to 11kW in power

- The stand comprises an eddy current brake unit mounted to a steel framework. The system has an interface plate for mounting various standard Armfield engines on vibration-absorbing mounts

- Dedicated petrol and diesel fuel systems with unique quick-release couplings to ensure correct fuel type is utilised

- The system can be fully instrumented with a 15” touchscreen panel (optional) for local use or can be run remotely via a USB interface

- The control system will enable incremental load adjustments and speed control of the engine in both open fixed-speed control or load/speed PID control

- Exhaust and inlet temperatures, rpm, load and air flow will be measured

- Additional ows for cylinder pressure and crank position can also be logged

- The test stand will enable:

- – Plotting of torque and power curves

- – Determination of specific fuel consumption (optional)

- – Determination of volumetric efficiency

- – Obtaining a PV diagram (optional engine accessory required)

- A modern, industrial range of single-cylinder, normally aspirated engines complete with all services and ancillaries required to run the engine in a laboratory environment

- Simple coupling and interchangeability for different engine test skids

- Protected by guards around all moving parts and around key hot surfaces

- Throttle and brake load can be controlled remotely

- Standard instrumentation includes sensors for:

- – Engine speed

- – Torque

- – Air flow

- – Exhaust gas Lambda sensor (petrol)

- Sensor variables are logged in real-time on a customer-supplied computer which must run Windows 7 or above via a USB interface, using sophisticated educational software. The software includes full data logging and analysis functions and incorporates detailed teaching material

- Pressure sensor – cylinder

- Touchscreen

- Engines: Petrol engine CM20-10 / Diesel engine CM20-20

- Fuel level option CM20-30

- Pressure sensor amp CM20-12-12

- 5 gas exhaust analyser: CO, CO2, HC, O2, NOx

Electrical supply:

- CM20-A: 220-240V / 1ph / 50Hz

- CM20-G: 220-240V / 1ph / 60Hz

- The user must have a PC with a USB port, running Windows 7 or above

- Extractor

- Hear Protection

PACKED AND CRATED SHIPPING SPECIFICATIONS

Volume: 2.84m³

Gross Weight: 378Kg

Length: 1.40m

Width: 0.75m

Height: 1.20m

- CM20-A Single cylinder test stand

- CM20-G Single cylinder test stand

- CM20-10-1 Petrol engine electrical start

- CM20-10-12 Petrol engine indicator set

- CM20-20-1 Diesel engine electrical start

- CM20-20-3 Diesel engine electrical start sensor prepared

- CM20-20-12 Diesel engine indicator set

- CM20-30 Fuel level option

- CM20-12-12 Pressure sensor amp

- CM50 5 gas exhaust analyser